Patents

Literature

66results about How to "Guarantee direction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Negative electrode slurry of lithium ion battery, positive electrode of lithium ion battery prepared by slurry and battery

ActiveCN103515607AThe compacted density does not decreaseHigh porosityActive material electrodesSecondary cellsPore distributionHigh energy

The invention provides negative electrode slurry of a lithium ion battery, a positive electrode of the lithium ion battery prepared by using the slurry, and the battery. The negative electrode slurry comprises a negative-electrode active material, a bonding agent, a solvent and a pore-forming agent, wherein the pore-forming agent is selected from one or more in azo-compound and / or sulfonylhydrazine compound. The slurry, the positive electrode and the battery have the advantages that under the condition of guaranteeing no reduction of the compaction density of a negative electrode piece, the porosity of the electrode piece can be increased, the uniformity of pore distribution is increased, the effective area of a liquid phase for conducting lithium ions is improved, the high energy density of the battery is guaranteed, simultaneously the rate capability and the low-temperature performance of the battery are improved and simultaneously the capacity is also improved.

Owner:BYD CO LTD

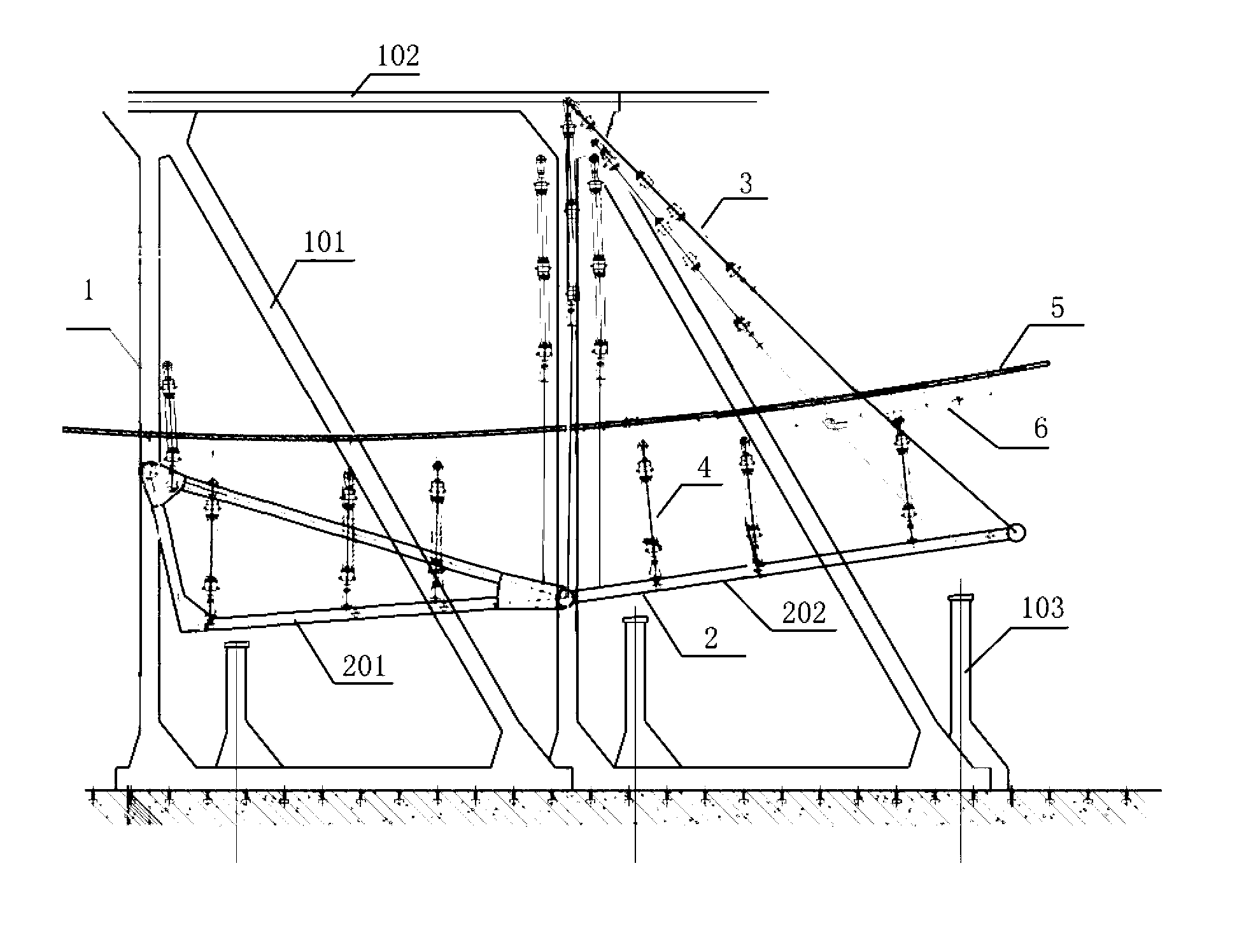

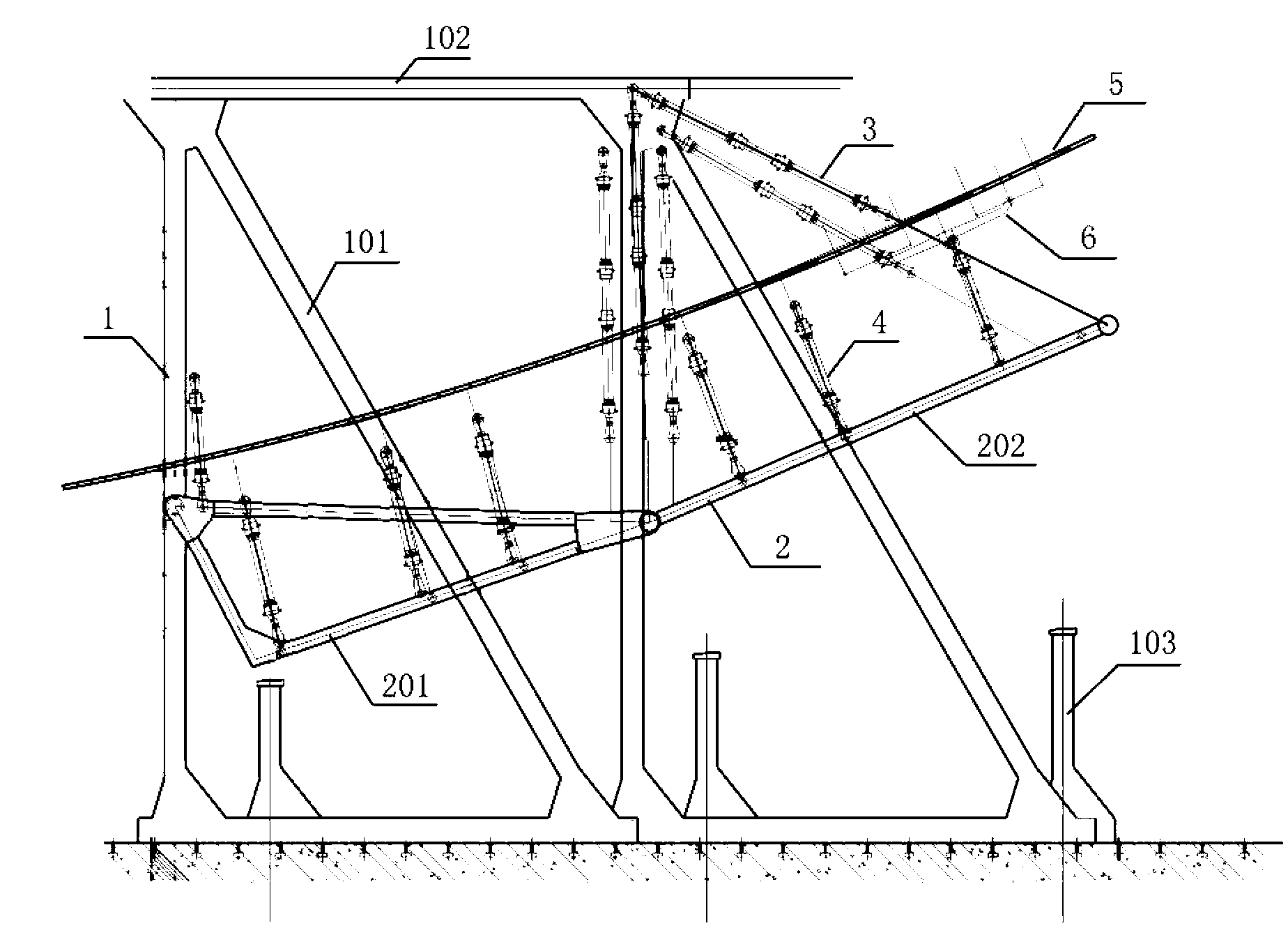

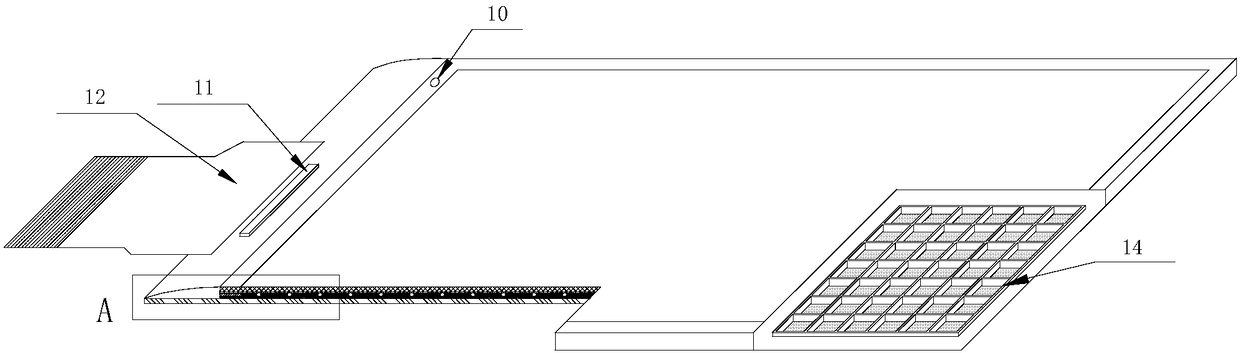

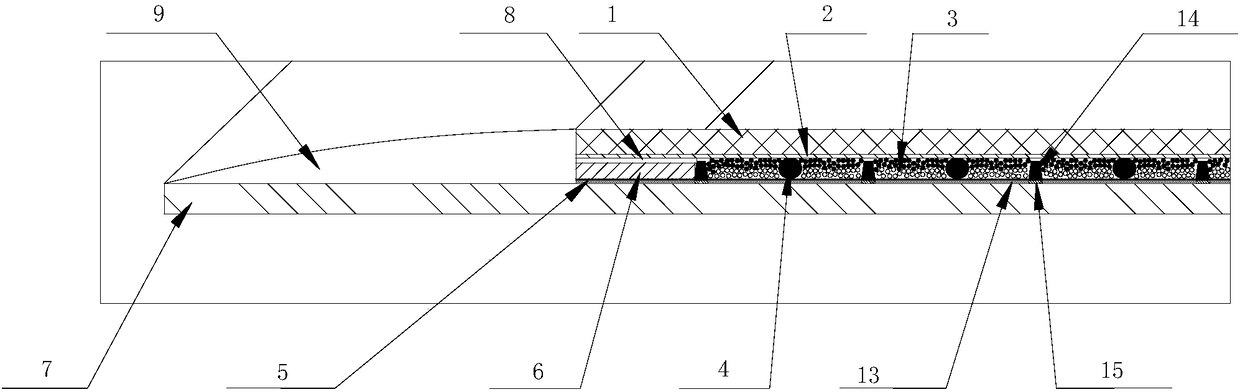

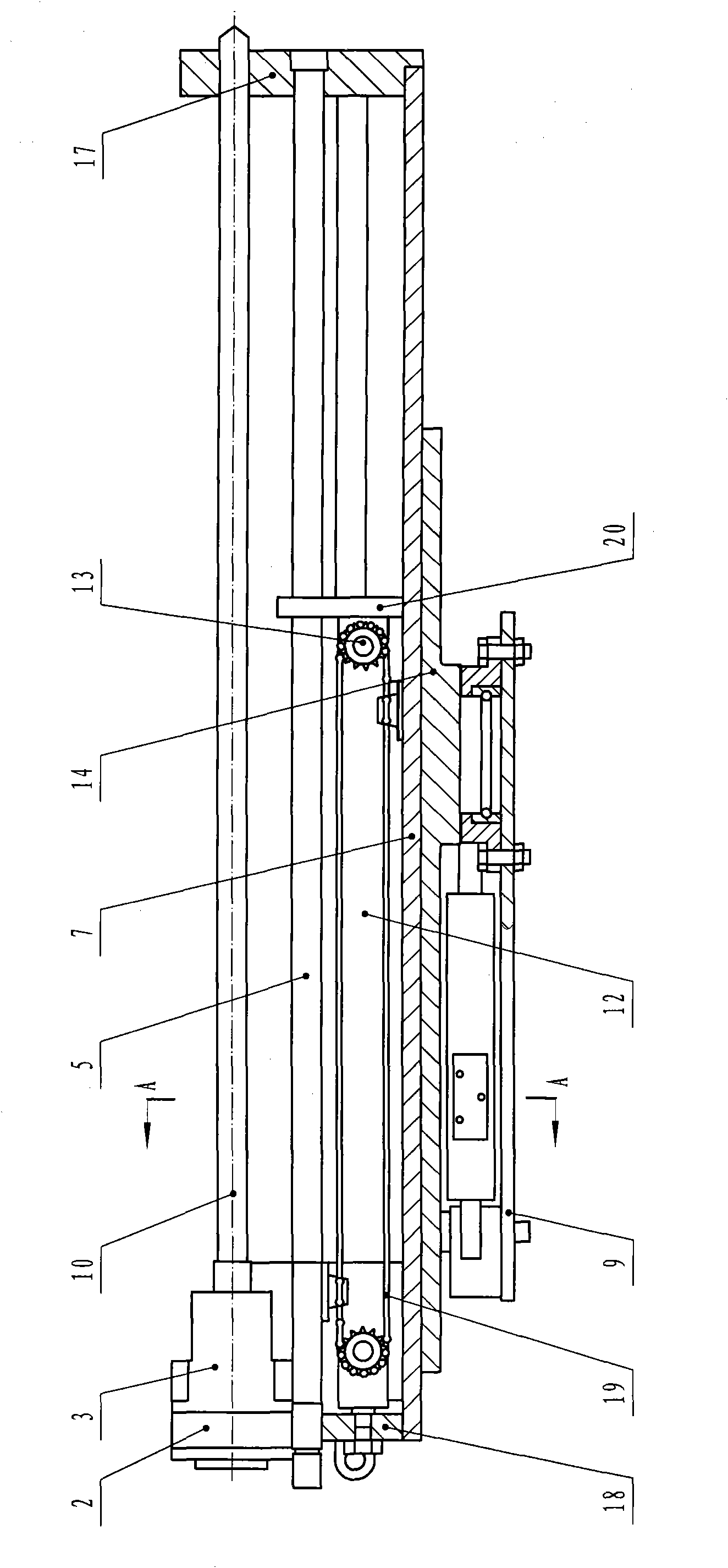

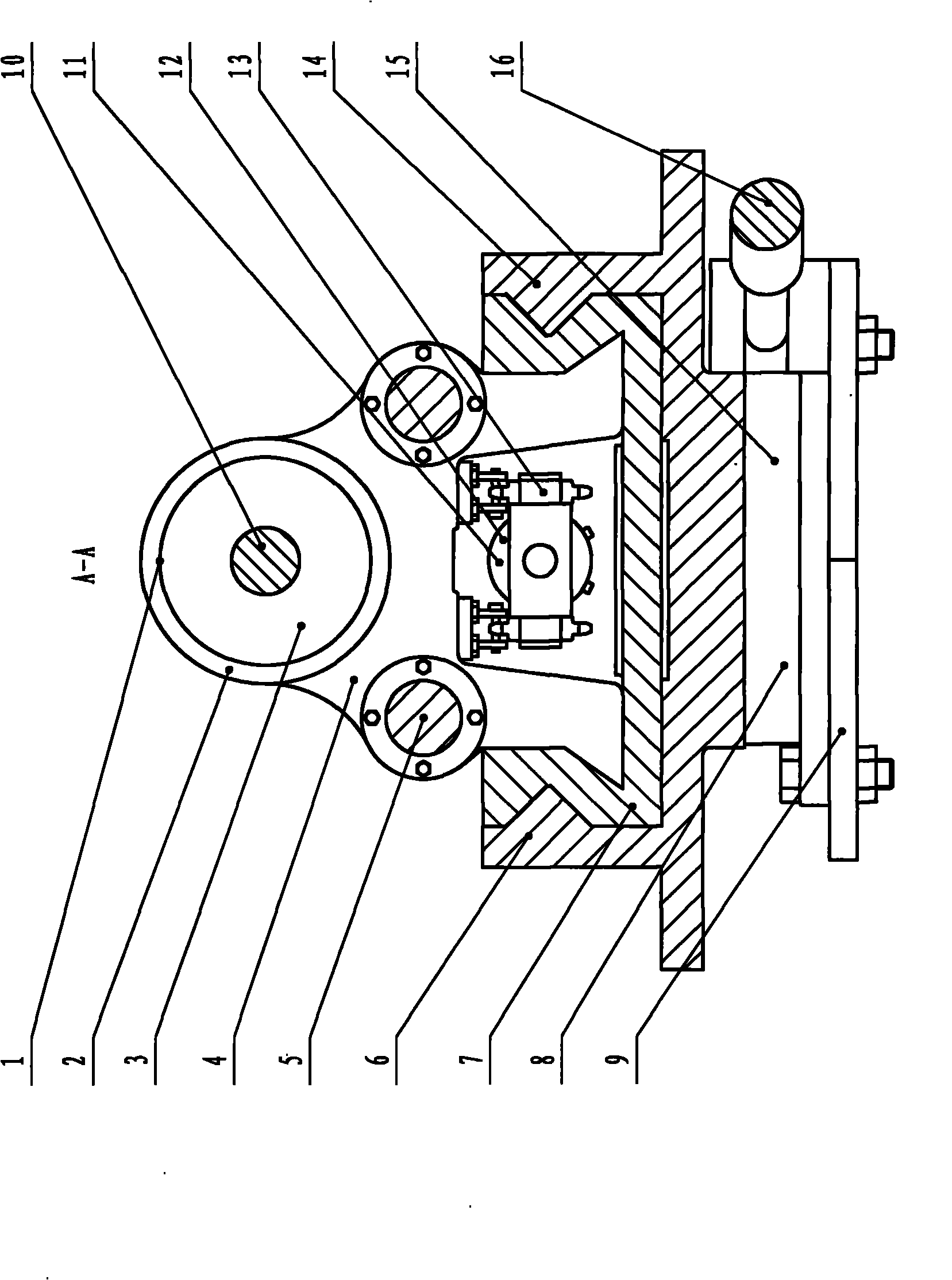

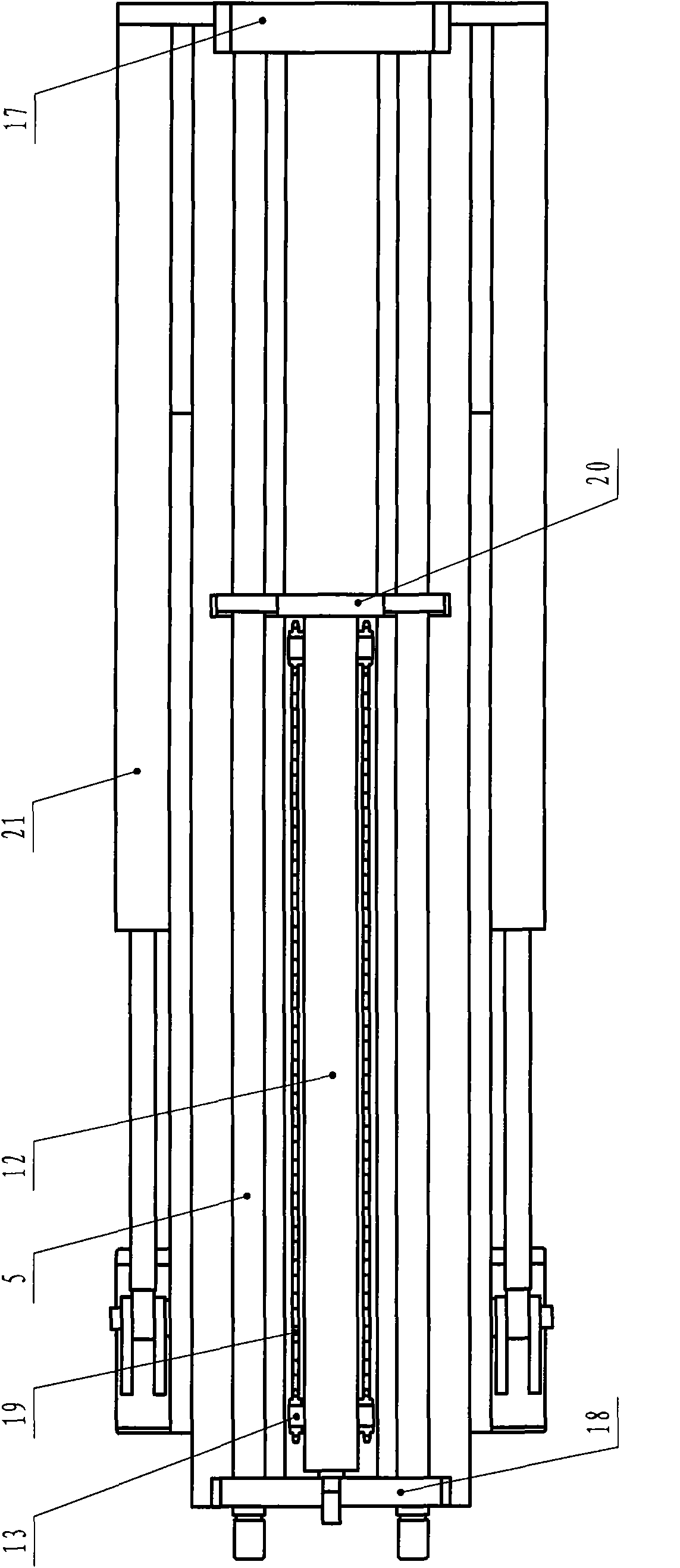

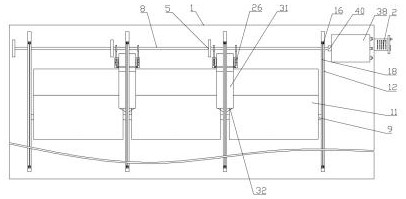

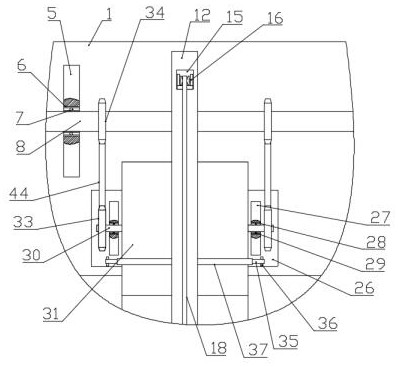

Wing load applying device for large aircraft strength test

The invention belongs to the field of aviation fatigue tests, and particularly relates to a wing load applying device for a large aircraft strength test. The wing load applying device comprises a brace system, a loading platform, a plurality of platform move actuator cylinders and a plurality of loading actuator cylinders. According to the wing load applying device, through the controllable adjustment of platform positions of the movable loading platform controlled by a computer according to wing deformation of load during aircraft stopping on ground and below 1 g load during flying, as well as the loading by the actuator cylinders arranged on the platform, load applying directions and values under the situation of large deformation of large aircraft wings are ensured, so that test loading and test precision are improved; through the accurate applying of wing load, balance of a conventional whole aircraft test is ensured, so that inaccurate structure test of constraint components, which is caused by unbalance of load is avoided; and the loading of wings under large deformation can be realized by using conventional actuator cylinders, and large-stroke special actuator cylinders and tandem actuator cylinders can be omitted, so that the experiment implementation difficulty is reduced and a test cycle is ensured.

