Vehicle hydraulic drill

A hydraulic drilling rig and drilling rig technology, applied in the field of hydraulic drilling rigs, can solve the problems of time-consuming and laborious, difficult adjustment of the drilling direction of the hydraulic drilling rig, etc., and achieve the effect of increasing the feed stroke

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

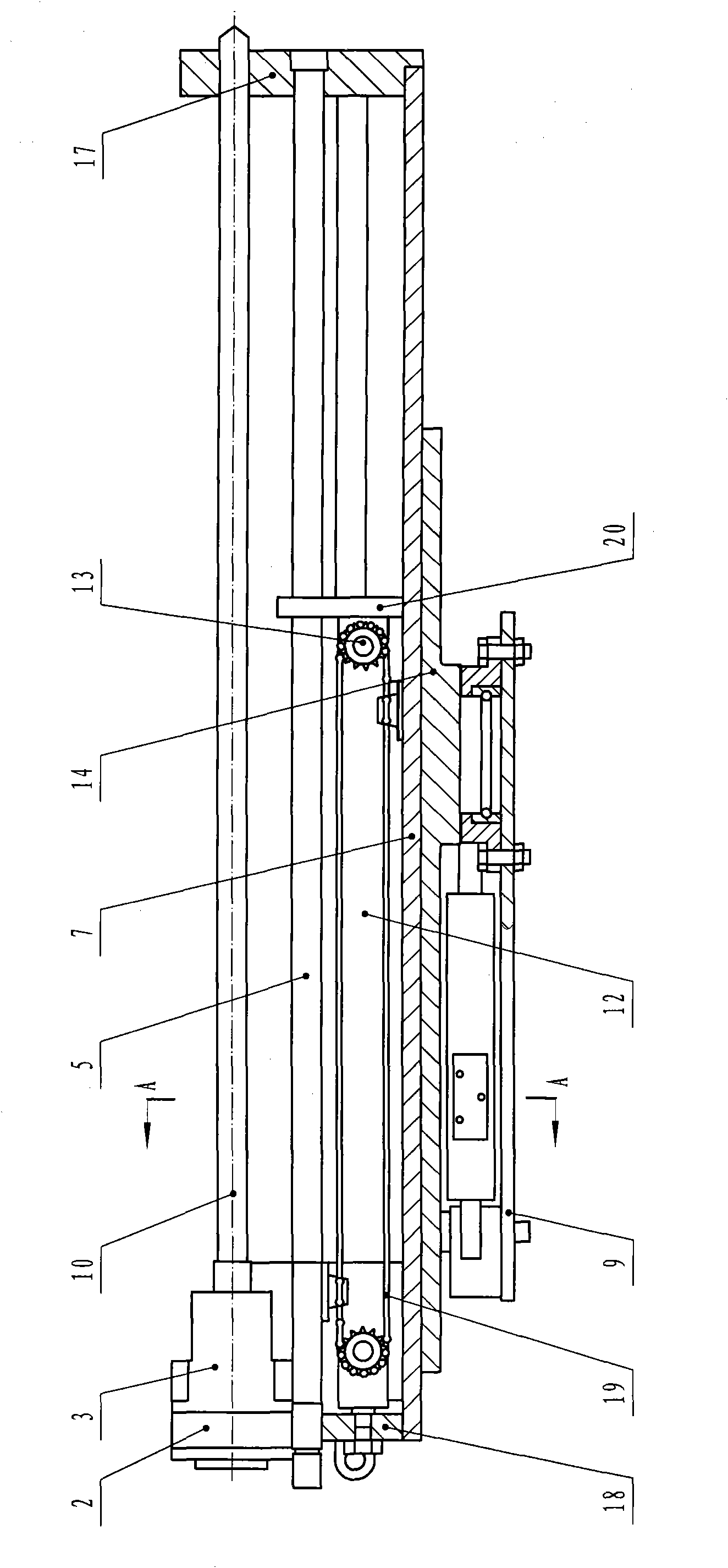

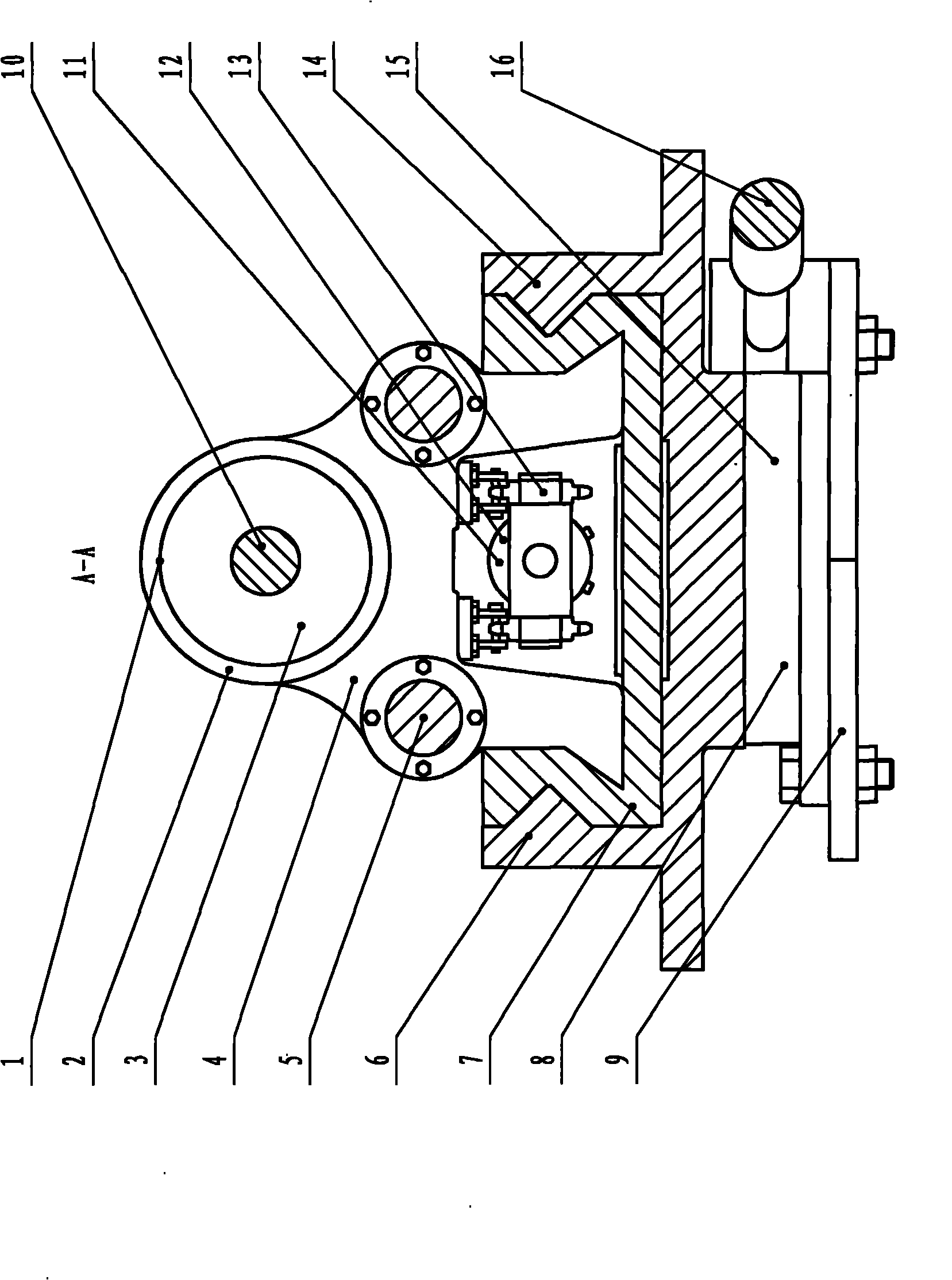

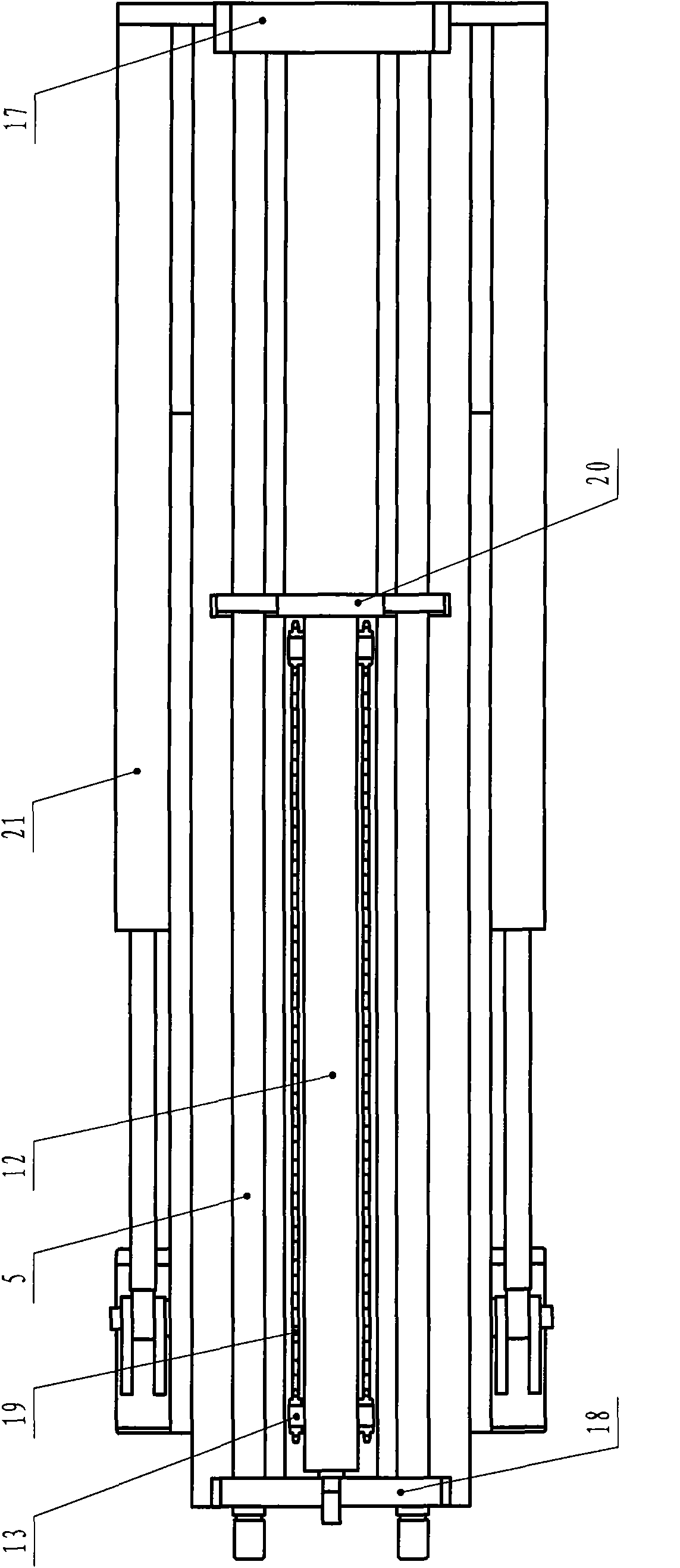

[0024] Such as figure 1 , figure 2 , image 3 , Figure 4 As shown, the airborne hydraulic drilling rig includes a rotary mechanism 8, a feed mechanism 11, a propulsion cylinder 21, a frame 6, a drilling machine component 1 and a base 9, the rotary mechanism 8 is arranged on the base 9, and the frame 6 is arranged on the rotary mechanism 8, the propulsion cylinders 21 are symmetrically arranged on both sides of the frame 6, the feed mechanism 11 is arranged in the frame 6, and the drilling rig components 1 are arranged on the frame 6;

[0025] Base 9 is fixed on the side of the boring machine cutting arm, the rear portion of the cutting head.

[0026] Frame 6 comprises slideway 14, dovetail-shaped carriage 7, slide bar 5, guide frame 17 and baffle plate 18, and slideway 14 is fixed on the rotating disk 15, and dovetail-shaped carriage 7 is arranged in the slideway 14, and dovetail-shaped slideway One end of the frame 7 is fixed with a guide frame 17, the other end is fixe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com