Patents

Literature

39results about How to "To achieve the purpose of connection" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Household appliance and network configuration method and device thereof

InactiveCN109391529AAchieve scalabilityAchieve enhanced effectsAssess restrictionNetwork topologiesHome applianceNetwork access point

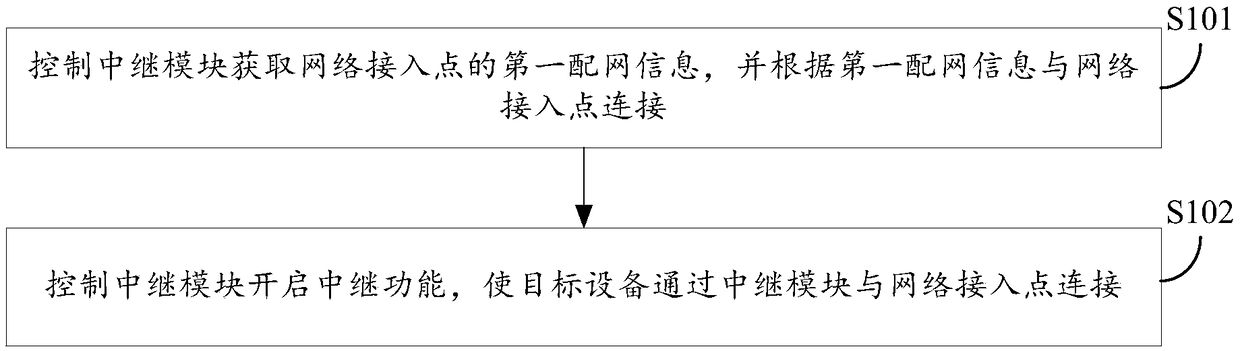

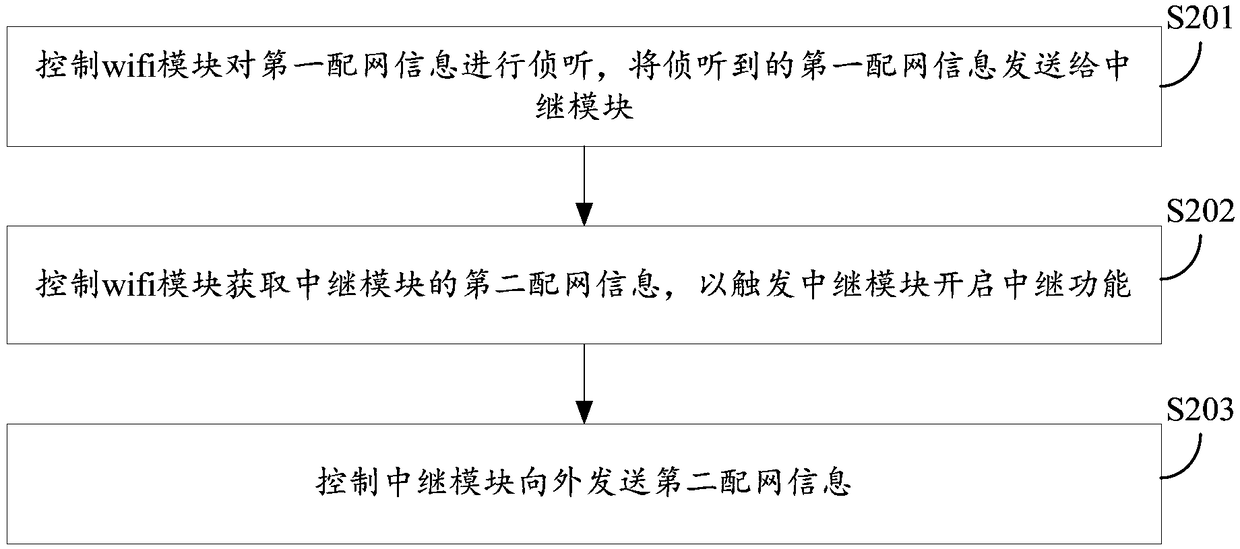

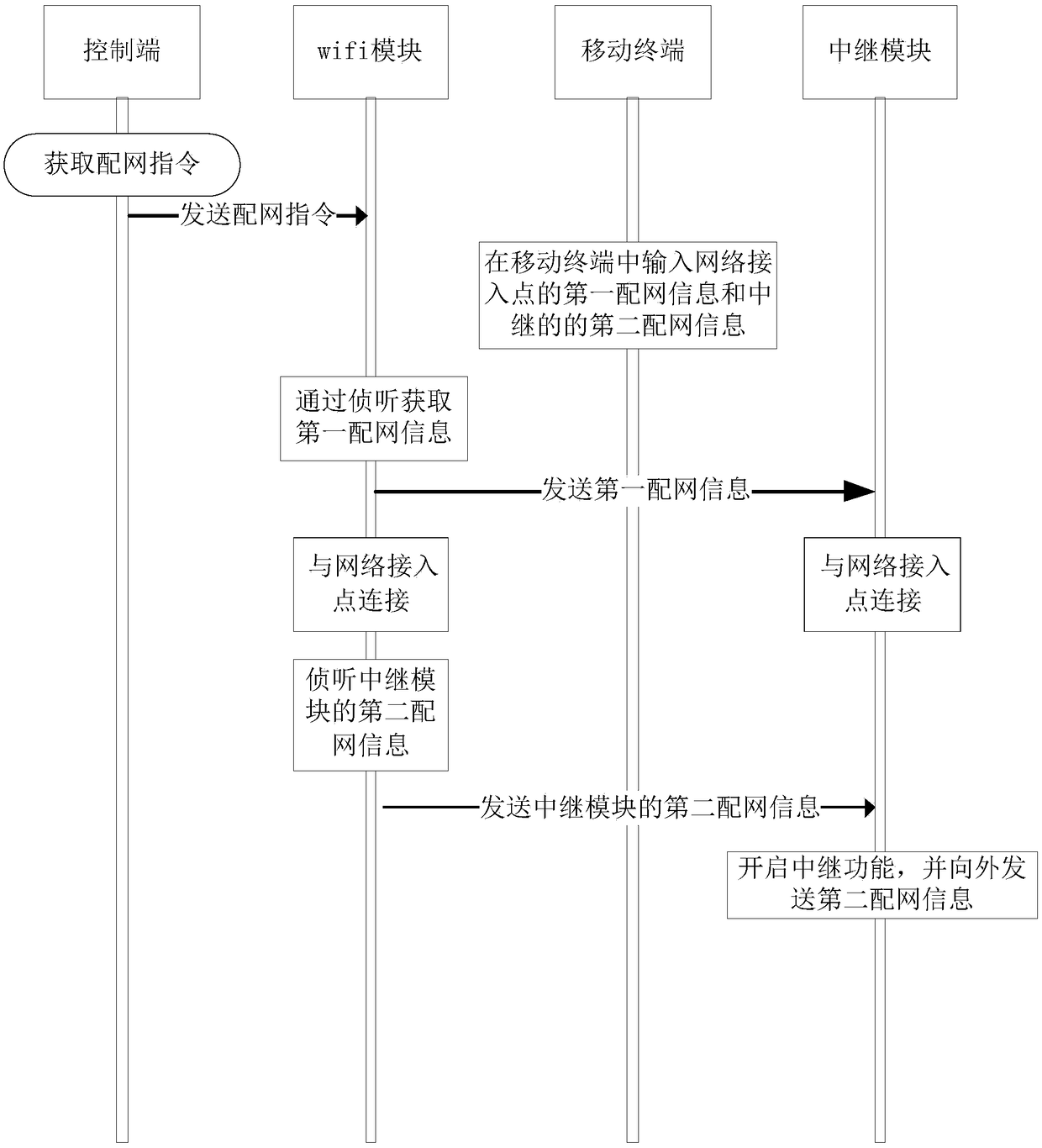

The invention discloses a household appliance and a network configuration method and device thereof, wherein the household appliance is provided with a relay module. The method comprises the steps of:controlling the relay module to acquire the first network configuration information of a network access point, and connecting the relay module to the network access point according to the first network configuration information; and controlling the relay module to enable a relay function so that a target device is connected to the network access point through the relay module. The technical scheme of using the household appliance for forwarding wifi signals enables the household appliance to have an effect of expanding and enhancing the wifi signals.

Owner:GD MIDEA AIR-CONDITIONING EQUIP CO LTD +1

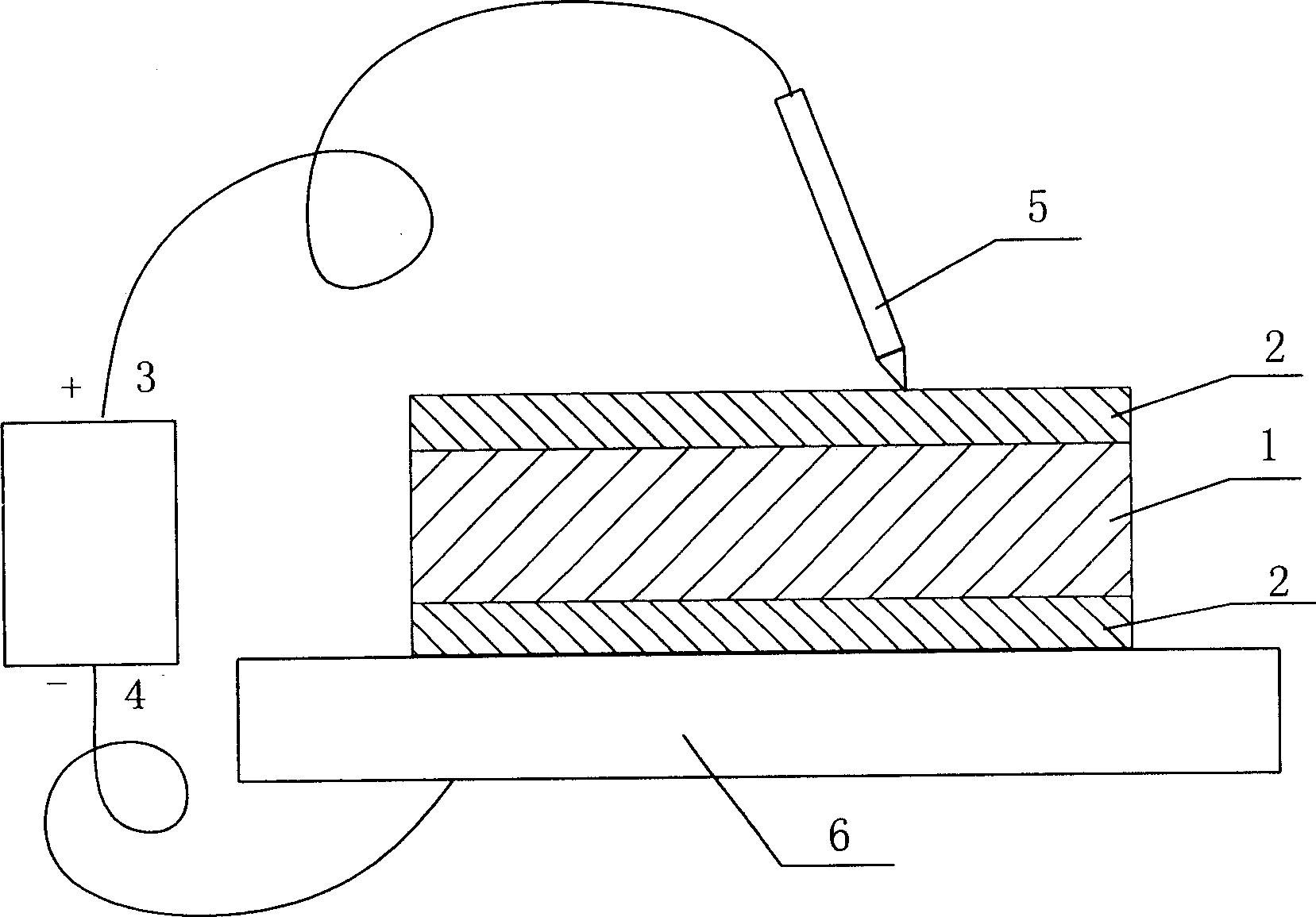

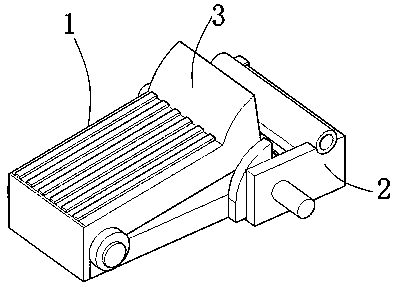

Heterogeneous metal laser-ultrasonic compound welding method and device

ActiveCN107984085ANarrow phase change rangeInhibition of mass productionLaser beam welding apparatusUltrasonic weldingLap joint

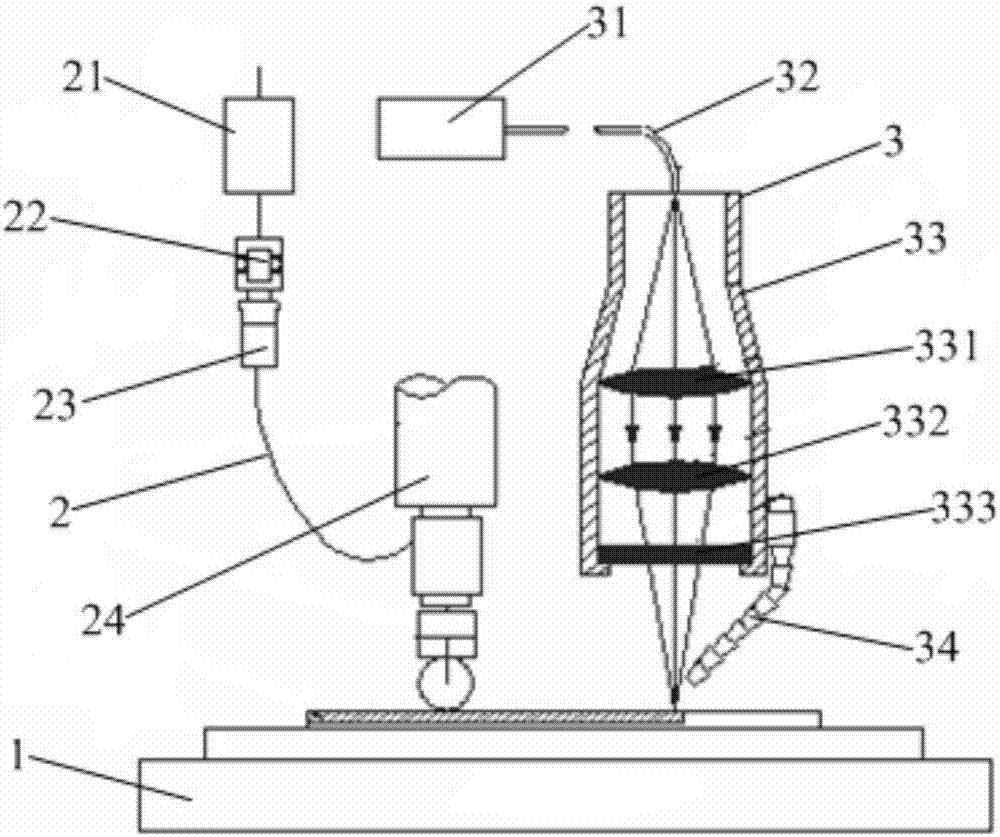

The invention provides a heterogeneous metal laser-ultrasonic compound welding method and device. The two advanced technologies of laser welding and ultrasonic consolidation are combined, that is, heterogeneous materials to be welded are connected in an overlap mode to form a lap joint, the position to be welded is welded in a laser welding mode, and the connecting purpose is realized. Under the condition that the temperature of the joint to be welded is below 10-30% of the melting point of an upper layer base material, ultrasonic welding is conducted, and efficient connection of the joint isrealized. According to the heterogeneous metal laser-ultrasonic compound welding method and device, the problem that a brittle joint is formed during welding of heterogeneous materials through a traditional welding method is solved, the problem that only a high energy beam welding method is adopted, though massive formation of intermetallic compound can be partially restrained, the strength of thejoint is still not high is also solved, and the problem difficult to solve that ultrasonic consolidation is only adaptive to low-melting-point thin plate welding is solved.

