Connecting system for parallel pipe type photobioreactor

A photobioreactor and connection system technology, which is applied to the connection system field of a flat tube type photobioreactor device, can solve the problems of borosilicate glass production error, installation and connection failure, and excessive use of brackets, so as to reduce light Shadows, good connections, the effect of using light energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

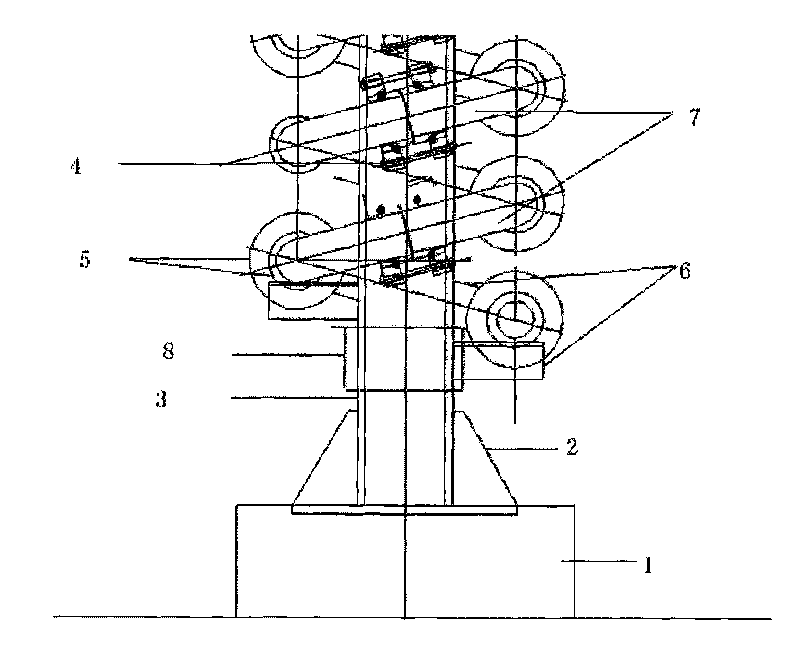

[0043] The present invention will be described in detail below by taking the borosilicate glass tube reactor as an example in conjunction with the accompanying drawings.

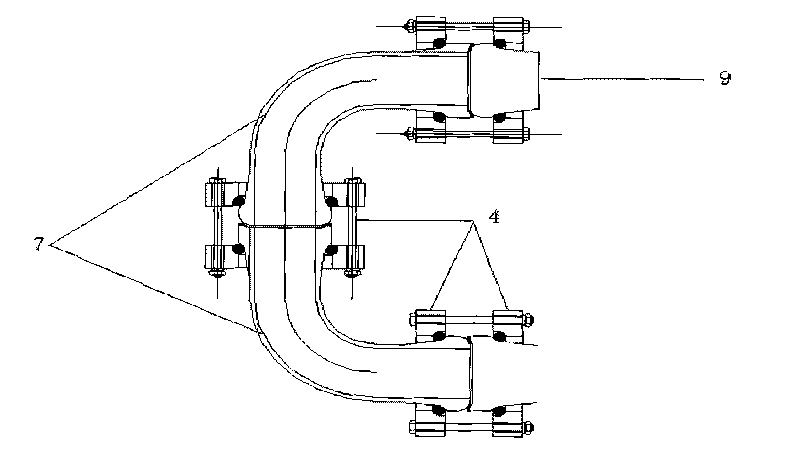

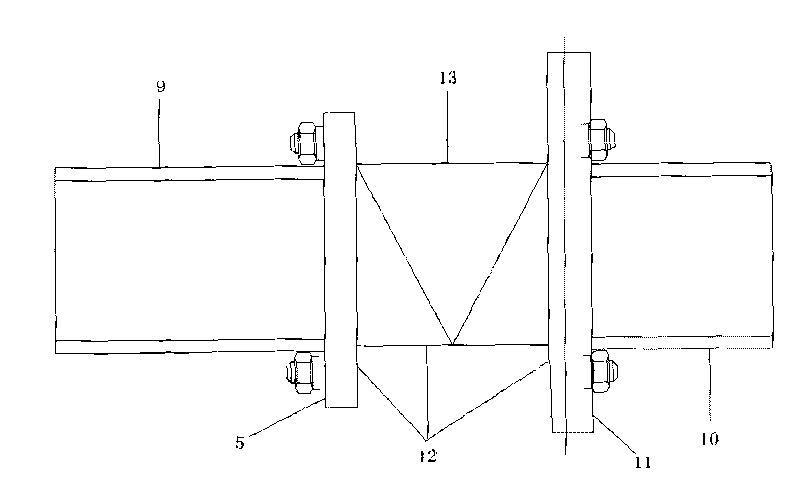

[0044] The installation structure of the tubular photobioreactor of the present invention mainly includes a glass tube connection system; a glass tube and iron pipe connection system; a glass tube fixed connection system; an iron pipe, a pump and a storage tank connection system; and / or one of the automatic control connection systems One or any combination of multiple connections. The glass tube connection system is mainly connected by a special flange (4), between the transparent borosilicate glass tubes (9); between the glass tube (9) and the right-angle elbow (7); and between the right-angle elbow (7). It is connected through a special flange (4); the special flange is fixed by bolts (22), and the bolts are adjusted by (21) to adjust the fixed pressure, and the round plastic strip (23) prevents the flange...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com