Husking device on corn combine harvester

A technology of combine harvester and corn, applied in the direction of harvesters, cutters, agricultural machinery and implements, etc., can solve the problems of low work efficiency, small horizontal area, large upper and lower volumes, etc., to improve work efficiency and increase the horizontal area , the effect of improving the stripping rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The peeling device on a kind of corn combine harvester of the present invention is further described below in conjunction with accompanying drawing and specific embodiment:

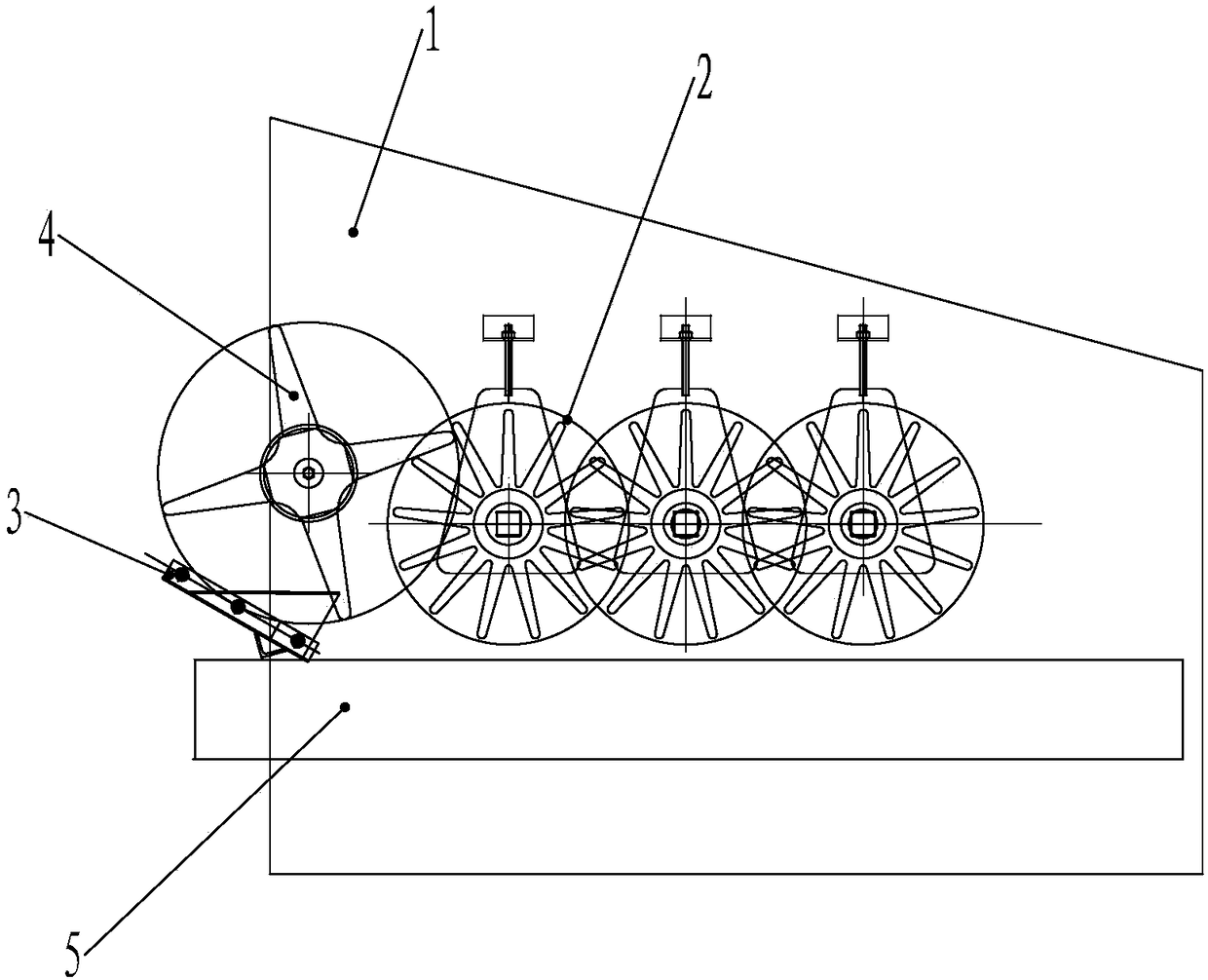

[0014] figure 1 Among them, the stripping roller group 5 arranged horizontally side by side is set at the bottom of the peeling device, and multiple sets of presses 2 are arranged on the side wall 1 of the stripping device, and the presses 2 are placed above the stripping roller group 5. The axes of the presses 2 and the stripping rollers The axes of the roller group 5 are perpendicular to each other. A guide hopper 3 and a feeding assembly 4 are arranged at the entrance of the peeling device. The guide hopper 3 is placed on the upper front end of the peeling roller group 5. above.

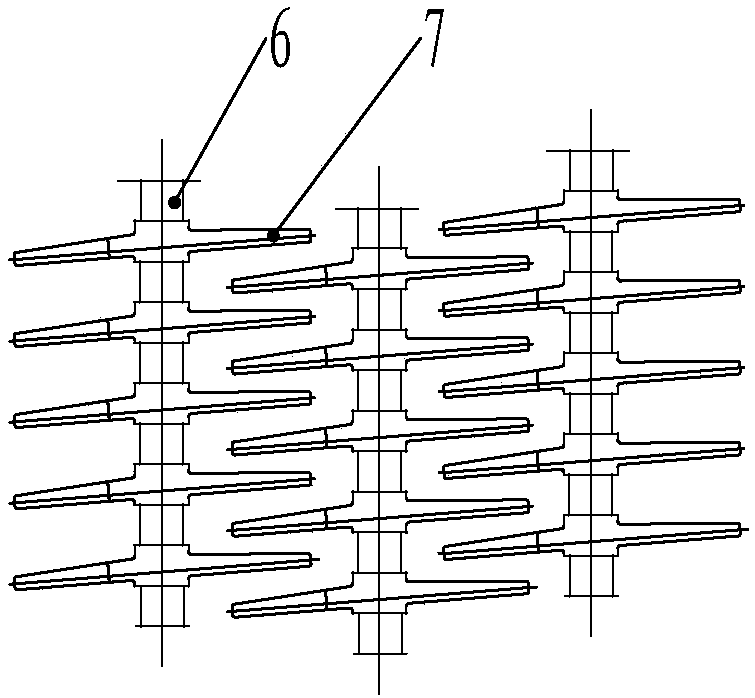

[0015] figure 2 yes figure 1 The top view schematic diagram of the middle part 2, in the figure, the pressing wheels 7 on the presser 2 are arranged alternately, and the plane of the pressing wheels 7 is set at an ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com