Owner:NANCHANG UNIV

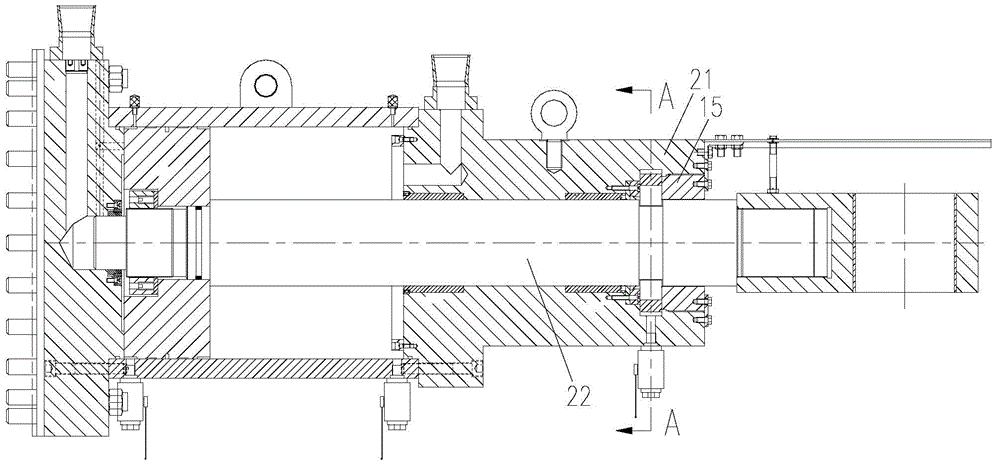

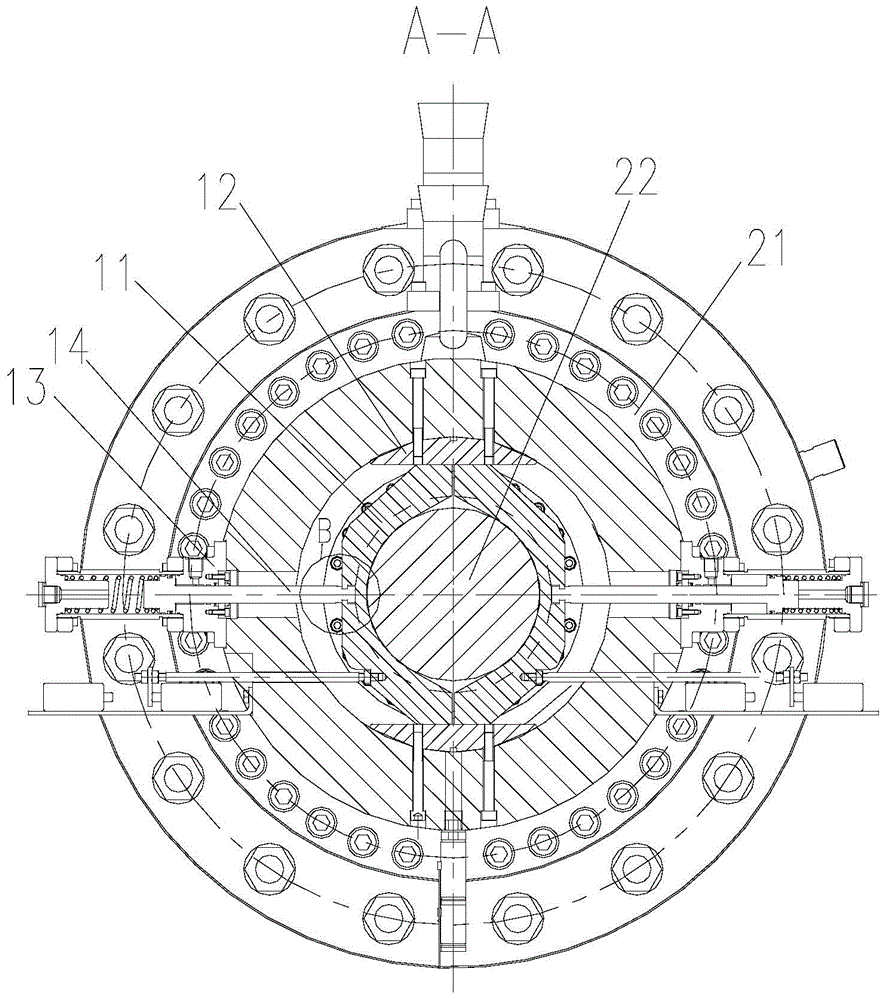

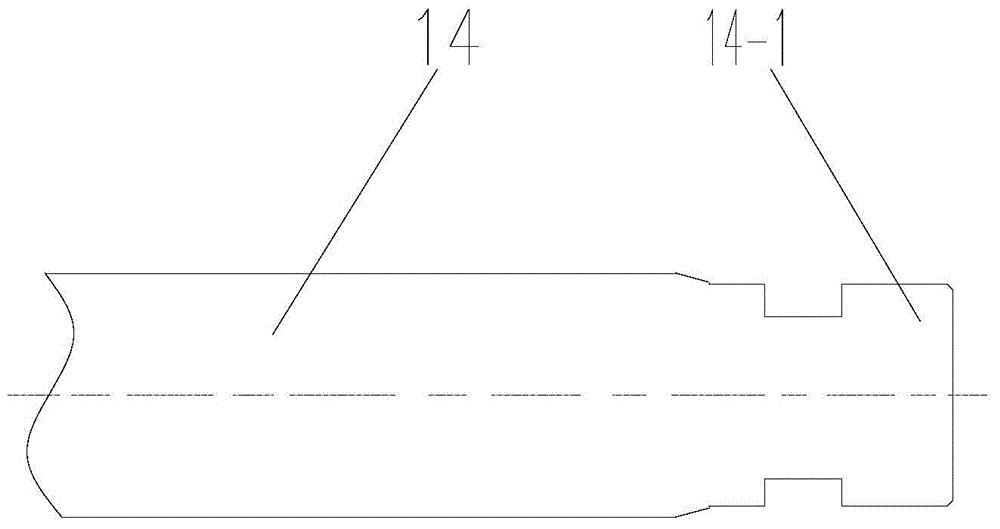

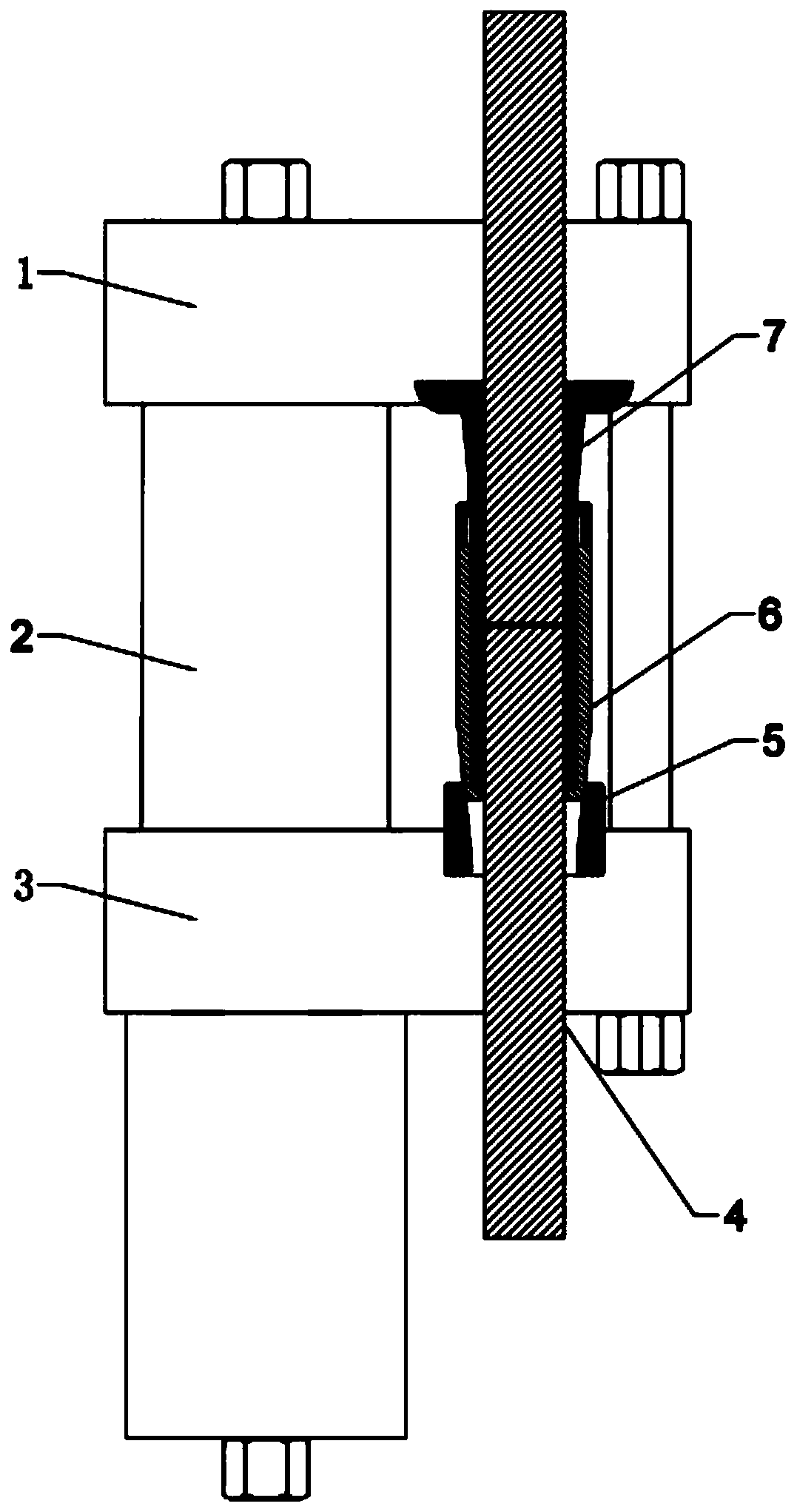

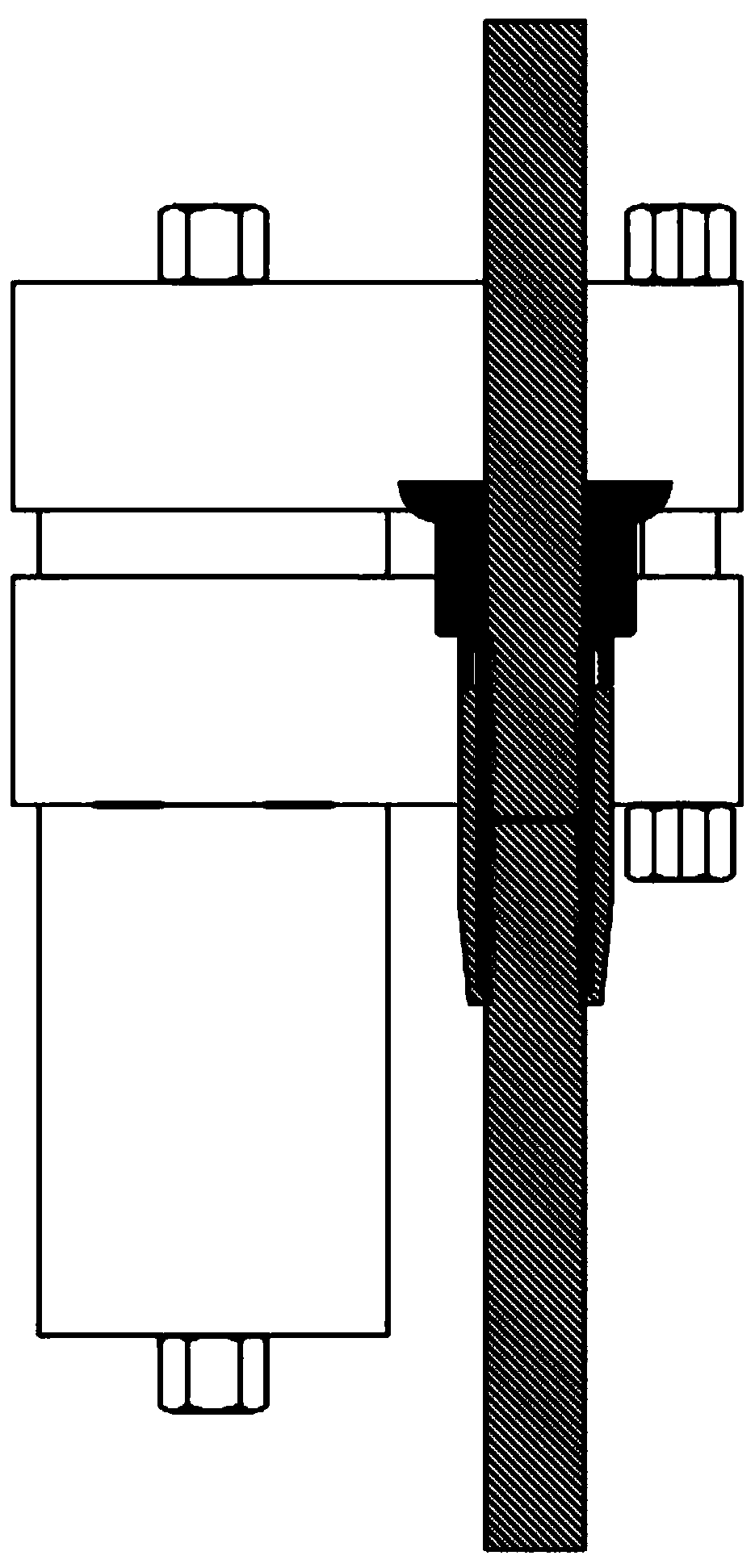

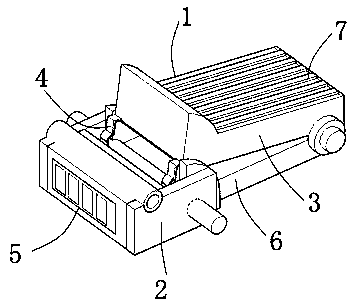

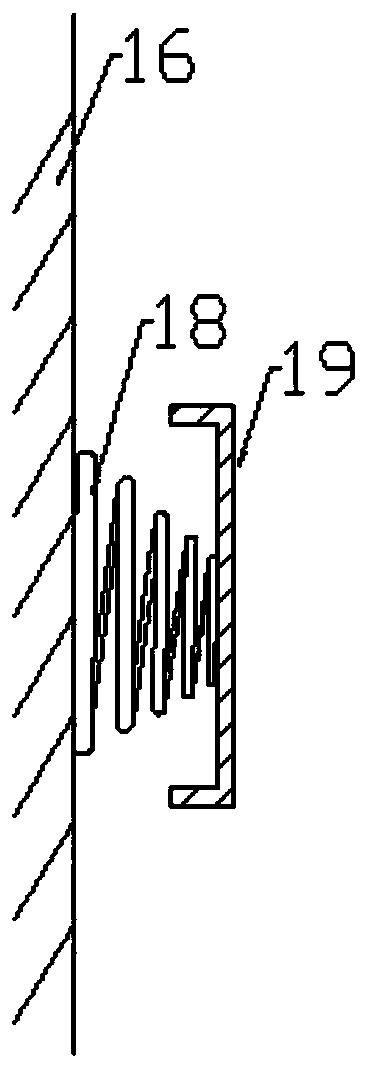

Locking device for locking servomotor

ActiveCN104533690ATo achieve the purpose of connectionEasy to operateHydro energy generationReaction enginesHydraulic cylinderServomotor

The invention provides a locking device for a locking servomotor. The locking device comprises a locking hydraulic cylinder, a locking flashboard and a guide block. A front end cover of the locking hydraulic cylinder is fixedly connected to a servomotor cylinder cover, the locking flashboard is provided with a T-shaped groove, the protruded tail end of a piston rod of the locking hydraulic cylinder is provided with a lock head matched with the T-shaped groove, the guide block is fixedly connected to the servomotor cylinder cover, and the locking flashboard is slidably connected with the guide block. When the locking device is used, the lock head is inserted in the T-shaped groove which is formed in the locking flashboard and matched with the lock head, and accordingly the piston rod of the locking hydraulic cylinder is connected with the locking flashboard; the problem that the locking flashboard is difficult to install in a small space is solved, and the device is convenient to operate and greatly improves installing efficiency.

Owner:CHANGZHOU HYDRAULIC COMPLETE EQUIP

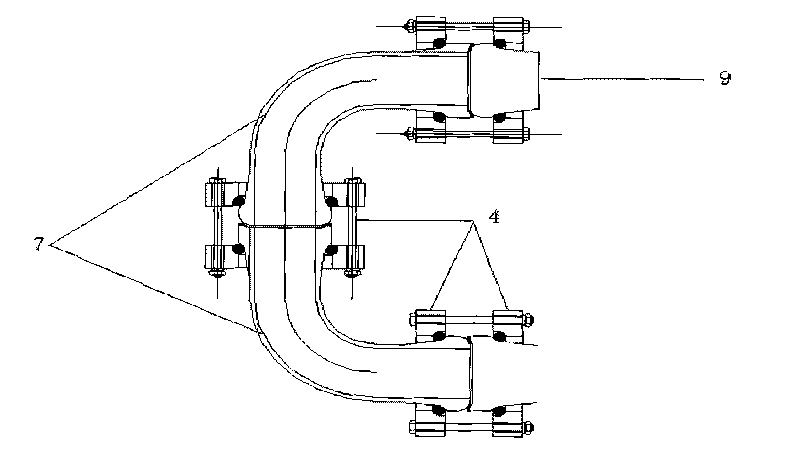

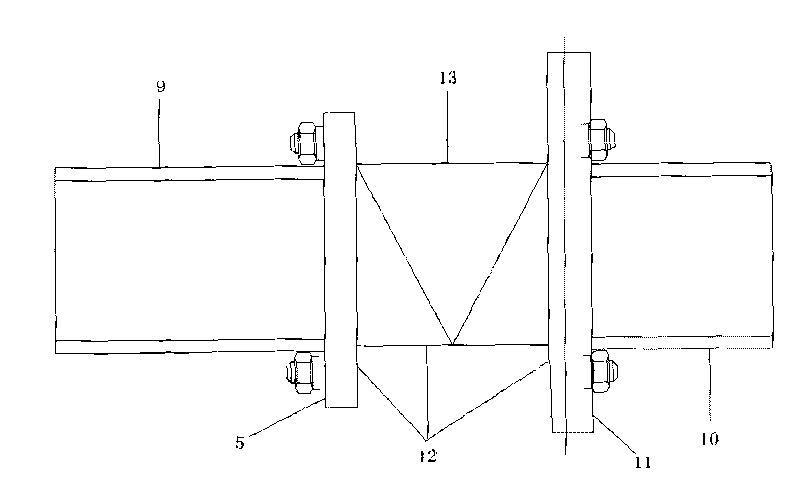

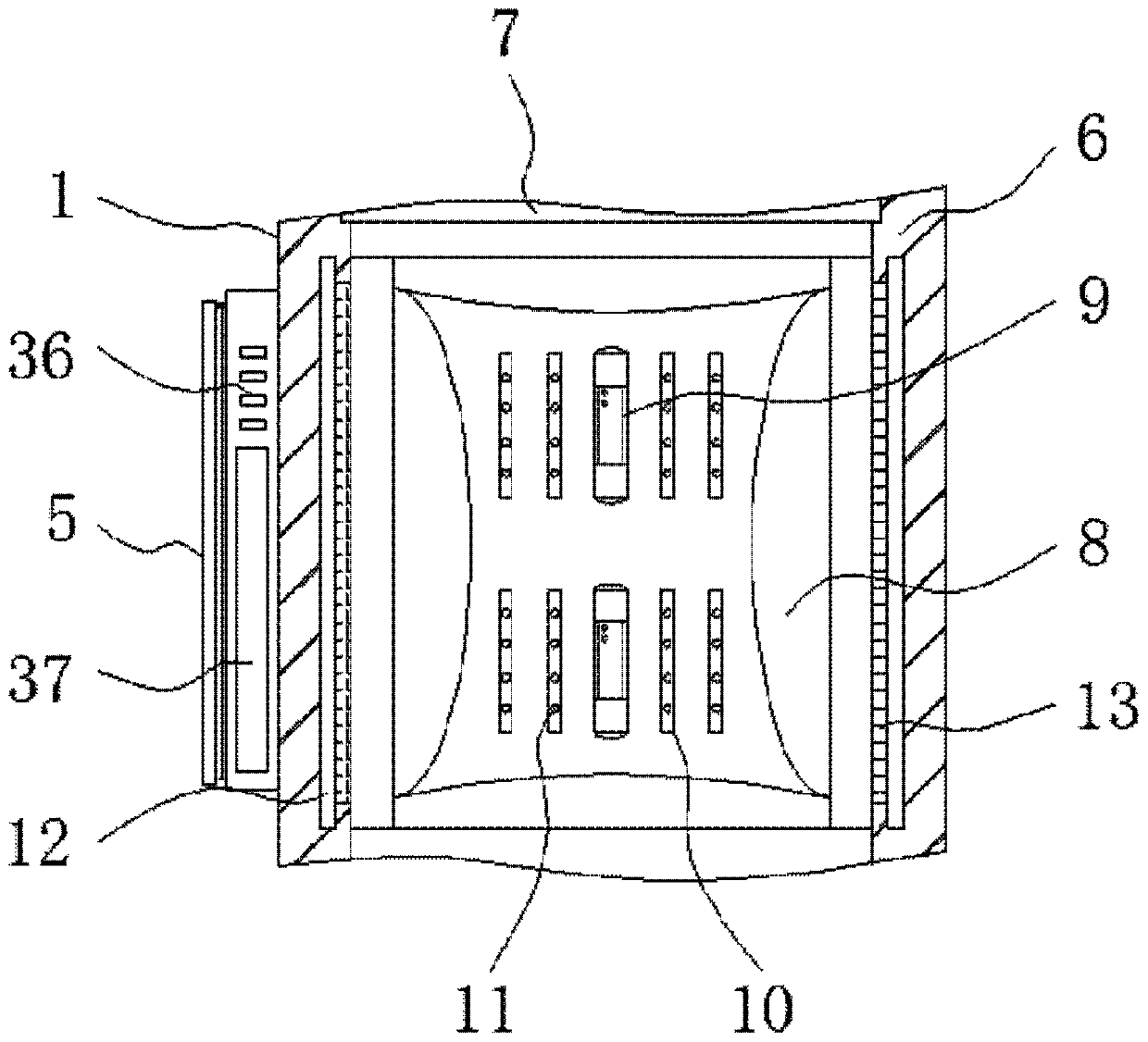

Connecting system for parallel pipe type photobioreactor

ActiveCN101760418AAvoid breakageEffectively connectedBioreactor/fermenter combinationsBiological substance pretreatmentsAutomatic controlLight energy

The invention provides a connecting system for a parallel pipe type photobioreactor. The connecting system mainly comprises one or more of a photo-reactor connecting system, a photo-reactor and iron tube connecting system, a photo-reactor fixing system, an iron tube, pump and storage tank system and / or a self-control connecting system, which are combined and connected. The connecting system of the invention can overcome the defects of the prior art, provide a solution of a whole set of closed culture microalgae device which has the advantages of simple manufacture, convenient disassembly, highly efficient light energy utilization, conveniently assembly and self control, and effectively utilize the light energy; and in the process of assembling and using the connecting system, the photo-reactor products are protected to a great extent, and the assembly of the industrial scale-up type reactor is guaranteed.

Owner:ENN SCI & TECH DEV

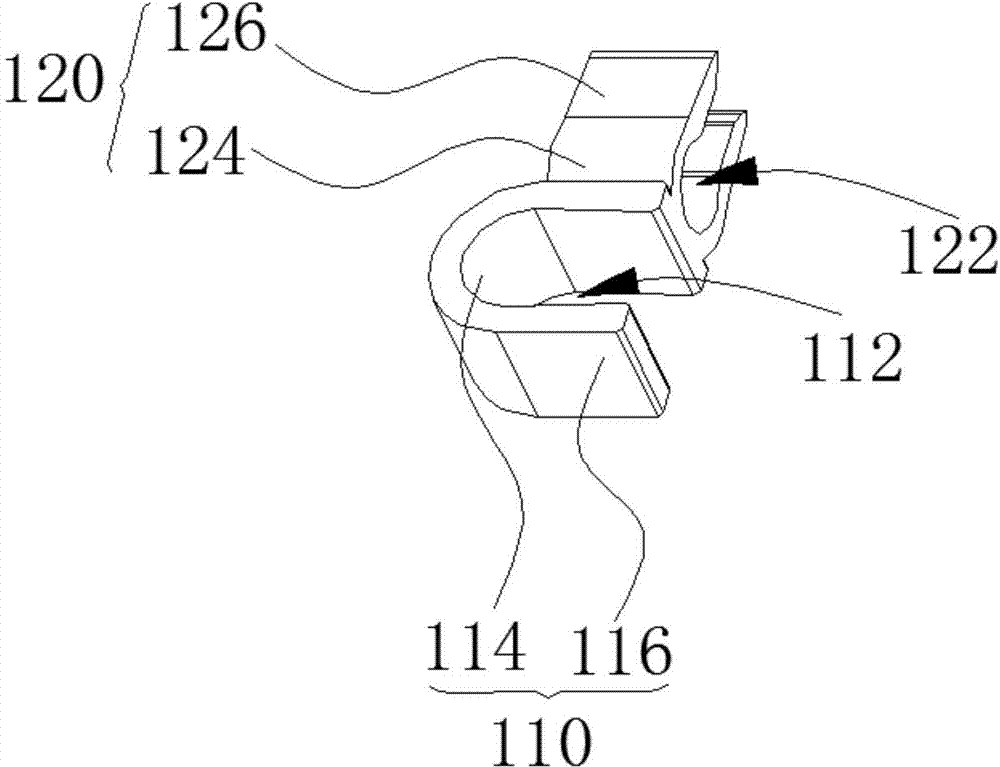

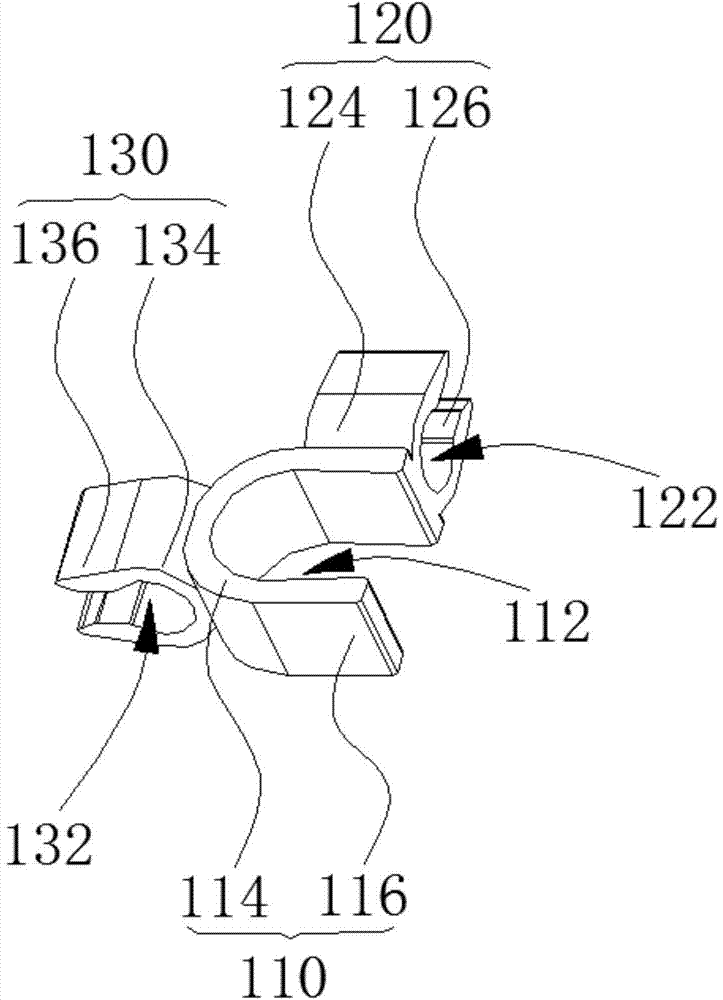

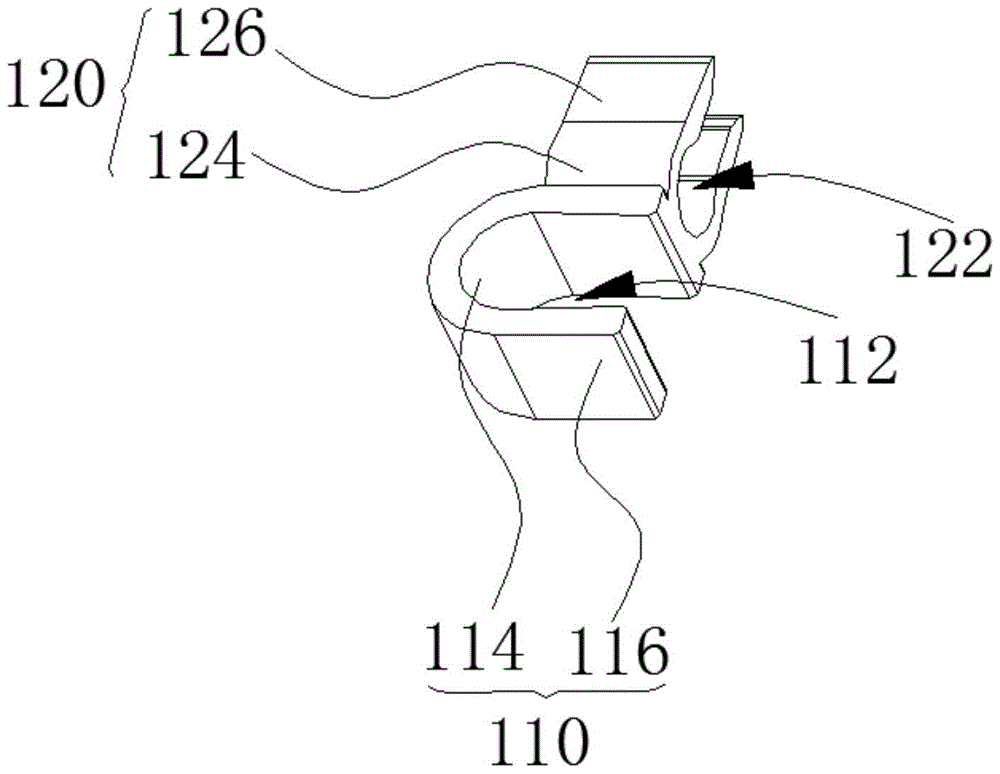

Fastener structure

InactiveCN104494839ATo achieve the purpose of connectionEasy loading and unloadingAircraft componentsBiochemical engineeringBolt connection

The invention discloses a fastener structure comprising a main fastener body and a first clamping lug. A first clamping groove is formed in the inner wall of the main fastener body, the first clamping lug is arranged on the outer wall of the main fastener body, and a second clamping groove is formed in one side, back to the main fastener body, of the first clamping lug. During use of the fastener structure, a support rod is clamped by each the first clamping groove and the second clamping groove, so that the purpose of connecting the adjacent support rods is achieved; compared with bolted connection, the fastener structure is simple to assemble and disassemble without a professional assembling and disassembling tool, and is easy to use.

