Welding joint and welding method of marine crack arrest steel

A welding method and crack arresting technology, applied in welding equipment, welding accessories, arc welding equipment, etc., can solve problems such as low production efficiency, increased welding time, and difficulty in removing slag shells, and achieve improved production efficiency and high impact toughness Reserve, achieve the effect of welding quality and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

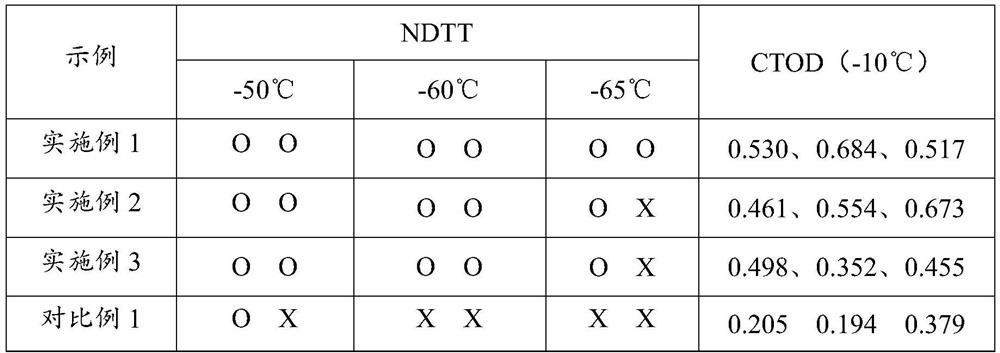

Embodiment 1

[0034] This embodiment provides a welding method for marine crack arresting steel, comprising the following steps,

[0035] (1) Use 60mm thick EH47BCA1 boxed marine crack arrest steel, the supply status is TMCP, and the crack arrest toughness at -10°C is Kca≥6000N / mm 3 / 2 ;The welding groove is X-shaped groove, the groove angle is 60±5°, equal thickness butt joint, and the test plate size is 1000mm×400mm×60mm;

[0036](2) The flux-cored welding wire used in flux-cored gas-shielded welding (FCAW) is A5.29 E81T1-K2C, and has passed the classification society 5Y46 H5 certification, and the diameter of the welding wire is 1.2mm; The combination of arc welding wire and flux meets ENISO 26304-A:S69 4FB TZ H5, and has passed the classification society 5Y46 certification. The diameter of the first welding wire and the second welding wire is 2.0mm, and the diameter of the third welding wire is 4.0mm;

[0037] Preheat to 70°C before welding, and the interpass temperature is 70-180°C. Th...

Embodiment 2

[0039] This embodiment provides a welding method for marine crack arresting steel, comprising the following steps,

[0040] (1) Use 80mm thick EH47BCA1 boxed marine crack arrest steel, the supply status is TMCP, and the crack arrest toughness Kca at -10°C is ≥ 8000N / mm 3 / 2 ;The welding groove is X-shaped groove, the groove angle is 55±5°, equal thickness butt joint, and the test plate size is 1000mm×400mm×80mm;

[0041] (2) The flux-cored welding wire used by FCAW is A5.29 E81T1-K2C, and has passed the classification society 5Y46 H5 certification, and the diameter of the welding wire is 1.2mm; the submerged arc welding wire and flux combination used by dual-power three-wire submerged arc welding meet EN ISO 26304-A: S69 4FBTZ H5, and certified by classification society 5Y46, the diameter of the first welding wire and the second welding wire is 2.0mm, and the diameter of the third welding wire is 4.0mm;

[0042] Preheat to 70°C before welding, and the interpass temperature is ...

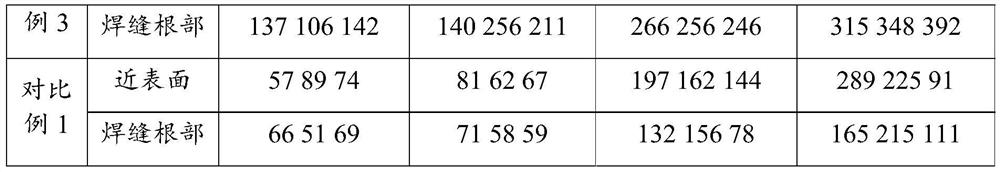

Embodiment 3

[0044] This embodiment provides a welding method for marine crack arresting steel, comprising the following steps,

[0045] (1) Use 100mm thick EH47BCA1 boxed marine crack arrest steel, the supply status is TMCP, and the crack arrest toughness at -10°C is Kca≥8000N / mm 3 / 2 ;The welding groove is X-shaped groove, the groove angle is 55±5°, equal thickness butt joint, and the test plate size is 1000mm×400mm×100mm;

[0046] (2) The flux-cored welding wire used by FCAW is A5.29 E81T1-K2C, and has passed the classification society 5Y46 H5 certification, and the diameter of the welding wire is 1.2mm; the submerged arc welding wire and flux combination used by dual-power three-wire submerged arc welding meet EN ISO 26304-A: S69 4FBTZ H5, and certified by classification society 5Y46, the diameter of the first welding wire and the second welding wire is 2.0mm, and the diameter of the third welding wire is 4.0mm;

[0047] Preheat to 85°C before welding, and the interpass temperature is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com