Owner:XIAN AIRCRAFT DESIGN INST OF AVIATION IND OF CHINA

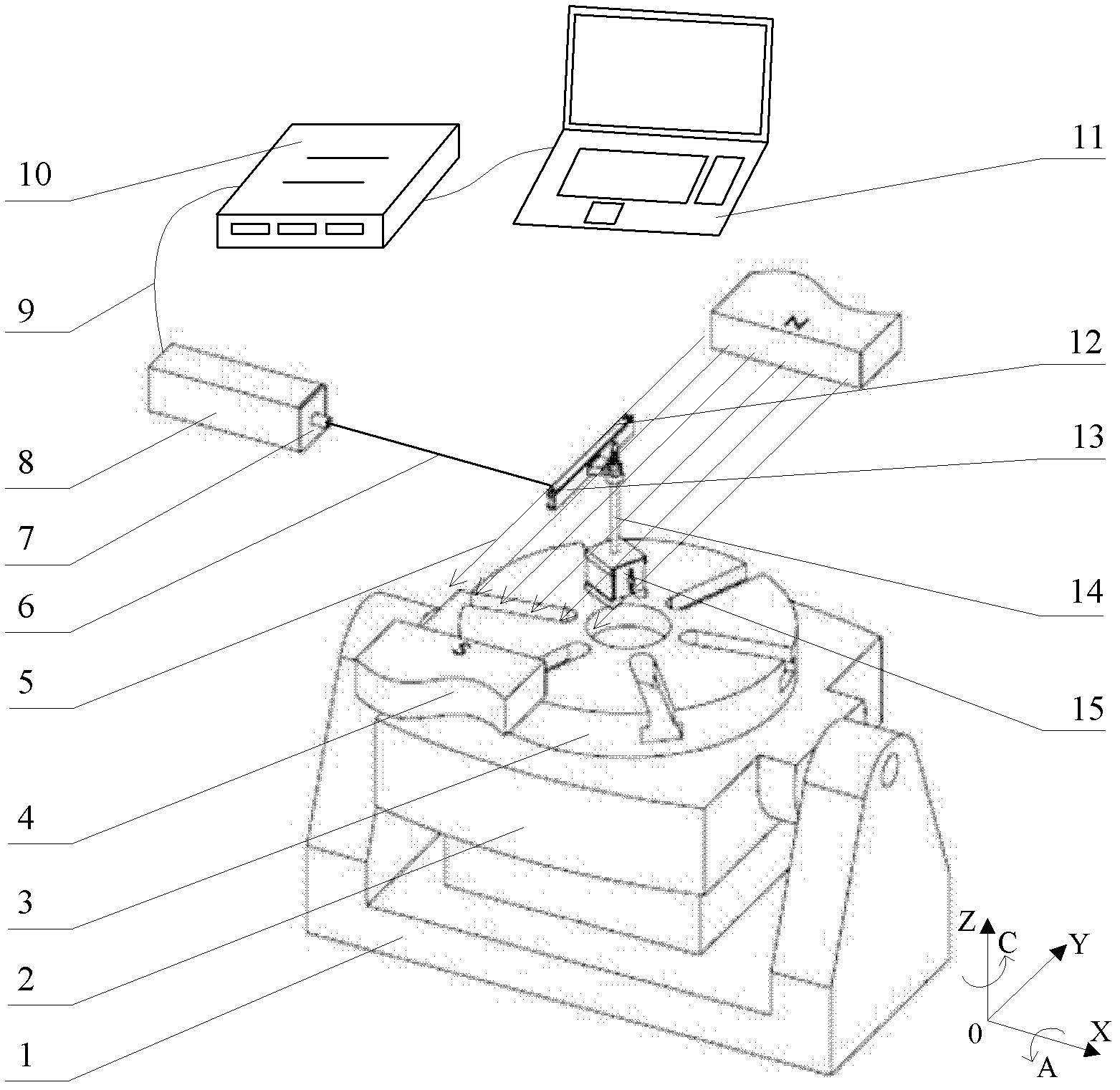

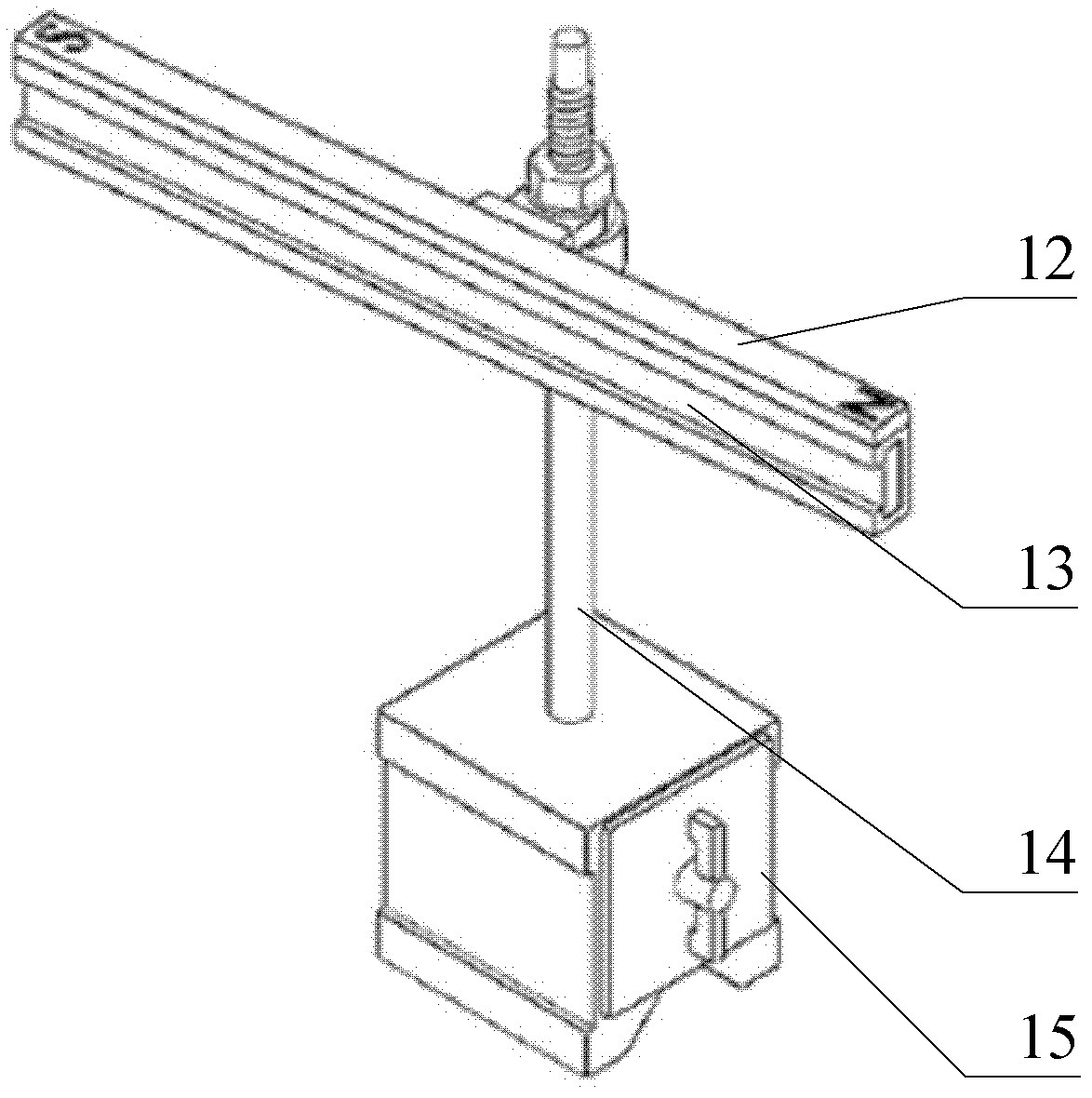

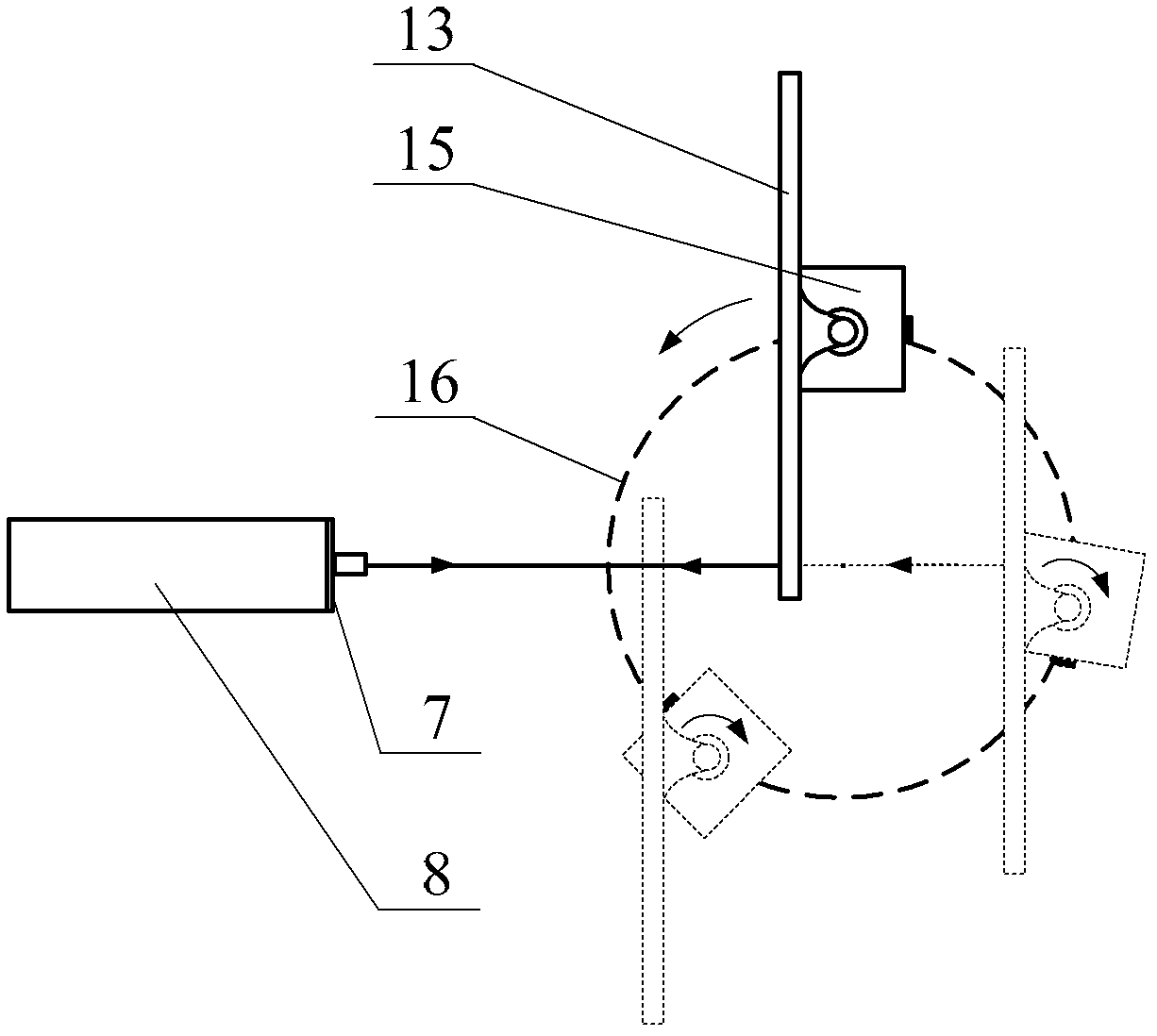

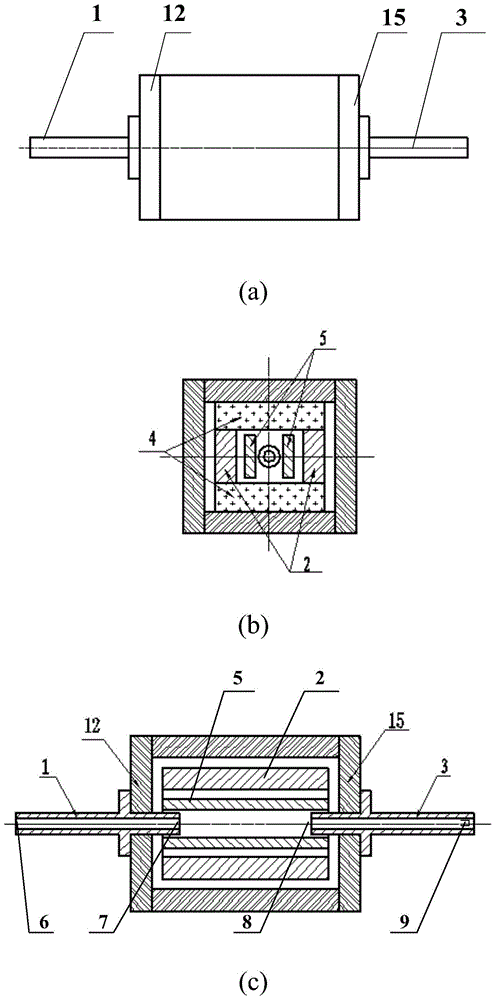

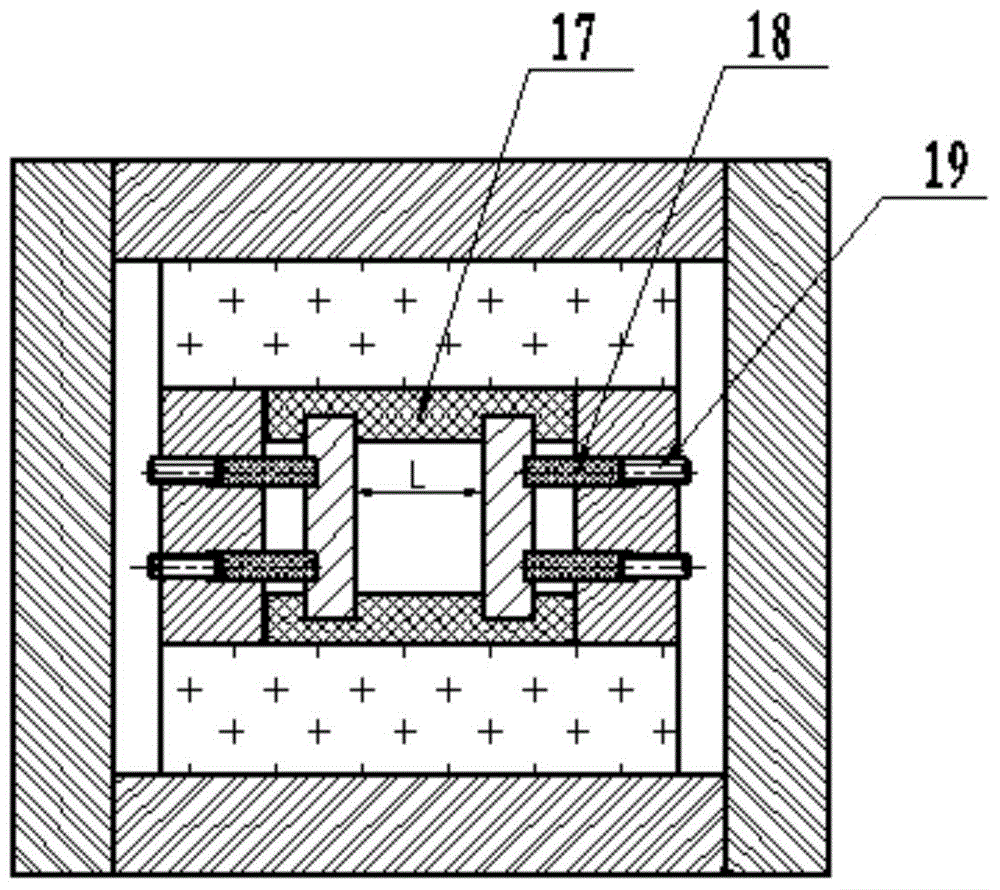

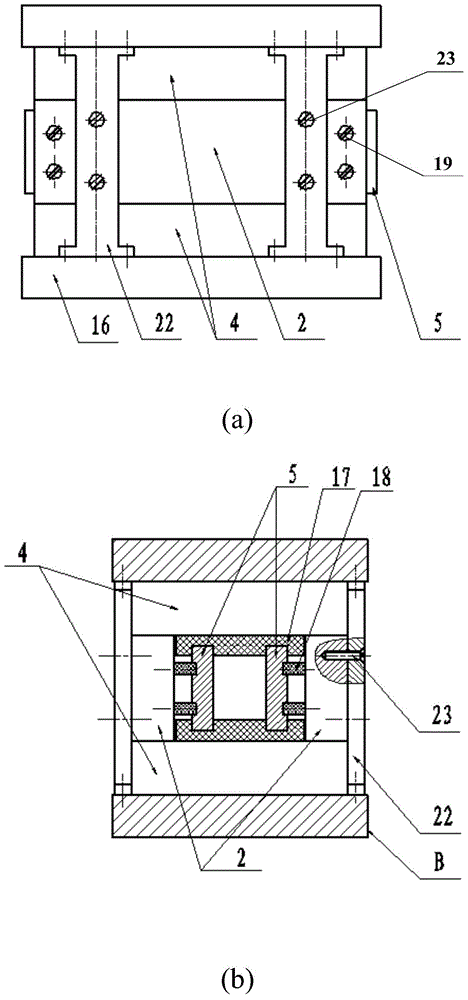

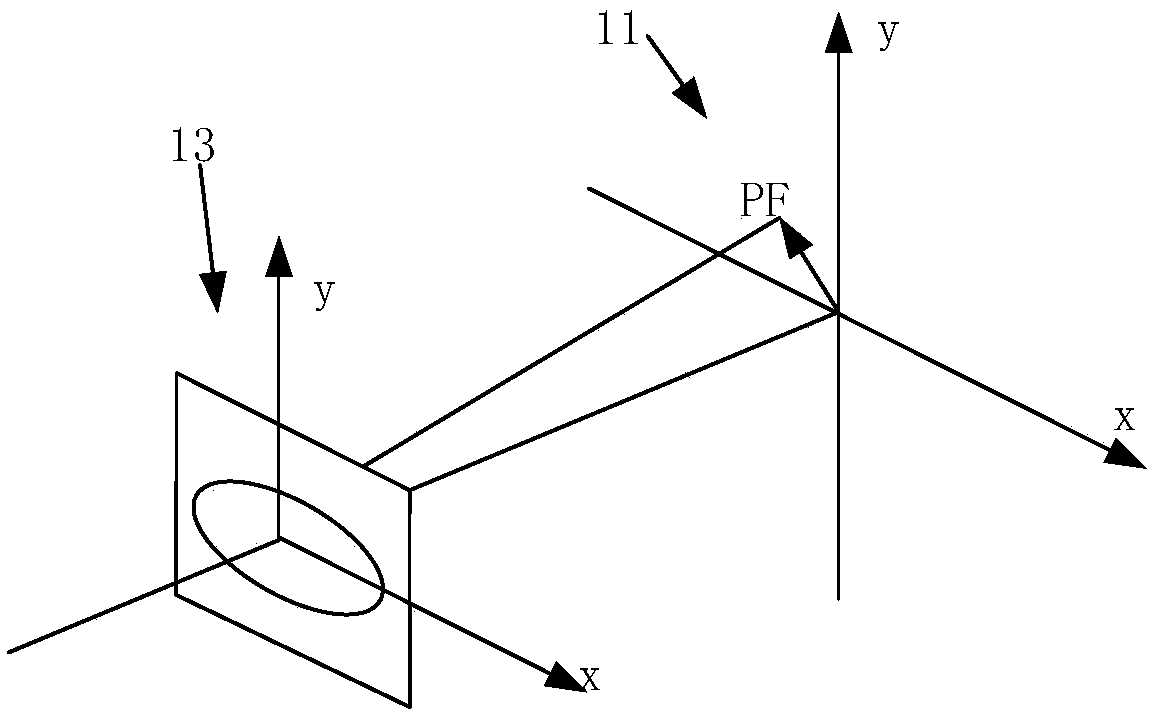

Device and method for measuring rotation angle error of rotary table of machine tool

InactiveCN102554710AGuarantee directionEasy to measureMeasurement/indication equipmentsLaser rangingMeasurement device

The invention discloses a device for measuring rotation angle error of a rotary table of a machine tool. The device comprises a support fixed on the rotary table; a reflecting mirror keeping running fit with the support; a magnetic field generator for generating a magnetic field; a magnetic field sensing member fixedly mounted on the reflecting mirror for keeping the direction of the reflecting mirror under the action of the magnetic field; and a laser ranging device for transmitting / receiving a laser beam to / from the reflecting mirror, and transforming the distance change of the reflecting mirror to the actual rotation angle of the rotary table. The device is simple in structure, convenient in measurement and easy to implementation, and can guide the direction of the reflecting mirror without contacting the reflecting mirror through the magnetic field and the magnetic field sensing member so as to facilitate distance measurement by the laser ranging device. The invention also discloses a method for measuring the rotation angle error of the rotary table of the machine tool. The method is convenient and accurate in measurement, and can calculate the error according to the actual rotation angle and a preset angle so as to provide the basis for error compensation of the machine tool.

Owner:ZHEJIANG UNIV

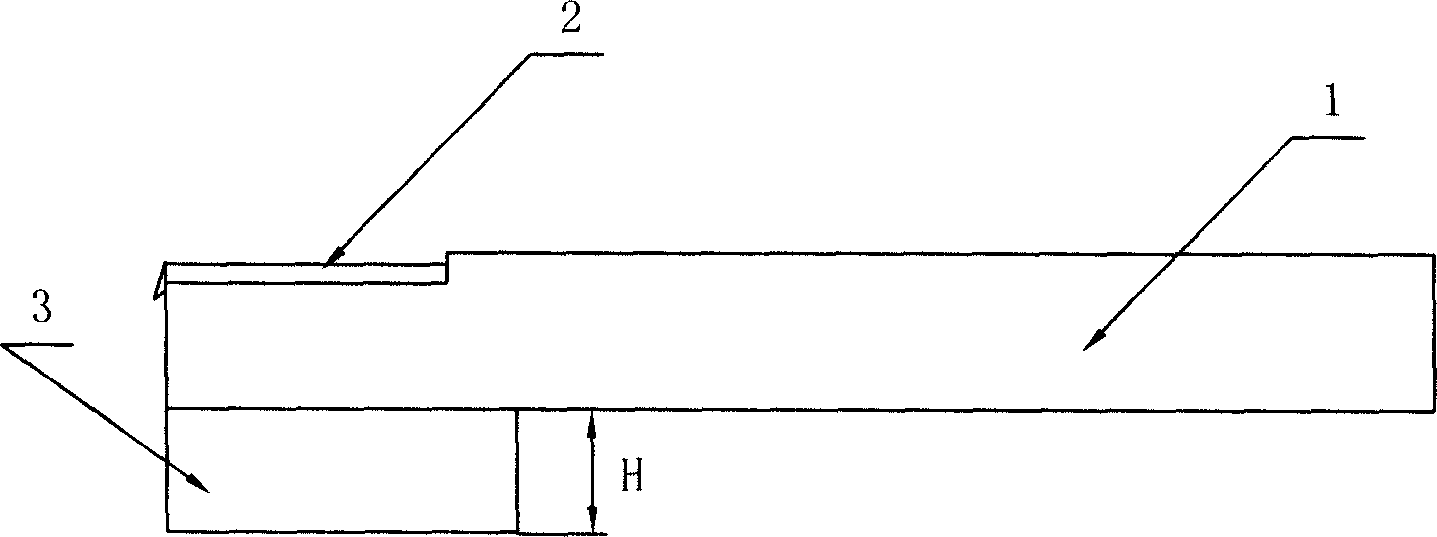

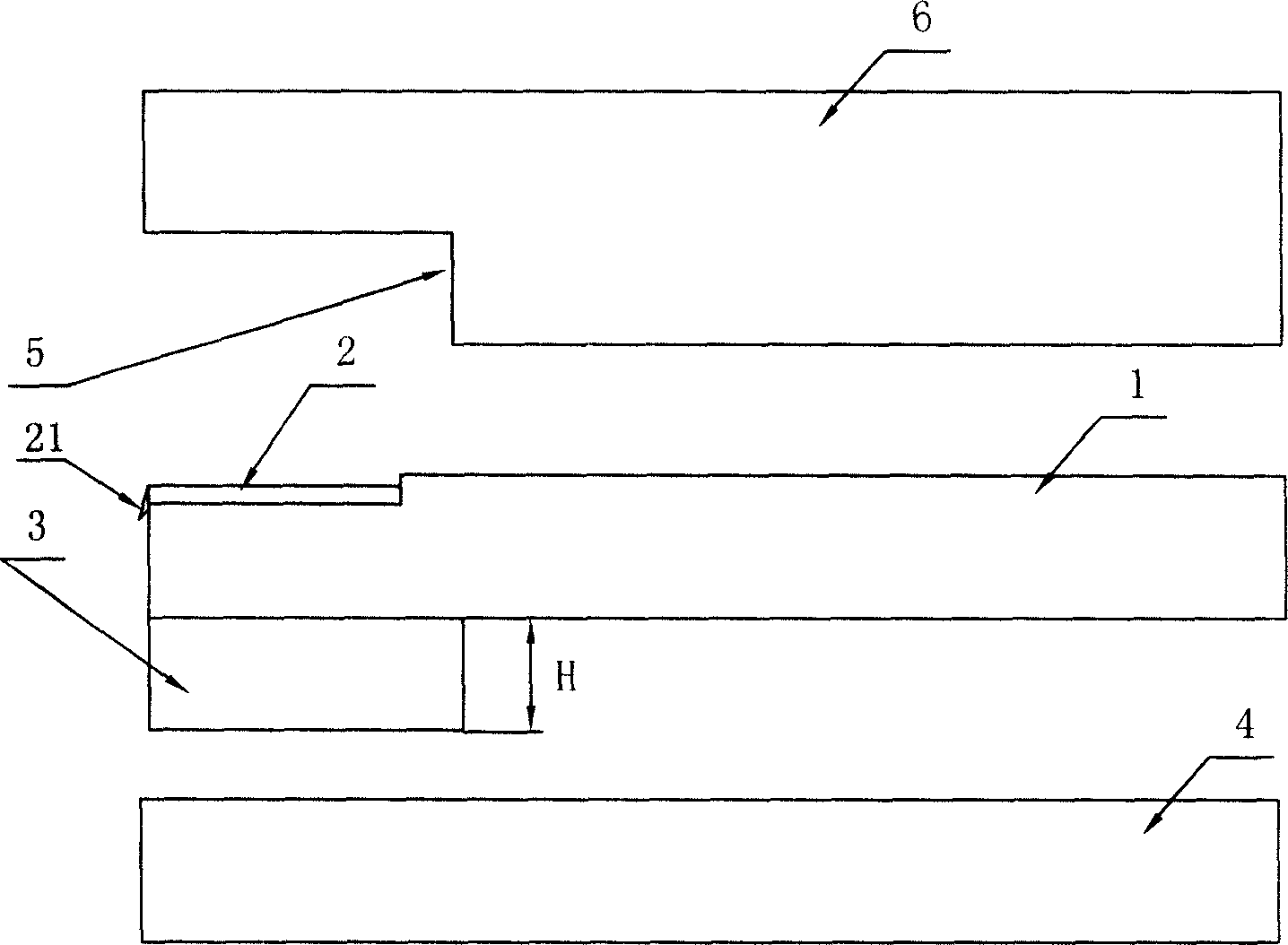

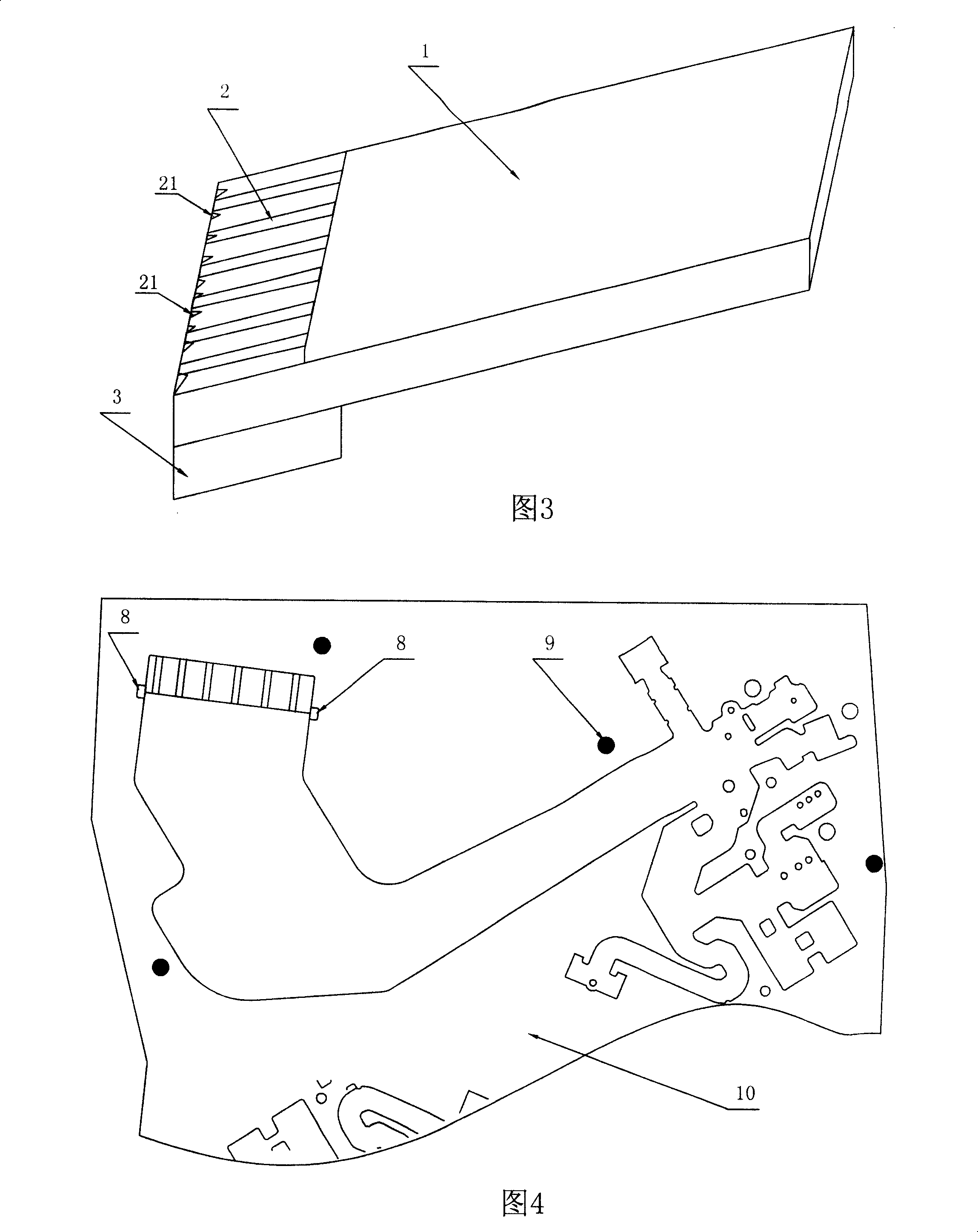

Production method of flexible circuit board

InactiveCN101175375AGuarantee directionNo need to change the structurePrinted circuit manufactureFlexible circuitsEngineering

The present invention discloses a manufacturing method for flexible line with a stiffening plate at the back of the golden finger of a flexible line board. The first step is that the golden finger part is formed on one surface of the corresponding flexible line board on a connecting plate. The second step is the working procedure of gluing stiffening plate, namely that the stiffening plate is glued on the other surface corresponding to the surface provided with the golden finger on each flexible line board. The third step is a stamping process for punching external form, namely that the working procedure of punching external form is carried on to each flexible line glued with stiffening plate on the connecting plate. In particular that after the first step is finished, a stamping process for punching opening is added, namely that an opening is punched correspondingly on the flexible line board at the two ends of the junction line of the height difference formed on the surfaces of the stiffening plate and the flexible line board, then the work of the second step is started. The manufacturing method can effectively solve the problem that the two ends of the junction line of the height difference formed between the stiffening plate on the flexible line board and the flexible line board are torn.