Owner:湖南基石信息技术有限公司

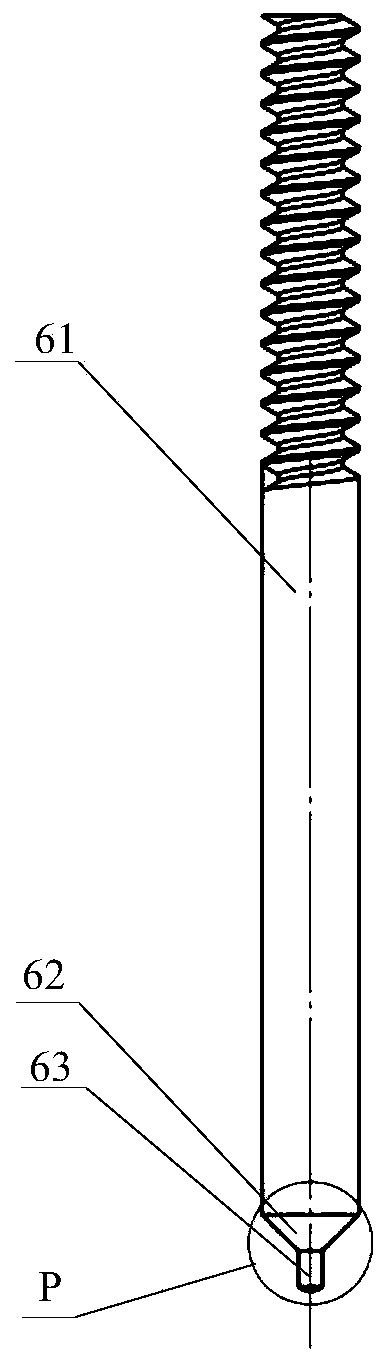

Flexible graphite lightning protection grounding electrode grounding device

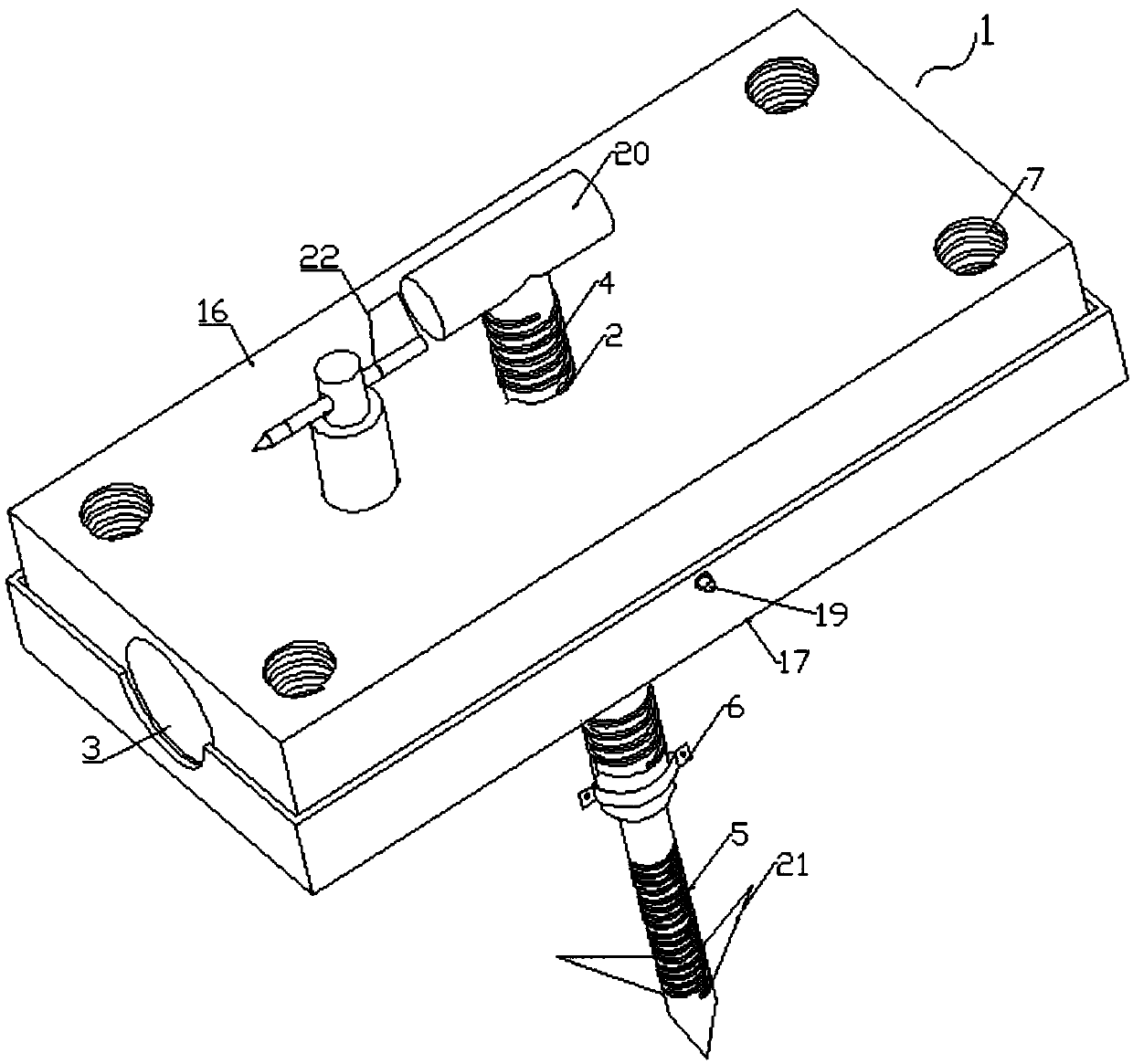

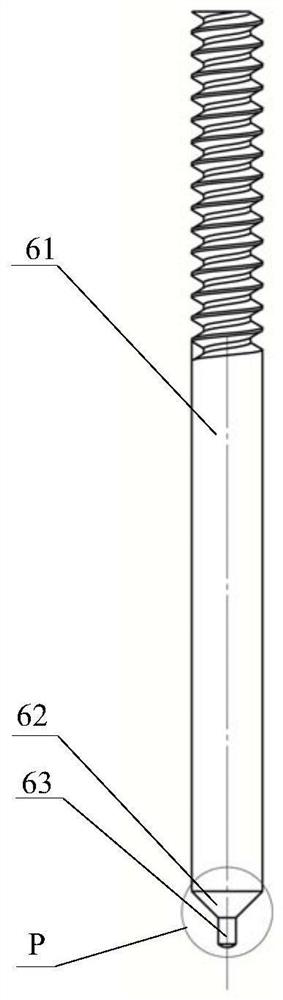

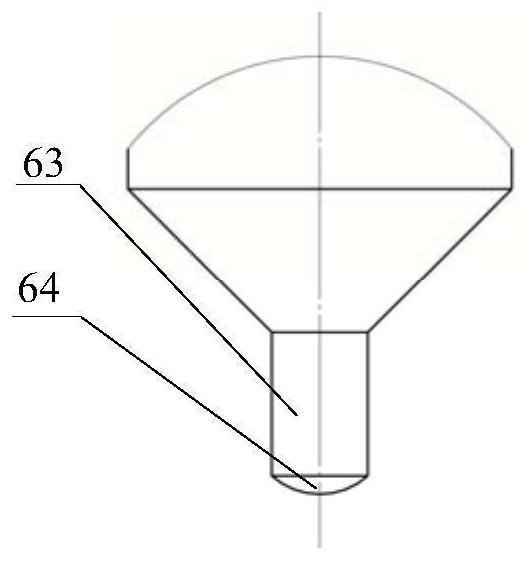

ActiveCN109256624ACause separationTo achieve the purpose of connectionClamped/spring connectionsConnection contact member materialGraphiteDrill

The invention discloses a flexible graphite lightning protection grounding electrode grounding device, in accordance with that present invention, include a housing, An upper surface of that shell is provided with a threaded hole penetrate the bottom surface, A lateral surface of that shell is provided with a through hole, the advantages of that invention are simple structure, easy operation, so that that tension device is arranged, The flexible graphite lightning grounding electrode can be avoided from being separated from the foundation when the flexible graphite lightning grounding electrodeis affected by bad weather. The purpose of connecting the flexible graphite lightning grounding electrode with the foundation can be realized by setting a screw rod and a drill nail, and the positionof the drill nail in the screw rod can be adjusted and adapted to be used in various foundations, so that the utility model is high and the maintenance is convenient.

Owner:ANHUI HUAXI ELECTRIC POWER TECH CO LTD

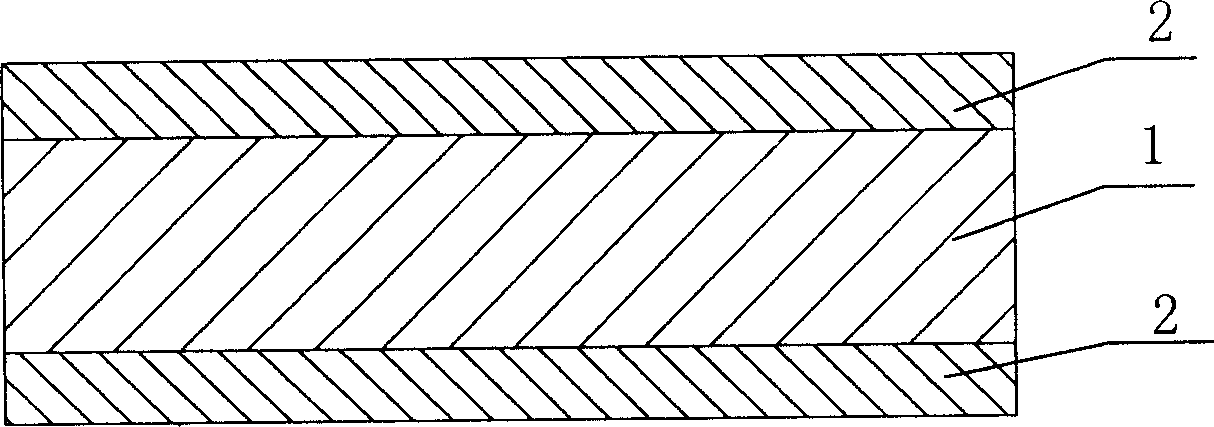

Aluminium-nickel metal welding bond and process for preparing the same

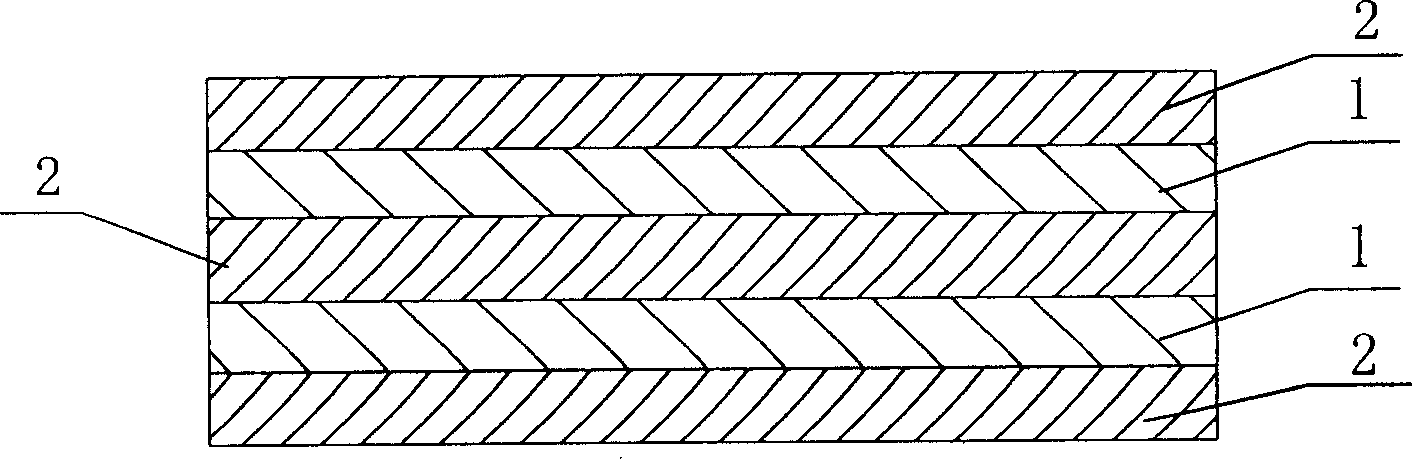

InactiveCN1733467AEasy to implementEfficient implementationLaminationLamination apparatusFusion weldingUltimate tensile strength

The invention relates to aluminum-nickel welding belt, which comprises connected thin aluminum belt and thin nickel belt to form complex layers structure; particularly, both the top and lowest layers of welding belt are thin nickel belts. This invention can realize easily the fusion welding between the said belts with high strength, reliable effect.

Owner:广东风华新能源股份有限公司

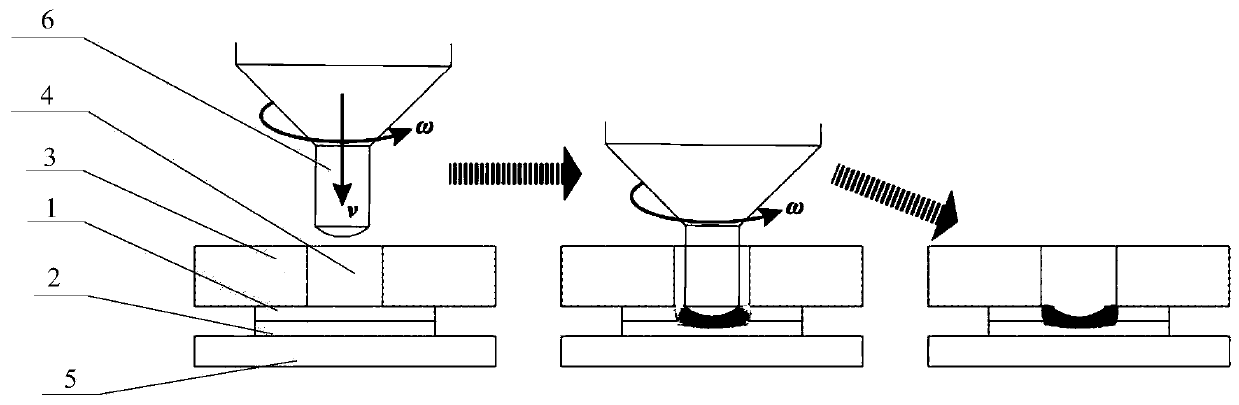

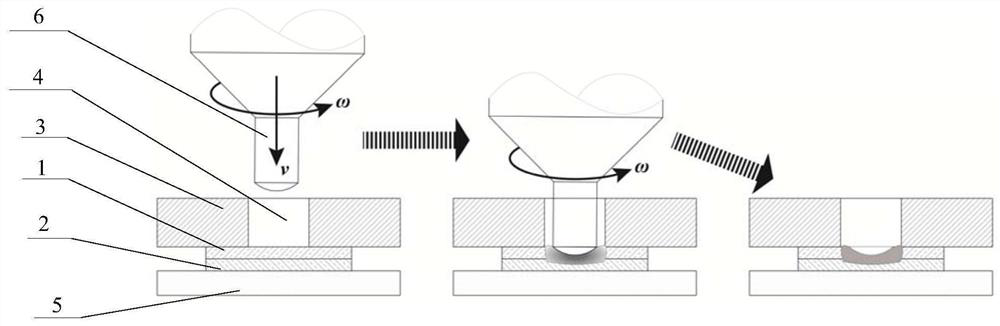

Micro-stirring friction welding process for electronic packaging

ActiveCN111230282ALow profileAchieve high densityMetal working apparatusNon-electric welding apparatusFriction weldingEngineering

The invention discloses a micro-stirring friction welding process for electronic packaging and belongs to the technical field of electronic packaging. The problem that an existing electronic packagingtechnology is not ideal in densification and pollution freeness achieving effect and the problem that an existing stirring friction welding technology can hardly achieve direct welding on micro, small and thin structures. Firstly, a first bonding pad and a second bonding pad to be welded serve as a welding pad set; when the welding pad set is arranged at single points, a press-in hole is prefabricated and machined in a first substrate, the welding pad set is arranged between the first substrate and a second substate in parallel, the press-in hole and the center position of the welding pad setare arranged in a centering manner, and then the first substrate and the second substrate are compressed through a clamp; and a stirring head is coaxially aligned to the upper portion of the press-inhole, the stirring head is controlled to rotate at high speed and move downwards into the press-in hole and then is pressed into the first welding pad; and under the set press-in amount and holding time, the permanent metallurgy connection of the first welding pad and the second welding pad is achieved, and finally the stirring head is controlled to move out of the press-in hole upwards.

Owner:HARBIN INST OF TECH

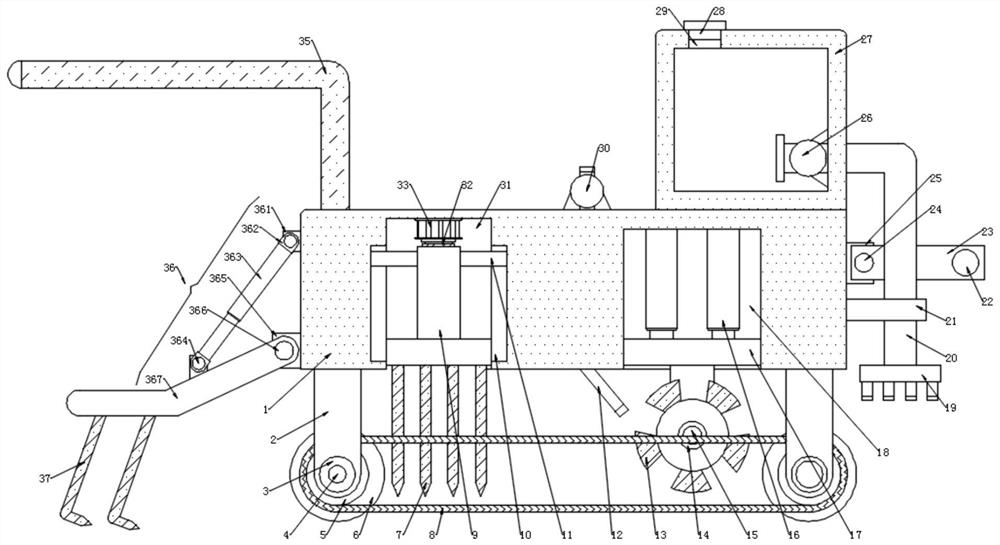

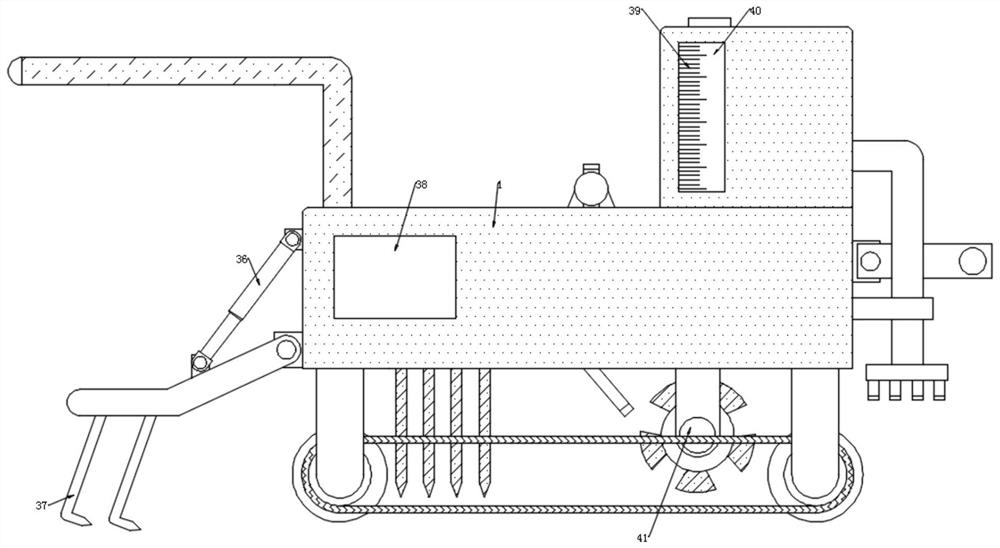

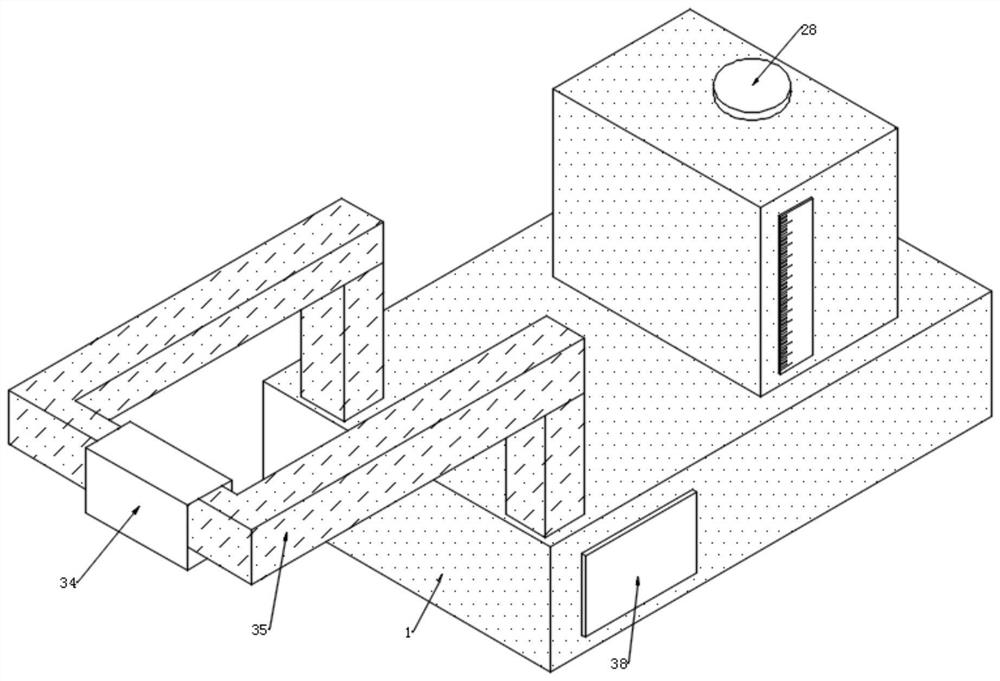

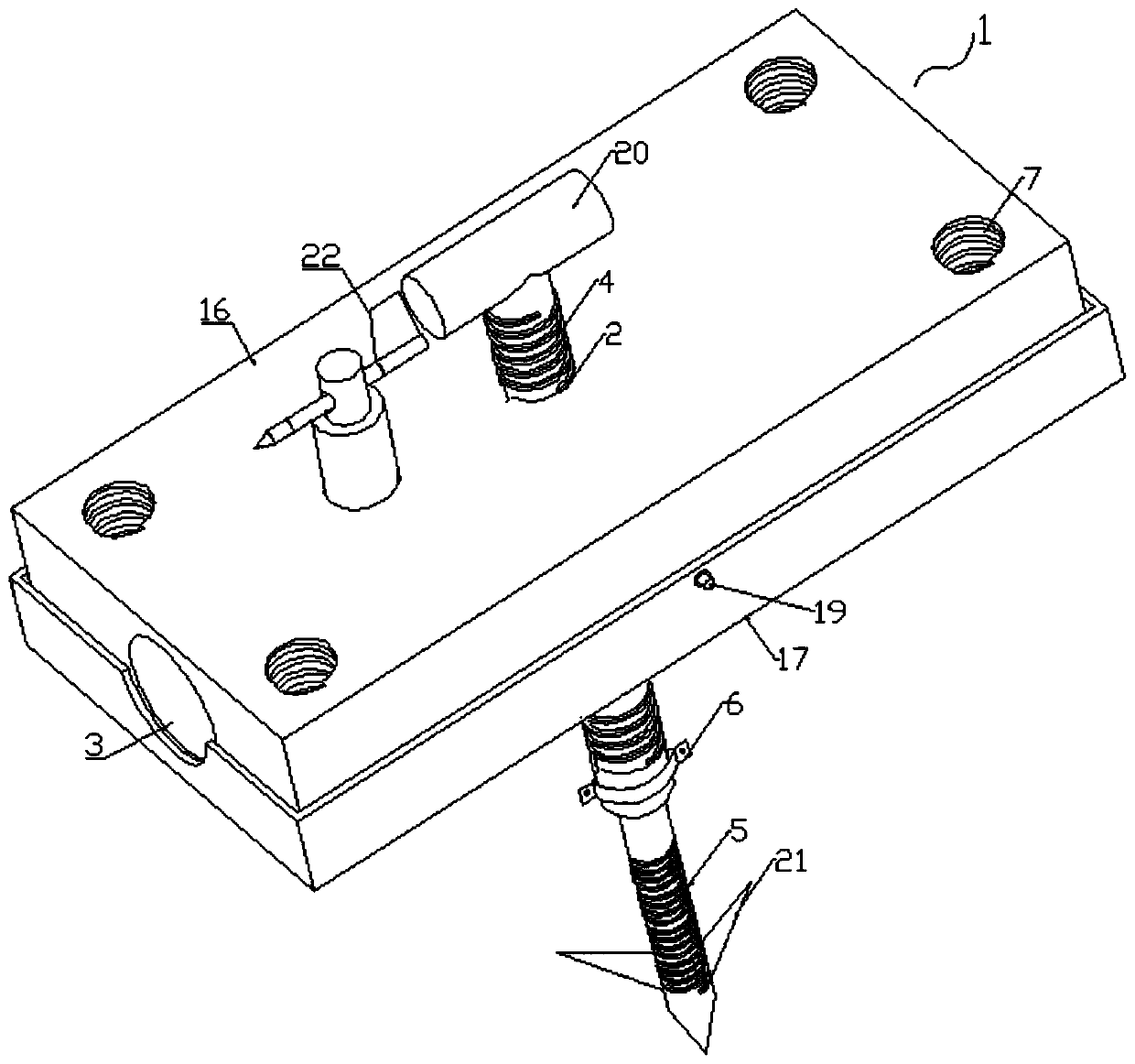

Soil turning equipment for agricultural planting

InactiveCN112385338AIncrease humidityIncrease softnessSpadesAgricultural machinesAgricultural scienceAgricultural engineering

The invention belongs to the technical field of soil turning equipment, and relates to soil turning equipment for agricultural planting. The soil turning equipment comprises a base, a first groove isformed in the bottom of the base, a first motor is fixedly connected to the top of the inner wall of the first groove, and a threaded column is fixedly connected to an output shaft of the first motor.The soil turning equipment for agricultural planting has the beneficial effects that through work of a water pump, water in a water tank can be conveyed to a spray head through a second pipeline to be sprayed, the soil humidity is improved, the soil turning efficiency is prevented from being affected by too hard land, a second motor works, a second rotating shaft can be driven to rotate, and thena soil turning wheel can be driven to rotate through the second rotating shaft, so that the purpose of soil turning is achieved; and a hydraulic push rod works and can drive a second supporting plateto move up and down along with extension and contraction of the hydraulic push rod, so that the purpose of moving the soil turning wheel up and down is achieved, the purposes of using and folding thesoil turning wheel are achieved, and meanwhile the purpose of adjusting the soil turning depth is achieved.

