Bearing Ring Slant Oil Hole Processing Tooling

A technology of bearing rings and inclined oil holes, applied in the field of bearing processing, can solve problems such as difficult processing and difficult control, and achieve the effects of less processing difficulty, easy control, and reduced drilling depth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

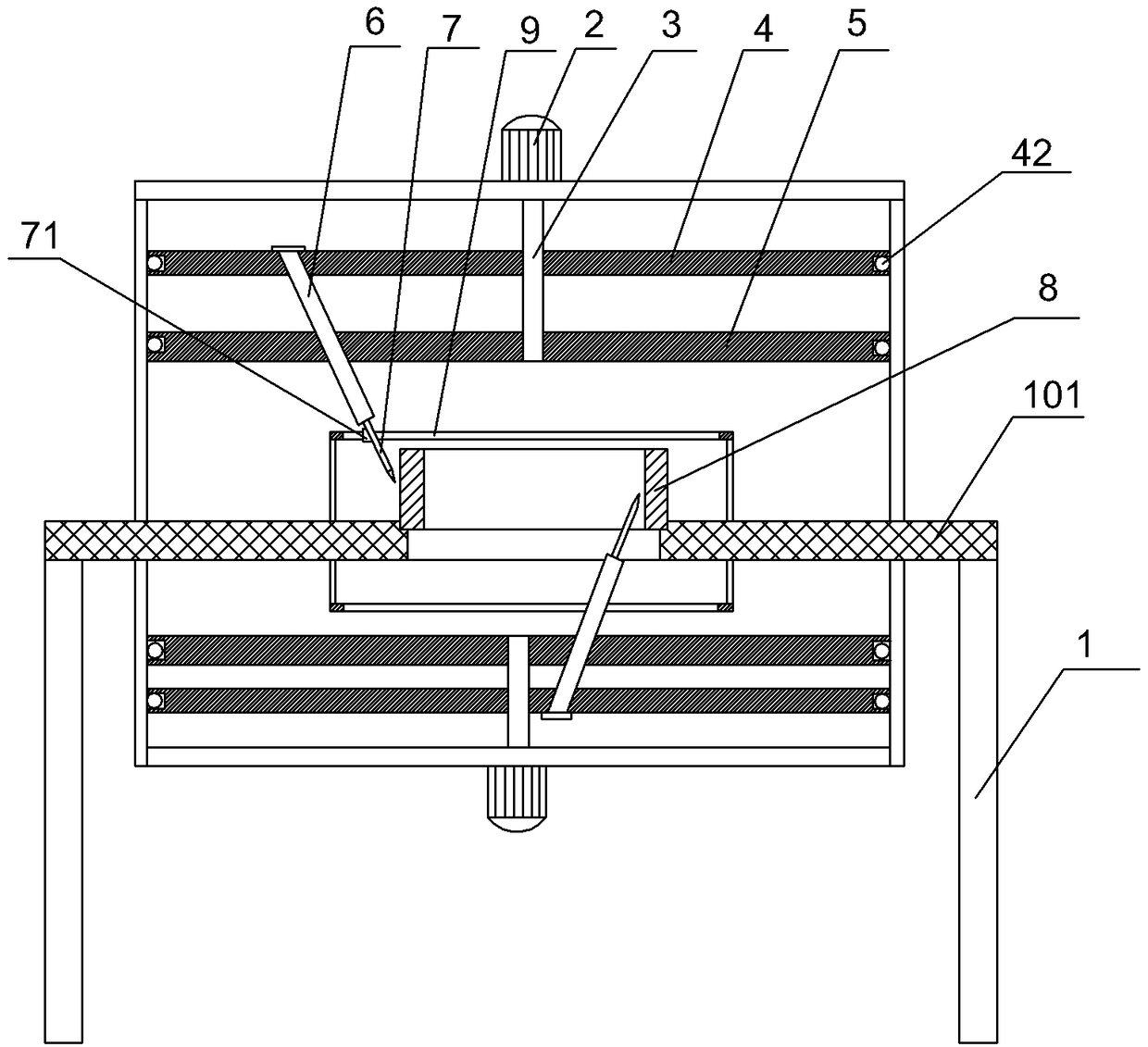

