Lead-free solder for aluminum soft soldering

A lead-free solder, aluminum soldering technology, used in welding/cutting media/materials, welding media, welding equipment, etc., can solve the problem of less reporting, and achieve the effects of good wetting performance, good joint performance, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

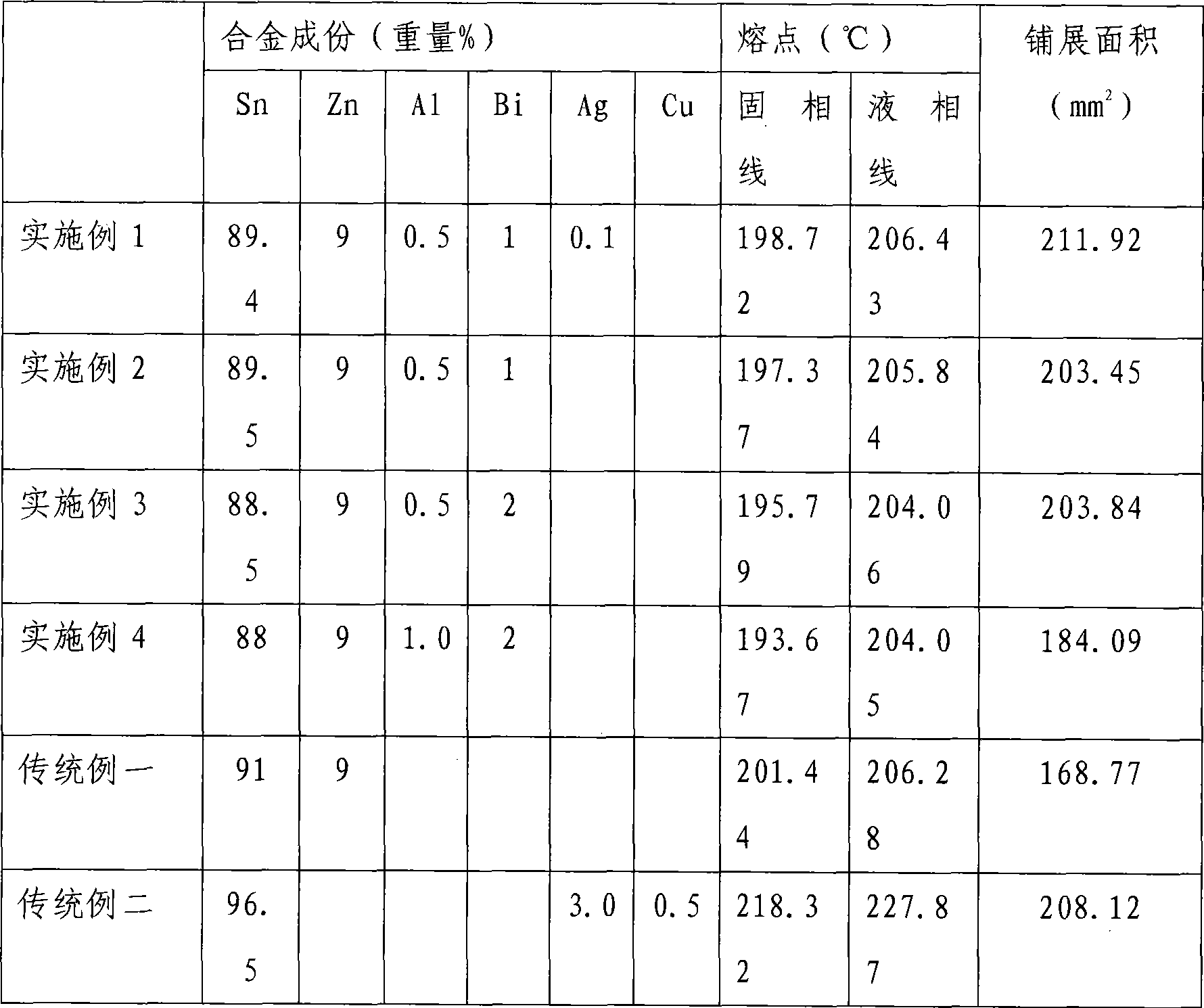

Embodiment 1

[0010] The lead-free solder of this embodiment is composed of the following components by weight percentage: Zn content 9%, Al content 0.5%, Ag content 0.1%, Bi content 1%, and Sn as the balance.

Embodiment 2

[0012] The lead-free solder of this embodiment is composed of the following components by weight percentage: Zn content 9%, Al content 0.5%, Bi content 1%, Sn as the balance.

Embodiment 3

[0014] The lead-free solder of this embodiment is composed of the following components by weight percentage: Zn content 9%, Al content 0.5%, Bi content 2%, Sn as the balance.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com