Owner:深圳市合力泰光电有限公司

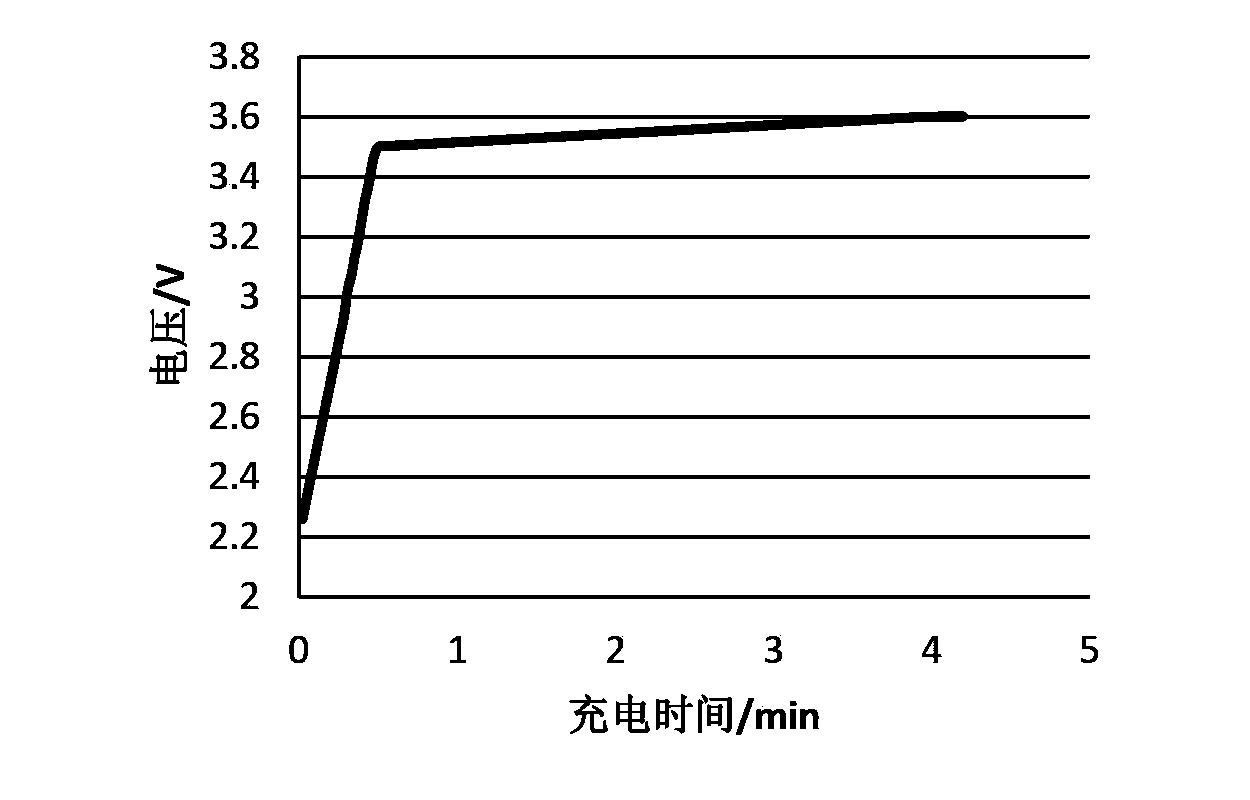

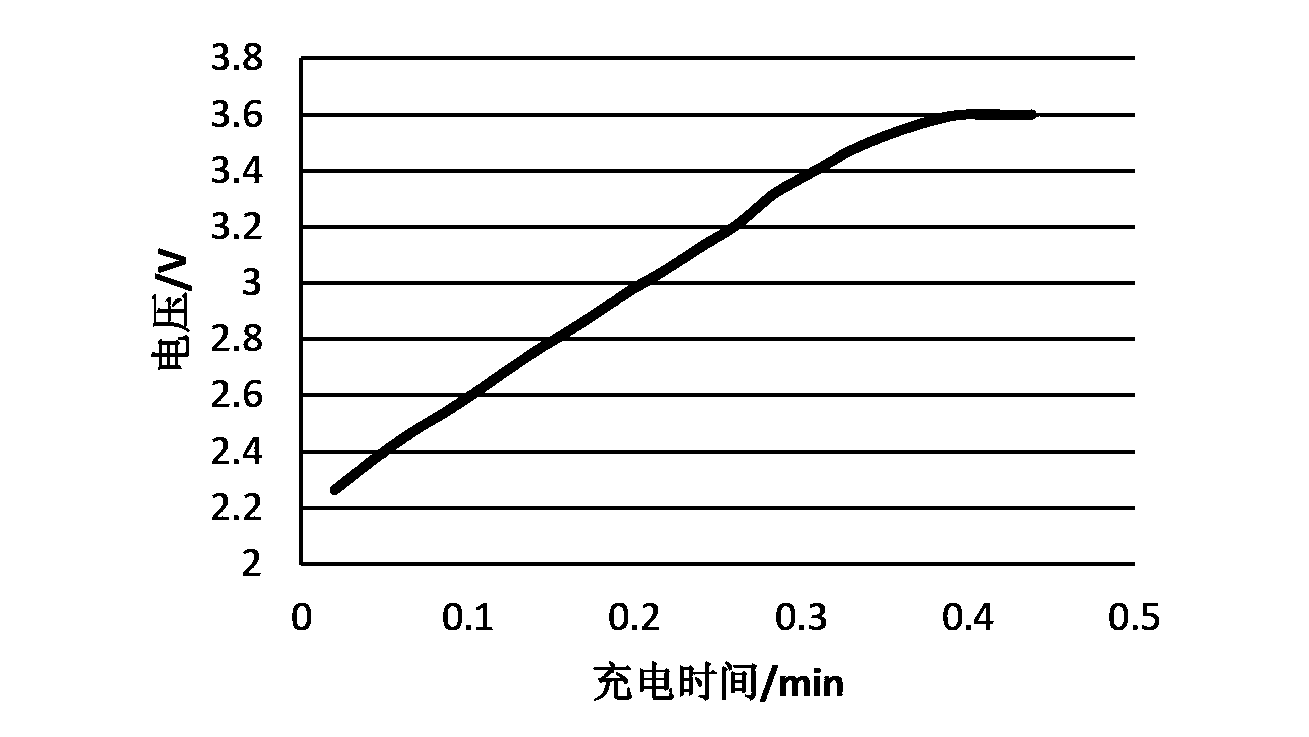

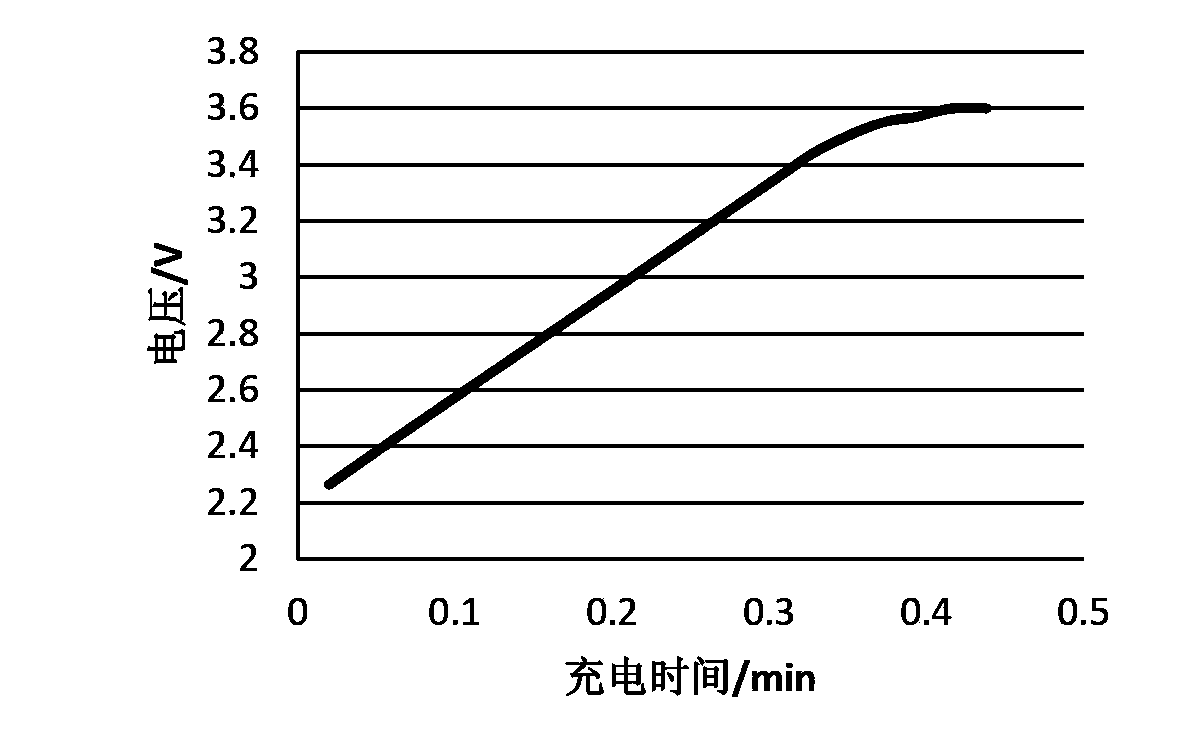

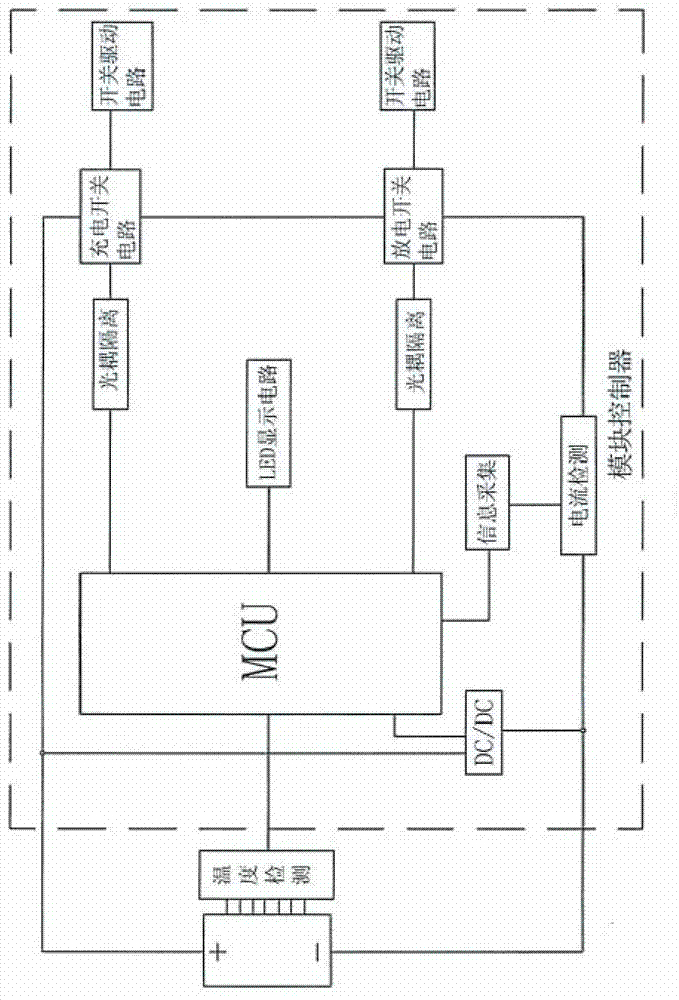

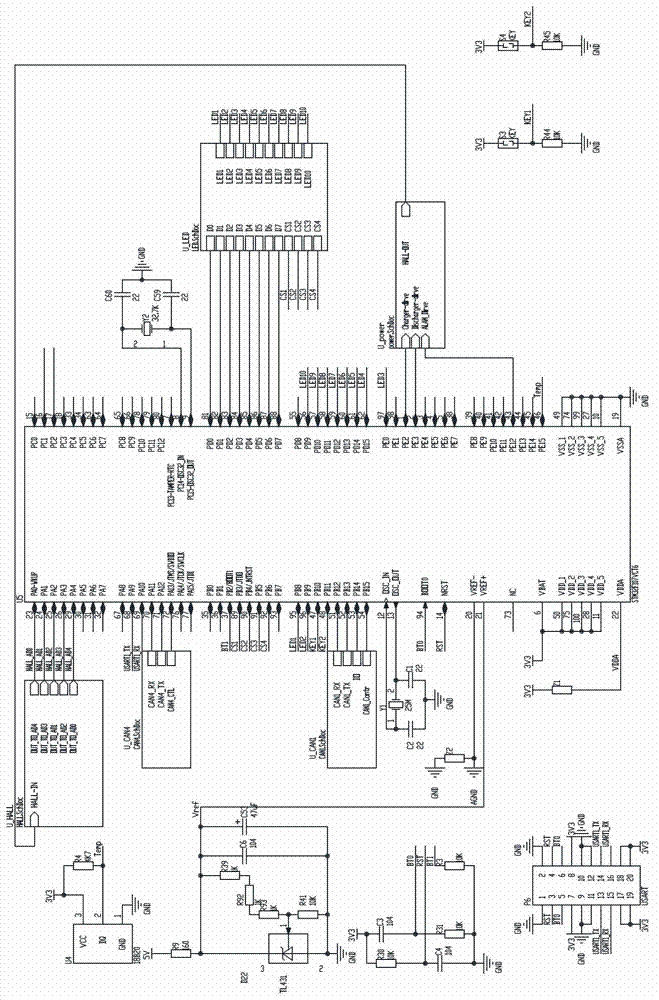

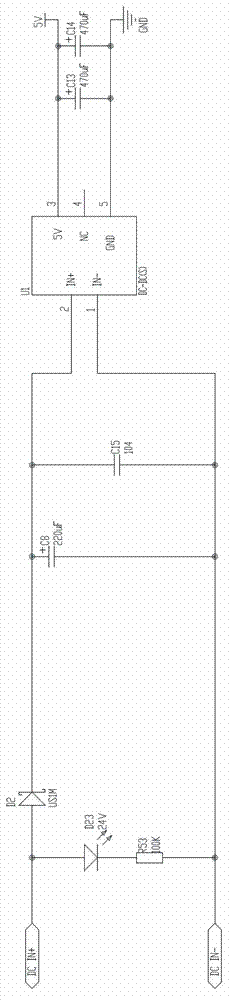

Module controller of lithium ion battery pack

InactiveCN103078358AEnsure safetyExtended service lifeBatteries circuit arrangementsElectric powerOvervoltageEngineering

The invention belongs to the field of a battery charge-discharge control technology and in particular provides a module controller of a lithium ion battery pack. The module controller comprises a power supply circuit, a micro controller unit (MCU), a charge-discharge control circuit, a current detection circuit, a temperature detection circuit and a light-emitting diode (LED) display circuit. The charge-discharge control circuit comprises a charge control unit and a discharge control unit, wherein the charge control unit and the discharge control unit are controlled to realize the charge-discharge selection of the lithium ion battery pack through the MCU; and the current detection circuit is used for detecting a bus bar current of the lithium ion battery pack. The module controller provided by the invention can detect voltage, current and temperature of the lithium ion battery pack in the charge-discharge process, guarantee the lithium ion battery pack to charge and discharge reasonably, and does not appear the phenomenon of damaging the battery life caused by overvoltage, overcurrent, short circuit, over-temperature and the like, so that the battery can work durably and effectively.

Owner:SHANDONG UNIV OF SCI & TECH

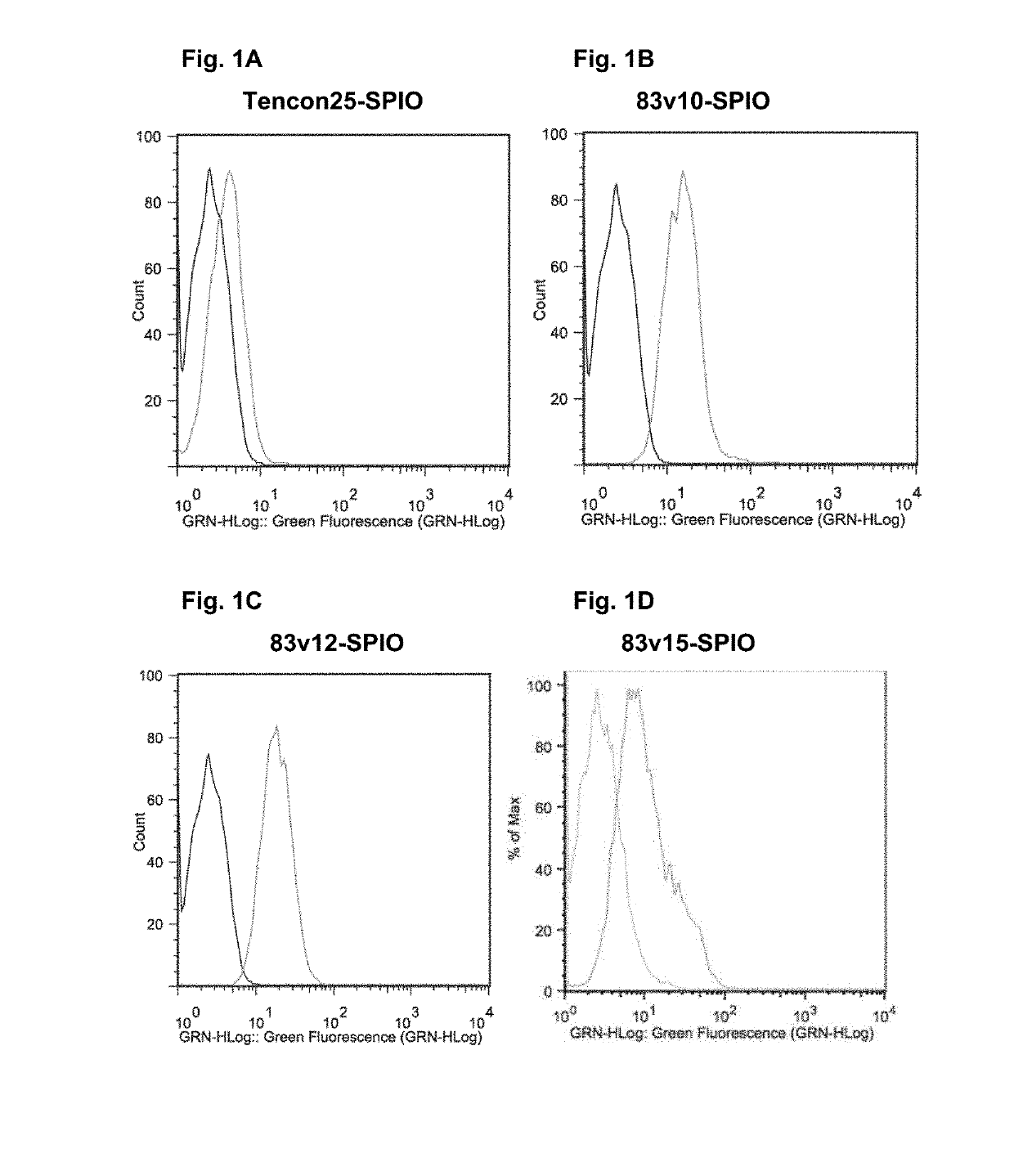

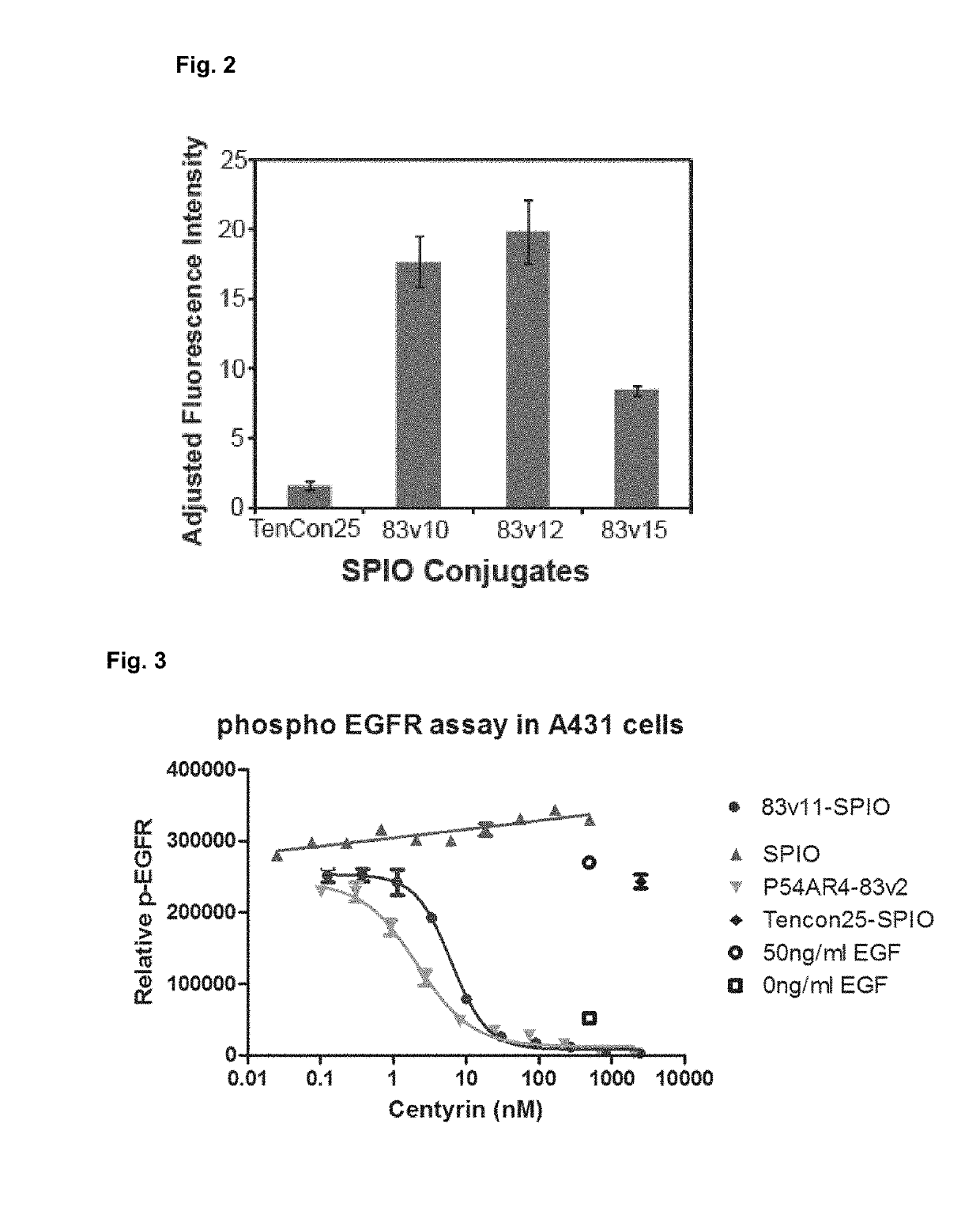

Targeting with firbronectin type iii like domain molecules

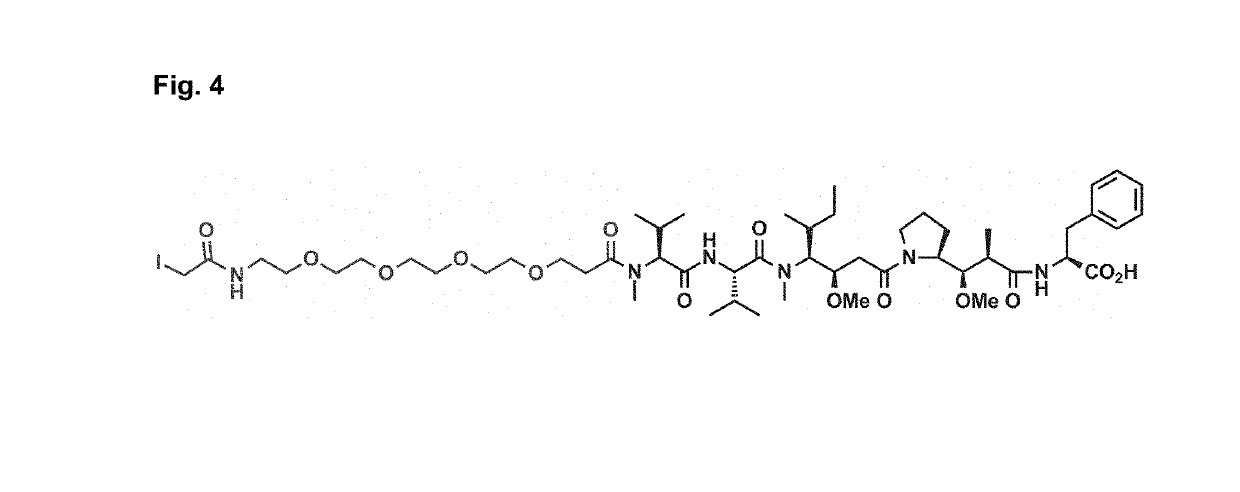

InactiveUS20190184028A1Guarantee directionPowder deliveryOrganic active ingredientsNanoparticle ComplexToxin Conjugates

A fibronectin type III (FN3) domain-nanoparticle or direct conjugate complex containing a polynucleotide molecule, a toxin, polynucleotide molecule or other pharmaceutically active payload is obtained by panning an FN3 domain library with a protein or nucleotide of interest, recovering the FN3 domain and conjugating the FN3 domain with a toxin or nanoparticle containing an active polynucleotide, such as an ASO or siRNA molecule. A fibronectin type III (FN3) domain-nucleic acid conjugate is obtained by panning an FN3 domain library with a protein or nucleotide of interest, recovering the FN3 domain and conjugating the FN3 domain to a nucleic acid (e.g., ASO or siRNA). The nanoparticle complex, nucleic acid conjugate or FN3 domain toxin conjugate may be used in the treatment of diseases and conditions, for example, oncology or auto-immune indications.