Owner:李永翔

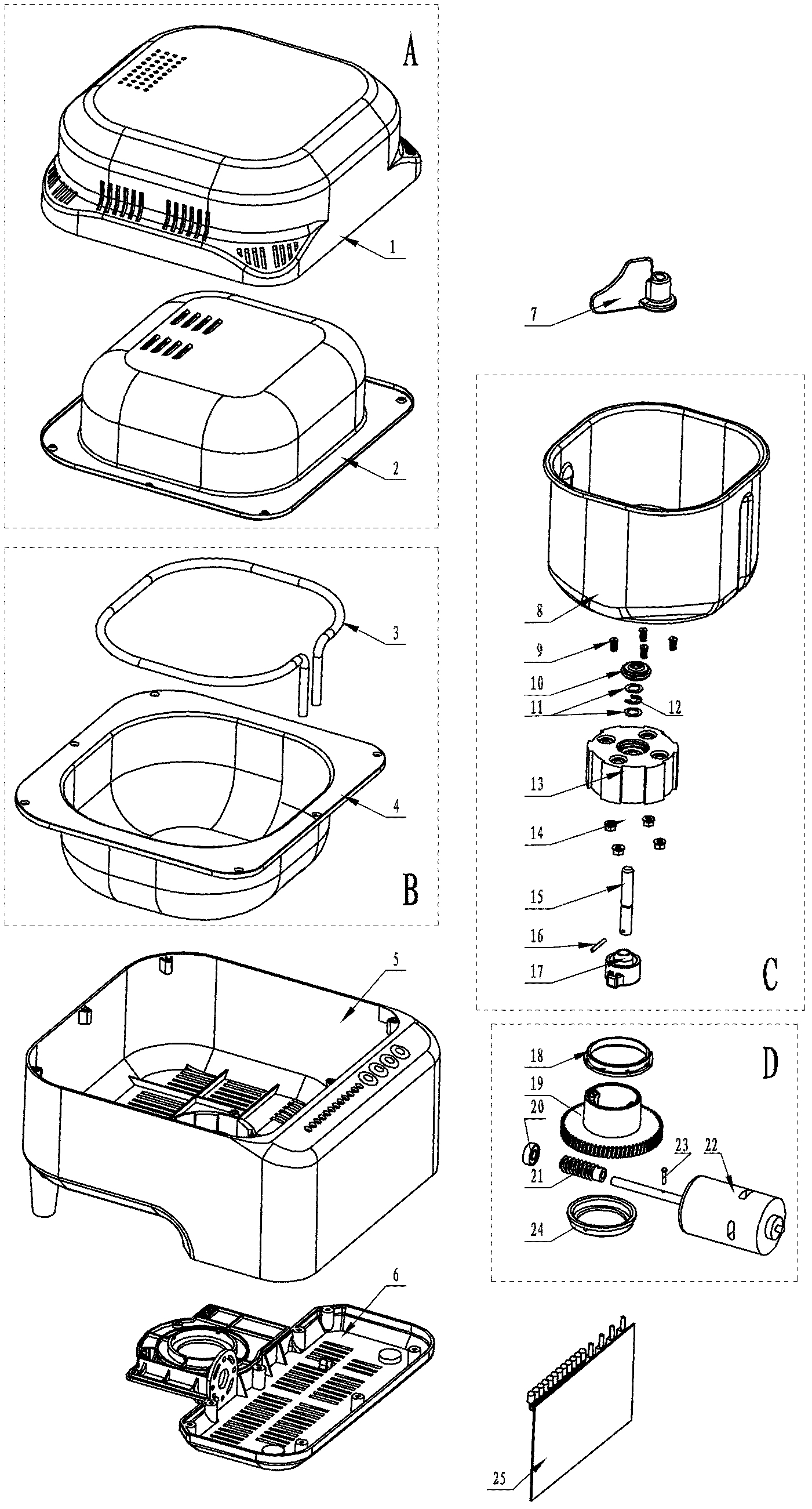

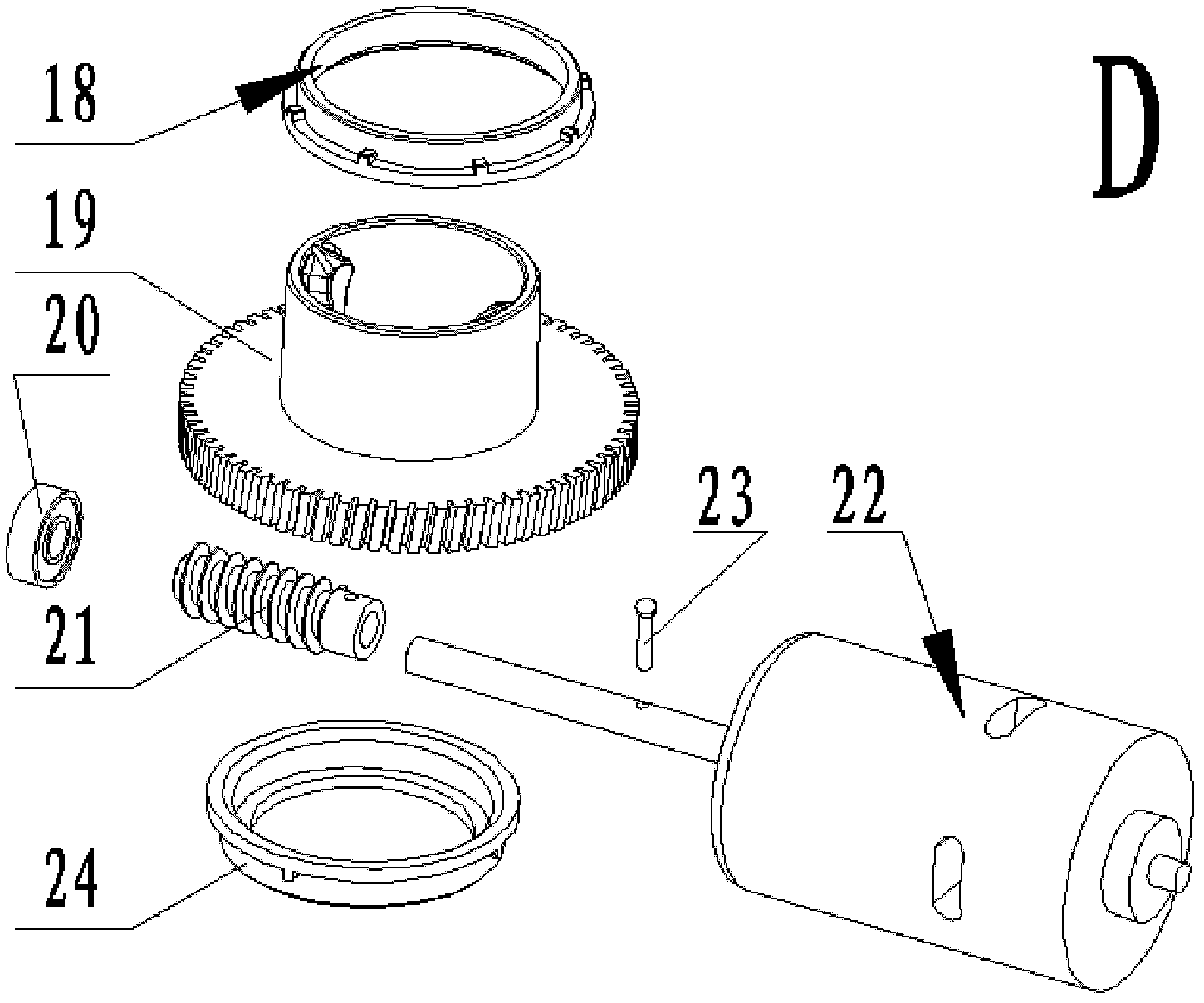

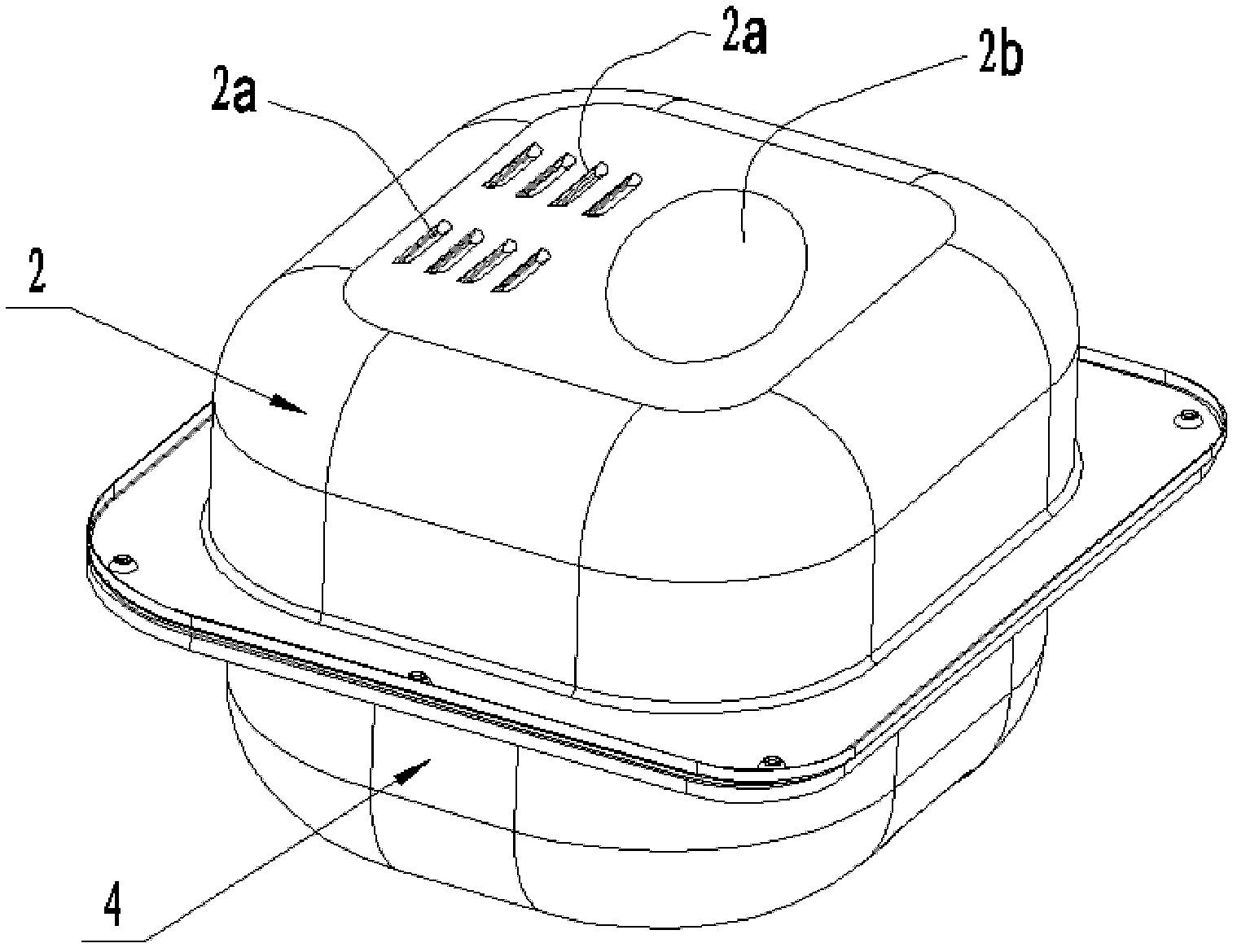

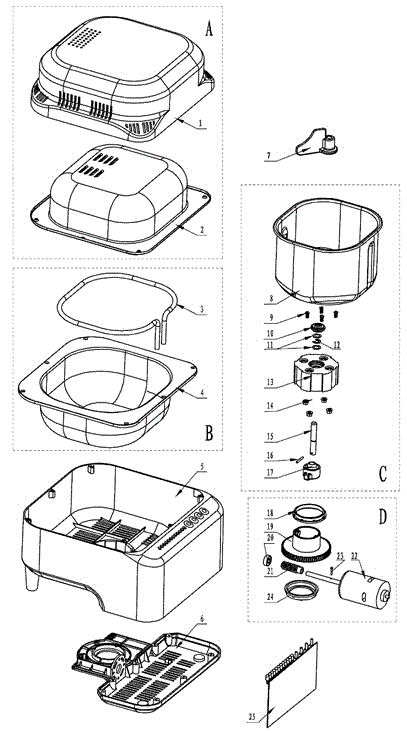

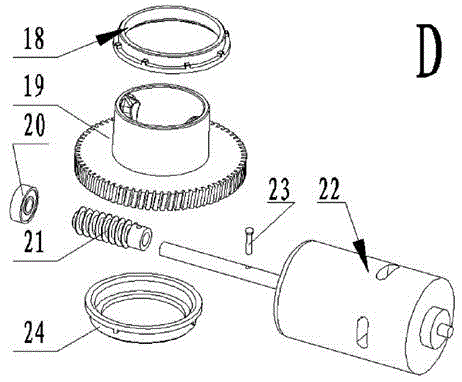

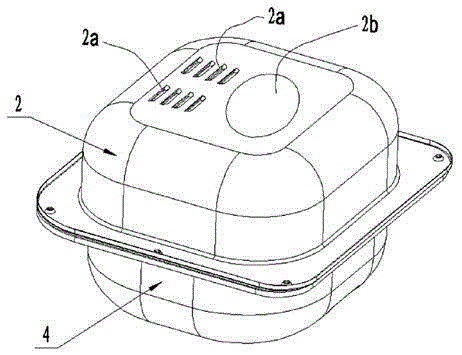

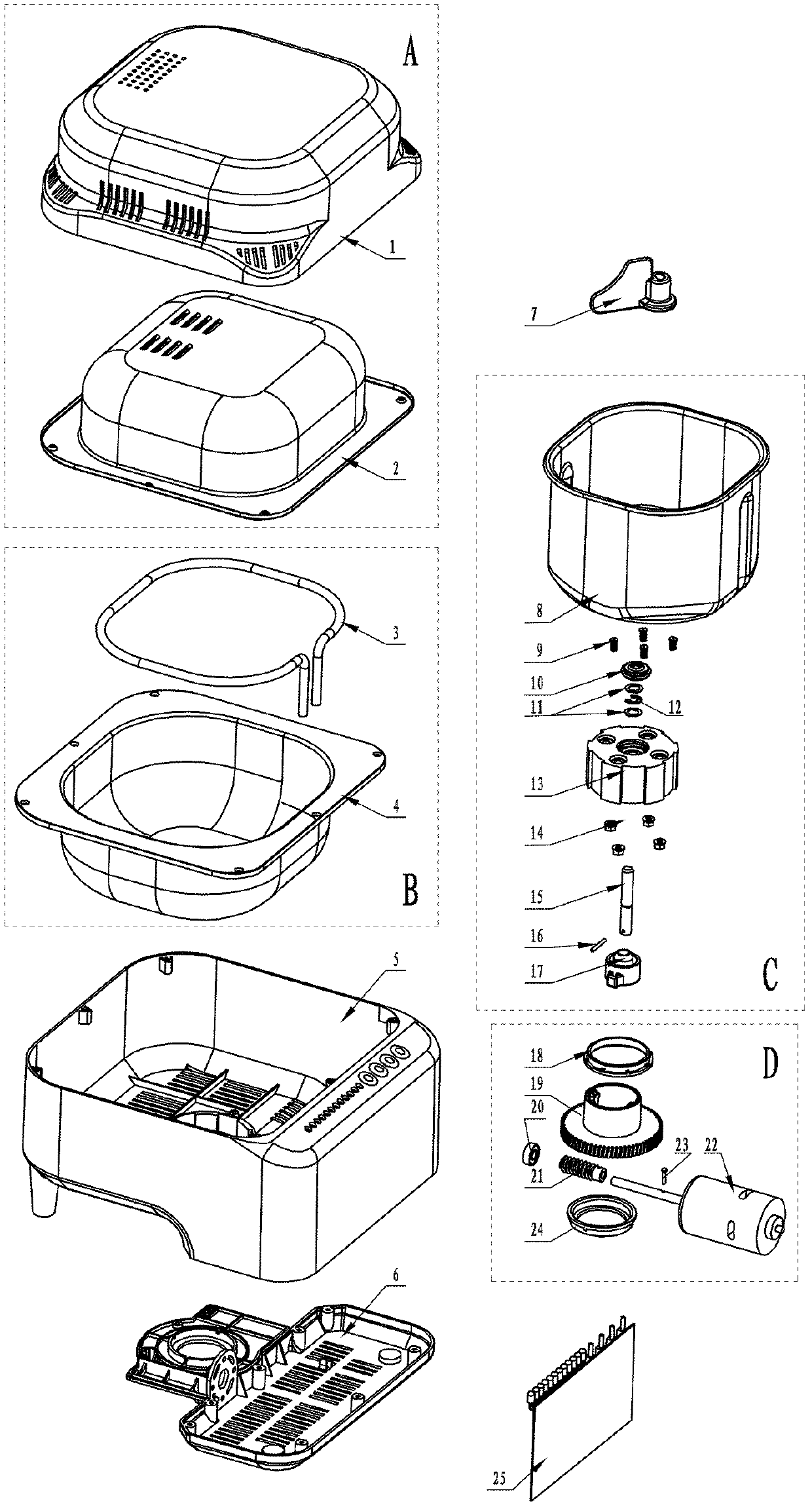

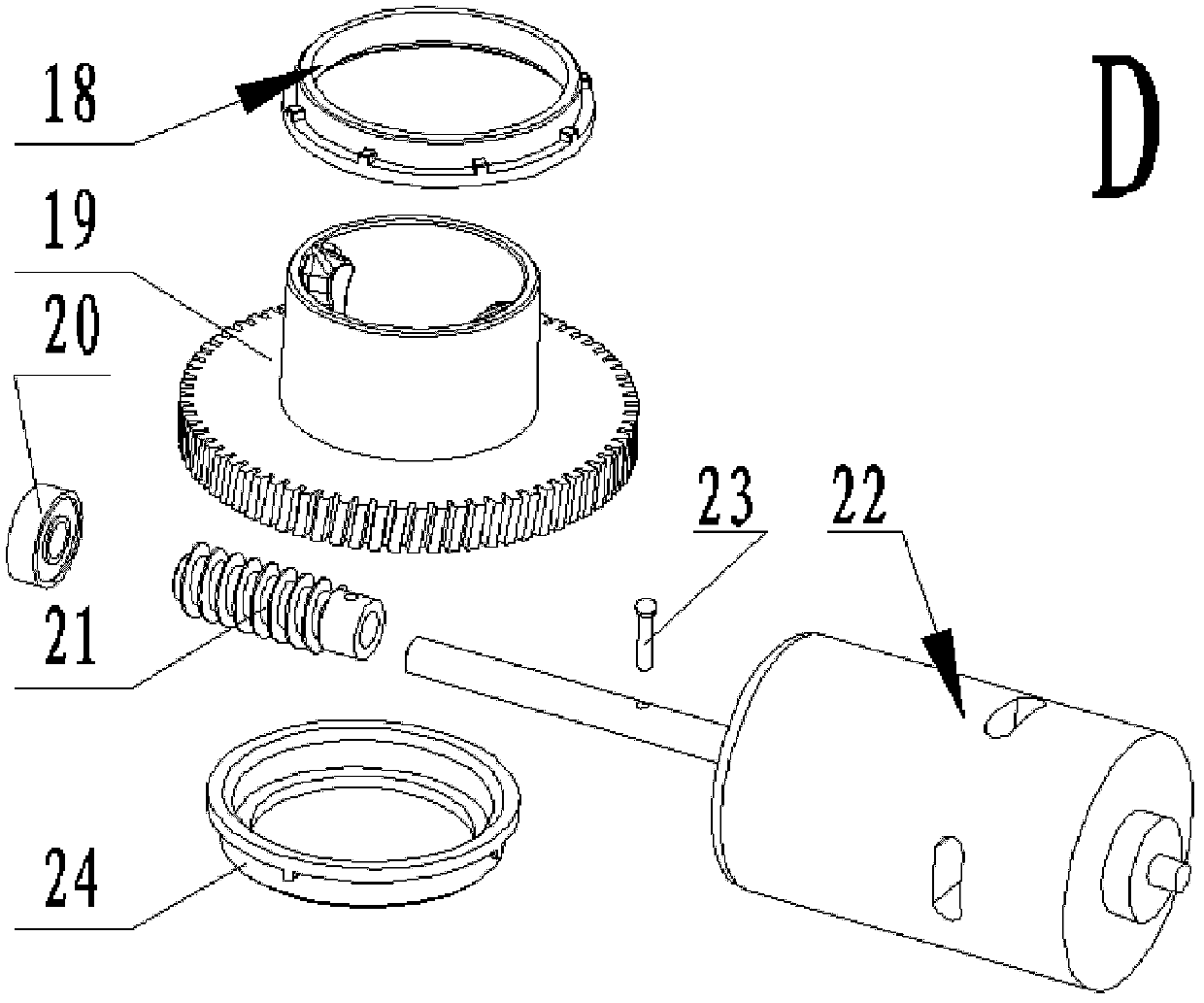

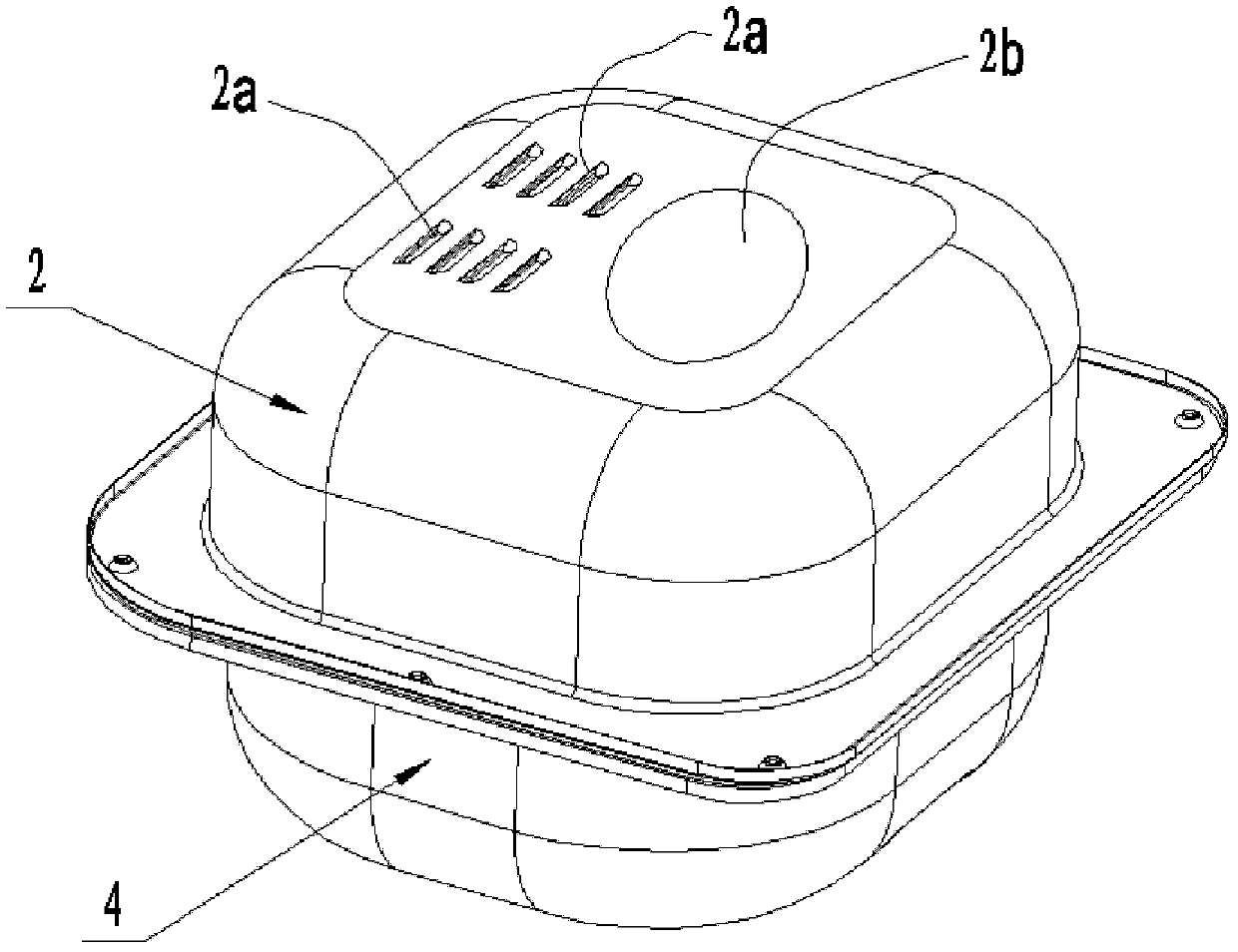

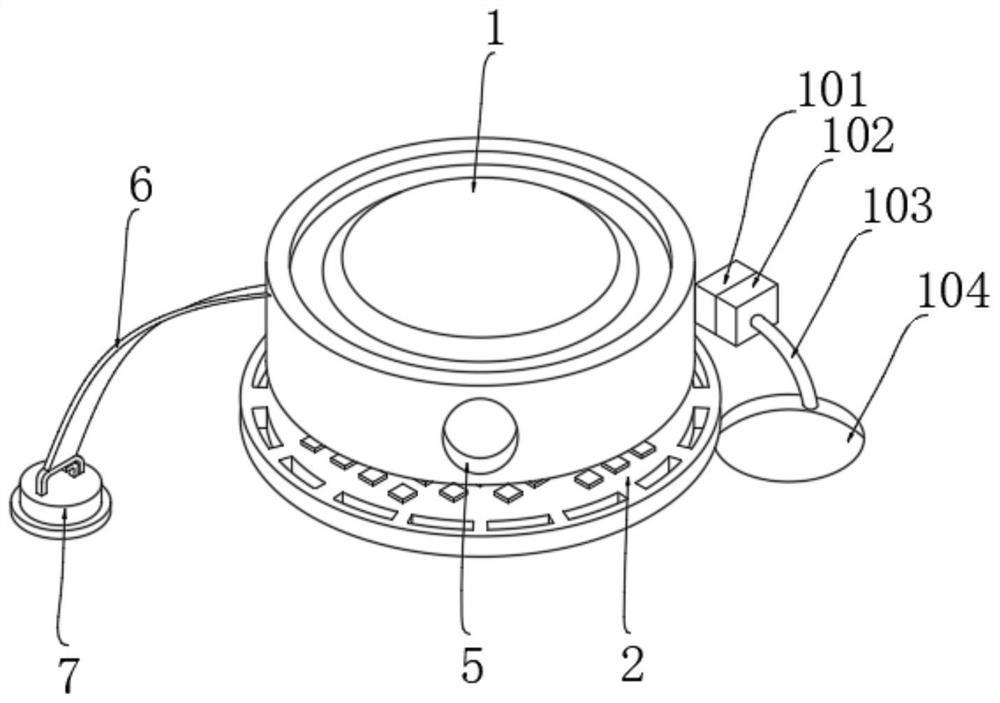

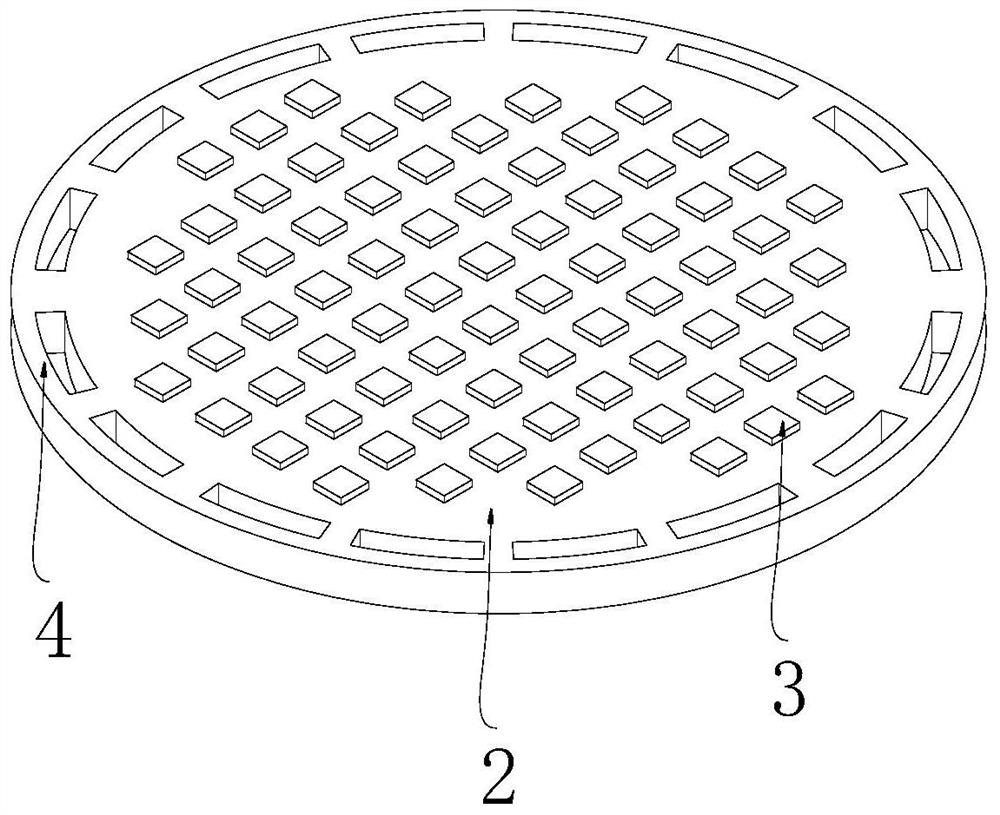

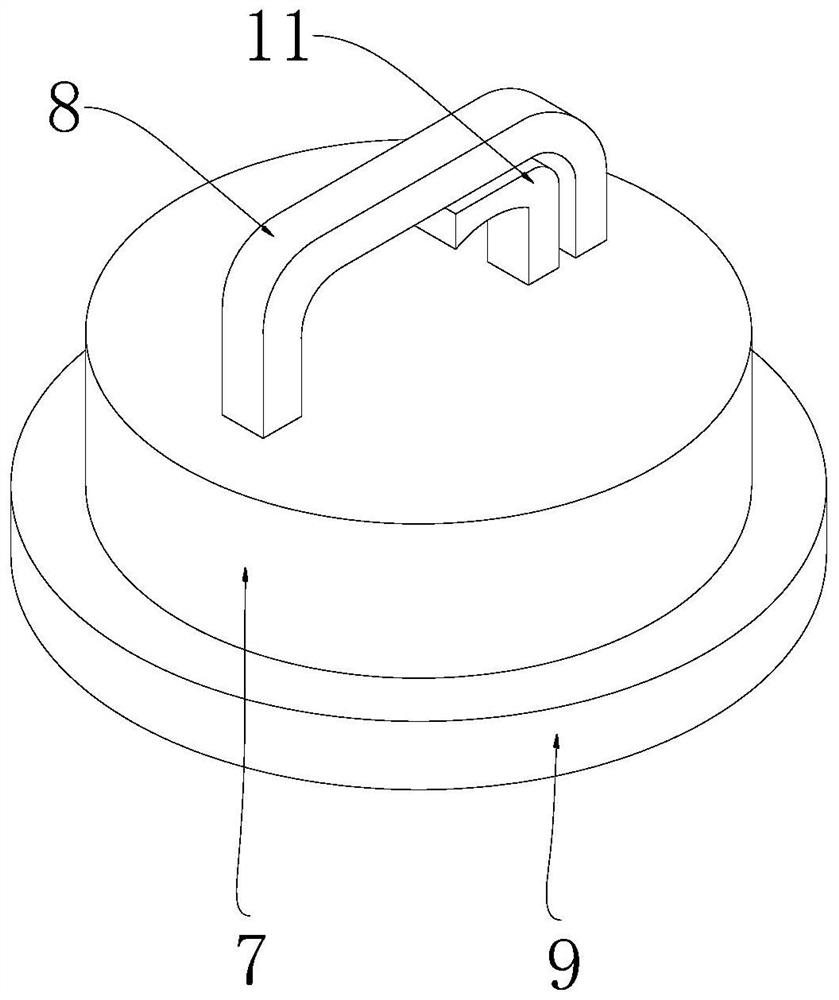

a bread machine

ActiveCN102283267AReduce Part HeightReduce production processBakery productsRoasters/grillsEngineeringMechanical engineering

Owner:ZHEJIANG SHAOXING SUPOR DOMESTIC ELECTRICAL APPLIANCE CO LTD

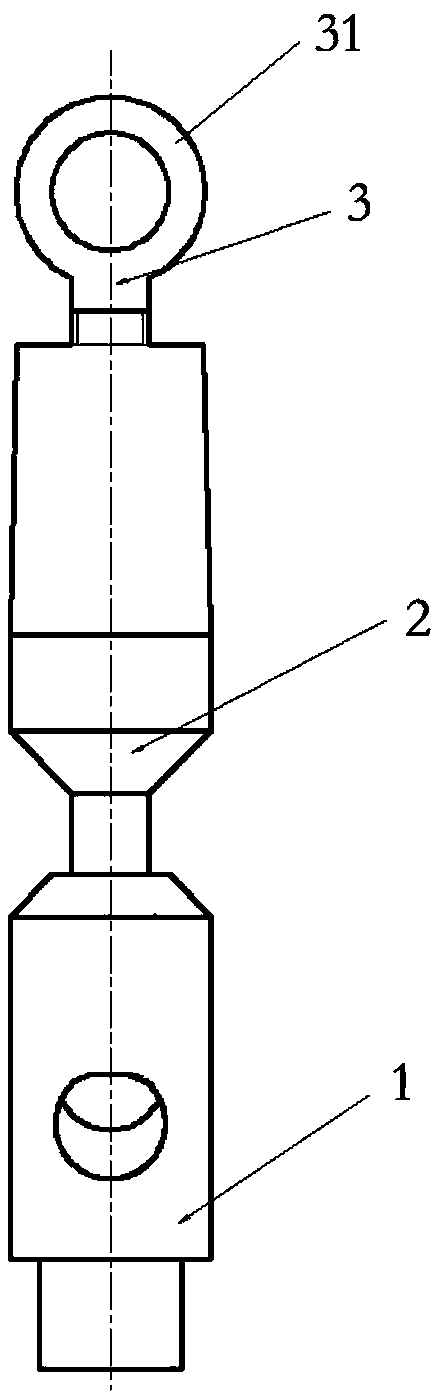

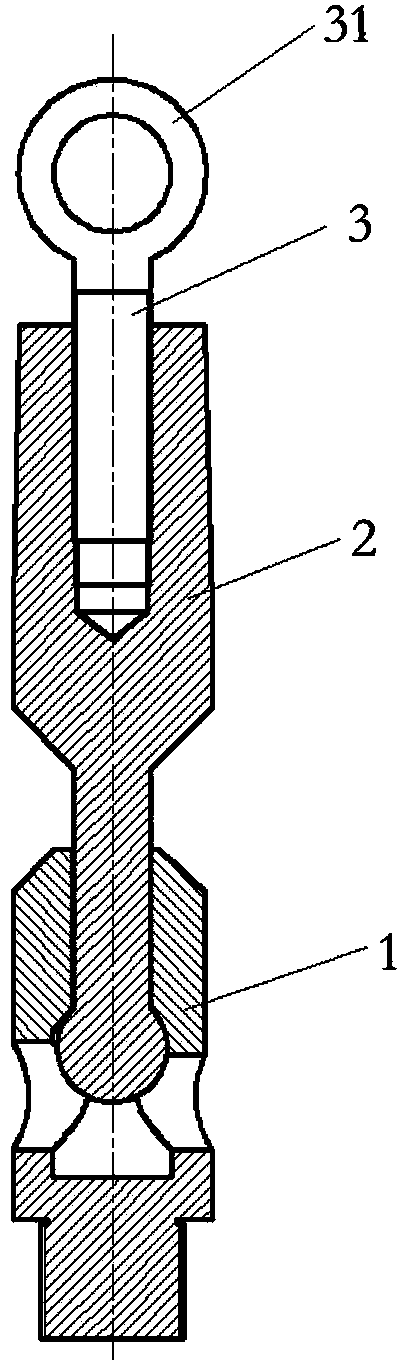

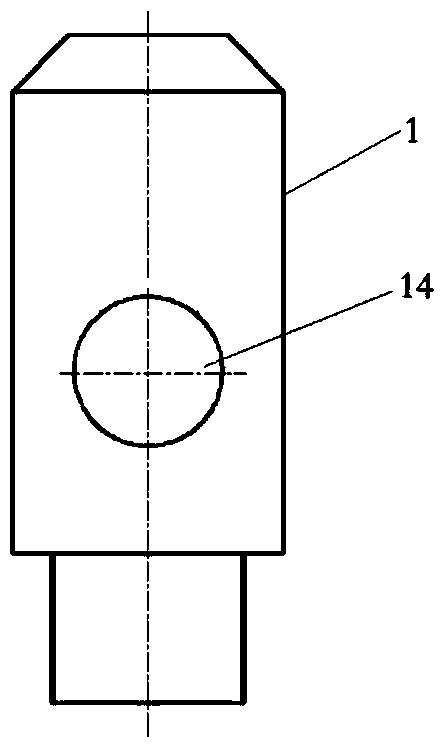

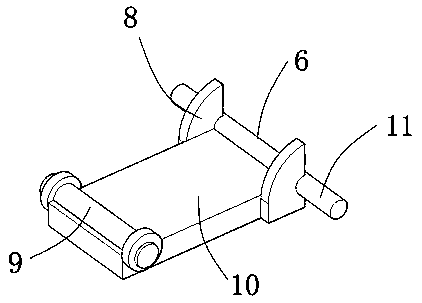

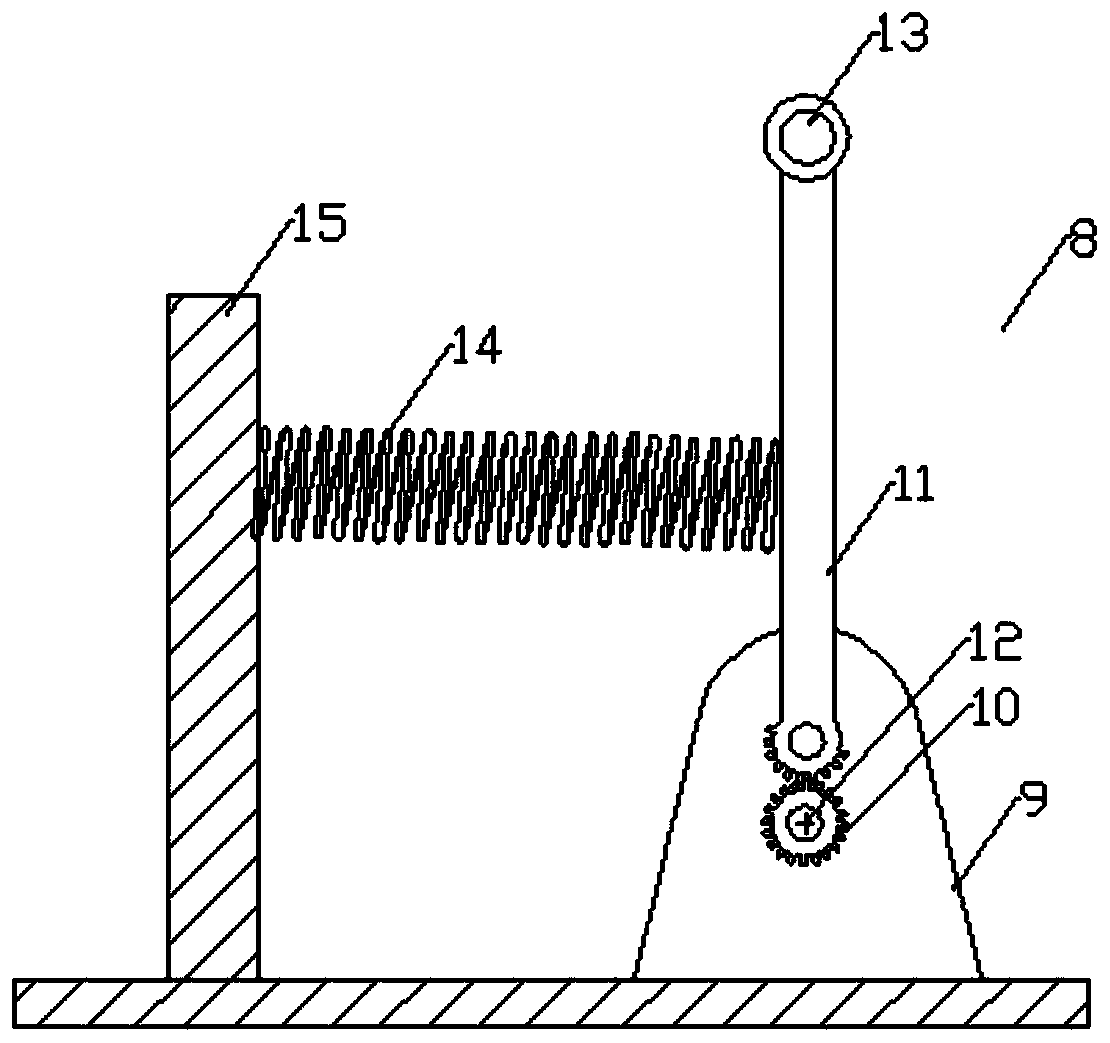

Steel wire rope twisting preventing device for bailing pumping unit

InactiveCN104314528AShorten the timeLoading and unloadingDrilling rodsFluid removalArchitectural engineeringScrew thread

The invention relates to a steel wire rope twisting preventing device for a bailing pumping unit. The steel wire rope twisting preventing device is characterized by comprising a lower joint, a connecting block and a rope sleeve, all of which are orderly and detachably connected together, wherein an annular hole is formed in the top of the rope sleeve; the upper end of the connecting block is in threaded connection with the lower end of the rope sleeve; the steel wire rope goes through the annular hole and then is fixed by use of a fastener; the lower end of the lower joint is in threaded connection with the upper part of the pumping unit, while a vertical hole is formed downwards in the top of the lower joint, the bottom of the vertical hole is connected with a spherical cavity, and the connection part of the spherical cavity and the vertical hole is an annular stepped surface; a bulb arranged on the lower