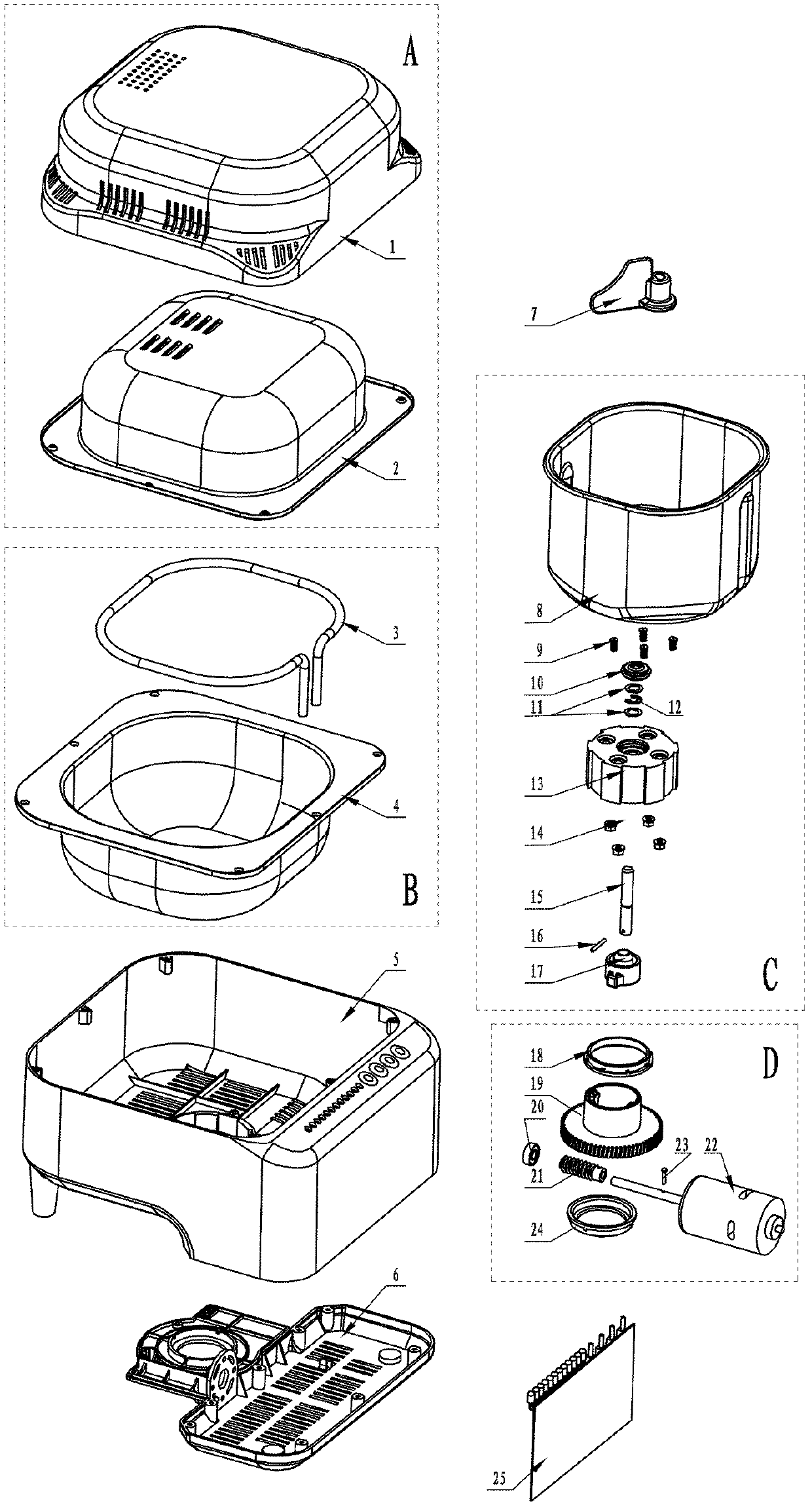

Bread maker

A bread machine and outer casing technology, applied in baking, kitchen utensils, home utensils, etc., can solve the problems of single oven structure, high manufacturing cost, increased scrap rate, etc., achieve compact and simple structure, reduce production processes, and save materials Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