Owner:JANSSEN BIOTECH INC

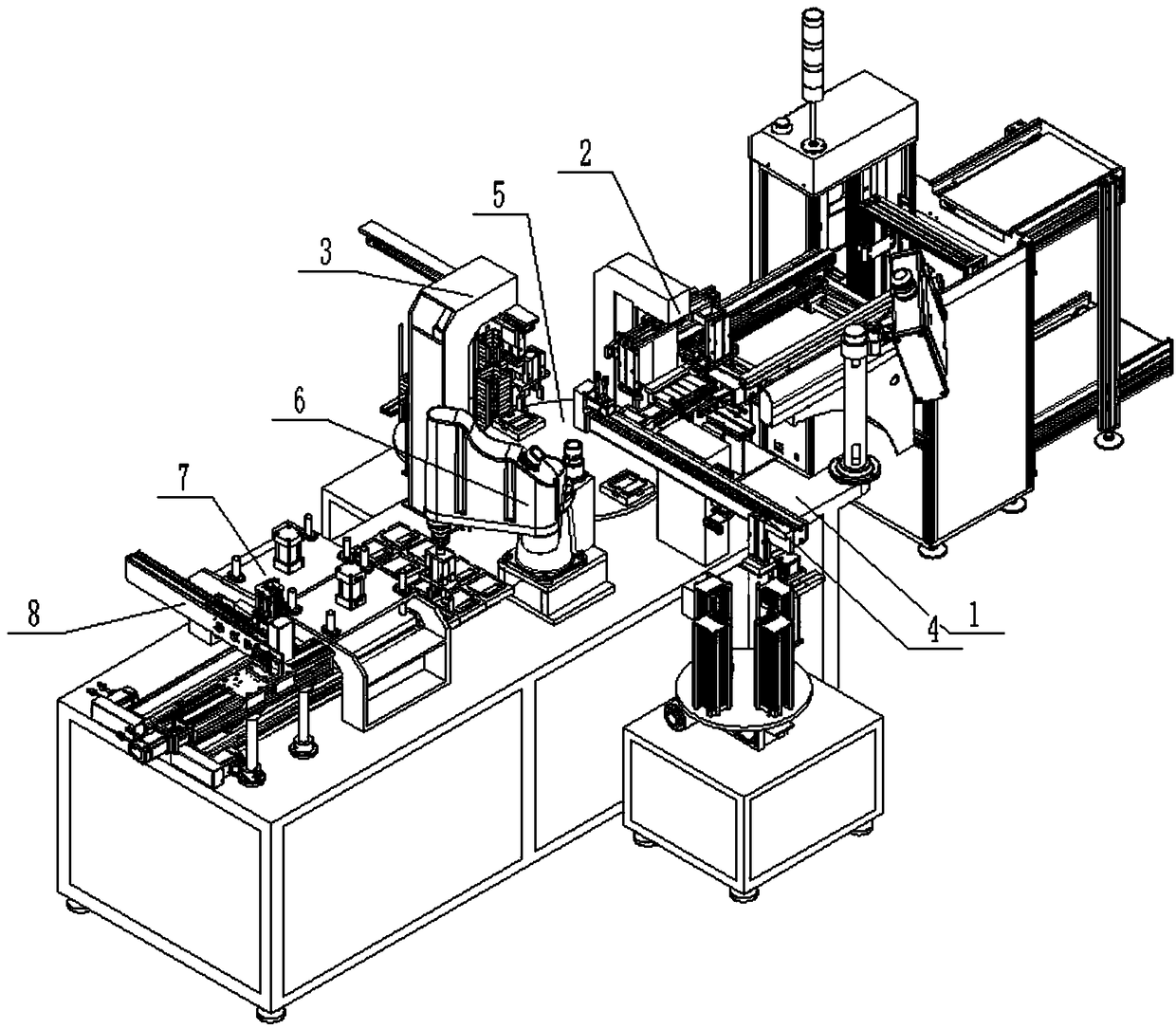

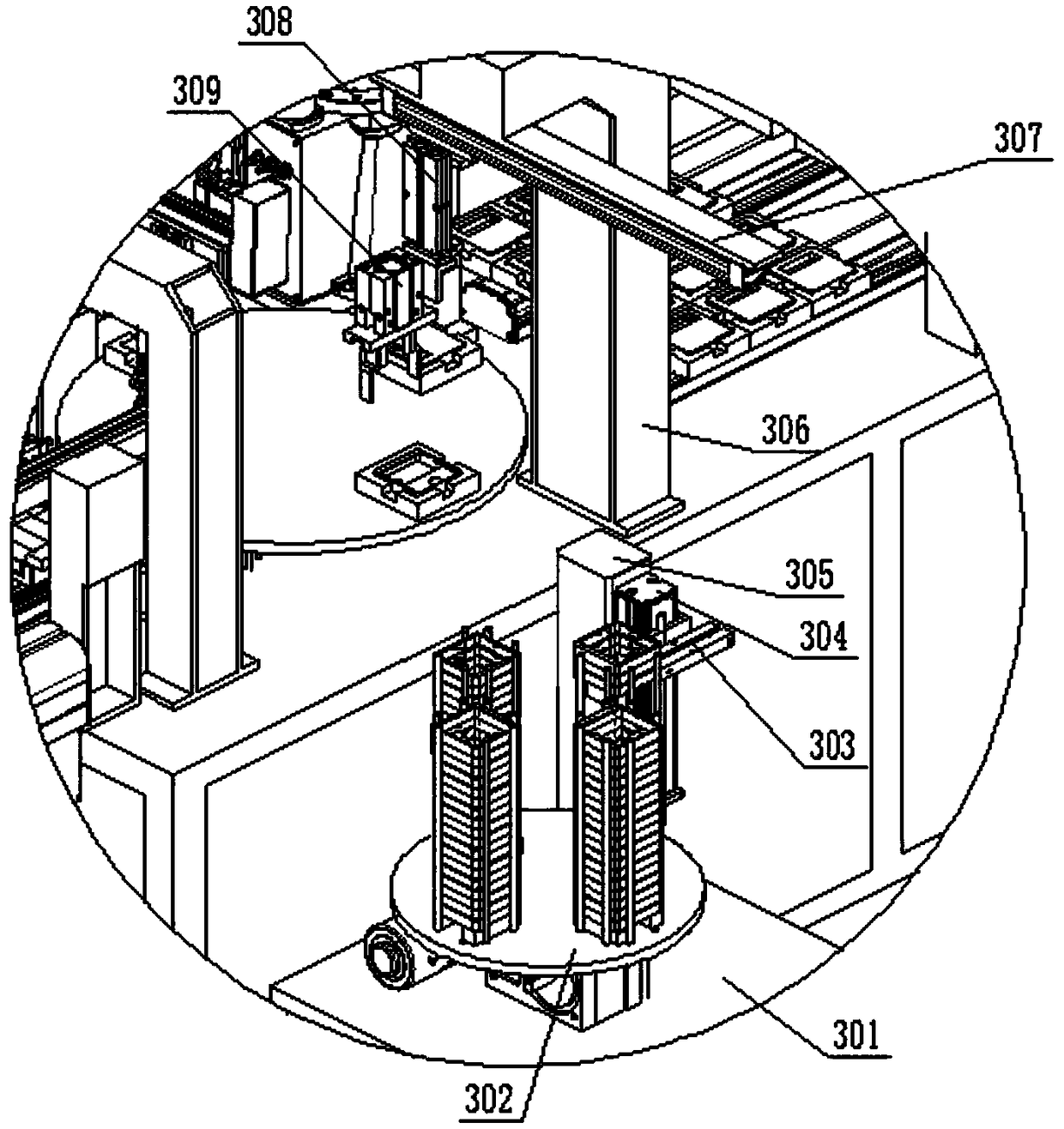

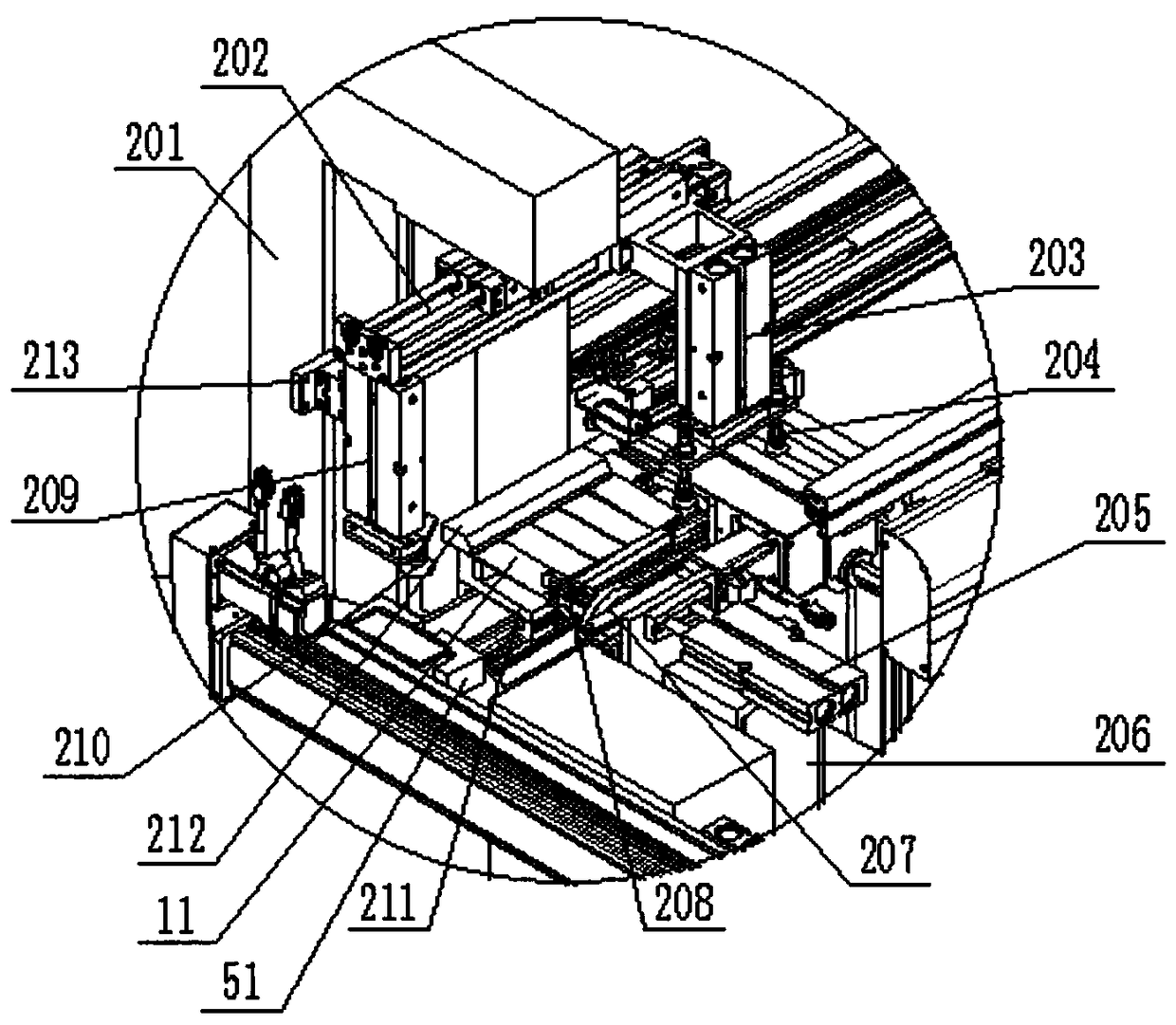

Faceplate assembly line

PendingCN108890291AIncrease productivityGuarantee product qualityAssembly machinesMetal working apparatusGrippersPrinted circuit board

Owner:山东红宝自动化有限公司

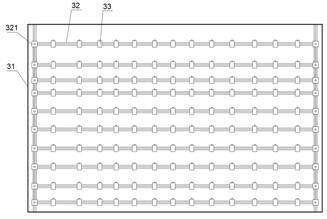

High-resolution display plasma module and manufacturing method thereof

PendingCN108181772AImprove the display effectIncrease contrastNon-linear opticsOptoelectronicsElectron

The invention belongs to the technical field of electronic display and relates to a high-resolution display plasma module and a manufacturing method thereof. The high-resolution display plasma modulecomprises a pixel electrode and a transparent electrode; a liner frame which is used for displaying plasma and is arranged at the periphery of the plasma is arranged between the pixel electrode and the transparent electrode; the pixel electrode is provided with a plasma isolation weir array; the plasma isolation weir array comprises a plurality of plasma isolation weirs which are distributed in anarray; the pixel electrode comprises a plurality of pixel electrode units which are distributed in the array; and the plasma isolation weirs, each of which contains one pixel electrode unit only, arearranged in intervals among the pixel electrode units respectively. By adopting the high-resolution display plasma module provided by the invention, display plasma is used to replace the existing microcup structure or microcapsule, and the plasma isolation weir array which is of a patterned structure and is arranged in the intervals among the pixel electrode units is arranged on the pixel electrode and encircles the pixel electrode units, so that high-resolution display effect is acquired, and multicolor and multi-gray display effect can be realized.

Owner:WUXI VISION PEAK TECH

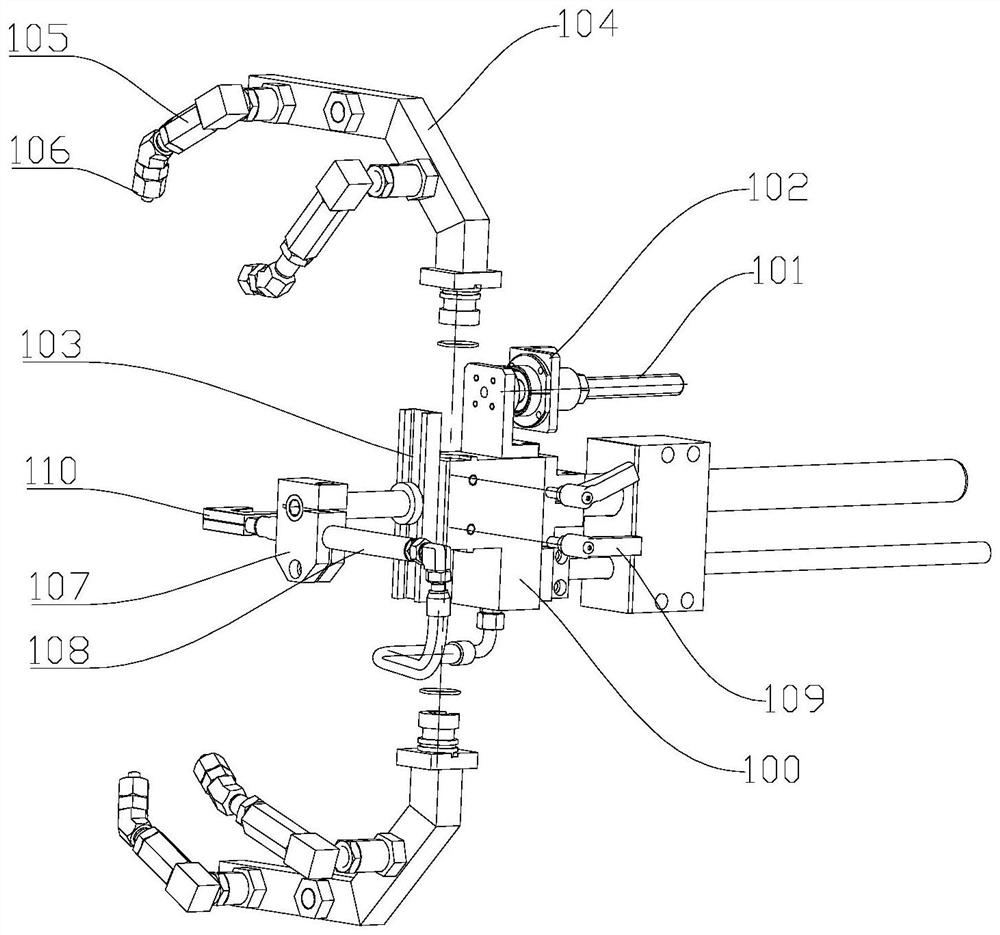

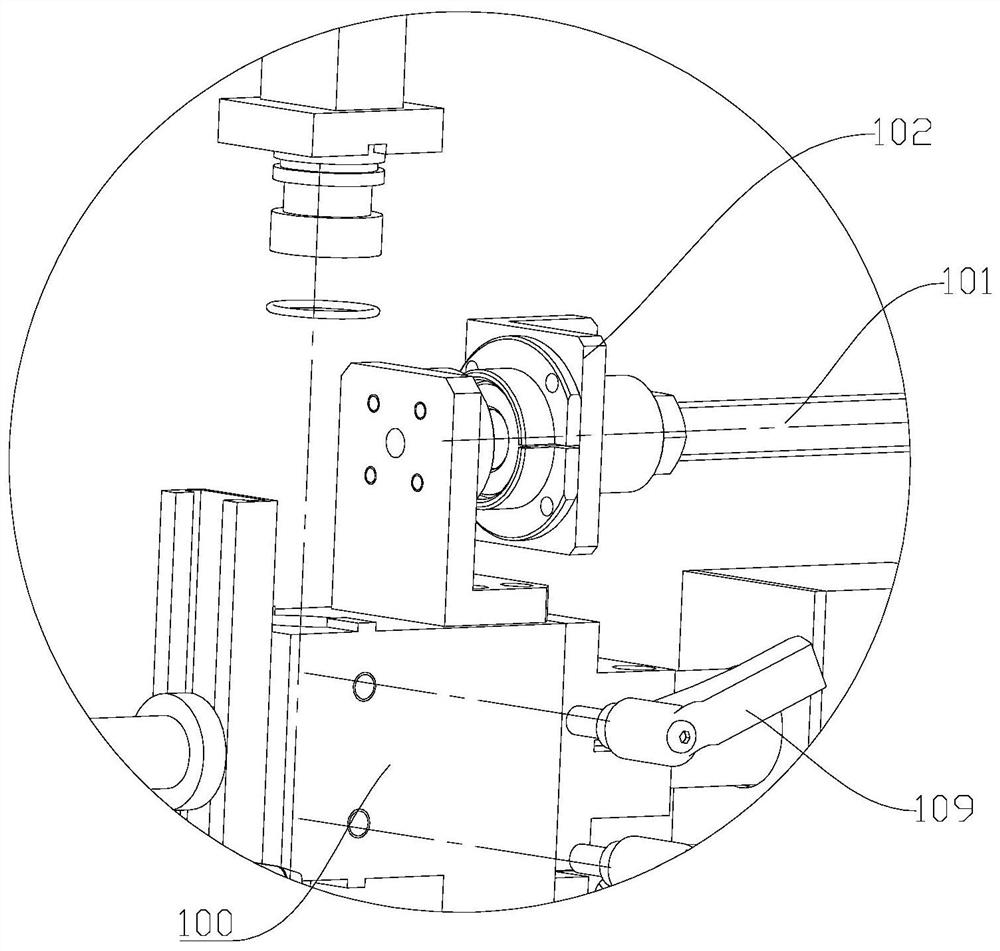

Vehicle hydraulic drill

InactiveCN101942963ADoes not affect normal workReduce handlingDerricks/mastsCutting machinesDrill pipeAutomatic tuning

The invention relates to a vehicle hydraulic drill, which belongs to the technical field of hydraulic drills, and in particular relates to underground drilling equipment. The technical problem to be solved is to provide the vehicle hydraulic drill which does not need to be manually transported and can automatically adjust the direction and the position of a drill rod before drilling, thereby saving the installation time of the hydraulic drill and reducing the labor intensity of workers. The invention adopts the technical scheme that the vehicle hydraulic drill comprises a rotary mechanism, a feeding mechanism, propulsion cylinders, a stand, a drill part and a pedestal, wherein the rotary mechanism is arranged on the pedestal, the stand is arranged on the rotary mechanism, the propulsion cylinders are symmetrically arranged at both sides of the stand, the feeding mechanism is arranged in the stand, the drill part is arranged on the stand, and the pedestal is fixed on the lateral surface of the cutting arm of a digging machine and at the rear part of a cutting head; and the invention is applied to the technical flied of underground hydraulic drills.

Owner:SHANXI DONGHUA MACHINERY

Ion electric propulsion beam doubly charged ion testing device and assembling method thereof

ActiveCN105022083AAchieve regulationTest Resolution AdjustmentAssembly machinesX/gamma/cosmic radiation measurmentIon currentImage resolution

The invention discloses an ion electric propulsion beam doubly charged ion testing device and an assembling method thereof, and can provide a magnetic field and an electric field, so as to realize testing of doubly charged ions in a beam. The device includes an outer shell, a collimation sleeve, a drifting tube, permanent magnets, electrode plates, an ion current collecting cup and a small hole assembly; the small hole assembly includes three small hole parts, and each has multiple sets of spare components which are the same in shape and have small inner holes with different apertures; and during testing, the spare component with the required aperture is selected according to intensity of a measured signal and a test resolution requirement to be mounted, thus adjustment of the test resolution can be realized through replacement of a small hole set, thereby enabling an adaptive range of the device to be expanded. Through the design of adjusting components and fixed components, parallelism between the permanent magnets, parallelism between the electrode plates and perpendicularity between the permanent magnets and the electrode plates are realized, thereby ensuring directions of the magnetic field and the electric field. The ion electric propulsion beam doubly charged ion testing device adopts a relation transformation method, thereby enabling an assembling process to be simpler and more convenient, and enabling an assembling result to be more accurate.

Owner:LANZHOU INST OF PHYSICS CHINESE ACADEMY OF SPACE TECH

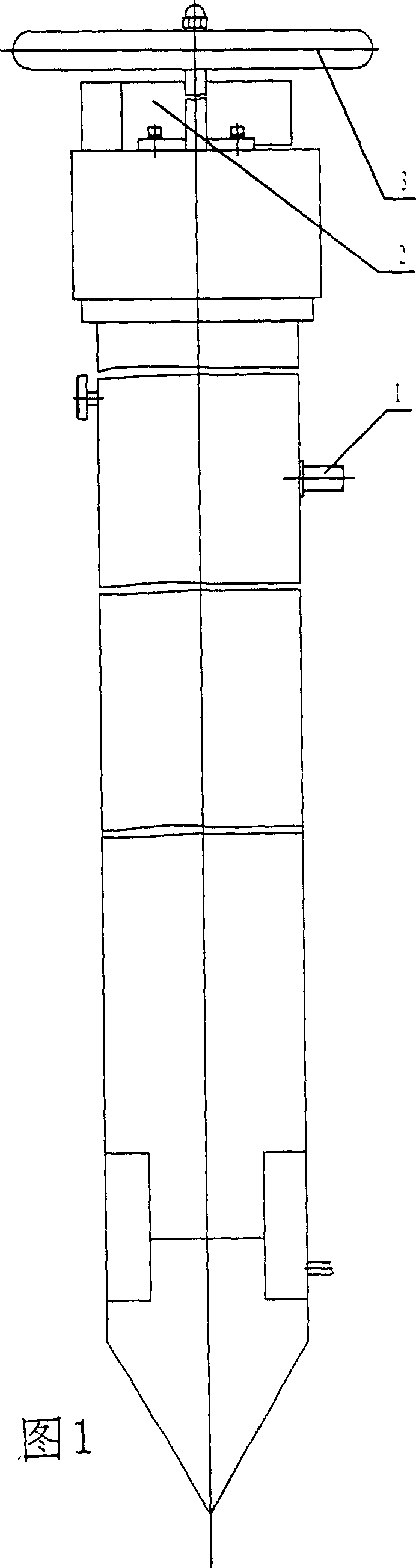

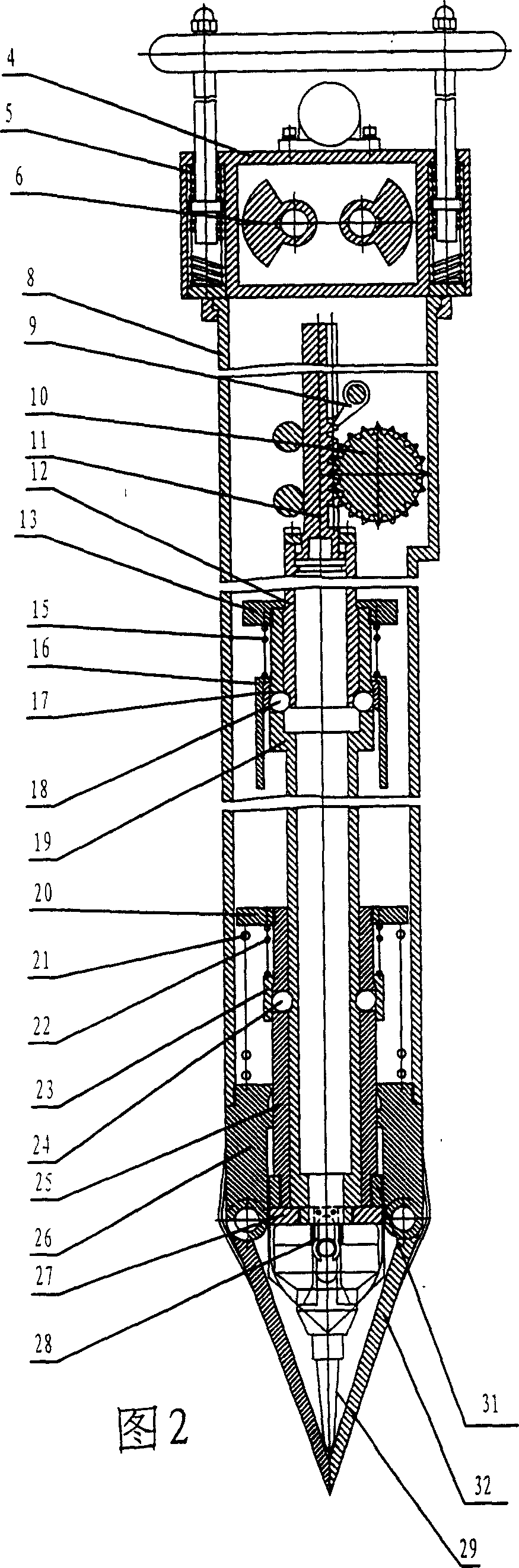

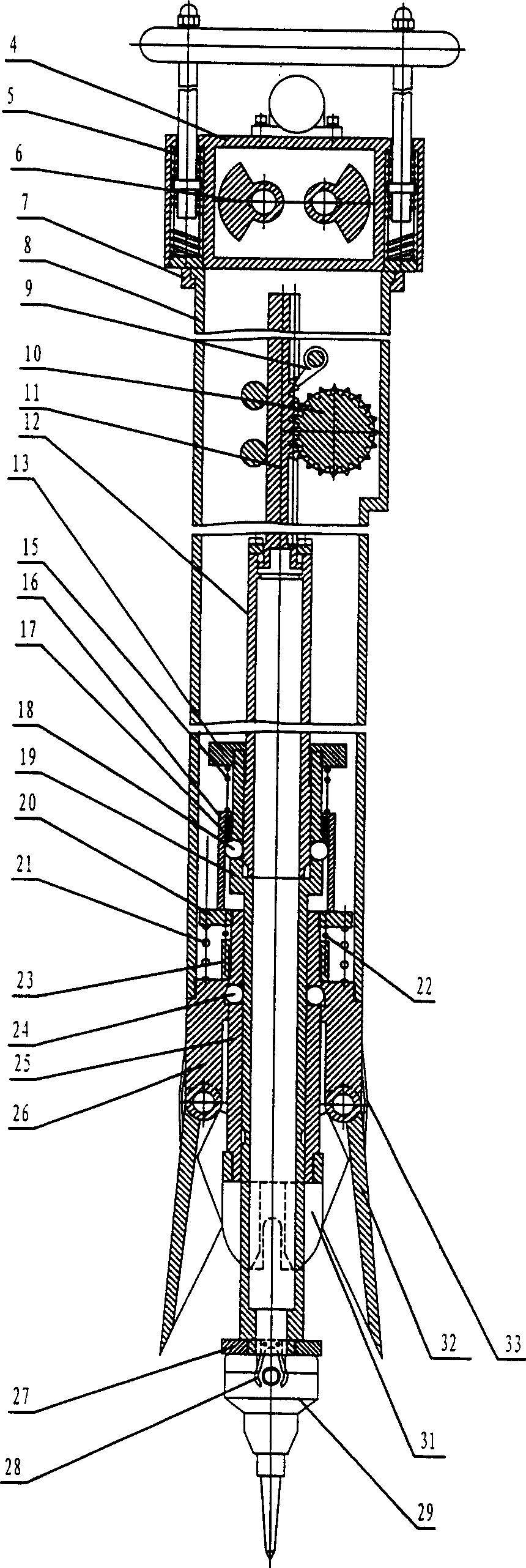

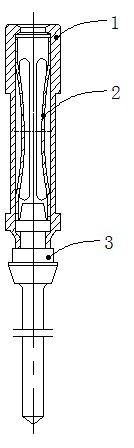

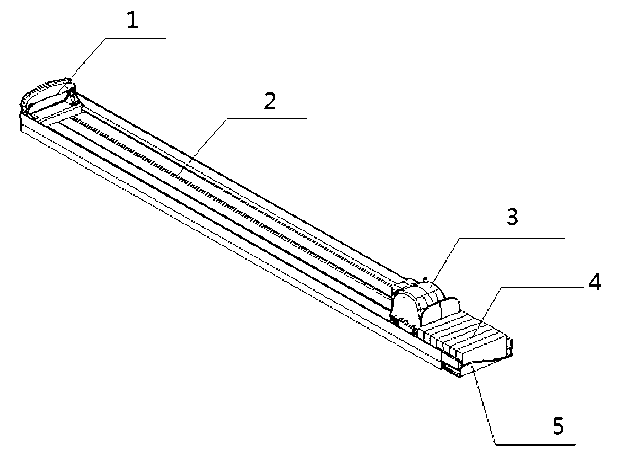

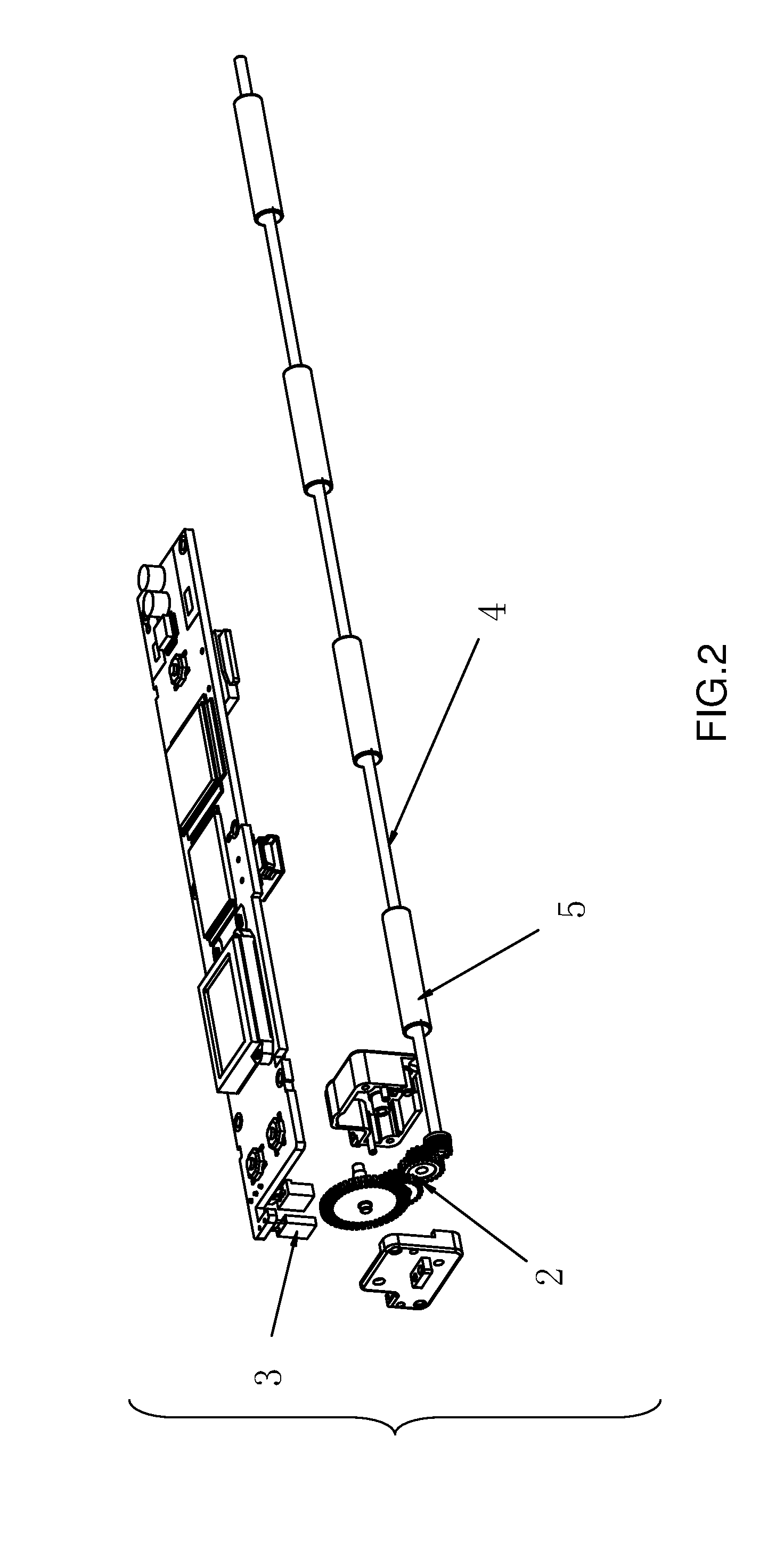

Wave detector embedding machine

InactiveCN1621862AReduce volumeReduce weightConstructionsSeismic signal receiversPhase detectorHand held