end of the connecting block, the spherical cavity and the annular stepped surface form a fastening structure, and the bulb can be put into the spherical cavity and fastened with the annular stepped surface. The steel wire rope twisting preventing device for the bailing pumping unit is capable of effectively preventing a steel wire rope from twisting and knotting by use of the untwisting measure, and therefore, the service life of the steel wire rope can be prolonged.

Owner:中国石油天然气股份有限公司勘探开发研究院

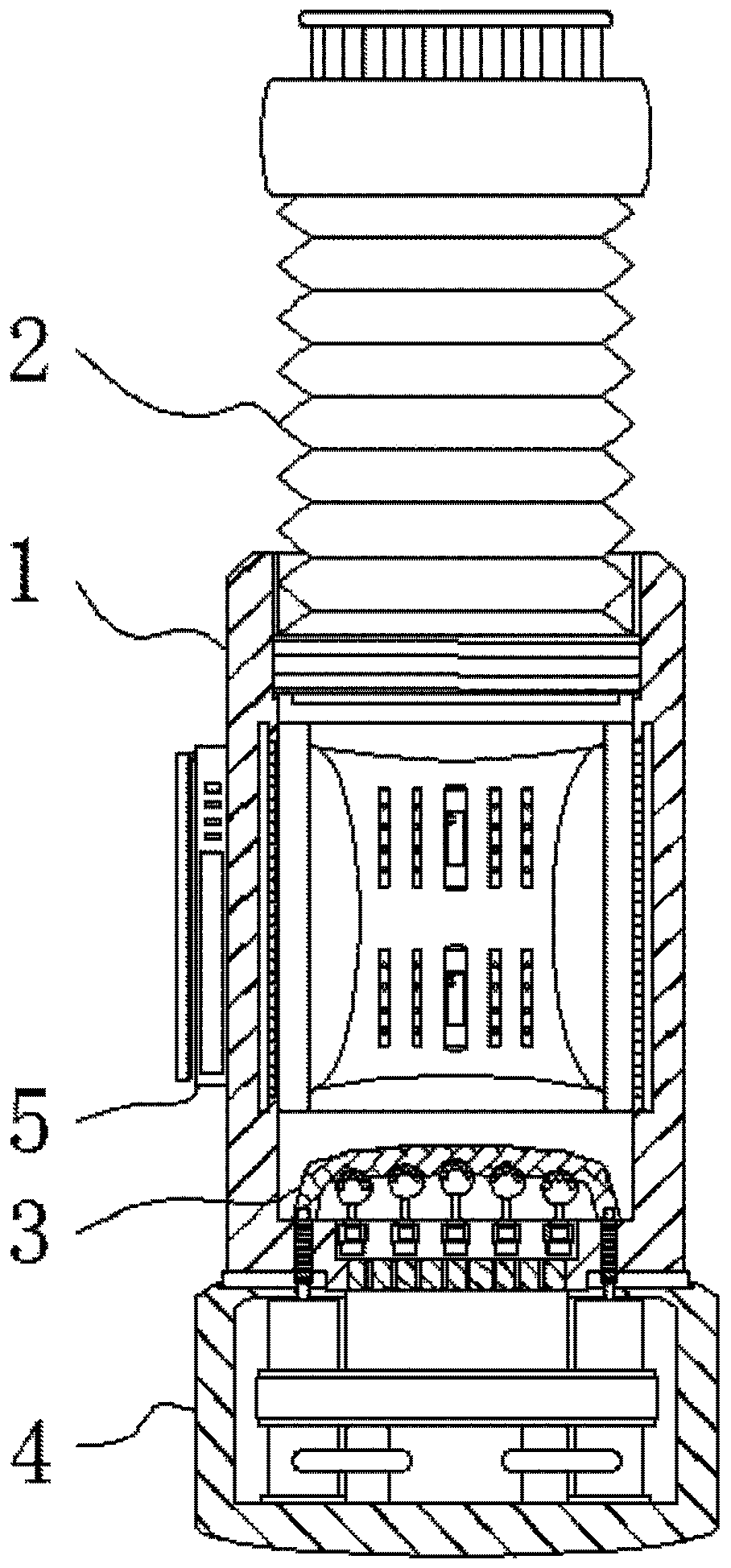

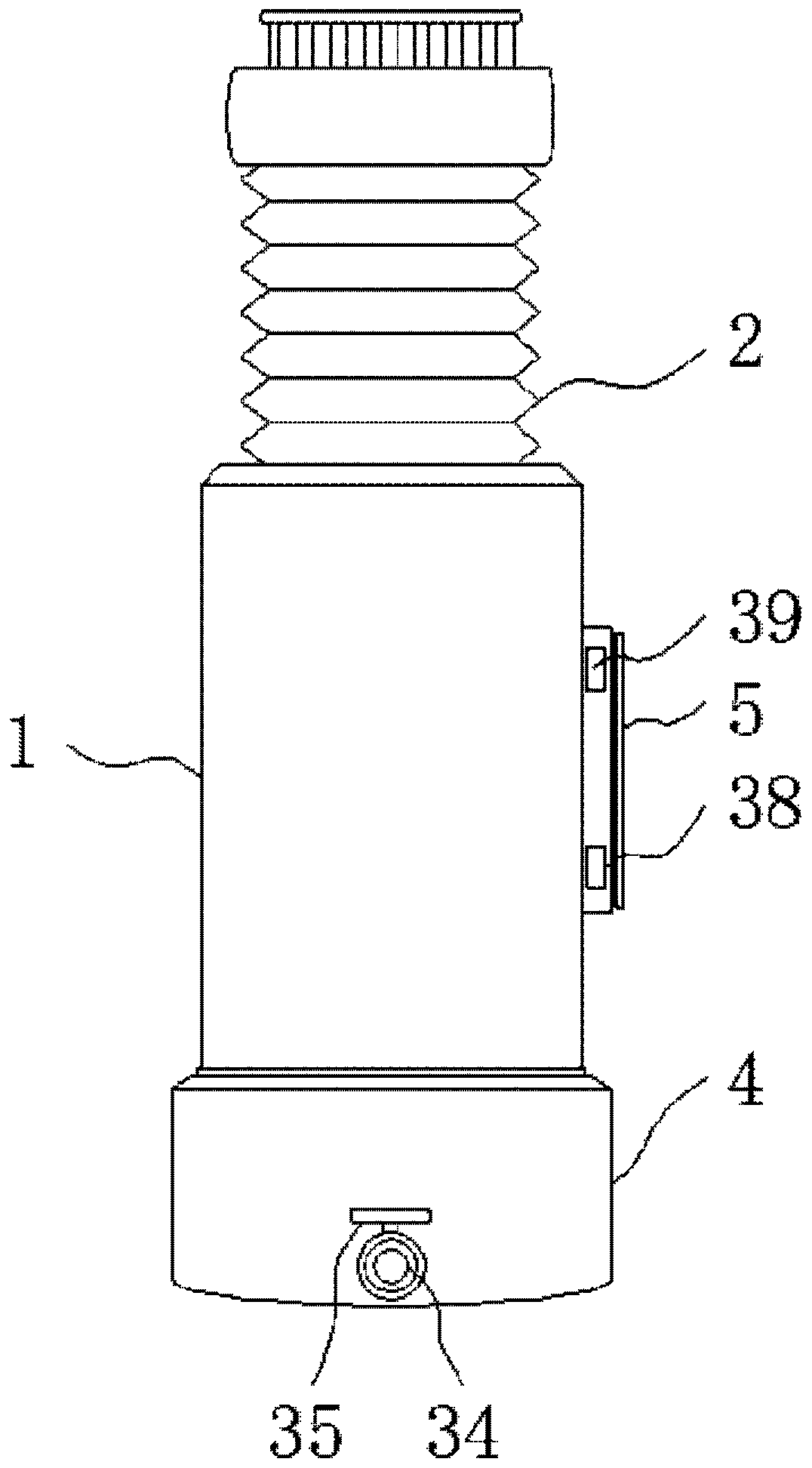

An intelligent hydrotherapy system and a control method thereof

ActiveCN109700655AStable wearIncrease structural flexibilityDevices for pressing relfex pointsVibration massageMassageEngineering

The invention relates to the technical field of hydrotherapy systems and particularly discloses an intelligent hydrotherapy system and a control method thereof. The system includes a main body mechanism, a binding mechanism, a massage mechanism, a water transfer mechanism and an intelligent box. The binding mechanism is disposed in the upper part inside the main body mechanism. The massage mechanism is disposed in the lower part inside the main body mechanism. The water transfer mechanism is below the main body mechanism. The intelligent box is fixed to the external side wall of the main bodymechanism. The binding mechanism includes a lifting base, a base and a rubber foldable tube, wherein the lifting base is fixedly connected to the upper part of the rubber foldable tube, the external wall of the base has a threaded structure, and the inner wall of the lifting base is evenly provided with memory metal rings in an annular manner. According to the system and the method, the objectivethat the system is wearable by a human body can be achieved through arrangement of the binding mechanism, and the rubber foldable tube is made of rubber, has good structural elasticity and can adapt to bending movements of human legs, thus facilitating movement.

