Display plasma module of dual-layer microstructure and manufacturing method of display plasma module

A microstructure and plasma technology, which is used in the manufacture of electrode systems, the manufacture of discharge tubes/lamps, and the manufacture of cold cathodes, to achieve the effects of improving contrast and display effect, good display effect and reducing manufacturing cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be further described below in conjunction with specific drawings and embodiments.

[0041] The present invention is not limited to the following embodiments, and the figures referred to in the following description are provided for understanding the content of the present invention, that is, the present invention is not limited to the structure of the electronic ink display screen exemplified in each figure.

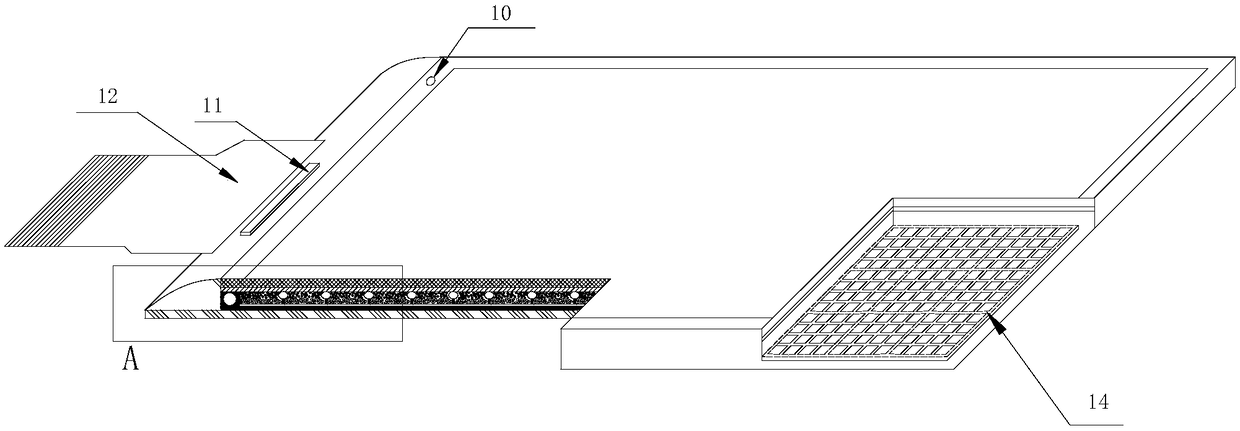

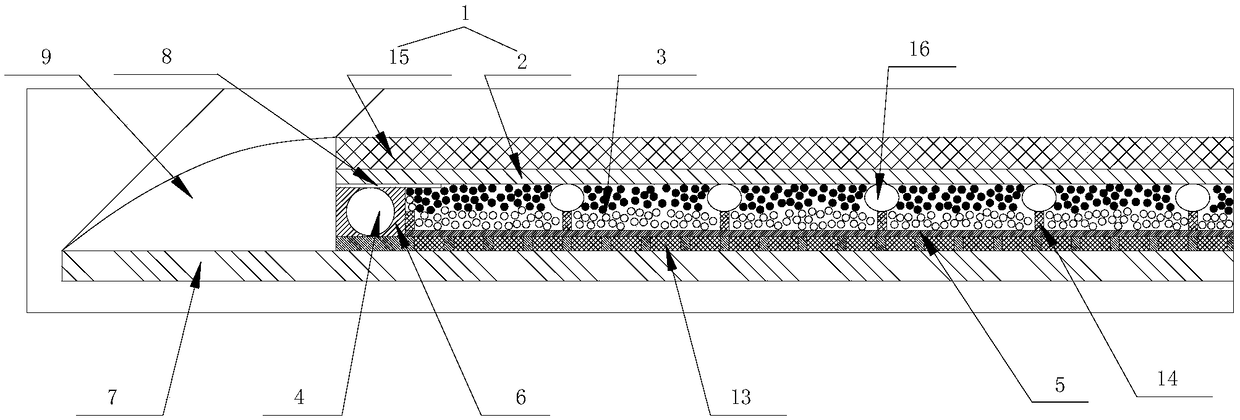

[0042] as attached figure 1 with figure 2 As shown, Embodiment 1 takes a dual-particle electronic ink display screen as an example, a display plasma module with a double-layer microstructure, including a pixel electrode 13 and a transparent electrode 1 located above the pixel electrode 13, the pixel electrode 13 and A display plasma 3 and a liner frame 6 surrounding the display plasma 3 are arranged between the transparent electrodes 1, and a plasma barrier array 14 for uniformly dispersing and stabilizing the display plasma 3 is arran...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com