The detector embedding machine includes casing, hand held frame on the upper part of the casing, shocking cone in the lower part, cone opening and guiding mechanism inside the casing, driving mechanism to drive the cone opening and guiding mechanism and re-positioning control mechanism for the cone opening and guiding mechanism. The detector embedding machine is small, light, compact in structure, low in cost, great in output force, high detector embedding quality and suitable for various soil environment, including desert, farm land, grassland, etc. and may be used in embedding detector deeply into stratum without man-made destruction.

Owner:谷军鉴 +2

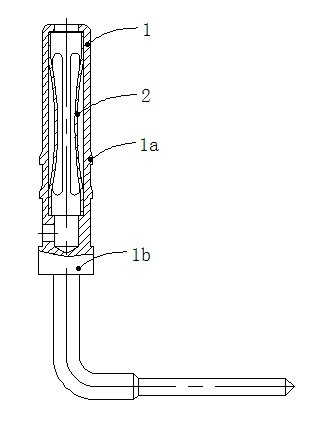

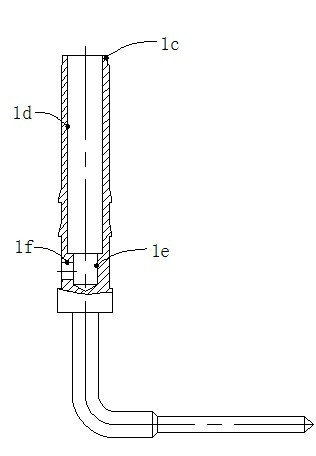

Bent type jack contact for crown spring

InactiveCN102683956ASimple structureImprove processing efficiencyCoupling contact membersInterference fitButt joint

The invention provides a bent type jack contact for a crown spring. The bent type jack contact consists of a bent type jack and a crown spring type contact ring. The tail end of the bent type jack is in a 90-degree bent structure; no inner space for mounting the crown spring type contact ring exists in equipment at a butt-joint end; and the crown spring type contact ring is fixed in the bent type jack through interference fit of an inner hole. The bent type jack contact provided by the invention has the advantages of simple structure, high machining efficiency, high machining precision of the 90-degree bent part, good consistency, reliable signal transmission, simple assembly and good structure stability, and can be used for effectively ensuring the direction of a bending pin. The bent type jack contact is applicable to a bend-plug type circuit connector for a printed board, and has the advantages of smaller contact distance, light plug force requirement and large contact row quantity.

Owner:ZUNYI JINGXING AEROSPACE ELECTRICAL APPLIANCE

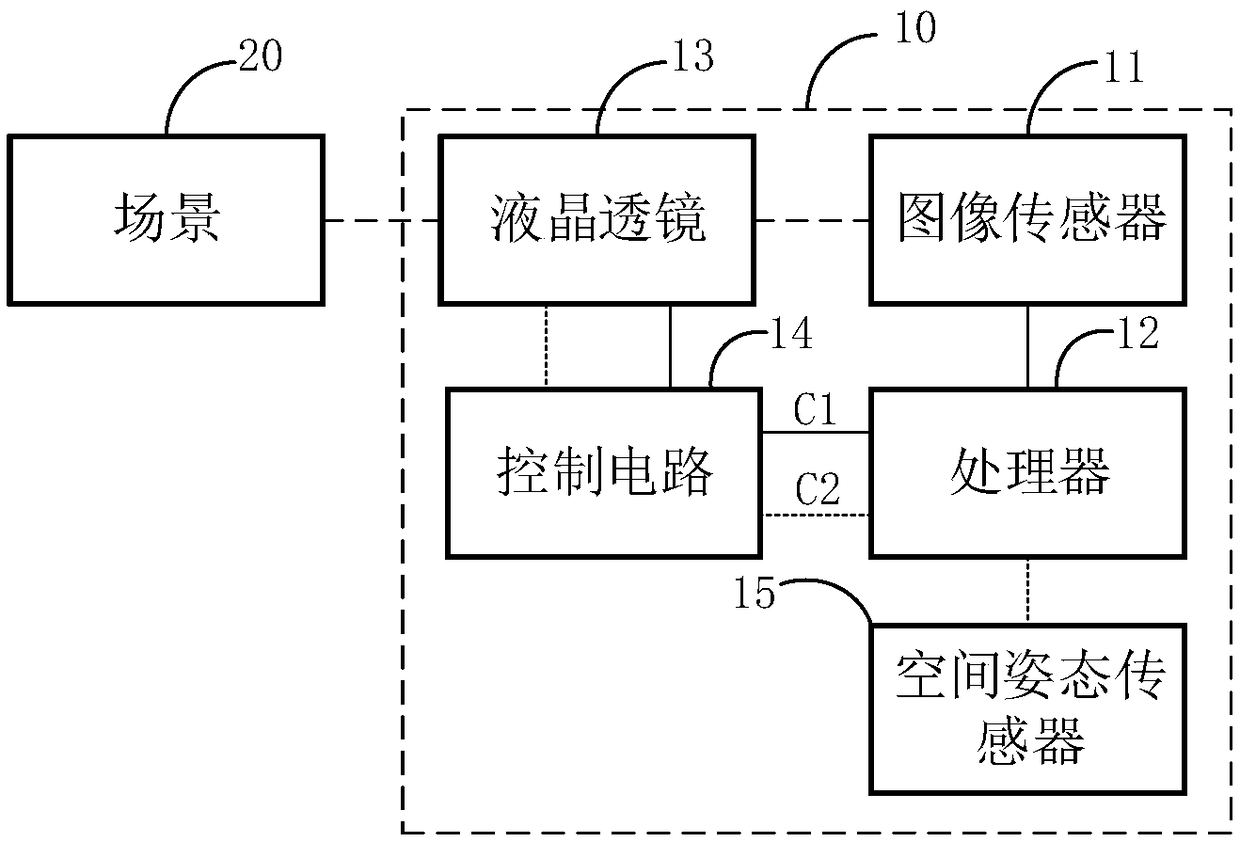

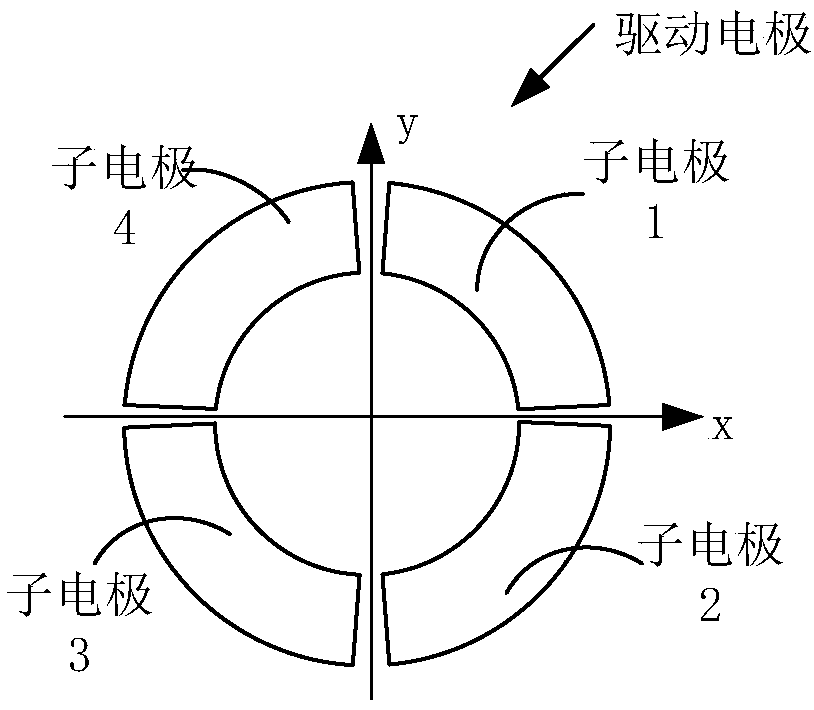

Imaging device, imaging control method, electronic device and readable storage medium

InactiveCN109116658AResolve blurImprove shooting experienceStatic indicating devicesNon-linear opticsControl signalControl circuit

The invention relates to an imaging device, an imaging control method, an electronic device and a readable storage medium. The imaging device comprises an image sensor, a space attitude sensor, a processor, a liquid crystal lens and a control circuit, wherein the liquid crystal lens is arranged on an imaging light path of the image sensor, and is connected with the control circuit; the space attitude sensor is used for obtaining the space attitude of the imaging device, and the space attitude is transmitted to the processor; the processor is used for calculating the offset vector of the imaging device according to the space attitude, determining the light emitting direction of the liquid crystal lens according to the offset vector and obtaining a first control signal to be transmitted to the control circuit according to the light emitting direction; and the control circuit is used for controlling the liquid crystal lens for focus swing according to the first control signal. In the embodiment, the problem of image blurring caused by shaking in the user shooting process can be solved, an optical anti-shake purpose is reached, and the user shooting experience is promoted.

Owner:BOE TECH GRP CO LTD

Storage drawer with coiled energy storage pushing trolley

ActiveCN102700883AAvoid contactConducive to push out warehouseStorage devicesEngineeringEnergy storage

The invention discloses a storage drawer with a coiled energy storage pushing trolley, which comprises a handle, a drawer rack, the pushing trolley and an out bin port, wherein three grooves are formed in the bottom plate of the drawer rack, and parallel to one another and to the extending direction of the drawer rack; the cross section of the middle groove is invented T-shaped; a power mechanism, a winding mechanism and a draught line are arranged in the pushing trolley; the power mechanism can drive the winding mechanism to rotate; the draught line is wound around the winding mechanism; the other end of the draught line is fixedly connected to the out bin port; a positioning bulge is arranged at the bottom of the pushing trolley; the cross section of the positioning bulge is invented T-shaped; rollers on the left and the right sides of the pushing trolley are arranged in grooves on two sides of the bottom plate of the drawer rack; the bulge at the bottom of the pushing trolley is arranged in the middle groove of the bottom plate of the drawer rack; after being led out, the draught line on the pushing trolley is also arranged in the middle groove of the bottom plate of the drawer rack; and the handle is arranged on the back of the storage drawer, so as to facilitate grabbing and pushing.

Owner:JIANGSU XUNJIE HARNESS TECH

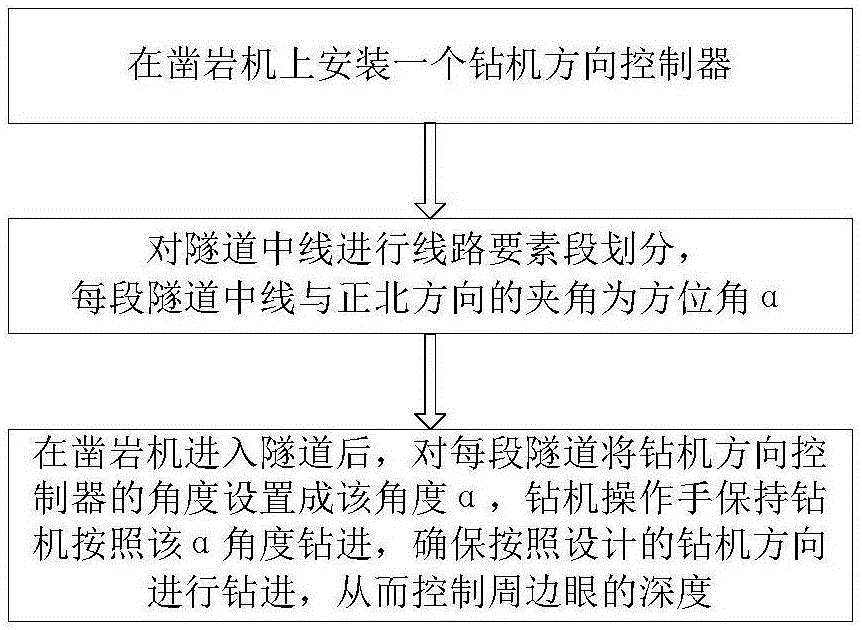

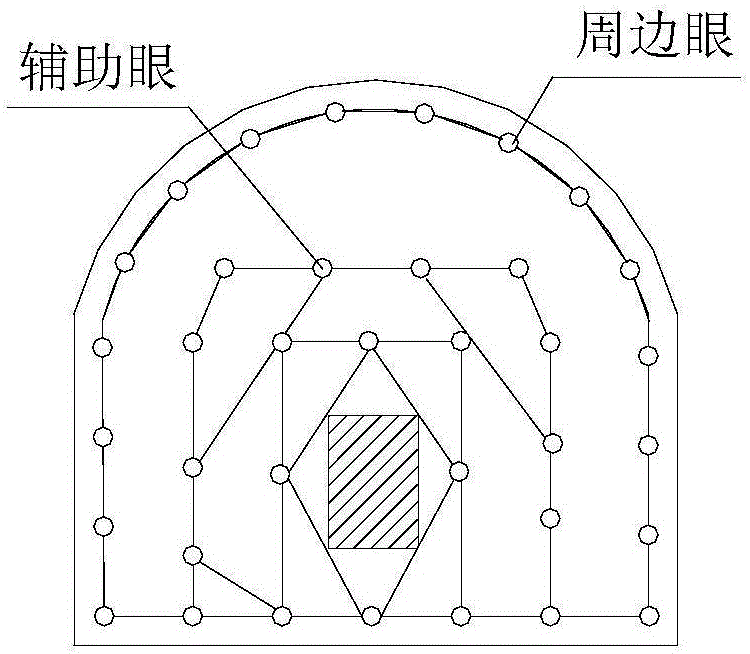

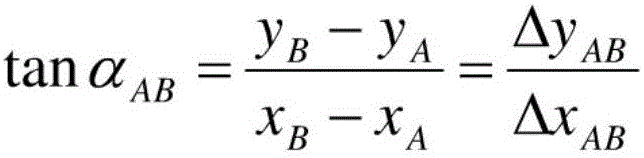

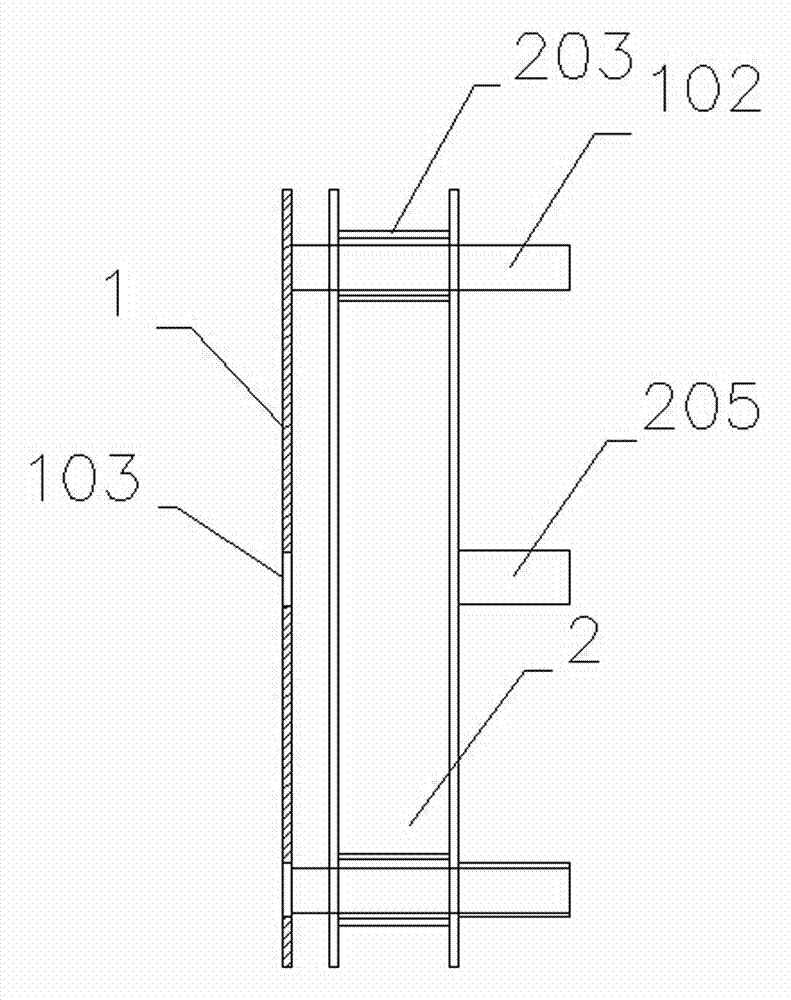

Method for tunnel smooth blasting drill construction

InactiveCN106368606AReduce construction costsReduce Secondary DisturbanceReciprocating drilling machinesConstructionsMiddle lineCircular section

The invention discloses a method for tunnel smooth blasting drill construction. The method comprises the steps of installing a drilling rig direction controller on a rock drill, wherein the drilling rig direction controller is used for directly displaying up-and-down and left-right deflection directions of a drilling rig; before the rock drill enters a tunnel, performing line element section segmentation on a tunnel center line, calculating an azimuth of each section of tunnel center line according to the line element section, wherein the line element section comprises a straight line section, a straight easement section, an easement circular section, a circular curved section, a circular easement section and an easement straight section; the azimuth is an included angle alpha of each section of tunnel center line and the true north direction; after the rock drill enters the tunnel, setting the angle of the drilling rig direction controller as the angle alpha for each section of tunnel, causing a drilling rig manipulator to perform drilling according to the angle alpha, guaranteeing that drilling is performed according to the designed drilling rig direction, and thus a periphery hole depth is controlled. According to the method, extensive type construction by experience during hand excavation is solved, and precise positioning in the rock drill drilling direction during tunnel excavation is achieved.

Owner:NO 1 CONSTR ENG CO LTD OF CHINA CONSTR THIRD ENG BUREAU CO LTD

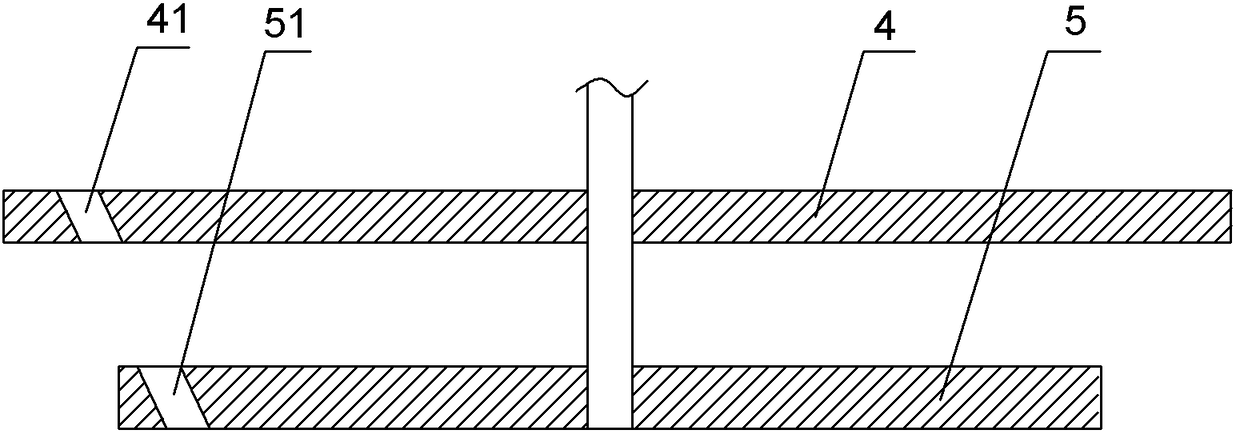

Device for controlling multi-hole type punching and bolt implanting accuracy of tunnel

ActiveCN104842323AEasy to operateGood effectPortable percussive toolsPortable drilling machinesPunchingEngineering

A device for controlling multi-hole type punching and bolt implanting accuracy of tunnel consists of a device I and a device II, wherein the device I is a slab of which the center is provided with an opening I, the slab is provided with multiple verifying rods vertical to the surface of the slab and multiple marking holes, the device II is formed by an upper-layer plate and a lower-layer plate, which are parallel to each other, through the combination a guide tube, the outer side of the upper-layer plate is vertically provided with a fixing rod, the centers of the upper-layer plate and lower-layer plate are provided with openings II respectively, the upper-layer plate and the lower-layer plate are respectively provided with multiple verifying holes that matches the verifying rod, the guide tube is vertically fixed between the verifying holes which are oppositely arranged in the upper-layer plate and the lower-layer plate, and forms a punching and verifying channel together with the verifying holes. According to the device for controlling the multi-hole type punching and bolt implanting accuracy of the tunnel, the device I and the device II can complete the accuracy control work of the punching and bolt implanting process before installing a multi-hole flange pedestal within a short time in the manner of alternative verification through 'fixation-verification-correction' operations, the operations are simple, and the effect is remarkable.