Owner:南通佳景健康科技股份有限公司

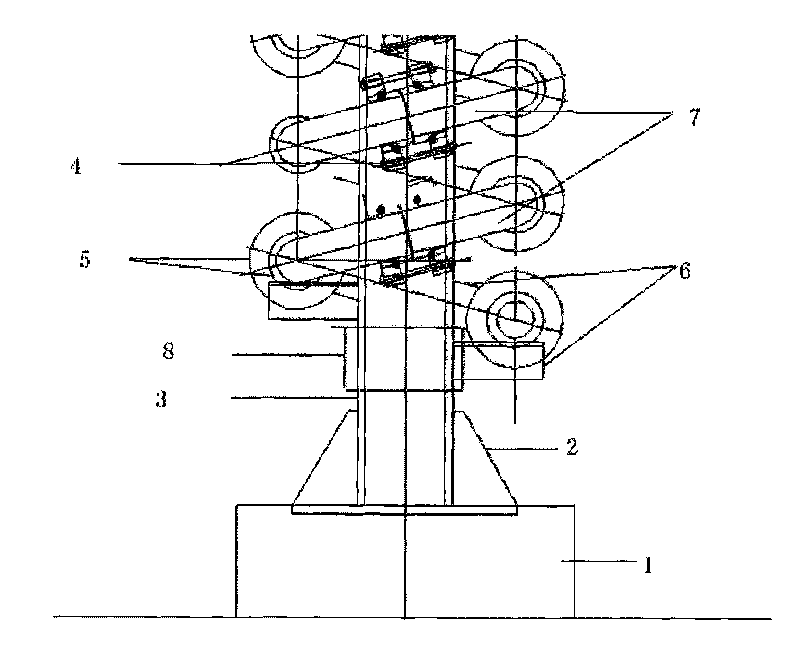

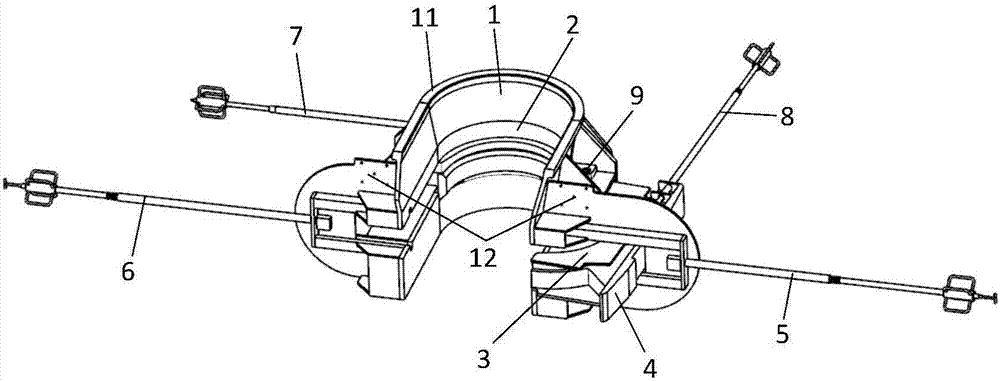

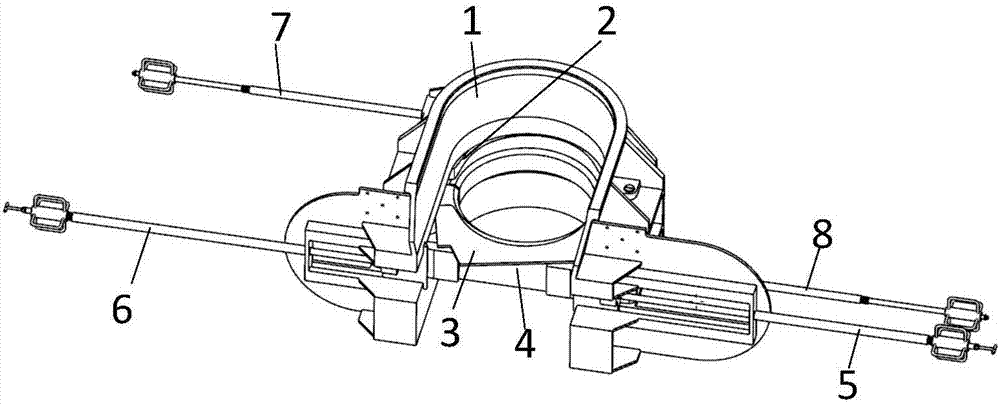

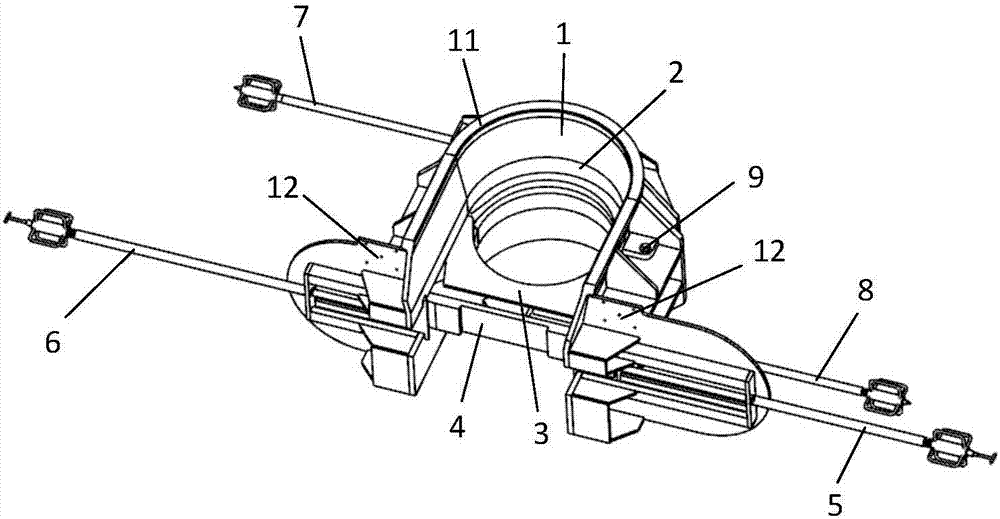

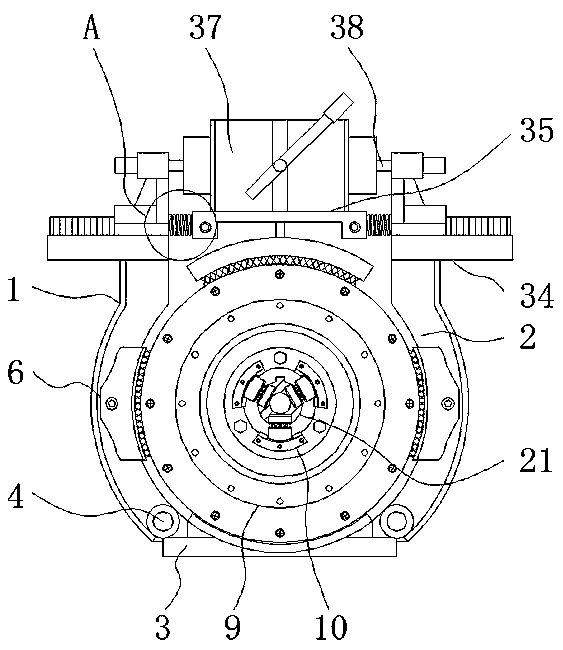

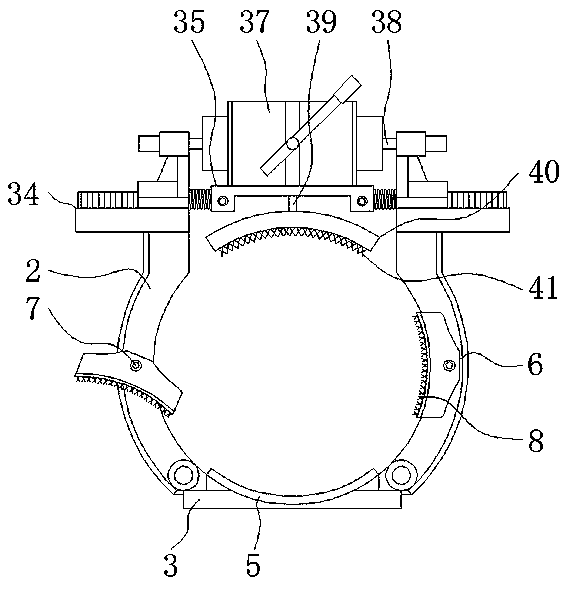

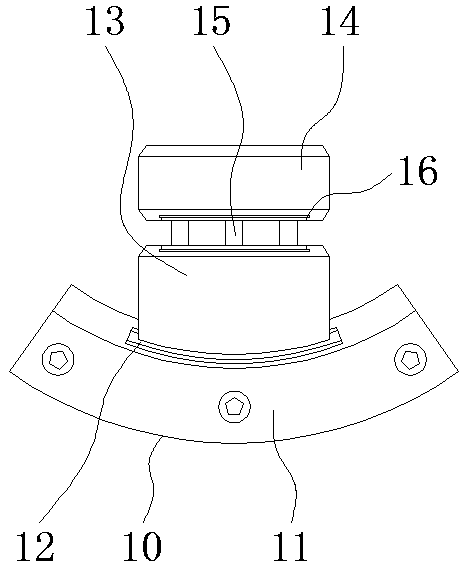

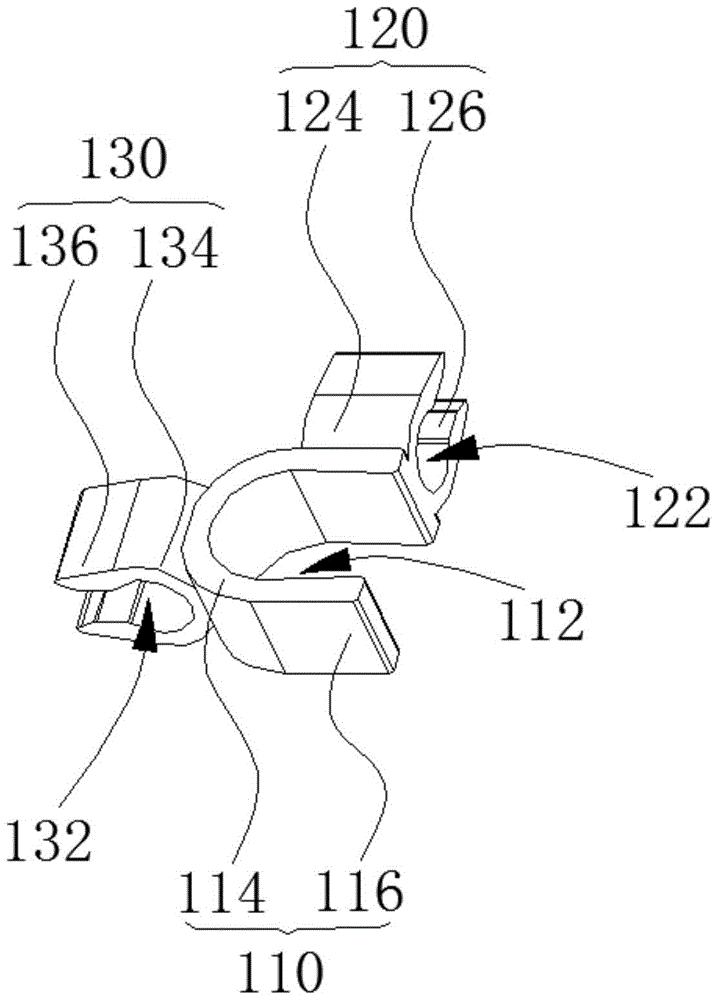

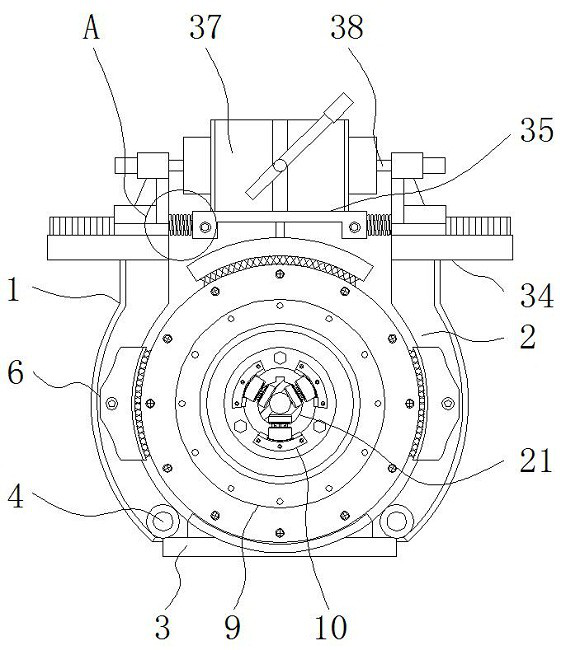

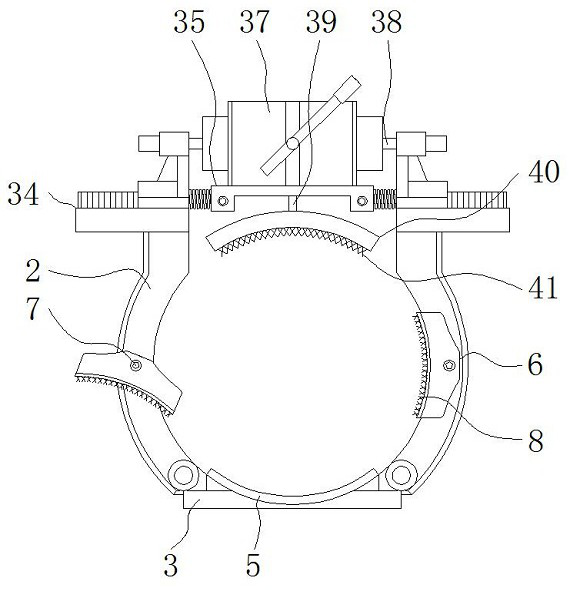

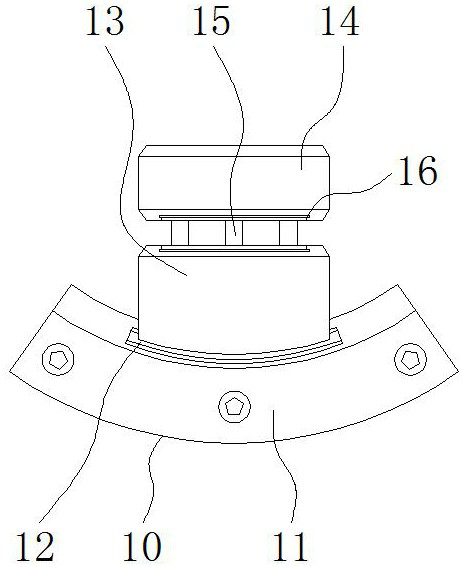

Embracing and clamping mechanism of deepwater stand pipe buoyancy device

The invention provides an embracing and clamping mechanism of a deepwater stand pipe buoyancy device. The embracing and clamping mechanism comprises a clamp frame, a rear movable clamp, a front movable upper clamp, a front movable lower clamp, a front movable lower clamp right locking mechanism, a front movable lower clamp left locking mechanism, a rear movable clamp locking mechanism and a front movable upper clamp locking mechanism. The embracing and clamping mechanism is connected to the stand pipe buoyancy device through a U-shaped load guide way on the clamp frame; and embracing and clamping mechanism fixing boards are fixed to the stand pipe buoyancy device through bolts, so that the embracing and clamping mechanism is prevented from falling off. A stand pipe stress ring is embraced through a clamp frame stand pipe stress surface, a rear movable clamp stand pipe stress surface, a front movable upper clamp stand pipe stress surface and a front movable lower clamp stand pipe stress surface, stand pipes and the stand pipe buoyancy device of a tension leg platform (TLP) are connected, all the movable clamps are locked through the locking mechanisms, and connection reliability is guaranteed. The embracing and clamping mechanism of the deepwater stand pipe buoyancy device has the advantages of being simple in structure, convenient to operate, high in bearing capacity, reliable in connection, low in manufacturing cost and the like.

Owner:HARBIN ENG UNIV

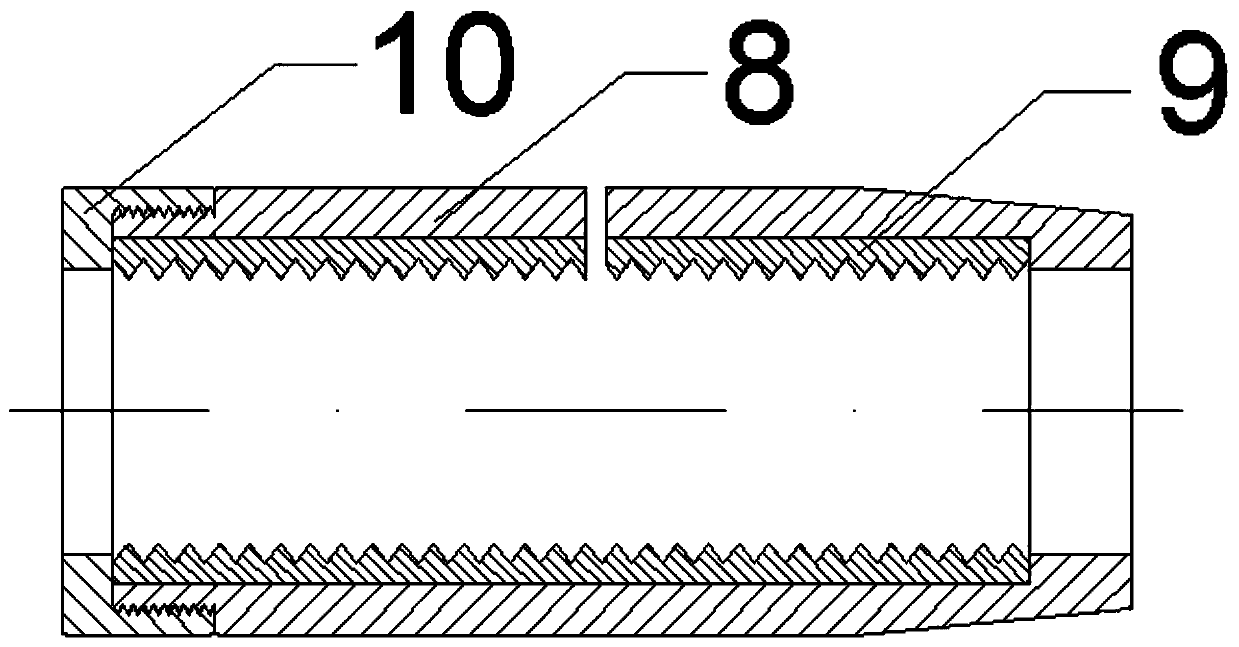

Cold extrusion combination type reducing reinforcing steel bar connection device and method

InactiveCN110202077AGuaranteed connection strengthImprove efficiencyWire networkRebarMaterial resources

The invention provides a cold extrusion combination type reducing reinforcing steel bar connection device and method and relates to the field of reinforcing steel bar connection. The cold extrusion combination type reducing reinforcing steel bar connection device comprises a support, an extrusion assembly and a connection workpiece. The support is provided with a reinforcing steel bar fixing structure. The extrusion assembly is installed on the support. The connection workpiece is arranged on a second extrusion tool. The first extrusion tool and the second extrusion tool are both provided withthrough holes allowing the reinforcing steel bar to pass through. The connection workpiece is of a hollow structure with the two ends being open. The inner wall of the connection workpiece is provided with an inner thread. The first extrusion tool and the second extrusion tool cooperate to extrude the connection workpiece through an extrusion device. A balance structure is arranged in the middleof the connection workpiece. According to the cold extrusion combination type reducing reinforcing steel bar connection device, the extrusion assembly and the connection workpiece cooperate to extrudethe two ends of the connection workpiece, since the inner portion of connection workpiece is provided with internal threads, in the compression process of the connection workpiece, the internal threads protrude to a higher extent, so that the internal thread and longitudinal and transverse ribs of the reinforcing steel bar are mutually engaged so as to achieve the connection purpose. Meanwhile, by the adoption of the cold extrusion combination type reducing reinforcing steel bar connection method, one or two people can complete operation, and therefore the manpower and material resources aregreatly saved.

Owner:高旻

Armored car fault analysis braking device with adjusting protection function

ActiveCN110701214AEffective protectionAvoid wear and tearDrum brakesActuatorsArmored carFault analysis

The invention discloses an armored car fault analysis braking device with an adjusting protection function, and relates to the technical field of armored car fault analysis. A clamping body and a braking chuck are specifically included. The clamping body is composed of a holding arm, a base and an elevating base. The holding arm is arranged above the base. The elevating base is fixed to the upperend of the holding arm. A double-head air cylinder is fixed to the upper surface of a base plate base. Pneumatic rods are fixedly matched and connected with the elevating base. A bottom support is integrally arranged above the base. The braking chuck is arranged on the inner side of the clamping body. A braking clamping shaft piece is arranged on the inner side of the clamping assembly. Accordingto the armored car fault analysis braking device with the adjusting protection function, through the arrangement of the clamping body, the braking pressure completely exerted on the braking chuck originally is scattered, the braking chuck is effectively protected, and abrasion or torsion deformation caused by large braking pressure exerted on the braking chuck for a long time is avoided.

Owner:JIAXING DAMING INDAL

Food baking machine

InactiveCN104905691AIncrease the horizontal areaImprove cooling effectRoasters/grillsSymmetric designSymmetric structure

The invention provides a food baking machine. An oven comprises a first oven component and a second oven component. The depth ratio of the second oven component to the first oven component ranges from 2:3 to 1:1. Due to the fact that the oven is manufactured in a separated mode by adopting the symmetric structure, the oven is divided into the two components, the symmetric design is adopted, and the height of the components is decreased, so that the upper portion and the lower portion of the oven are stretched out at a time, the production procedures are simplified, meanwhile, materials are saved, and the purposes of energy conservation and consumption reduction are achieved.

