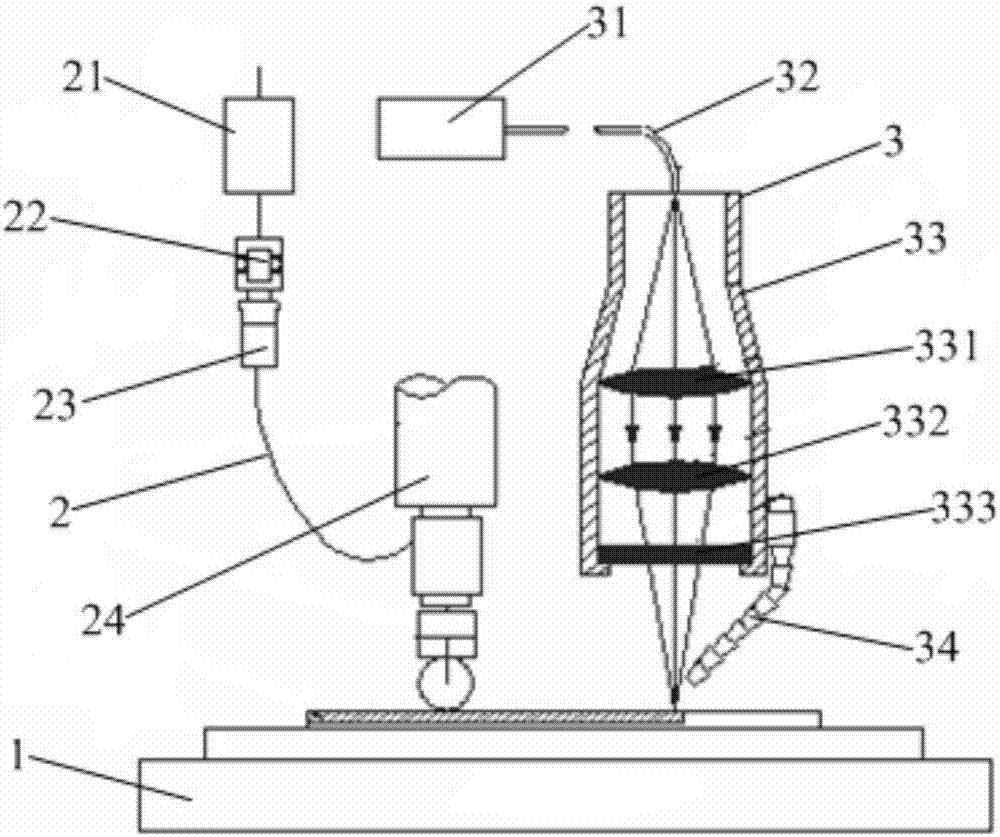

Heterogeneous metal laser-ultrasonic compound welding method and device

A heterogeneous metal and composite welding technology, which is applied in laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of increasing the effective connection cross-sectional area and reducing the energy consumption of consolidation, and achieves a significant effect of reducing brittleness and joints Effects of performance improvement and narrow phase transition range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Below in conjunction with accompanying drawing, take TC4 titanium alloy / 304 stainless steel welding as embodiment, the embodiment is described in detail.

[0023] A laser-ultrasonic composite welding method for heterogeneous metals, comprising the following steps:

[0024] Step 1: Preprocessing

[0025] According to the NB / T47014-2011 industry standard, 304 stainless steel and Ti6Al4V titanium alloy sheet materials with a size of 100mm×50mm×0.5mm were selected as the test materials. Before welding, 320# sandpaper was used to polish the oxide layer on the surface of the workpiece, and acetone was used to remove the 15mm near the lap joint. Grease.

[0026] Step 2: Riveting

[0027] The melting point of Ti6Al4V titanium alloy is 1540-1650°C, and the melting point of 304 stainless steel is about 1400°C. In view of the difference in melting point of the two materials and the low density of Ti6Al4V titanium alloy, and the high absorption rate of the two materials for laser...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com