Owner:THE 1ST ENG CO LTD OF CHINA RAILWAY CONSTR ELECTRIFICATION BUREAU GRP

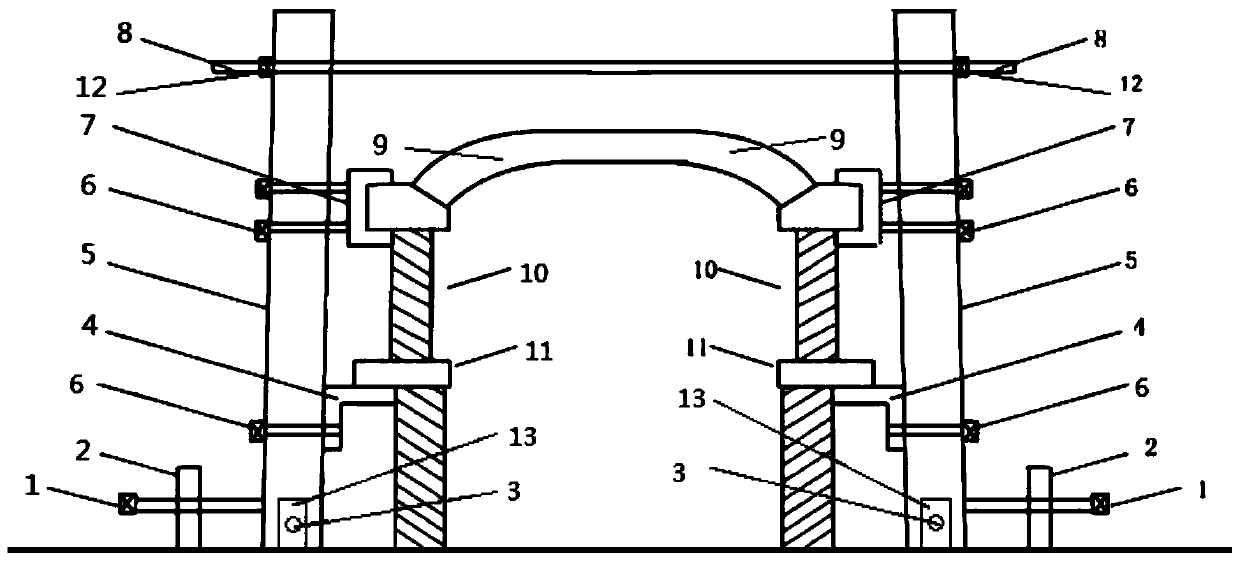

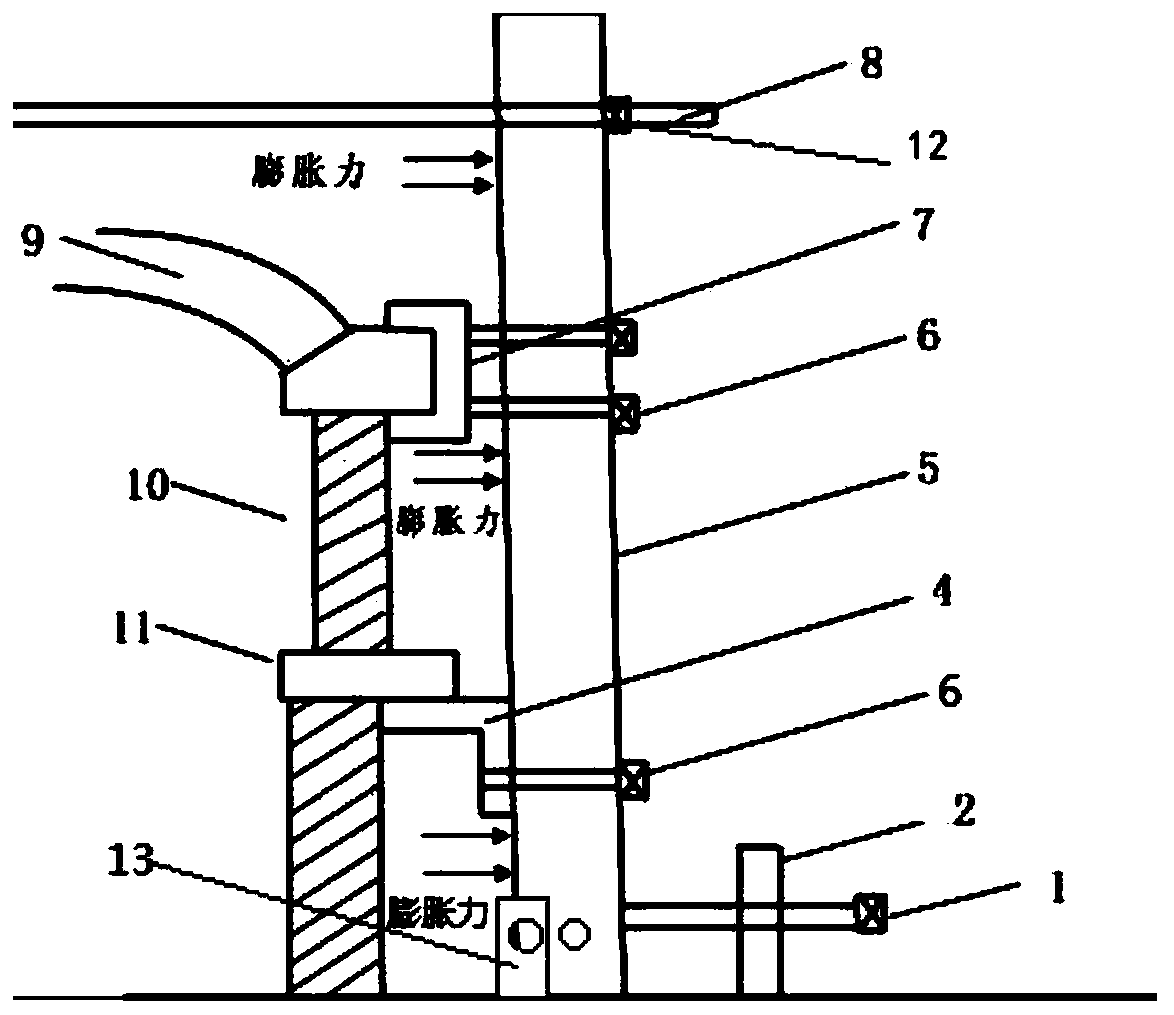

Thermal expansion adjusting device and method for glass tank furnace

PendingCN111018315ASolve structural deformationNo structural deformationGlass furnace apparatusStructural engineeringManufacturing engineering

The invention discloses a thermal expansion adjusting device for a glass tank furnace. The thermal expansion adjusting device comprises adjusting bolts, fixed columns, a release brace and adjusting nuts, wherein stand columns are symmetrically arranged on the two sides of the glass tank furnace and located and fixed to a bottom platform of the glass tank furnace through locating bolts; the fixed columns are fixedly connected to the parts, located at the outer sides of the stand columns on the two sides of the tank furnace, of the bottom platform respectively; the adjusting bolts are in threaded connection with the fixed columns, and the ends of screws abut against the bottoms of the stand columns on the same side; the two ends of the release brace are provided with threads, penetrate through the upper portions of the stand columns on the two sides of the glass tank furnace respectively and are connected with the adjusting nuts. According to the thermal expansion adjusting device for the glass tank furnace, the bottom positioning bolts are disassembled, and the tightness state of the adjusting screws and the release brace is adjusted by rotating the adjusting bolts and the adjustingnuts, so the stand columns of the glass tank furnace are continuously moved and adjusted, and structural deformation caused by expansion of the glass tank furnace is effectively solved.

Owner:IRICO DISPLAY DEVICES

Grinding wheel cooling nozzle assembly and gear grinding machine

InactiveCN111958057AAchieve replacementTimely replacementGear-cutting machinesMaintainance and safety accessoriesGear grindingLubrication

The invention discloses a grinding wheel cooling nozzle assembly and a gear grinding machine. The gear grinding machine is provided with the grinding wheel cooling nozzle assembly. The grinding wheelcooling nozzle assembly comprises a liquid distribution base and a plurality of nozzles, wherein the liquid distribution base is provided with a cooling liquid passage connected with a cooling liquidpipe; and the angles of the nozzles are fixed, and the nozzles are detachably mounted on the liquid distribution base and communicate with the cooling liquid passage. According to the grinding wheel cooling nozzle assembly adopting the structural arrangement, by fixedly arranging the nozzles, the spraying angle and direction can be effectively ensured compared with traditional structural arrangement of a universal bamboo pipe; when the assembly is applied to the gear grinding machine, lubrication, cleaning and cooling of a grinding wheel can be effectively ensured, and smooth proceeding of machining is guaranteed; and moreover, the nozzles can be replaced due to detachable arrangement, so that the nozzles matched with the grinding wheel are replaced in time according to different production requirements, or the quantity and the like of the nozzles are changed, and practicability is high.

Owner:HUNAN ZDCY (ZHONGDA CHUANG YUAN) CNC EQUIP CO LTD

An automatic rolling shutter device for agricultural greenhouses

ActiveCN111108981BReduce frictionPrevent deviationClimate change adaptationGreenhouse cultivationAgricultural scienceGreenhouse

Owner:杭州稼禾秀实农业科技有限公司

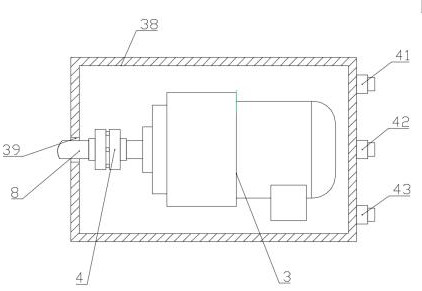

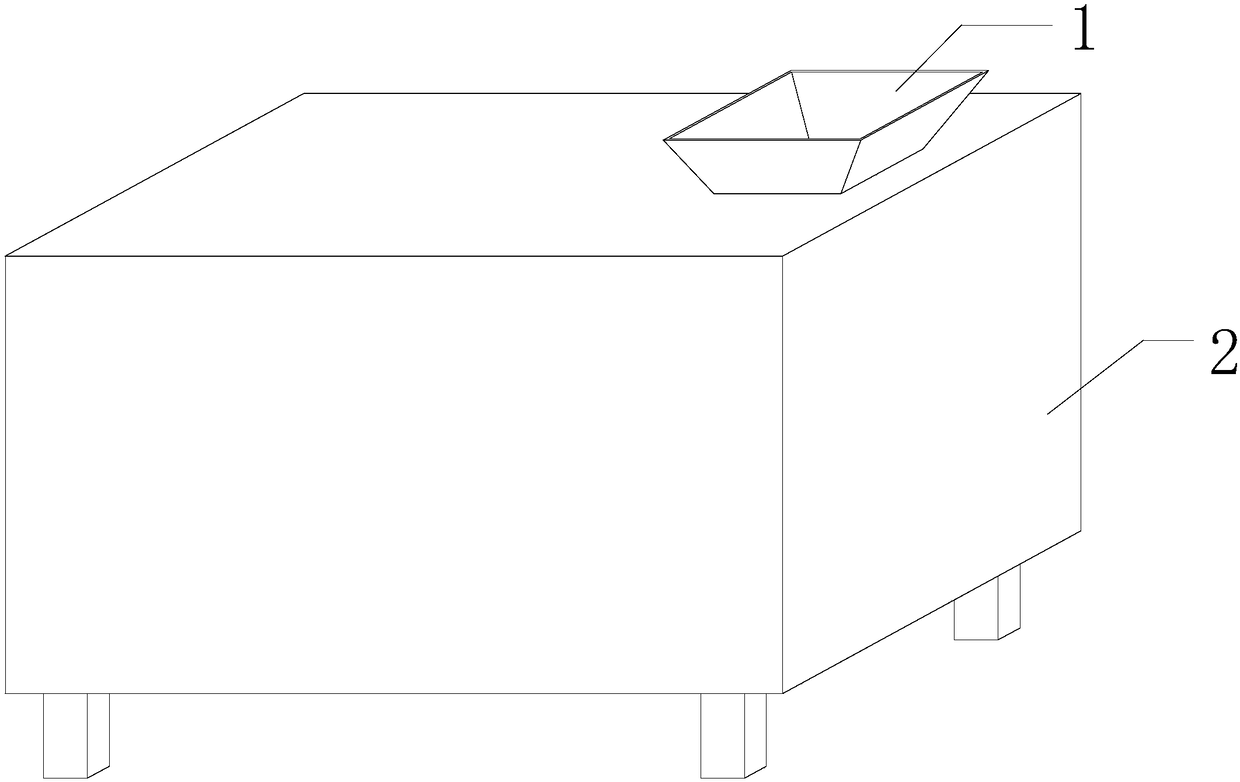

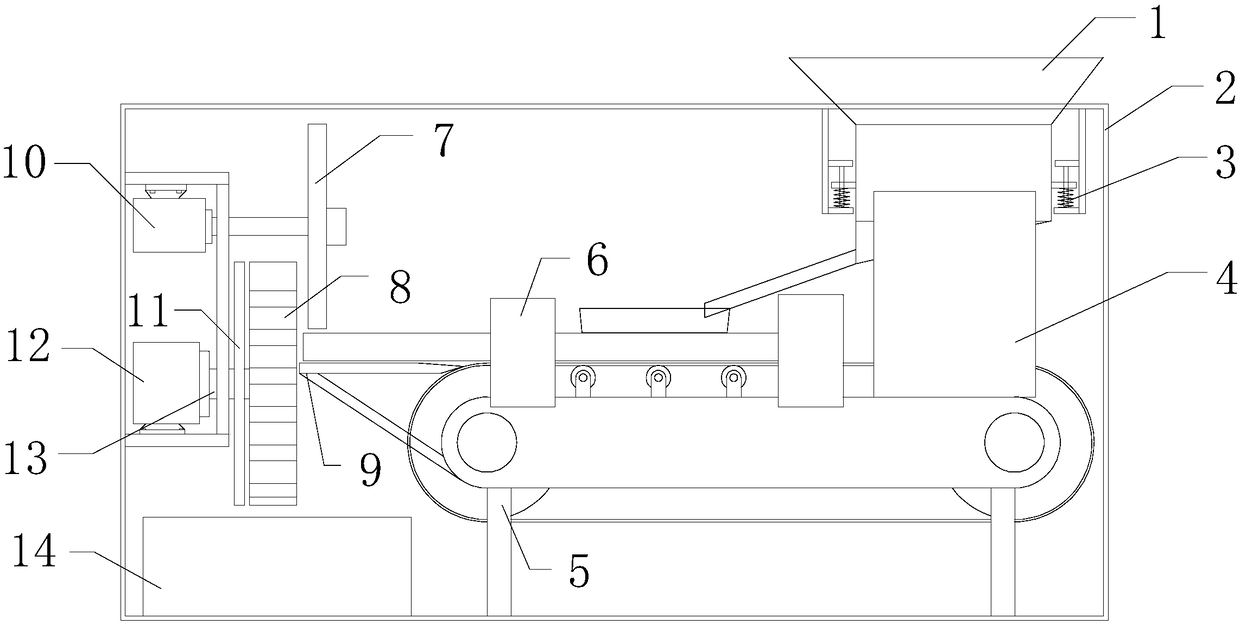

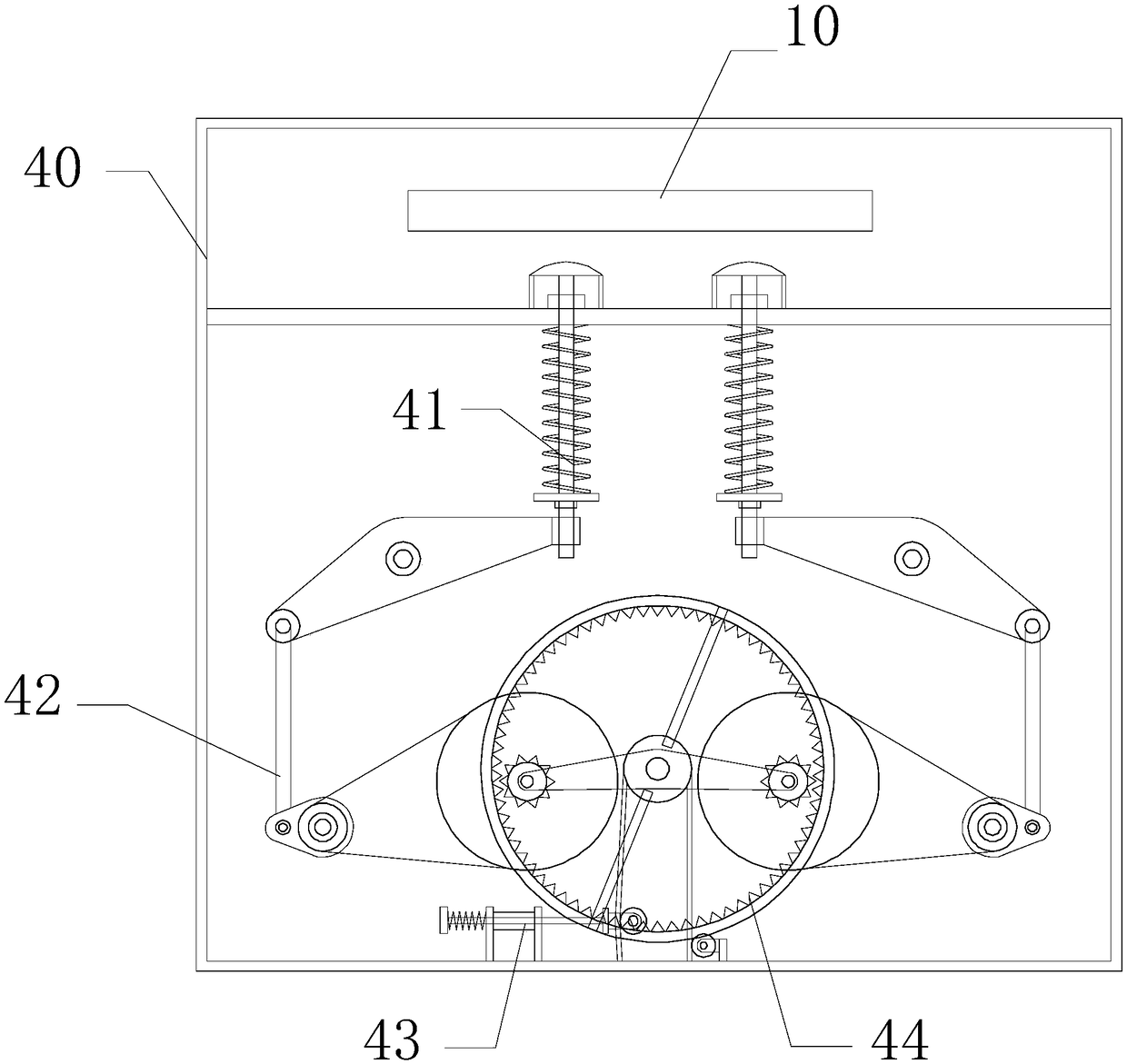

Grinding device for spring manufacturing

InactiveCN108453580APrevent slippingAvoid getting stuckGrinding drivesGrinding feedersPower equipmentMagnet

The invention discloses a grinding device for spring manufacturing. The device structurally comprises a material barrel, a housing, spring seats, vibrating devices, a conveyor, a guide mechanism, a grinding plate, a spring tray, a guide plate, a grinding motor, a magnet disc, a motor, a rotating shaft and a collecting box, wherein the left side and the right side of the material barrel are connected into the housing through the spring seats; the vibrating devices are correspondingly arranged at the front side and the rear side of the material barrel and are connected to two sides of the conveyor; the left end of the conveyor is arranged below the material barrel; the guide mechanism is mounted on the conveyor; and the guide plate is welded at the right end of the conveyor. The device has the beneficial effects that the material barrel is shaken through the vibrating devices, so that the material barrel is prevented from being clamped; the conveyor rotates to supply power to the vibrating devices, and thus power equipment is saved, and the equipment utilization rate is increased; the guide mechanism is capable of adjusting the springs based on the size of the spring in real time, sothat the springs can conveniently enter the spring trays during being conveyed, and the work is smoothly carried out, and as a result, the working efficiency is improved.

Owner:胡祥

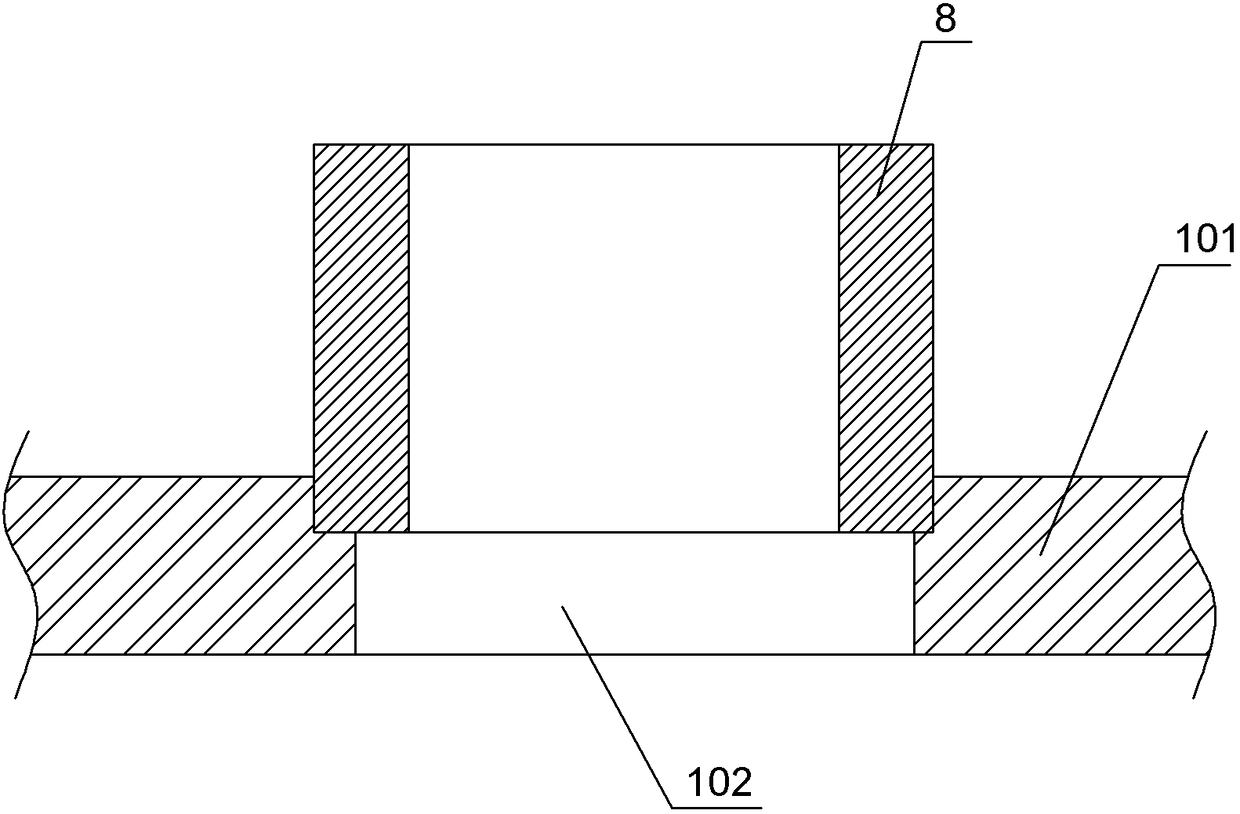

Closed type display plasma module and manufacturing method thereof

PendingCN109188822AGood displayIncrease contrastGas discharge electrodesGas discharge vessels/containersElectric fieldOptoelectronics

The invention belongs to the technical field of electronic display, and relates to a closed type display plasma module. The closed type display plasma module comprises a pixel electrode and a transparent electrode located above the pixel electrode; display plasma and a liner frame surrounding the display plasma are arranged between the pixel electrode and the transparent electrode; the pixel electrode is provided with a plasma resistance separation array used for uniformly dispersing and stabilizing the display plasma; in a vertical direction, the plasma resistance separation array penetratesthrough the whole display plasma; the transparent electrode is coated with a transparent glue layer; and the transparent glue layer is in contact with the display plasma and is pressed together with the top end of the plasma resistance separation array. According to the display plasma module, the display plasma is directly used for replacing an existing micro-cup structure or a micro-capsule, theplasma resistance separation array is arranged in the display plasma, and the transparent electrode with the transparent glue layer is pressed on the plasma resistance separation array to form a closed structure, so that the disorderly flowing of the display plasma is effectively prevented and the perpendicularity of an electric field direction between the pixel electrode and the transparent electrode is guaranteed.

Owner:WUXI VISION PEAK TECH

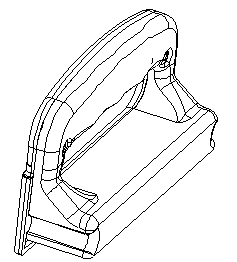

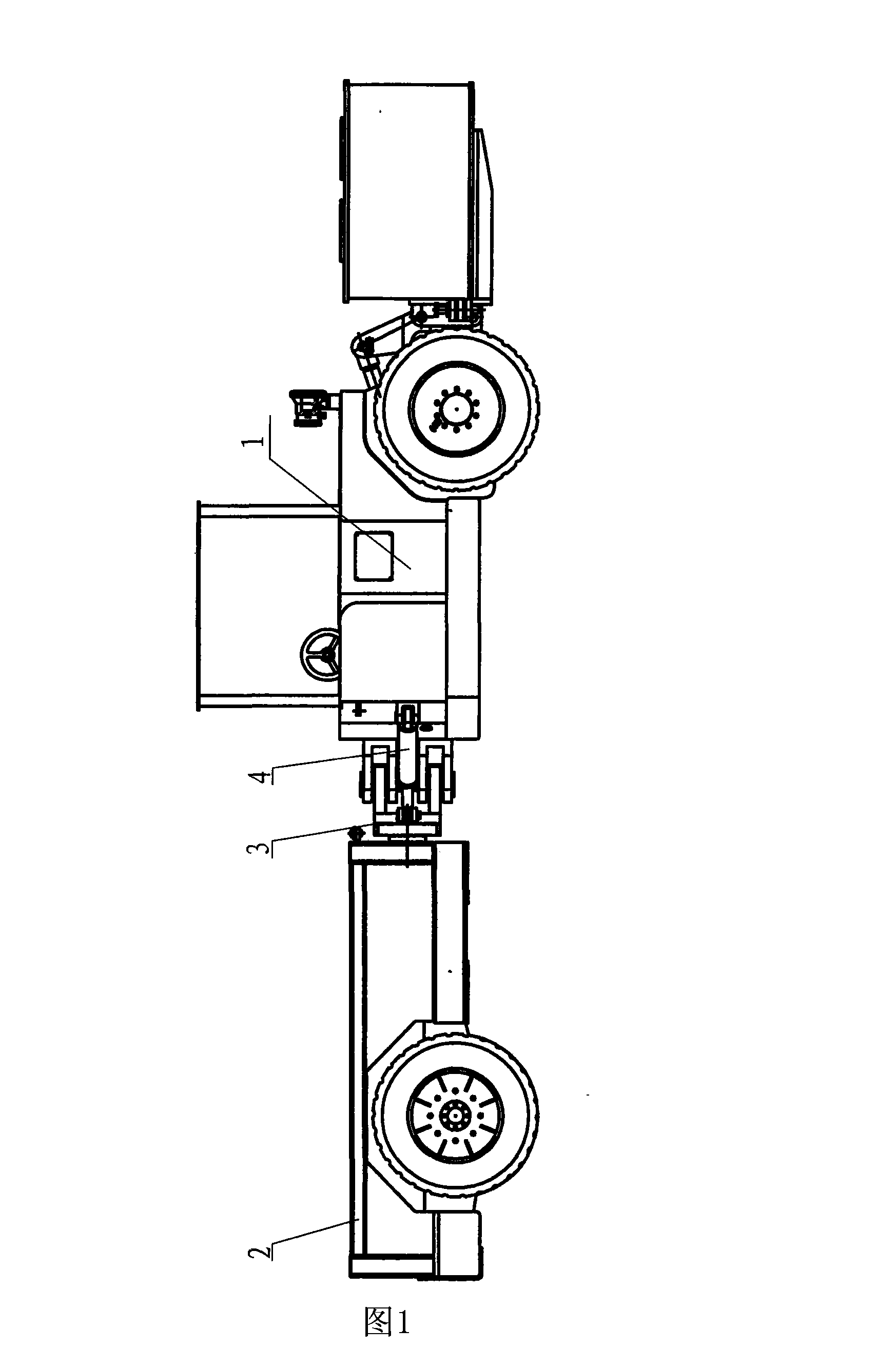

Bidirectional mine transport vehicle

InactiveCN101214831AWith two-way driving functionSmall turning radiusTractor-trailer combinationsWellheadTransportation cost

A bidirectional mine transporter comprises a power engine (1), a trailer (2), a connecting piece (3) and an oil cylinder (4). The power engine (1) is designed as the motor with dynamic and bridgeless wheel-side hydraulic driven type. The trailer (2) is designed as bridgeless wheel-side hydraulic driven type. The connecting piece (3) is positioned on the central line of the power engine (1) and the trailer (2) and between the power engine and the trailer. One end of the connecting piece (3) is hinged with the power engine (1) and the other end of the connecting piece is hinged with the trailer (2). One end of the oil cylinder (4) is hinged with the trailer (2) at the central line of the trailer (2), and the other end of the oil cylinder is hinged with the power engine (1) at the angle range of more than 50 degree and less than 90 degree to the central line of the power engine (1). The oil cylinder (4) is connected with the steering device of the power engine (1). Therefore, the invention can carry out the direct transportation from the ground to the working face of mining or from the wellhead to the working face of mining without transloading, and has the advantages of rapid transportation speed, large transportation ability, and flexibility and low mobile transportation cost.