Owner:吴健辉

Bread maker

ActiveCN102283267BIncrease the horizontal areaImprove cooling effectBakery productsRoasters/grillsMechanical engineeringFood science

Owner:ZHEJIANG SHAOXING SUPOR DOMESTIC ELECTRICAL APPLIANCE CO LTD

Support for connecting pure electric vehicle and tidal lane robot

InactiveCN111890969AImprove stabilityEasy to disassembleCharging stationsElectric vehicle charging technologyAutomotive engineeringElectrical and Electronics engineering

The invention discloses a support for connecting a pure electric vehicle and a tidal lane robot, and belongs to the field of municipal construction. The support for connecting a pure electric vehicleand a tidal lane robot comprises a robot shell, wherein a rubber plate is arranged at the bottom end of the robot shell; a plurality of first magnet blocks are arranged in the middle of the rubber plate; a pull ring is arranged on the outer side of the rubber plate; a clamping groove and an elastic belt are arranged on the outer side of the robot shell; a clamping block is arranged at the end partof the elastic belt; a protective pad is arranged at the bottom end of the clamping block; a second magnet block is arranged in the middle of the protective pad; and a movable frame is arranged at the top end of the second magnet block. According to the invention, the robot shell can be tightly attached to the surface of the vehicle body through the rubber plate and the plurality of first magnetblocks, the purpose of connecting the robot shell with the vehicle body is achieved, then the tidal robot can conveniently charge the pure electric vehicle, and the risk that the pure electric vehicleblocks a road due to power failure is reduced.

Owner:孝感峰创智能科技有限公司

Quick timing device for sports competitions

InactiveCN111346361AAchieve connectionTo achieve the purpose of connectionSport apparatusStructural engineeringMechanical engineering

The invention discloses a quick timing device for sports competitions. The device comprises a timing device main body, and a bottom frame is arranged at the bottom of the inner end of the timing device body. A timer is mounted at the inner end of the bottom frame; the front end of the bottom frame is connected with a connecting plate. The upper end of the connecting plate is elastically connectedwith a foot stand; a friction pad is arranged at the upper end of the foot stand. The rear end of the friction pad is fixedly connected with a contact frame; a bottom plate is arranged at the bottom of the center of the inner end of the connecting plate, a sleeve rod is arranged on one side of the bottom plate, a wing plate is arranged on the other side of the bottom plate, an inserting rod is inserted into the inner end of the wing plate, a clamping plate is arranged in the center of the inner end of the contact frame, a transverse shaft is connected to the side end of the clamping plate, anda fixing frame is fixedly connected to the transverse shaft. According to the quick timing device for sports competitions, through the arrangement of the connecting plate, the purpose of mutual connection of the inner ends is achieved.

Owner:无锡汇跑体育有限公司

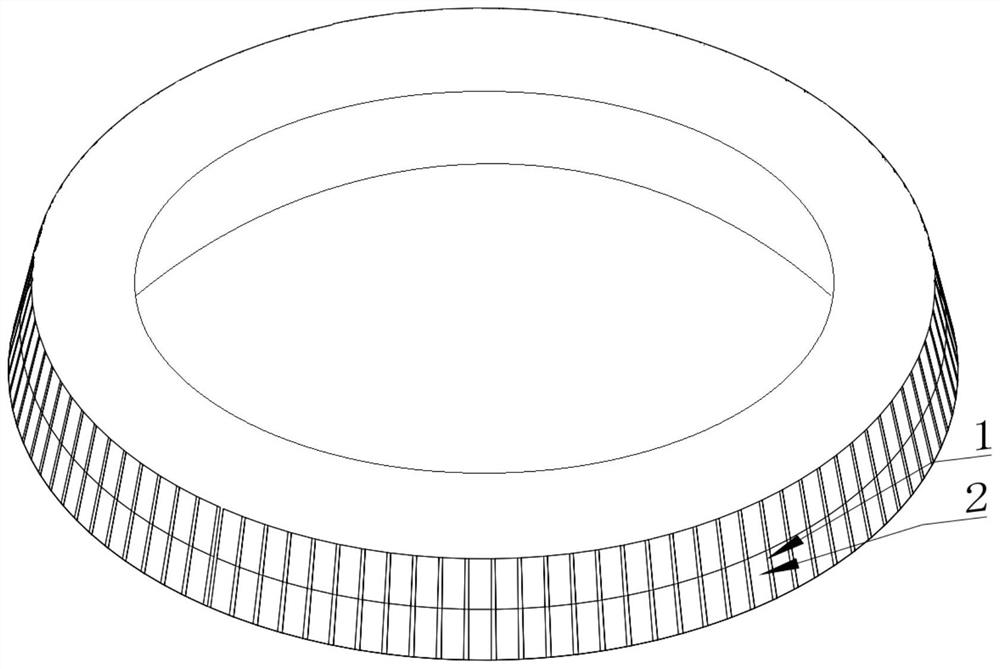

Connecting form, form erecting structure and form erecting method

PendingCN112144861AReduce labor wasteShorten construction timeForms/shuttering/falseworksAuxillary members of forms/shuttering/falseworksStructural engineeringMechanical engineering

The invention discloses a connecting form, a form erecting structure and a form erecting method. The connecting form comprises a plate body and at least two connecting parts, the section size of the plate body in the length direction of the plate body is arranged in a reduced manner, the connecting parts are arranged on the two sides of the plate body, the connecting parts are arranged in an extending mode in the length direction, and the connecting parts are used for being connected with a standard form. The plate body is arranged in a reduced manner in the length direction so that after theconnecting parts are connected with the standard form, the connecting form and the standard form can form the form erecting structure required in a circular truncated cone shape, for example, when thebottom surface of the circular truncated cone is required to be larger than the top surface, the long edge of the plate body can be arranged on one side of the bottom edge of the circular truncated cone in the length direction, then the structure defined by the multiple connecting forms and the standard forms meets the shape requirement of the form erecting structure, so that labor waste is reduced, the construction time is greatly shortened, and the energy-saving and high efficiency construction requirements are met.

Owner:STATE GRID CORP OF CHINA +3

Tracheal cannula adapter and tracheal cannula

InactiveCN113384790ATo achieve the purpose of connectionImprove convenienceTracheal tubesHeat and moisture exchangerSurgery

The invention discloses a tracheal cannula adapter and a tracheal cannula. The tracheal cannula adapter comprises a cylindrical adapter head; a plurality of annular flanges are arranged on the inner wall of the adapter head; the inner diameter of each annular flange is gradually reduced from bottom to top; the annular flanges are integrally formed; an annular groove is formed between every two adjacent annular flanges; and the diameter of each annular groove is gradually reduced from bottom to top. The trachea cannula adapter can effectively solve the problems that an existing metal trachea cannula is diverse in size and cannot be connected with different instruments such as a breathing machine, a breathing air bag, a disposable heat and moisture exchanger and a filter for use.

Owner:FOURTH MILITARY MEDICAL UNIVERSITY

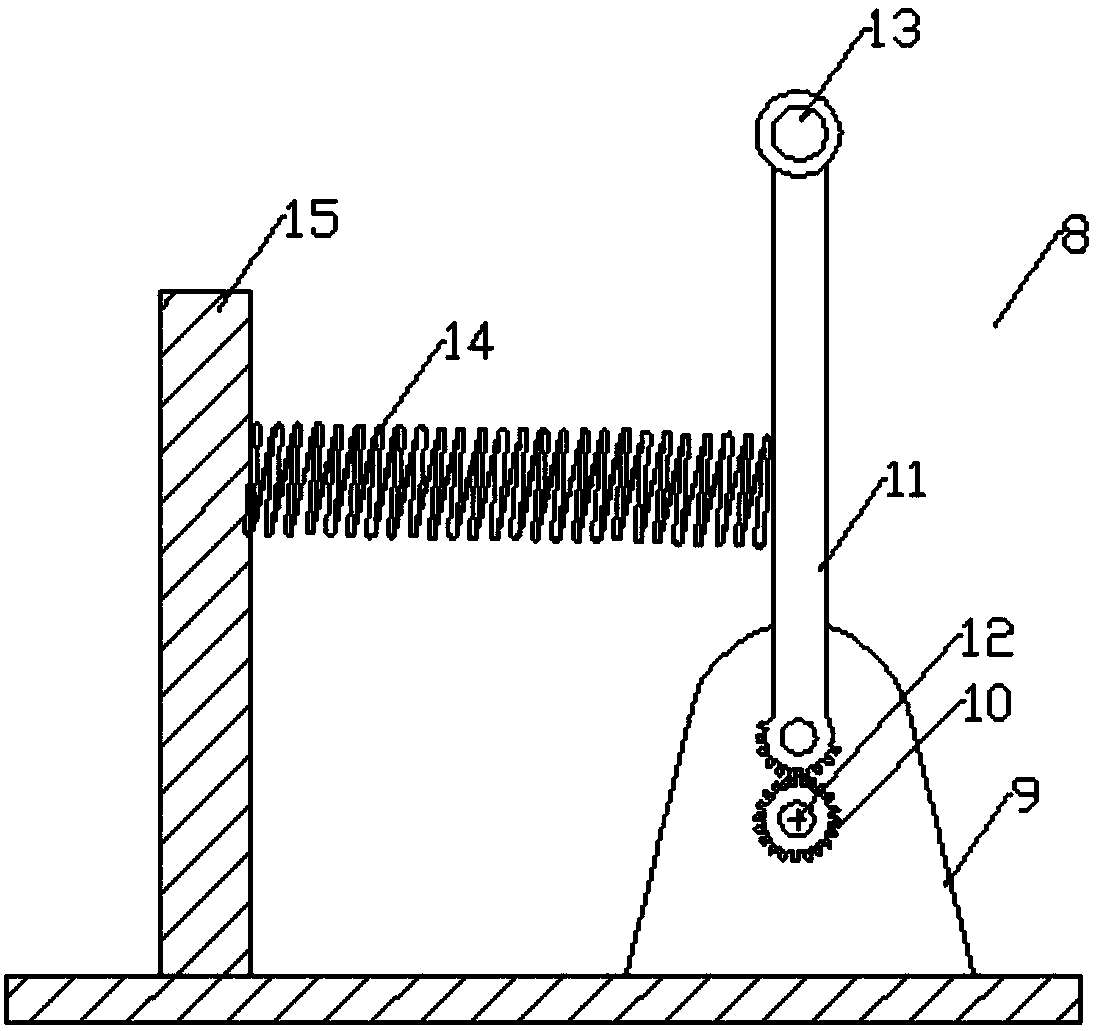

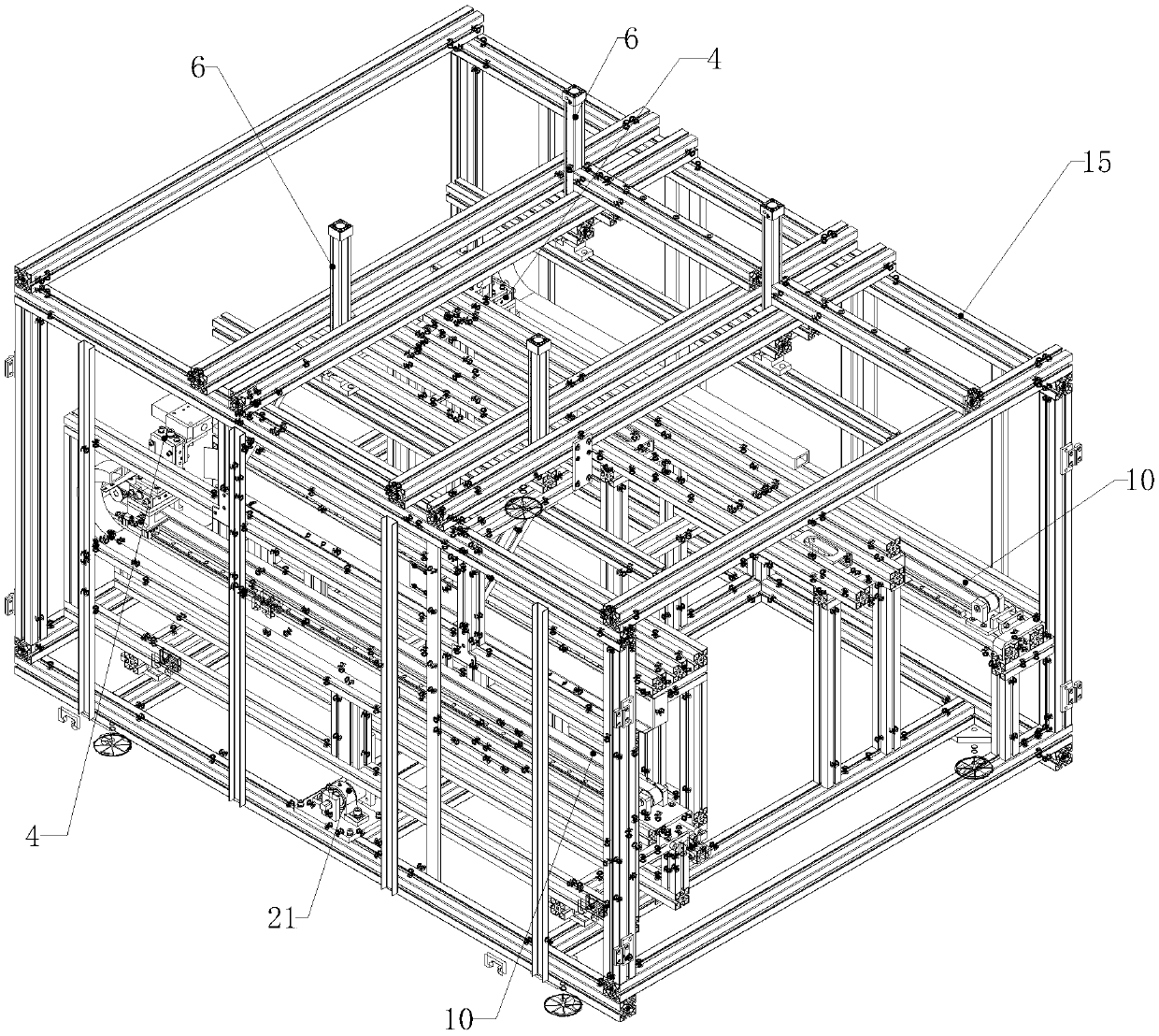

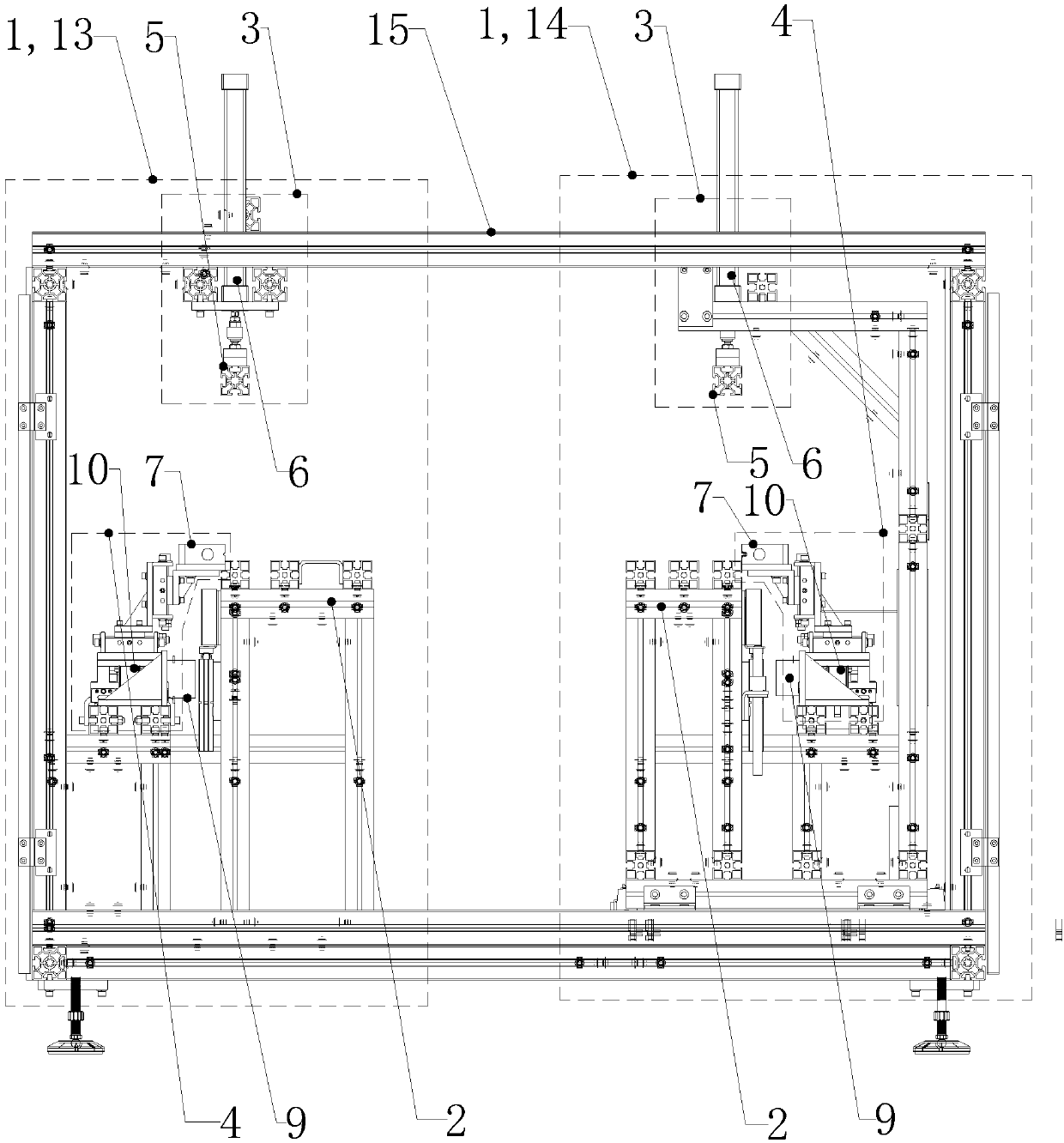

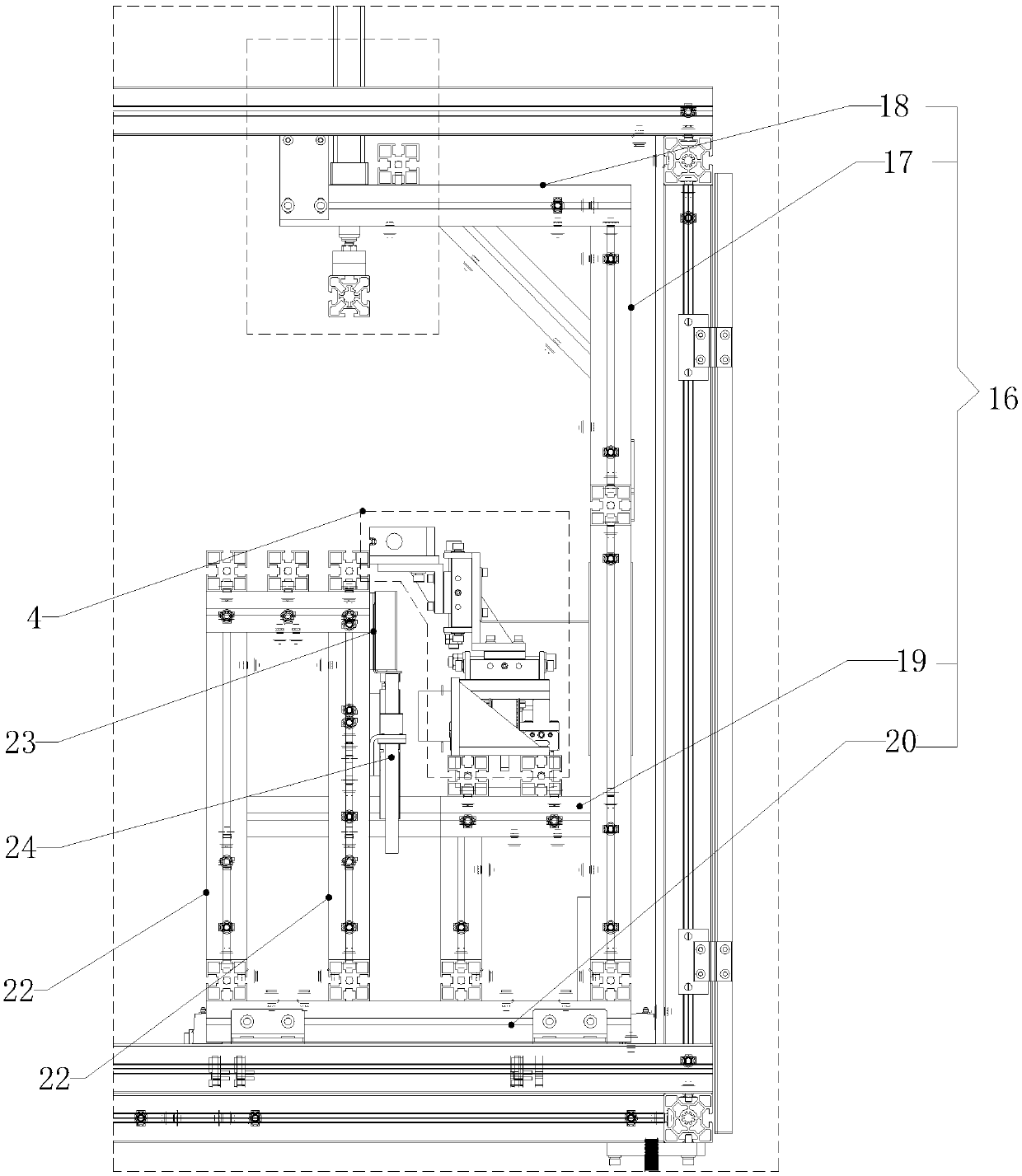

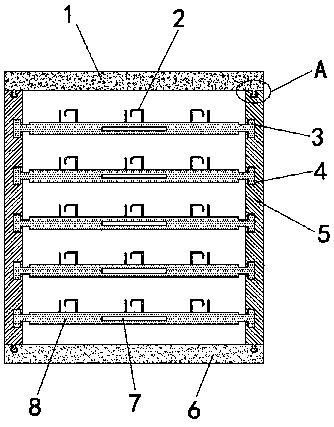

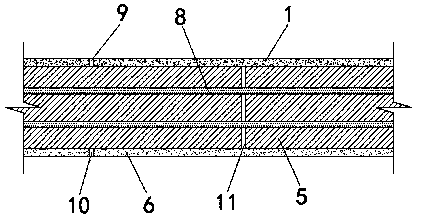

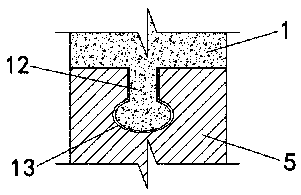

Longitudinal-transverse bidirectional plastic hollow sheet edge sealing machine

PendingCN107718612AImprove edge banding efficiencyRealization of edge bandingHollow articlesFastenerEdge banding

The invention relates to a longitudinal-transverse bidirectional plastic hollow sheet edge sealing machine which comprises edge sealing devices. Each edge sealing device comprises a working table usedfor containing a PP hollow sheet, a pressing device located above the working table and an edge sealing assembly located on the outer side of the working table. Each pressing device comprises a pressing block used for pressing the PP hollow sheet onto the face of the corresponding working table and a pressing block drive device driving the pressing block to move. Each edge sealing assembly comprises a zipper type edge sealing mold and a mold drive device driving the zipper type edge sealing mold to move along the edge of the PP hollow sheet. The longitudinal-transverse bidirectional plastic hollow sheet edge sealing machine is high in efficiency and good in effect.

Owner:JIANGSU YUANXIANG INTERNET OF THINGS SCI & TECH

A Micro Friction Stir Welding Process for Electronic Packaging

ActiveCN111230282BLow profileAchieve high densityMetal working apparatusNon-electric welding apparatusHigh densityEngineering

The invention relates to a micro-stir friction welding process for electronic packaging, which belongs to the technical field of electronic packaging. The invention solves the problem of unsatisfactory high-density and pollution-free effects of the existing electronic packaging technology, and the difficulty of direct welding of micro, small and thin structures by the existing friction stir welding technology. First, the first pad and the second pad to be soldered are a set of pad groups. When the pad group is arranged in a single point, press-in holes are prefabricated on the first substrate, and the pad groups are arranged in parallel. Between the first substrate and the second substrate, align the press-in hole with the center of the pad group, then use the clamp to press the first substrate and the second substrate, and align the stirring head coaxially on the press Above the insertion hole, control the stirring head to rotate at a high speed and move down into the pressing hole, and then press into the first pad. Under the set pressing amount and load holding time, the first pad and the second pad are realized. The permanent metallurgical connection between the discs, and finally the control of the stirring head moving up and out of the press-in hole.

Owner:HARBIN INST OF TECH

A flexible graphite lightning protection grounding body grounding device

ActiveCN109256624BCause separationTo achieve the purpose of connectionClamped/spring connectionsConnection contact member materialStructural engineeringGraphite

The invention discloses a flexible graphite lightning protection grounding electrode grounding device, in accordance with that present invention, include a housing, An upper surface of that shell is provided with a threaded hole penetrate the bottom surface, A lateral surface of that shell is provided with a through hole, the advantages of that invention are simple structure, easy operation, so that that tension device is arranged, The flexible graphite lightning grounding electrode can be avoided from being separated from the foundation when the flexible graphite lightning grounding electrodeis affected by bad weather. The purpose of connecting the flexible graphite lightning grounding electrode with the foundation can be realized by setting a screw rod and a drill nail, and the positionof the drill nail in the screw rod can be adjusted and adapted to be used in various foundations, so that the utility model is high and the maintenance is convenient.