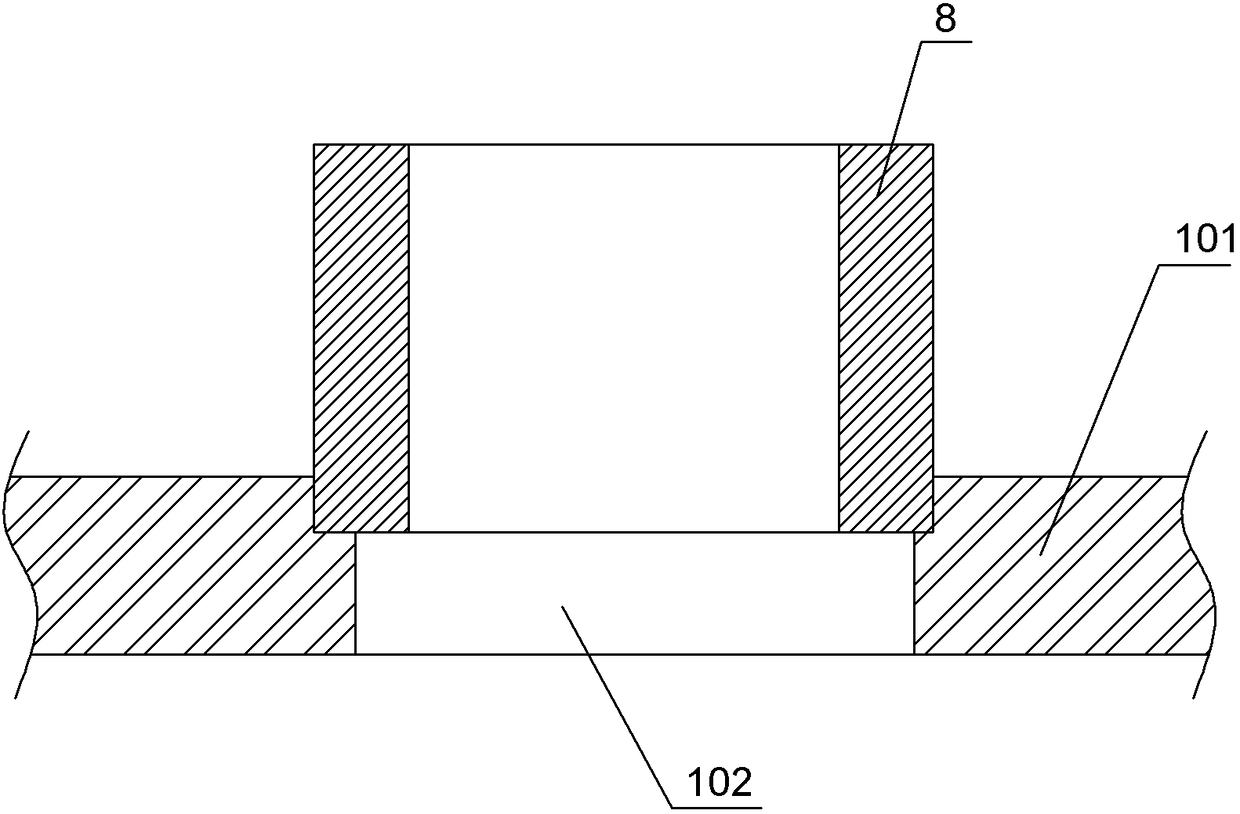

[0029] Embodiment 1 The bearing ring oblique oil hole processing device of the embodiment, such as figure 1 with figure 2 As shown, a frame 1 is included, and the table 101 of the frame 1 is an electromagnetic chuck. The table 101 is provided with a bearing ring fixing mechanism, and the bearing ring fixing mechanism includes a stepped hole 102 opened on the table 101 .