Owner:TAIAN TAISHAN CONSTR MACHINERY

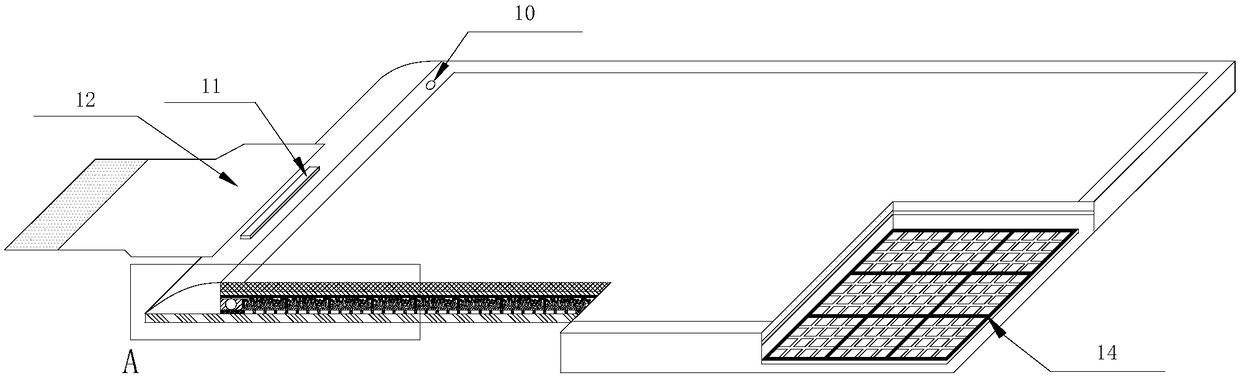

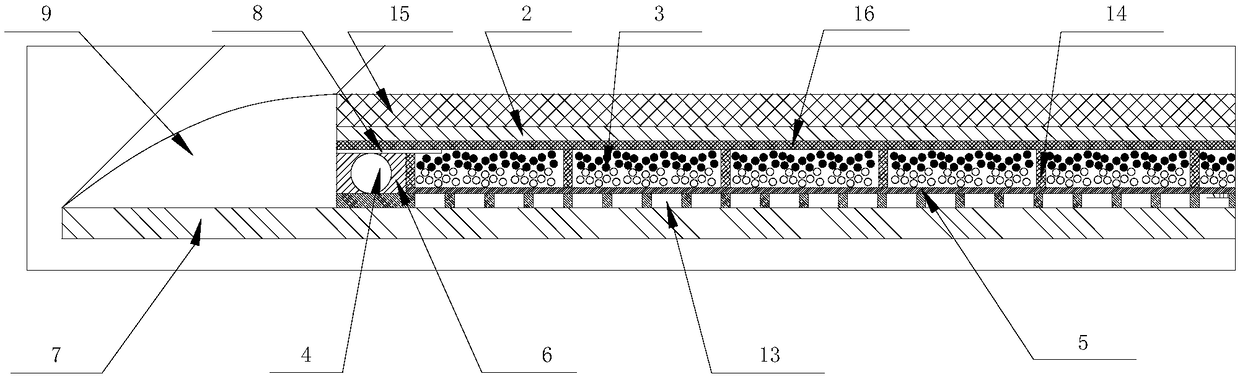

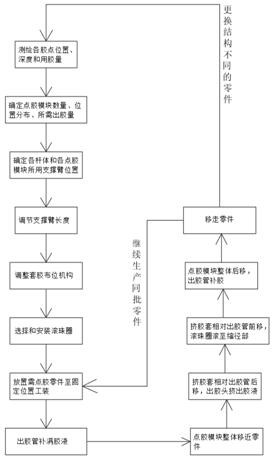

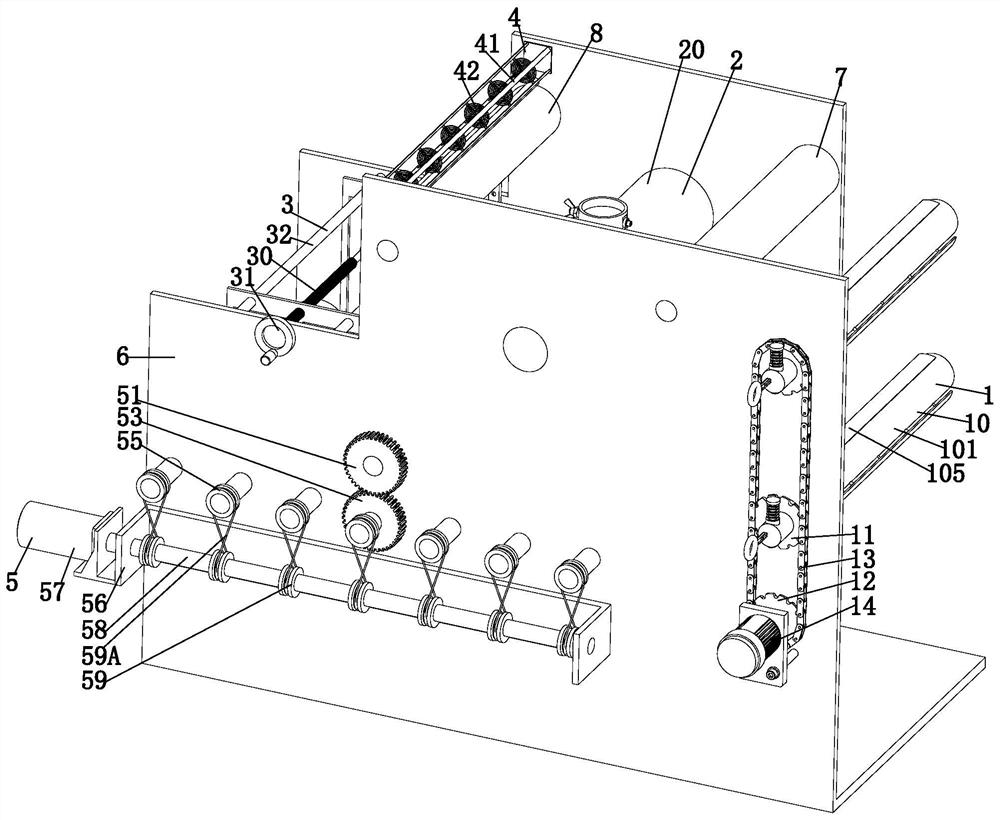

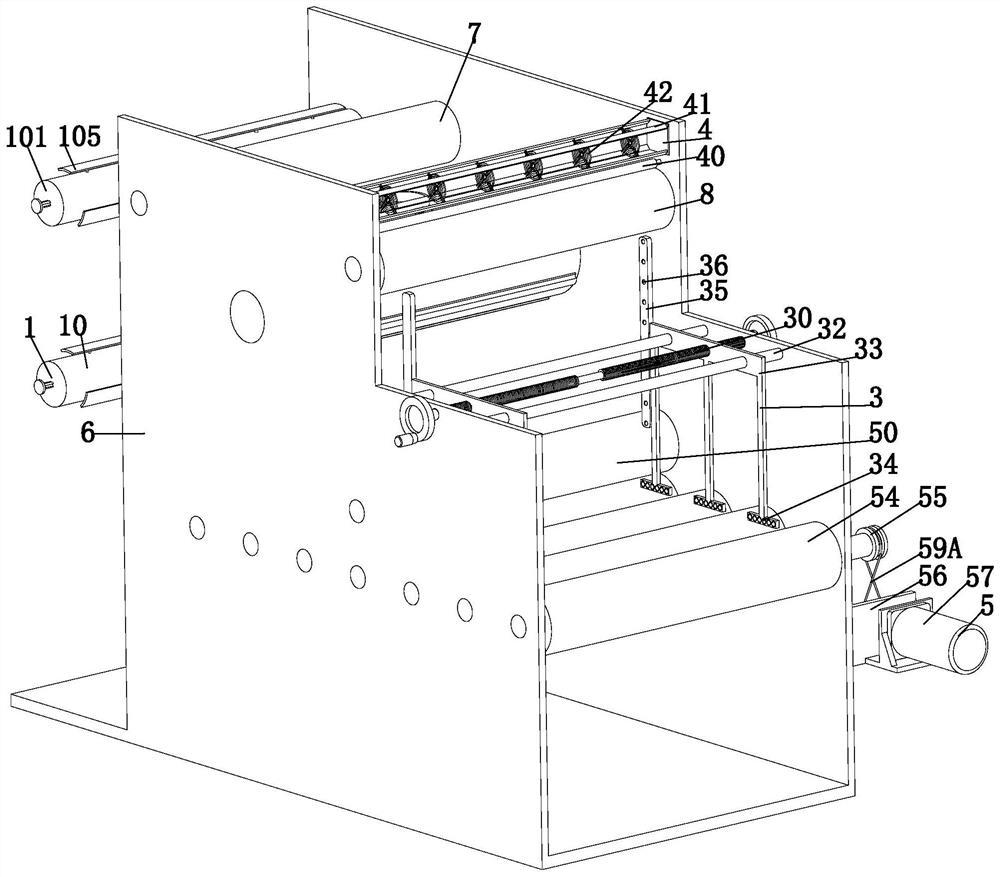

Multipoint synchronous dispensing machine and dispensing method

ActiveCN111632795ALarge structureEasy to adjustLiquid surface applicatorsCoatingsMachineIndustrial engineering

The invention relates to a multipoint synchronous dispensing machine and dispensing method. The dispensing machine comprises multiple dispensing modules achieving the dispensing function and a moduledistribution mechanism. The rear ends of the dispensing modules communicate with glue supplementary pipes. The module distribution mechanism is used for fixing the positions of the dispensing modulesand comprises a first frame and multiple parallel polygonal rods, and the rods are distributed in the first frame and are in sliding fit with the first frame in a locking and fixing manner. Multiple mounting blocks are in detachable sliding fit with the rods in a locking and fixing manner. According to the multipoint synchronous dispensing machine and dispensing method, dispensing can be subjectedto multiple points in a visual face of a part at the same time, the dispensing efficiency is greatly improved, and the dispensing machine and dispensing method are especially suitable for large-scalebatched production; the mechanical cooperation manner is mainly adopted, the number of needed electronic devices is small, work is extremely stable, the service life is long, and the maintenance costis low; dispensing control of different positions, depths and glue quantities can be achieved at the same time, and part structures which the dispensing machine and dispensing method can adapt to areextremely wide; and adjusting can be carried out rapidly and conveniently according parts of different structures, and the application range is wide.

Owner:XIAMEN XINAOGE AUTOMATION EQUIP CO LTD

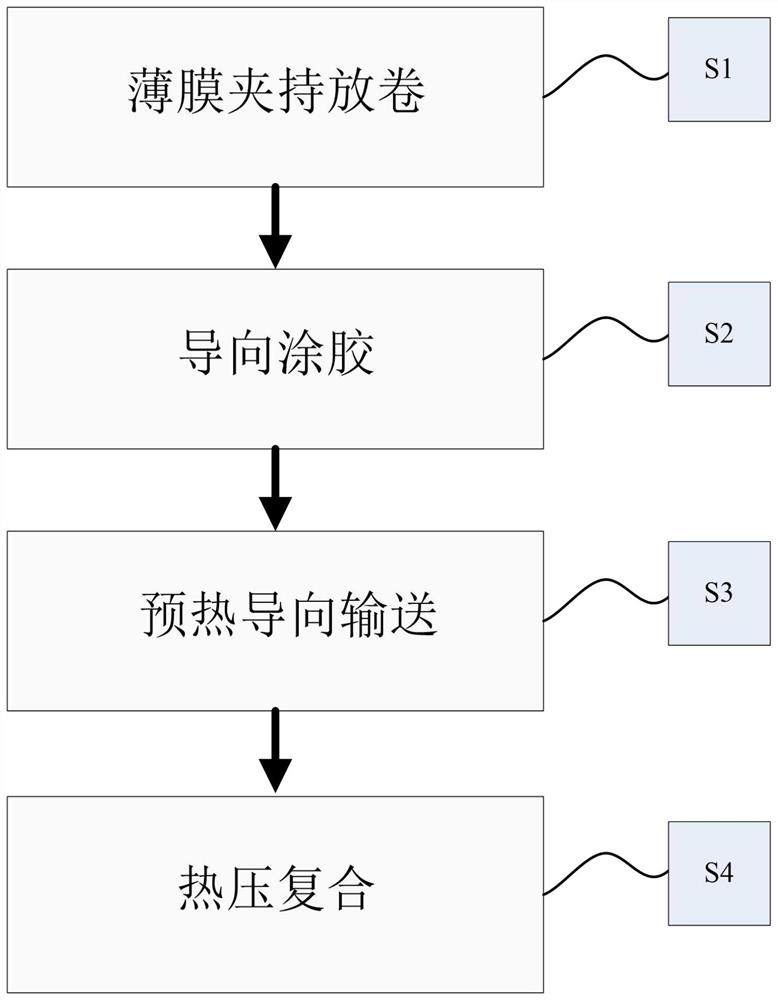

Film coating process for manufacturing packaging container

InactiveCN113500820ATension remains constantPrevent unbalanced transmission forcePaper-makingBox making operationsAdhesiveMechanical engineering

The invention provides a film coating process for manufacturing a packaging container. The film coating process comprises a winding mechanism, a coating mechanism, a guide mechanism, a drying mechanism, a conveying mechanism, a main beam plate frame, a guide roller I and a guide roller II. The film coating process solves the problems that clamping and fixing of an unwinding winding drum and a winding drum have limitation at present, and winding drums with different types and sizes cannot be clamped, so that the manufacturing of the film coating process is relatively single, and production and processing of film coating processes with different sizes cannot be realized; in the winding and unwinding processes, the execution actions cannot be synchronized, the tension in the film coating process is influenced to be constant, the film transmission stress is unbalanced, and the film is wrinkled or torn; no guide motion track exists for the transmission of paper printed matters and films, the deviation condition is easily caused after the films and the paper printed matters are compounded, and the film coating quality is influenced; and the coating of an adhesive on the surfaces of the films cannot be uniformly controlled, the coating flow speed of the adhesive cannot be controlled, and the film coating process is influenced.

Owner:武汉众诚科技有限公司

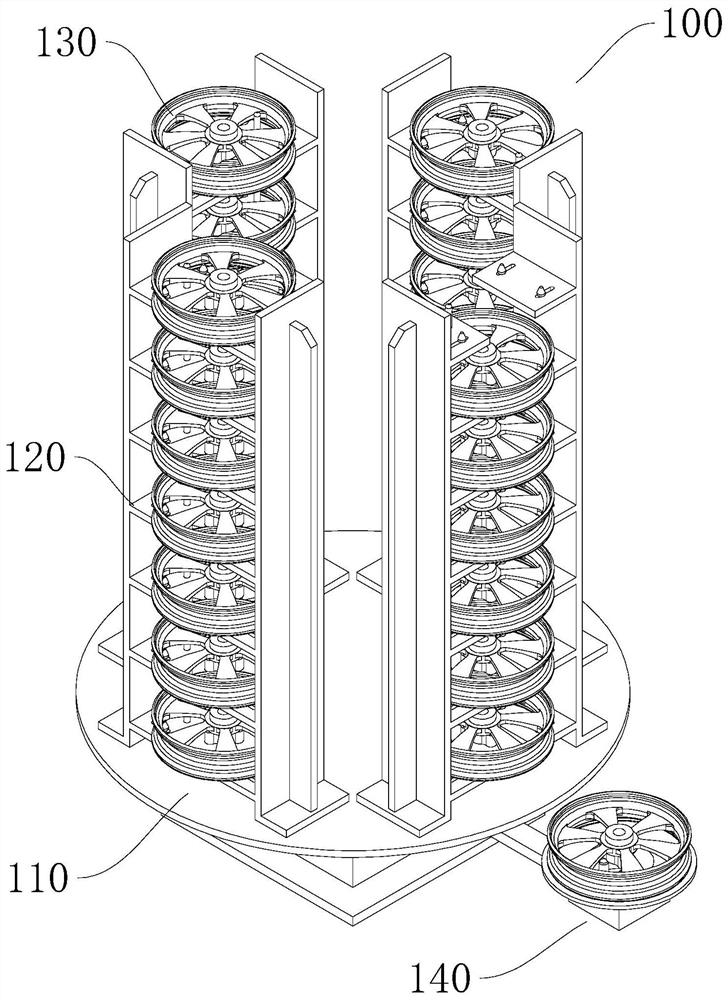

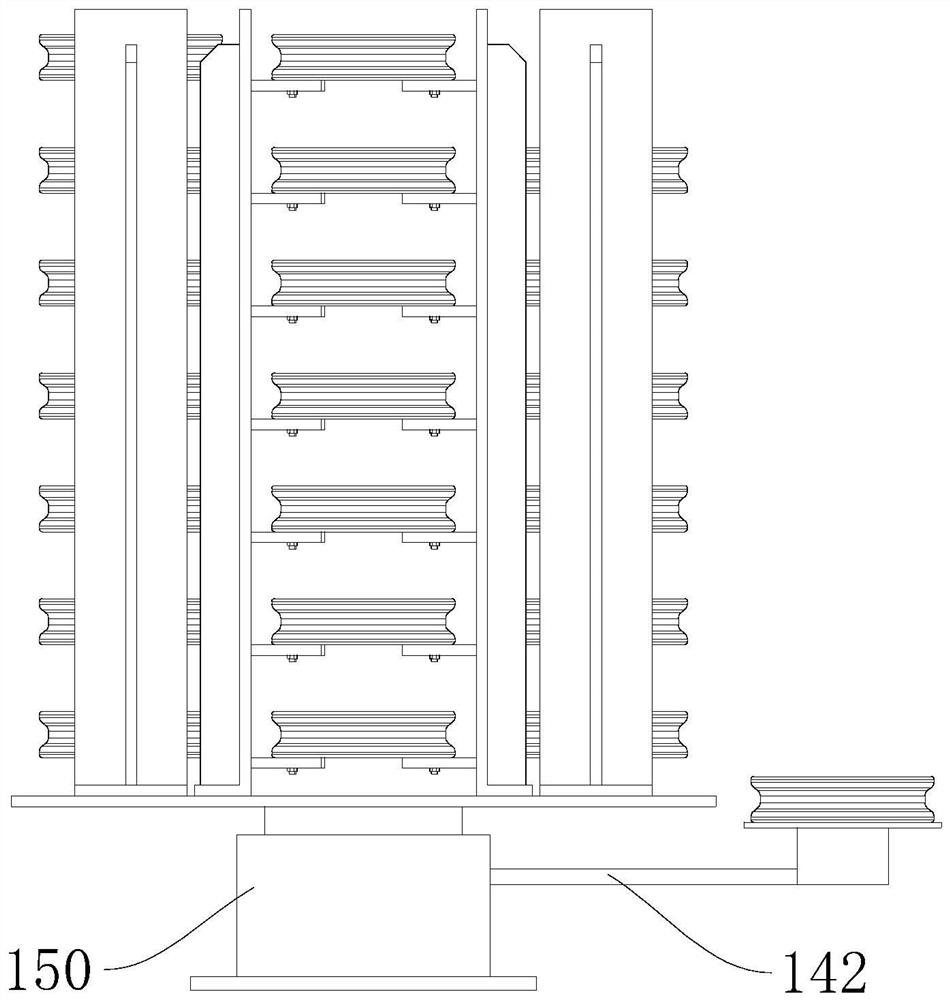

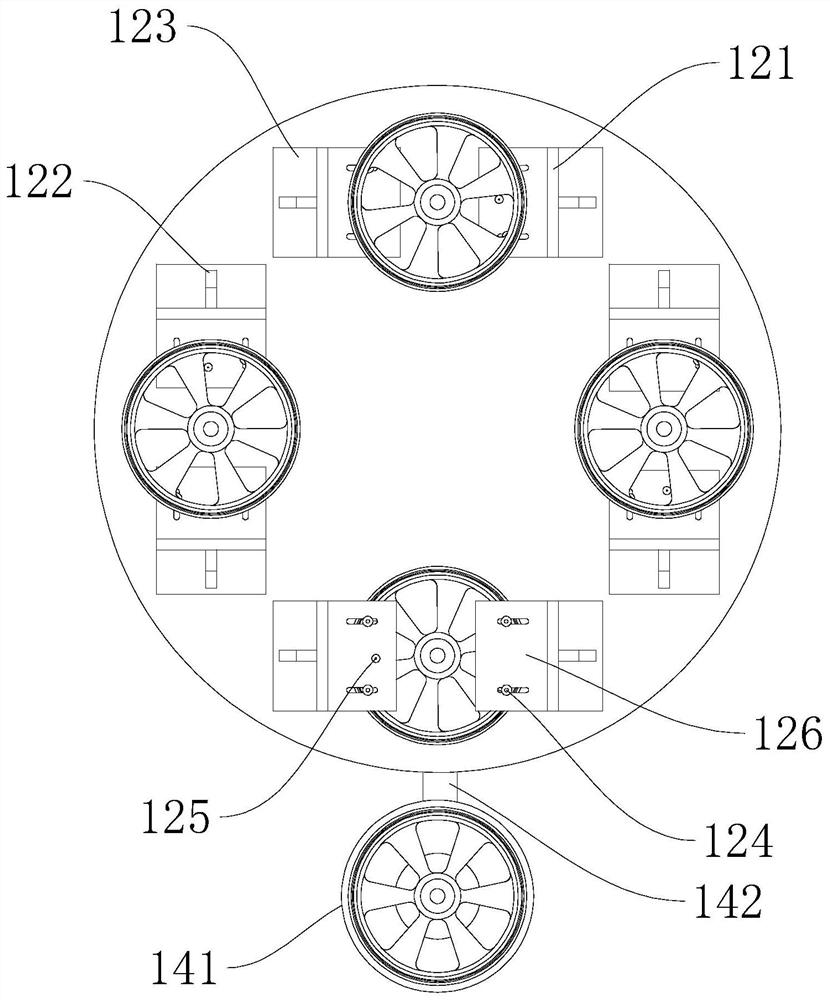

Hub storage device

The invention discloses a hub storage device. The hub storage device comprises a base arranged at the bottom of the storage device, a rotating disc, storage frames and a positioning and detection mechanism; the rotating disc is arranged on the upper portion of the base and is rotationally and slidably connected with the base; the multiple storage frames are arranged on the rotating disc, and positioning mechanisms aiming at hubs are arranged on the storage frames; and the positioning and detection mechanism is installed outside the range covered by the rotating disc, and a supporting table is arranged on the positioning and detection mechanism. Hubs about to be machined are placed in preset positions on the storage frames before a worker starts equipment, a certain number of hubs can be placed on the storage frames in a stacked manner, and meanwhile a high space utilization rate is achieved; and automatic production can be carried out after the worker starts the equipment, manpower is saved, meanwhile, cooperation of a conveying line is not needed, and the production takt time can be flexibly adjusted according to the production process.

Owner:台山市中镁科技有限公司

Display plasma module of dual-layer microstructure and manufacturing method of display plasma module

ActiveCN108957899AImprove the display effectIncrease contrastGas discharge electrodesGas discharge vessels/containersOptoelectronicsElectron

The invention belongs to the technical field of electronic display, and relates to a display plasma module of a dual-layer microstructure. The display plasma module comprises a pixel electrode and a transparent electrode located above the pixel electrode; display plasma and a lining frame surrounding the display plasma are arranged between the pixel electrode and the transparent electrode, plasmastopping and isolating arrays for uniformly dispersing and stabilizing the display plasma are arranged on the pixel electrode and / or the transparent electrode, and spaced particle layers are adsorbedon the plasma stopping and isolating arrays. The display plasma is directly adopted for the display plasma arrays to replace existing microcup structures or microcapsules, the plasma stopping and isolating arrays for uniformly dispersing, stabilizing and isolating the display plasma and the spaced particle layers are arranged in the display plasma, and the effects of supporting the whole display plasma module and controlling the thickness of the display plasma are achieved; meanwhile, disordered flow of the display plasma is effectively prevented, and the perpendicularity of the direction of an electric field between the pixel electrode and the transparent electrode is guaranteed.