Owner:ANHUI HUAXI ELECTRIC POWER TECH CO LTD

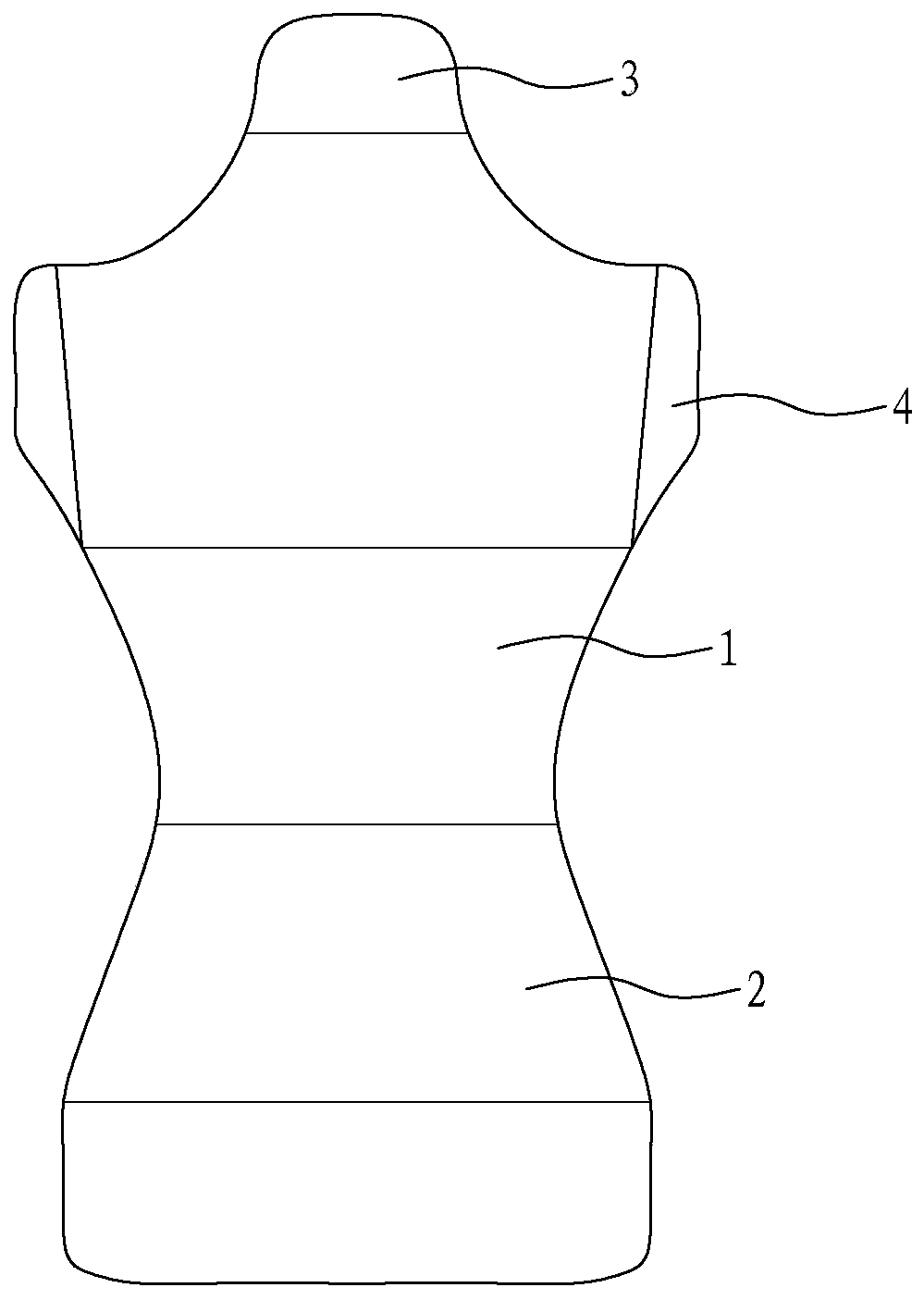

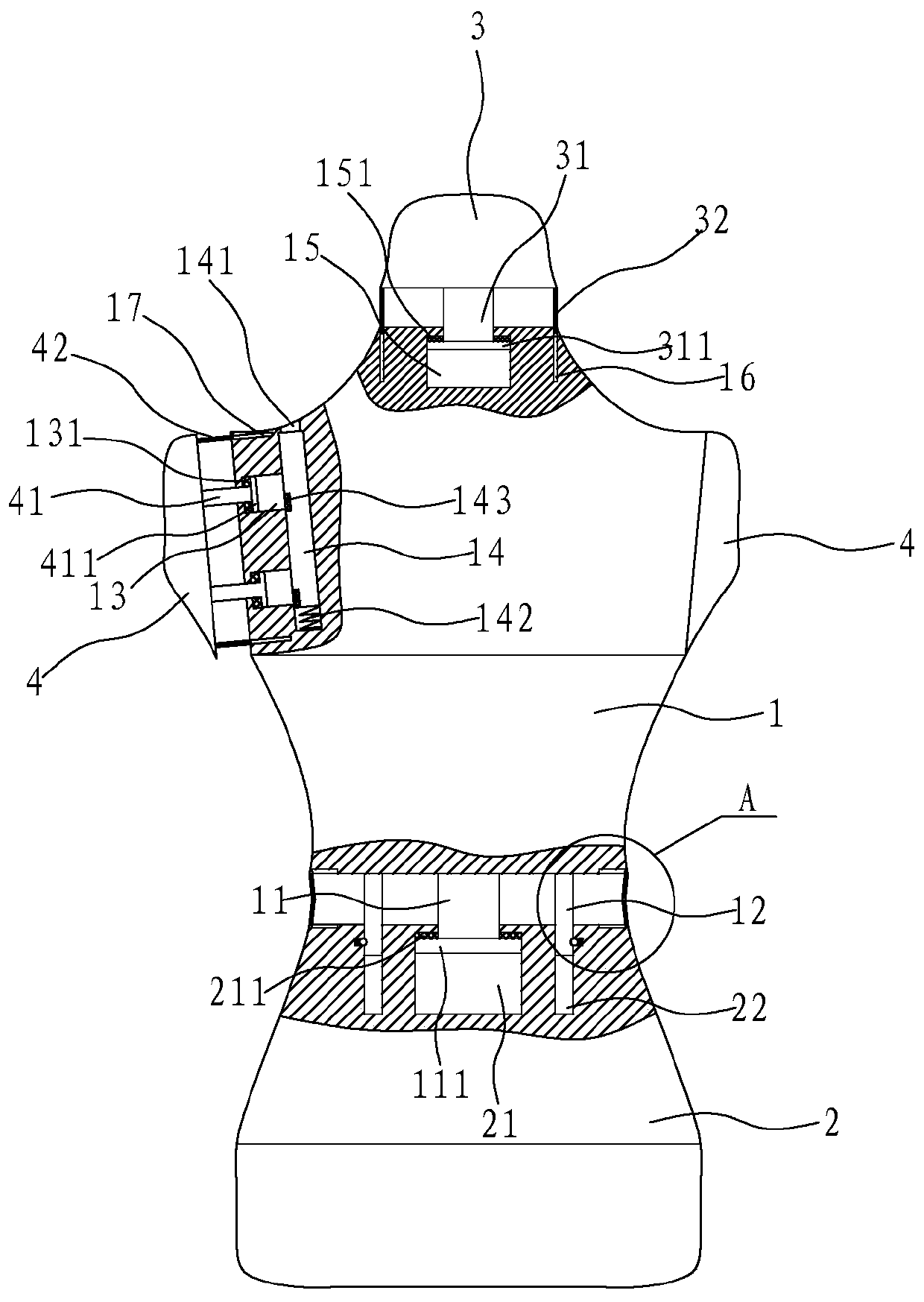

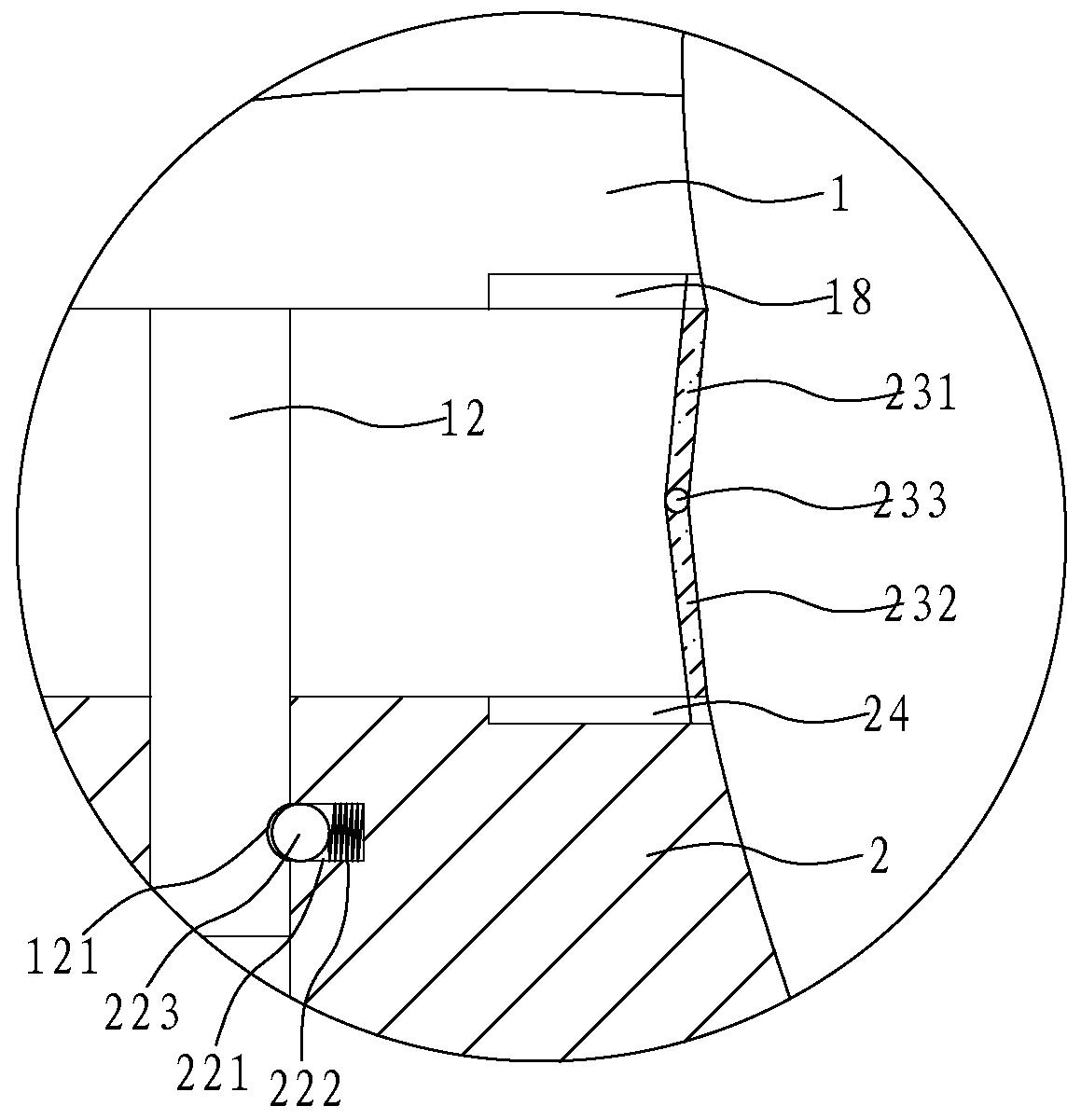

Body-size-adjustable garment model

ActiveCN111297127AImplement size changeEasy to disengageDummiesButtocksPhysical medicine and rehabilitation

The invention relates to a clothing model, in particular to a body-size-adjustable garment model including a body, wherein the body comprises a waist-hip part, an upper body part, a neck part and shoulder-arm parts; a first sliding rod is arranged at the lower end of the upper body part; a first sliding hole is formed in the upper end surface of the waist-hip part; the upper body part slides up and down relative to the waist and buttocks through cooperation of the first sliding rods and the first sliding holes. More than two second sliding rods are arranged on the shoulder-arm parts, two second sliding holes are formed in the upper body part close to the shoulder-arm parts, a third sliding hole is formed in the upper end of the upper body part, and the neck part can move up and down relative to the upper body part through the matching of the third sliding rod and the third sliding hole. The technical problem that an existing garment model cannot be adaptively adjusted is solved.

Owner:泉州市河兴陈列用品有限公司

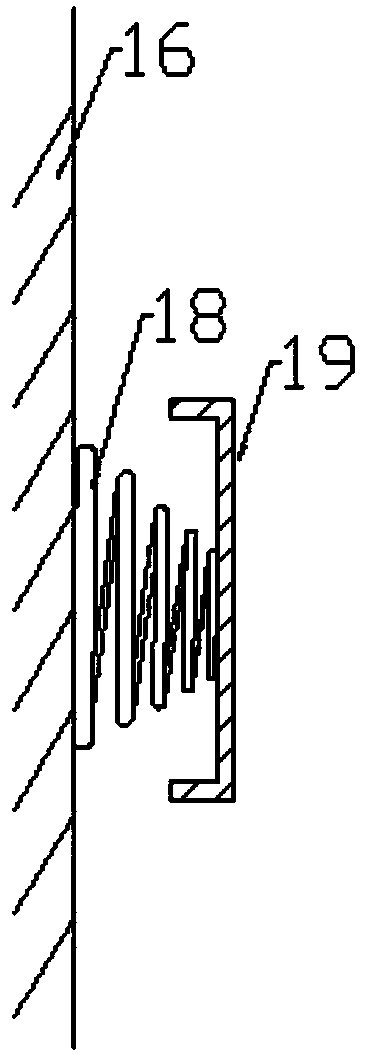

Novel comprehensive wiring clamping groove device

The invention discloses a novel comprehensive wiring clamping groove device. The device comprises an upper cover, side walls and a bottom plate, wherein the upper cover and the bottom plate are connected with the side walls through second buckling strips and second buckling grooves. According to the clamping groove device, layering plates are arranged in a clamping groove body formed by the uppercover, the bottom plate and the side walls; wire clamping strips are arranged on the layering plates to ensure that the wires in circuits are arranged in order and then winding chaos is avoided; meanwhile, the layering plates are made by materials in different colors, so that faulty circuits can be rapidly and timely found according to an earlier-stage mounting table; and pull rings are arranged to ensure that the layering plates can be pulled out conveniently, so that the maintenance is convenient, the time and labor are saved and the working efficiency is greatly improved. According to the clamping groove device, interfaces are alternately arranged on the upper cover, the bottom plate and the side walls in the length direction, and meanwhile, the layering plates are utilized to ensure that the interfaces on the upper cover, the bottom plate and the side wall in the length direction can realize the aim of connection without undergoing any processing, so that the construction is safe and convenient and the joints are beautiful.

Owner:SHAANXI HUABANG TECH DEV CO LTD

card structure

InactiveCN104494839BTo achieve the purpose of connectionEasy loading and unloadingAircraft componentsBiochemical engineeringEngineering

The invention discloses a fastener structure comprising a main fastener body and a first clamping lug. A first clamping groove is formed in the inner wall of the main fastener body, the first clamping lug is arranged on the outer wall of the main fastener body, and a second clamping groove is formed in one side, back to the main fastener body, of the first clamping lug. During use of the fastener structure, a support rod is clamped by each the first clamping groove and the second clamping groove, so that the purpose of connecting the adjacent support rods is achieved; compared with bolted connection, the fastener structure is simple to assemble and disassemble without a professional assembling and disassembling tool, and is easy to use.

Owner:湖南基石信息技术有限公司

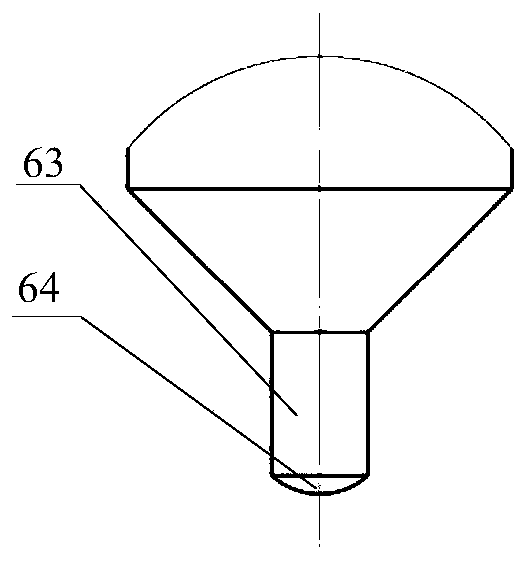

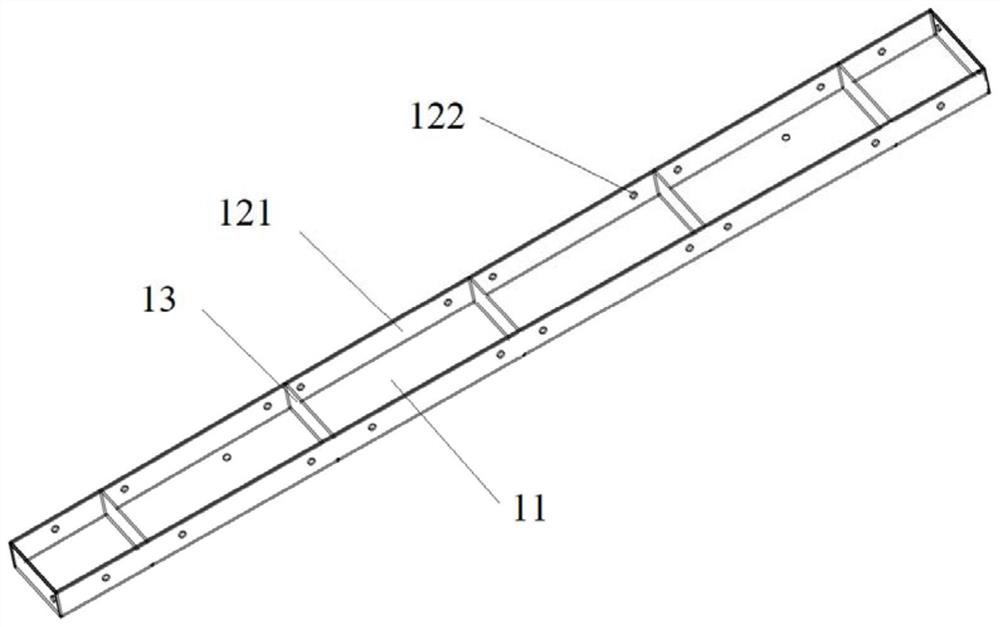

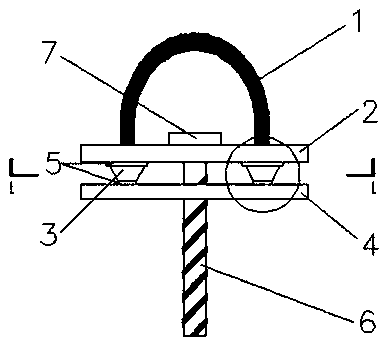

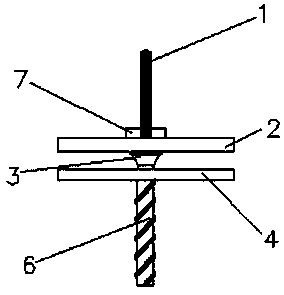

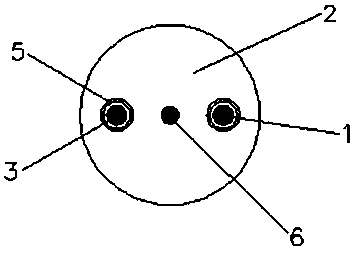

Prefabricated thin plate laminated type floor connector and manufacturing method and construction method thereof

The invention discloses a prefabricated thin plate laminated type floor connector and a manufacturing method and construction method thereof. The floor connector comprises a U-shaped smooth circular steel bar, a baffle, a base and a screw rod; the baffle and the base are arranged on the upper and lower sides in sequence, circular truncated cone-shaped nuts are arranged between the baffle and the base, the outer surfaces of the two ends of the U-shaped smooth circular steel bar are provided with threads, the two ends of the U-shaped smooth circular steel bar penetrate through holes in the baffle to be in threaded connection with the circular truncated cone-shaped nuts, the lower portion of the screw rod is reserved in a thin plate, and the top of the screw rod sequentially penetrates through the base and the middle of the baffle from bottom to top to be fixed by a nut. According to the floor connector, not only is the connection purpose achieved, but also the adhesion of two laminated surfaces is improved, and meanwhile the construction efficiency is improved.

Owner:SHENYANG JIANZHU UNIVERSITY

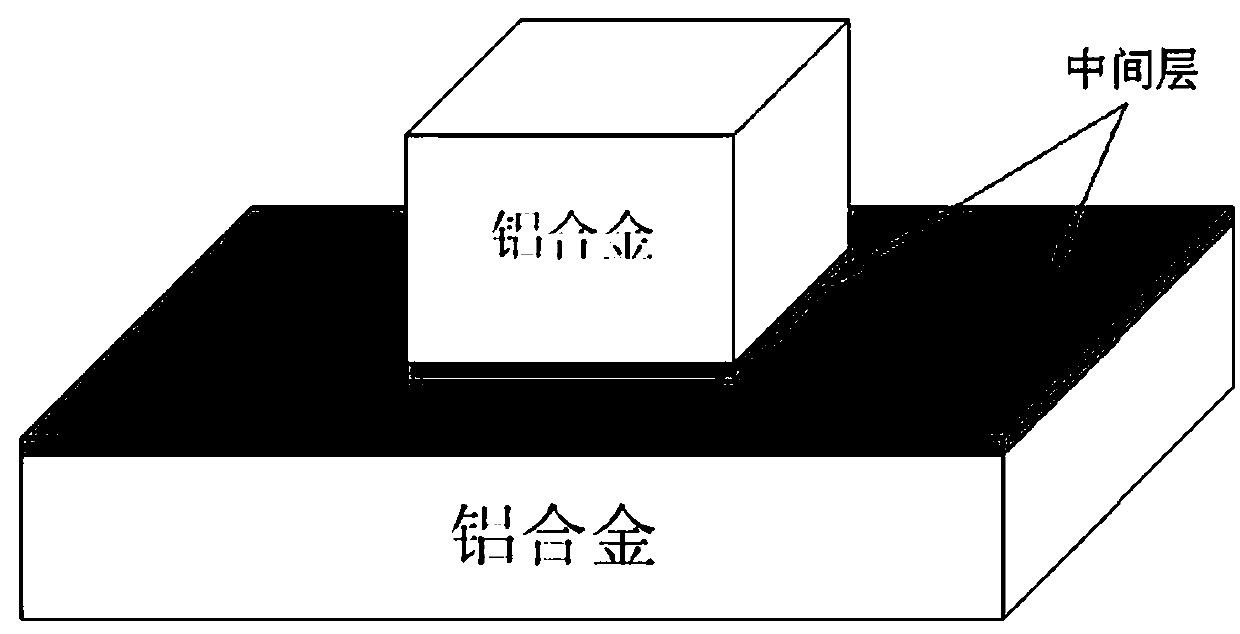

A kind of aluminum alloy surface activated connection method

ActiveCN105925948BReduce adverse effectsImprove performanceVacuum evaporation coatingSputtering coatingStructure propertyBiological activation

The invention provides a surface activation connection method of aluminum alloy, that is: firstly, pretreat the surface of aluminum alloy to remove oxide film and impurities, then use magnetron sputtering technology to activate the surface of aluminum alloy and deposit an intermediate layer, and In the protected state, the aluminum alloy sample assembly is heated to the connection temperature and held for a certain period of time, and the eutectic liquid phase is formed by the eutectic reaction between the intermediate layer and the aluminum alloy to achieve the connection of the aluminum alloy, and then the eutectic liquid is solidified at the same temperature to obtain the microstructure The aluminum alloy connecting joint with good performance, the invention combines the magnetron sputtering technology and the instantaneous liquid phase diffusion connection, realizes the activation of the aluminum alloy surface, effectively removes the oxide film on the aluminum alloy surface and hinders the formation of a new oxide film, and eliminates the oxide film The adverse effect on the connection of aluminum alloys relies on the generation of eutectic liquid phase to achieve the metallurgical combination of aluminum alloys, and finally obtains aluminum alloy connection joints with good structure and performance.

Owner:HARBIN INST OF TECH AT WEIHAI +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com