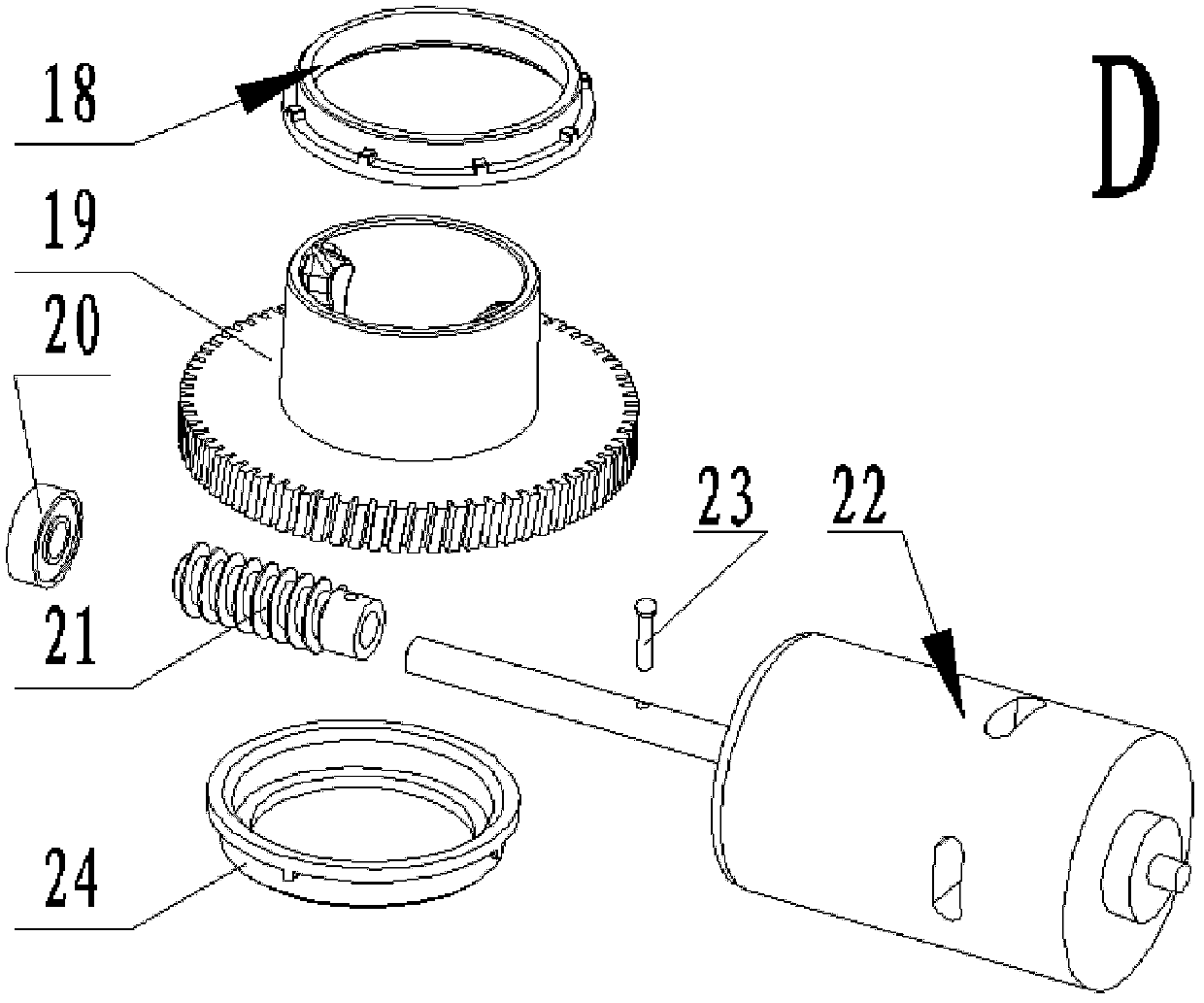

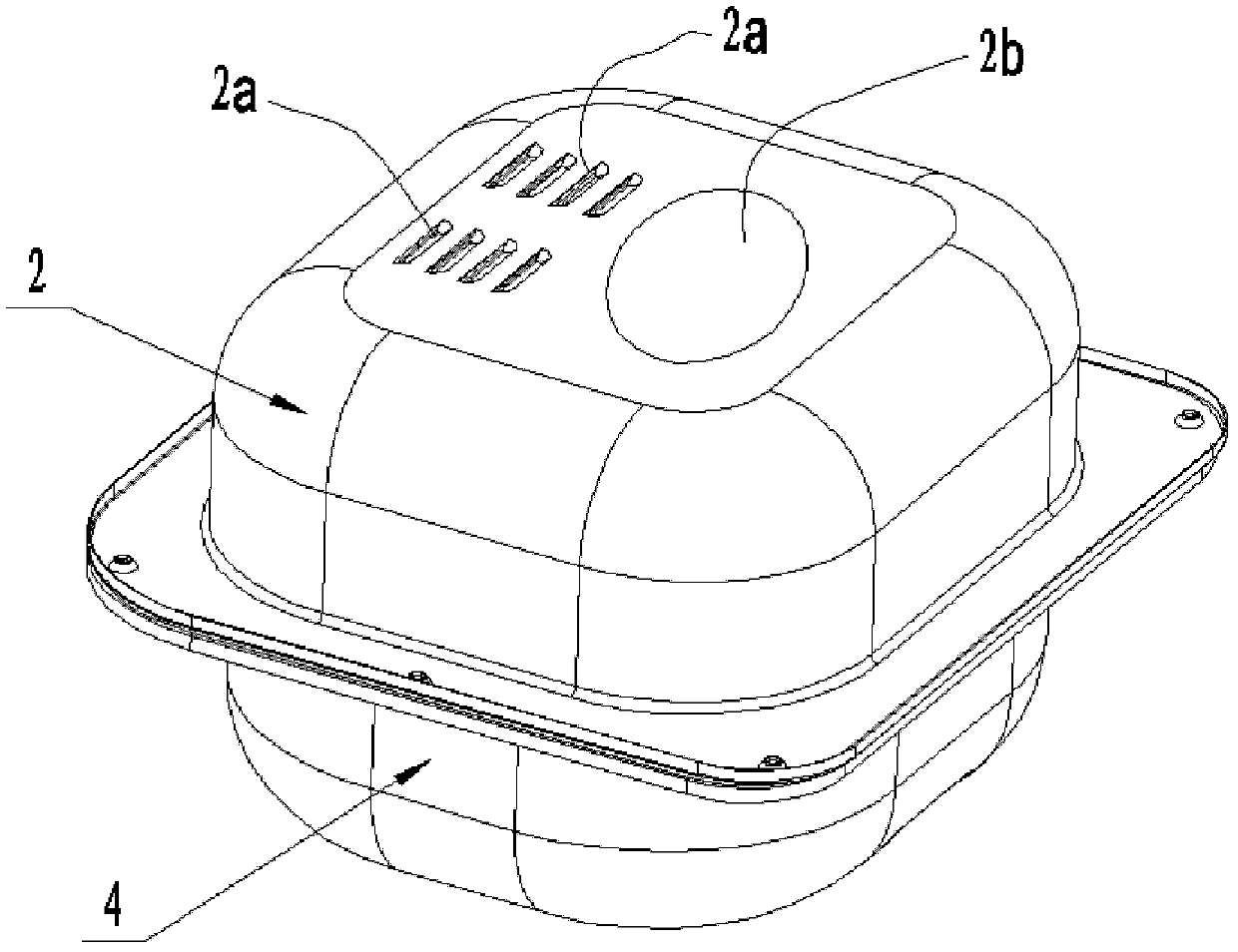

Method used

Image

Examples

example 1

[0033] If the oven height is calculated according to the maximum range of 150-220mm, now we take the minimum height of 150mm for calculation, the total height is C=150mm, choose B=2 / 3H, A=H, then C=2 / 3H+H=5 / 3H , when B=H, C=H+H=2H, now we can get the following result:

[0034] When B=2 / 3H, B=(150) / (5 / 3)X(2 / 3)≈60mm, A≈90mm;

[0035] When B=H, B=150 / 2=75mm, A≈75mm.

example 2

[0037] If the oven height is calculated according to the maximum range of 150-220mm, now we take the minimum height of 220mm for calculation, the total height is C=220mm, choose B=2 / 3H, A=H, then C=2 / 3H+H=5 / 3H , when B=H, C=H+H=2H, now we can get the following result:

[0038] When B=2 / 3H, B=(220) / (5 / 3)X(2 / 3)≈88mm, A=132mm;

[0039] When B=H, B=220 / 2=110mm, A≈110mm.

[0040] It can be seen from the above examples that due to the use of a symmetrical structure to manufacture the oven in parts, the height distribution of the oven is more reasonable, the difficulty of manufacturing has been effectively reduced, and materials have also been saved at the same time, achieving the goal of energy saving and consumption reduction. Purpose.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com