Owner:WUXI VISION PEAK TECH

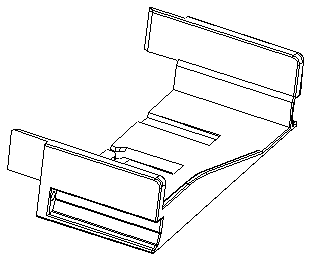

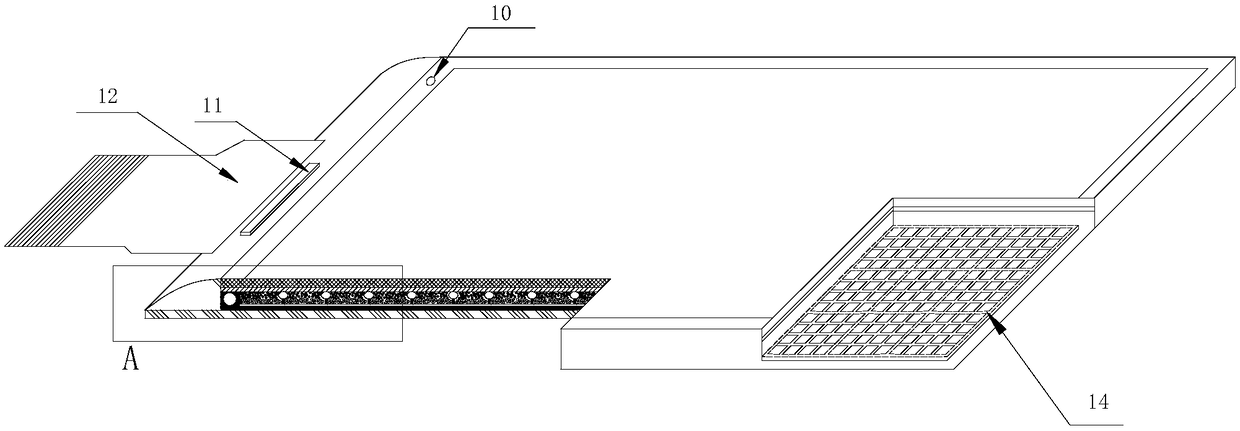

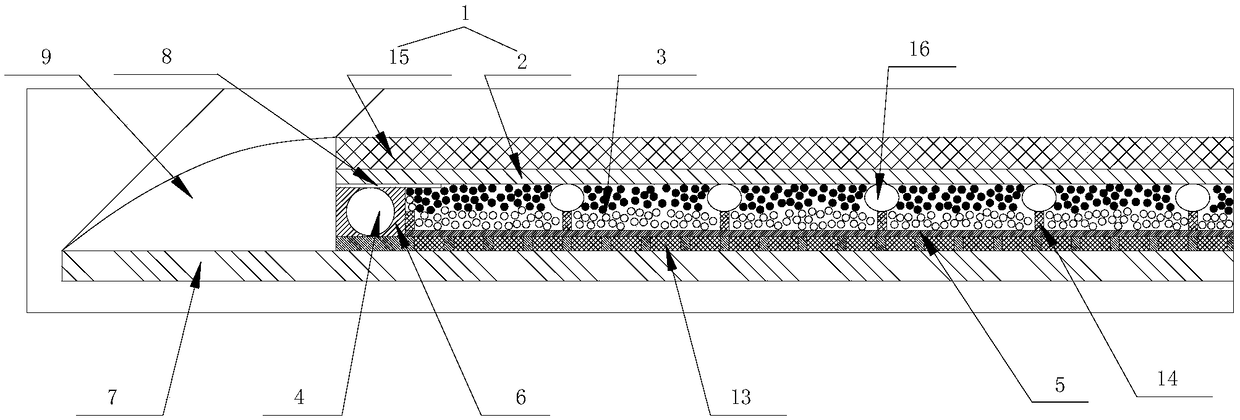

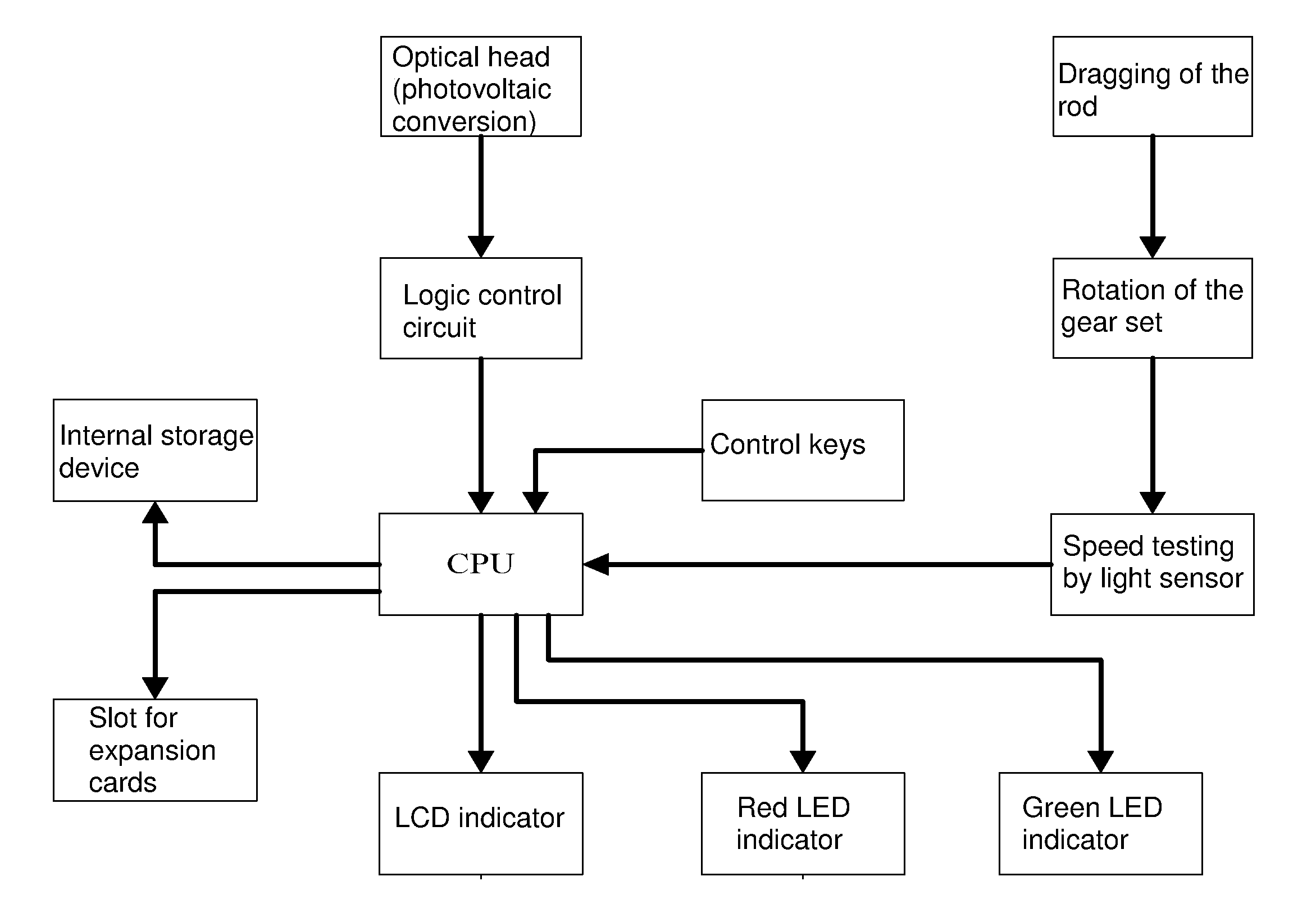

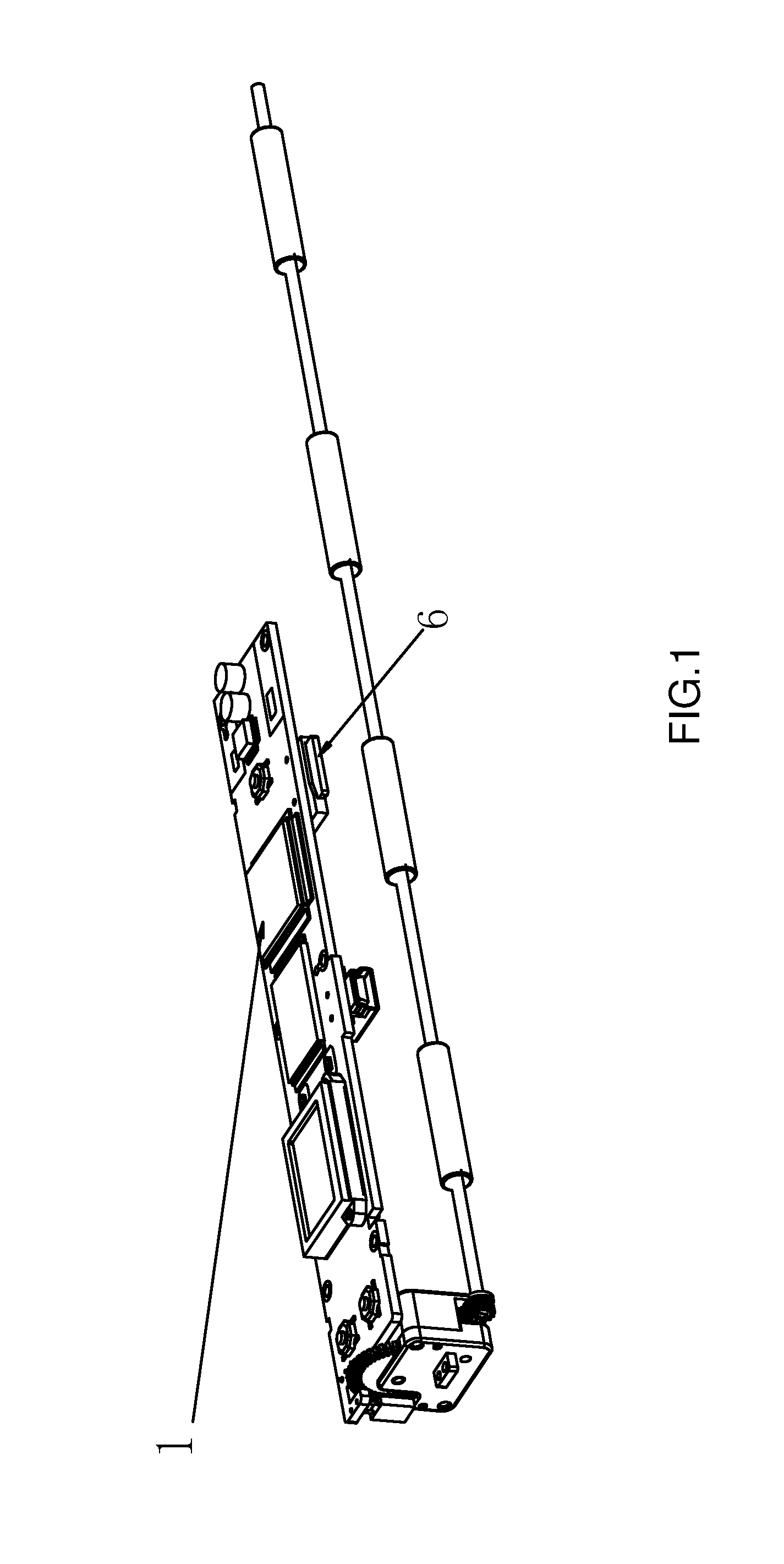

Handheld portable scanner

InactiveUS20120262764A1Increase frictionGuarantee directionPictoral communicationImaging processingDocumentation

The present invention relates to a scanner and more particularly pertains to a handheld portable scanner with integrated technologies which effectively combines lighting, electronics and mechanical technologies and has a small size and convenient portability, which comprises a scanner housing, a battery, scanning components and image processing components. The scanning components are composed of an optical scanning head and a scanning rod. The image processing components are composed of scan-speed testing components which are coupled with the scanning rod, a processing chip for processing of data scanned by the optical scanning head and image processing, and a scanner circuit. The present invention provides a handheld portable scanner which has a convenient portability and extensive functions. More importantly, with the coordination of the speed testing components and the processing chip, the present invention can correct scanning errors caused by uneven speed of manual scanning by means of computation of the chip, thereby ensuring that the scanning output is the same as the original document. To ensure the quality of the scanned document, reminder function is also available in case the dragging speed of the scanner is too fast.

Owner:SKY LIGHT ELECTRONICS SHENZHEN

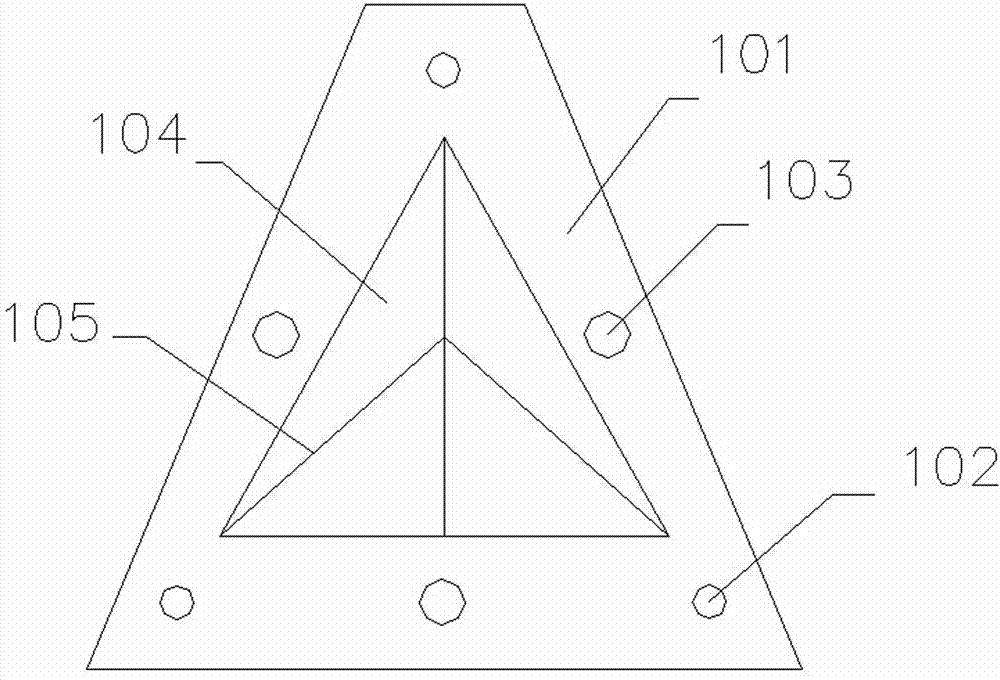

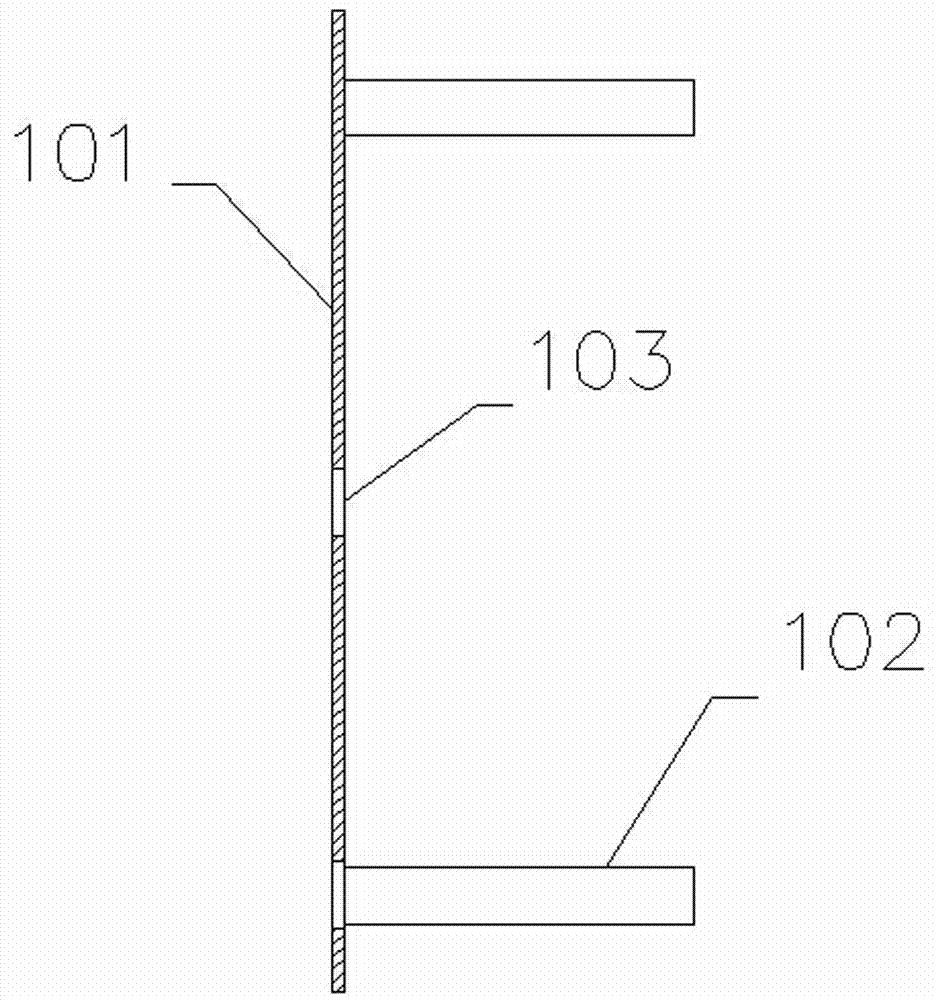

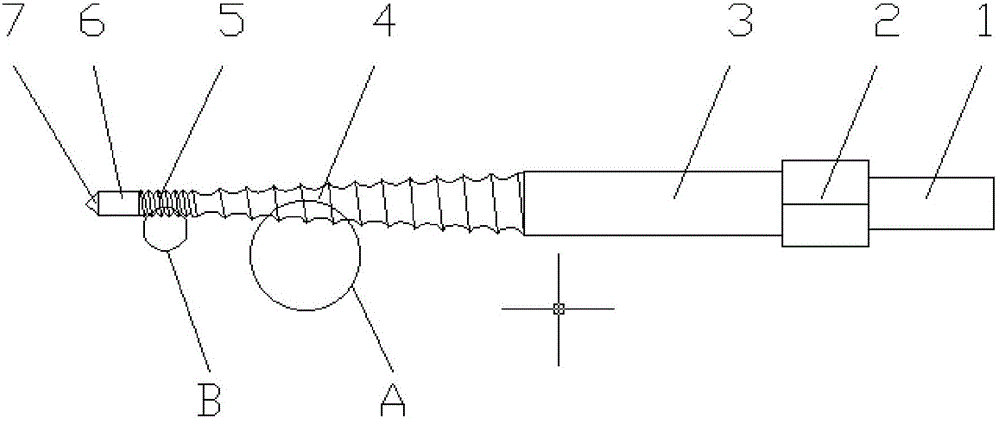

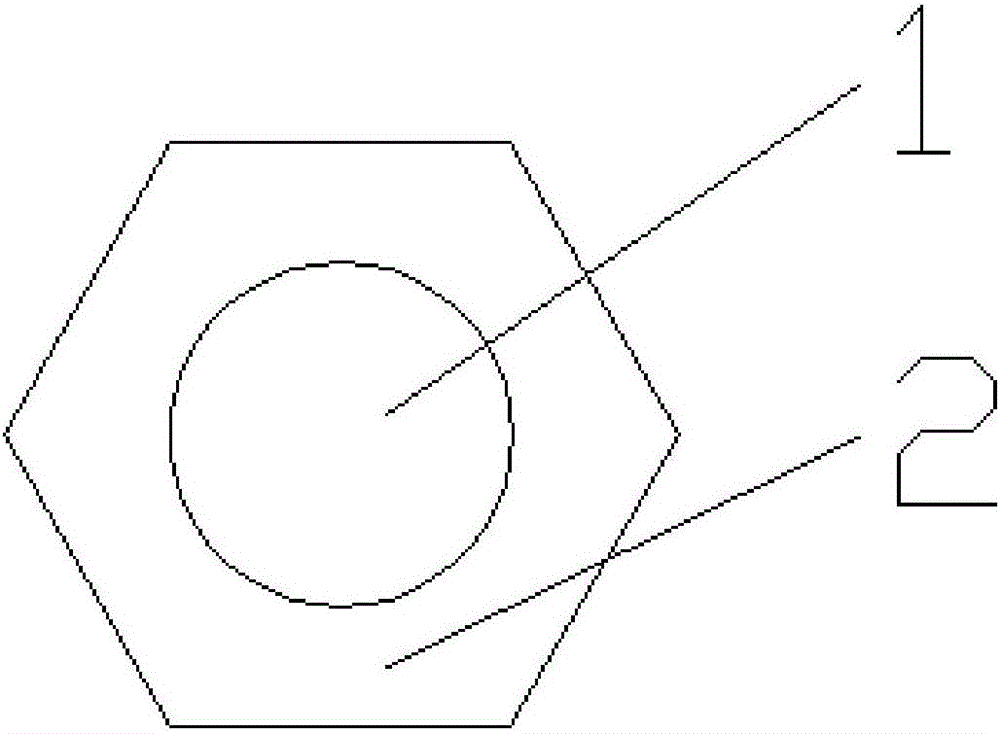

Pinhole bone extruding and expanding device

The invention discloses a pinhole bone extruding and expanding device, belonging to medical apparatus and instruments. The pinhole bone extruding and expanding device comprises a stabilizing part (1), a screwing part (2), a self-tapping thread part (4), a second thread part (5), a guide pillar (6) and a sharp head part (7), wherein the stabilizing part (1) is cylinder-shaped, the screwing part (2) is a non-round-section cylinder, the small end of the self-tapping thread part (4) is connected with the second thread part (5), the second thread part (5) is a cylinder, and is provided with external threads, the guide pillar (6) is cylinder-shaped, and the sharp head part (7) is tri-prism-shaped. With the adoption of the pinhole bone extruding and expanding device, the placement operation of an implant can be realized with the minimal trauma or no trauma.

Owner:吴大怡

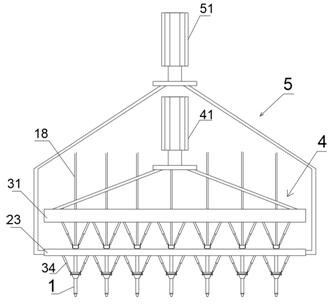

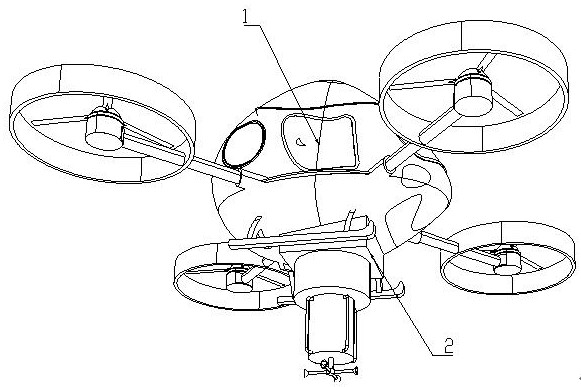

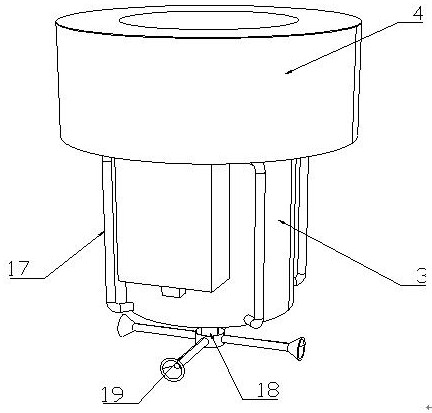

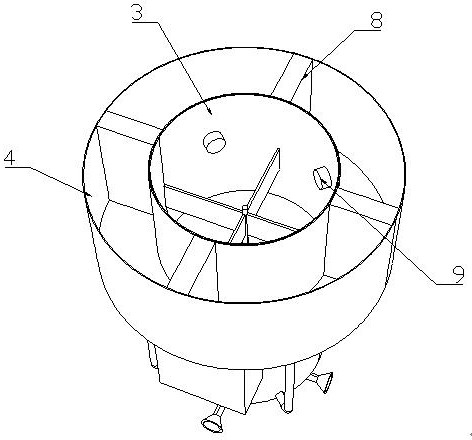

Multi-directional pressurizing sprinkling irrigation device of plant protection unmanned aerial vehicle

PendingCN113693046ARealize on-site dosingAccurate concentrationAircraft componentsLiquid spraying apparatusUncrewed vehicleEnvironmental engineering

The invention relates to a multi-directional pressurizing sprinkling irrigation device of a plant protection unmanned aerial vehicle and relates to the field of sprinkling irrigation devices. The device comprises a liquid outlet cylinder, a liquid storage cylinder, a driving assembly, a pressure adjusting assembly, a liquid mixing assembly, a piston plate, a water inlet pipe, a water outlet pipe, a sprinkling irrigation head and a controller. The pressure adjusting assembly and the liquid mixing assembly are respectively arranged in a pressure adjusting chamber and a liquid mixing chamber. The piston plate is matched with the pressure adjusting assembly. The water inlet pipe is communicated with the liquid mixing chamber and the pressure adjusting chamber. The water outlet pipe communicates with the pressure adjusting chamber and the sprinkling irrigation head. The liquid storage cylinder is sleeved on the periphery of the liquid outlet cylinder. According to the device, multiple independent liquid storage chambers are arranged, through the effect of a liquid level sensor and in cooperation with manual judgment, on-site liquid preparation is achieved, the concentration is accurate, and the irrigation effect is guaranteed; the driving assembly is arranged, synchronous work of the pressure adjusting assembly and the liquid mixing assembly is achieved, on one hand, the pressure in the pressure adjusting chamber is adjusted, liquid inlet-liquid outlet circulation is achieved, meanwhile, the liquid outlet pressure and direction are guaranteed, and the purpose of efficient and low-energy-consumption irrigation is achieved.

Owner:浙江极目机器人科技有限公司

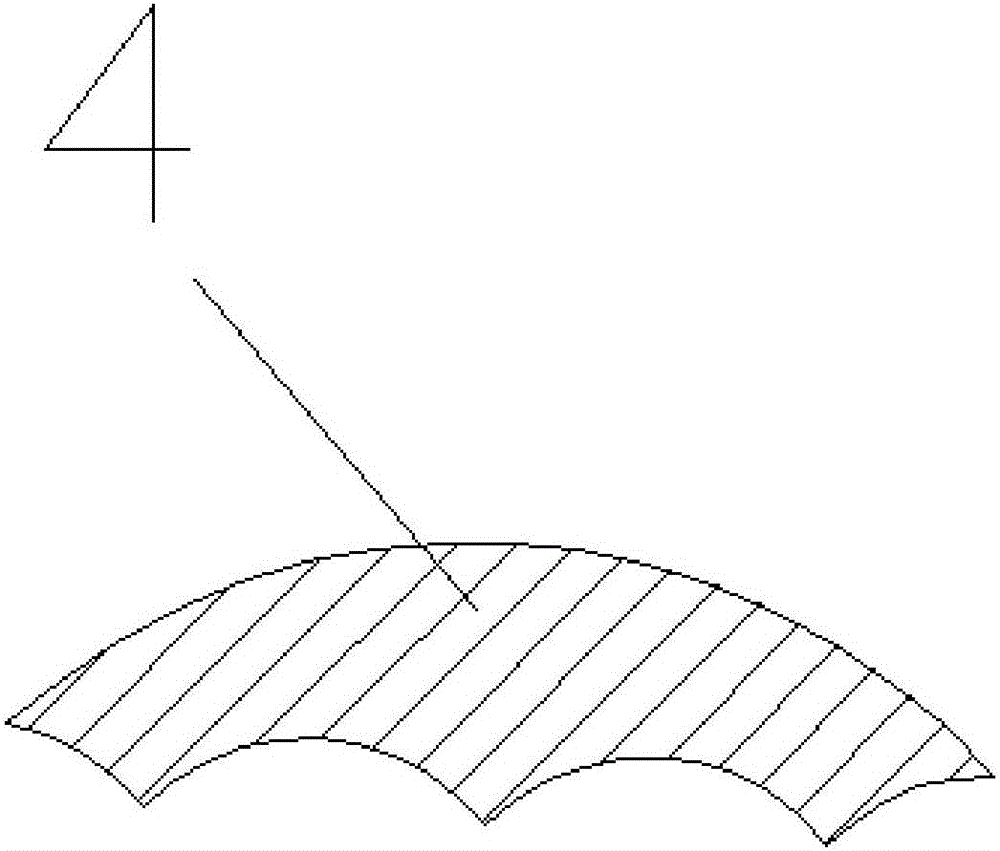

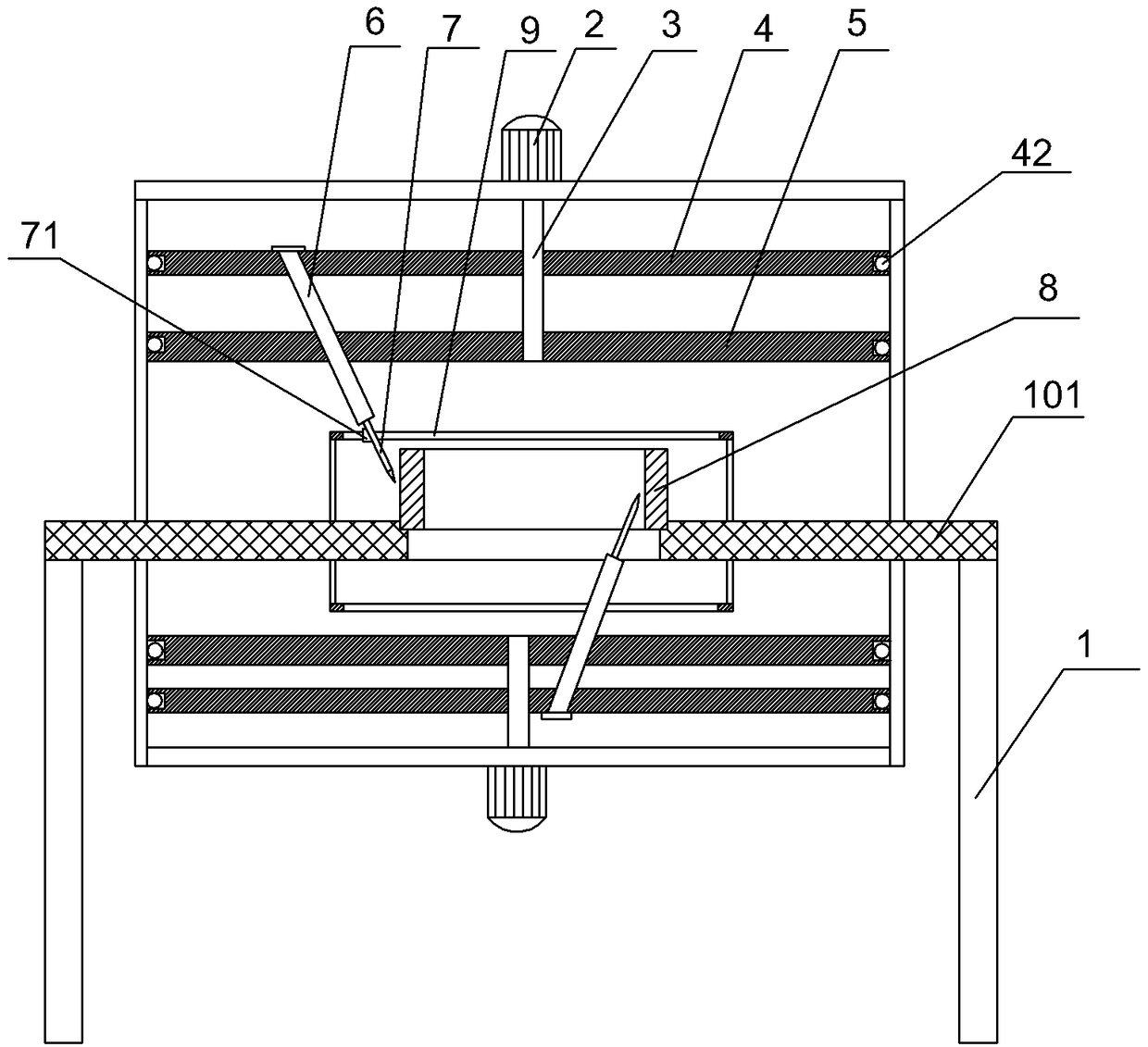

Bearing Ring Slant Oil Hole Processing Tooling

ActiveCN107511506BGuarantee directionReduce processing difficultyBearing componentsBoring/drilling machinesEngineeringMachine tool

The invention belongs to the technical field of bearing machining, and discloses a bearing ring inclined oil hole machining tool. The bearing ring inclined oil hole machining tool comprises a rack, a step hole is formed in a table top of the rack, the table top of the rack is an electromagnetic chuck, and a rotating mechanism and a drilling mechanism are arranged above and below the table top of the rack; the rotating mechanism comprises a first rotary disc and a second rotary disc which are rotationally connected to the rack, rotating centers of the first rotary disc and the second rotary disc are coincident with a center shaft of the step hole, a first through hole is formed in the first rotary disc, a second through hole is formed in the second rotary disc, and the turning radius of the first through hole is larger than the turning radius of the second through hole; the drilling mechanism comprises a rotating rod and electric drills, the two electric drills are staggered in the circumferential direction of a bearing ring, and the sum of the drilling depths of the two electric drills is equal to the depth of a bearing ring inclined oil hole; and the rack is further provided with a rotating parking mechanism which comprises a plurality of microswitches and trigger blocks. When the bearing ring inclined oil hole machining tool is used for machining the bearing ring inclined oil hole, positioning is accurate, and the machining difficulty is small.

Owner:重庆市合川区云天机械制造有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com