[0030] A rotating mechanism and a drilling mechanism are arranged above and below the table top 101 of the frame 1 .

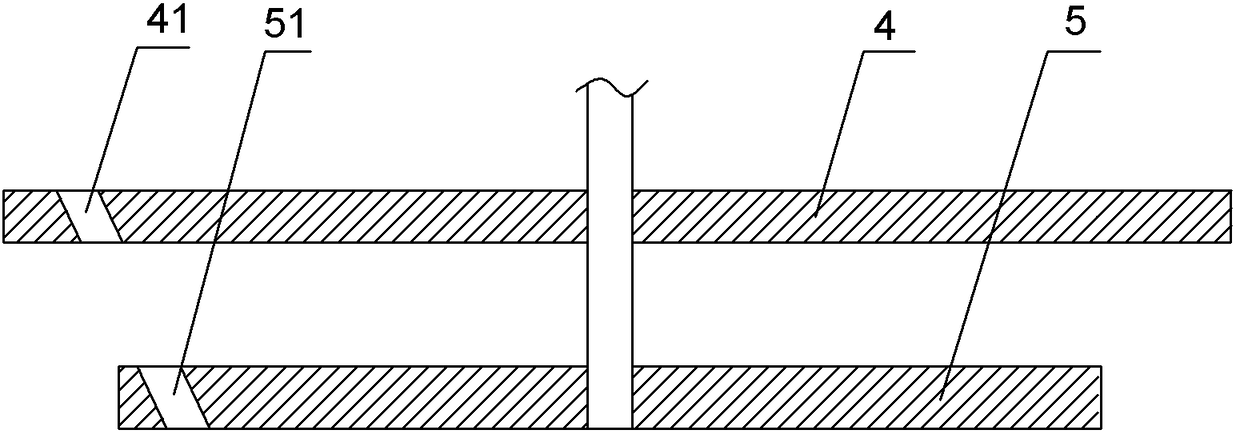

[0031] The rotating mechanism above includes a rotating shaft 3, a first turntable 4 and a second turntable 5. The rotating shaft 3 is connected to the frame 1 and is in a vertical state. A servo motor 2 is installed on the frame 1 above the rotating shaft 3. The servo motor 2 Used to drive the rotating shaft 3 to rotate, the centers of the first rotating disk 4 and the second rotating disk 5 are welded on the rotating shaft 3, the first rotating disk 4 and the second rotating disk 5 are in...

Embodiment 2

[0039] The difference between this embodiment and Embodiment 1 is:

[0040] The drilling depths of the two electric drills 7 are different. The drilling depth of the electric drill 7 above the table 101 of the frame 1 is 2 / 3 of the depth of the oblique oil hole of the bearing ring 8, and the electric drill 7 below the table 101 of the frame 1 The drilling depth is 1 / 3 of the oblique oil hole depth of the bearing ring 8, and the rotating shaft 3 turns a circle to complete the drilling of all oblique oil holes. When the electric drill 7 drilling is positioned at the top, the bearing ring 8 is not easy to shift, so the electric drill 7 drilling depth of the selection top is larger than the electric drill 7 drilling depth of the bottom.

Embodiment 3

[0042] The difference between this embodiment and Embodiment 1 is:

[0043] The drilling depths of the two electric drills 7 are different, and the times of drilling are different. The first drilling depth of the upper and lower electric drills 7 is 1 / 4 of the depth of the inclined oil hole, and the second drilling depth is the inclined oil hole. 1 / 2 of the depth. The rotating shaft 3 turns twice to complete the processing of all oblique oil holes. In this embodiment, compared with the first embodiment, the drilling depth of the same electric drill 7 is reduced, and the drill bit of the electric drill 7 is less likely to deviate or be broken.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com