Patents

Literature

30results about How to "Reduce drilling depth" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

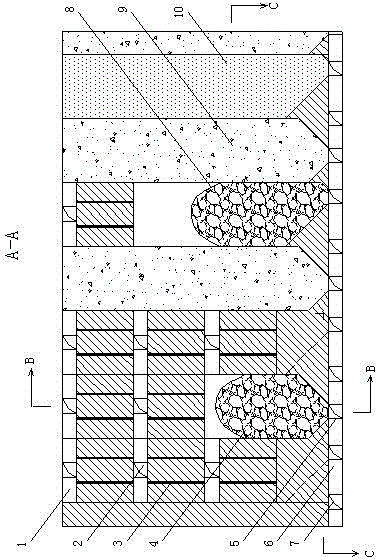

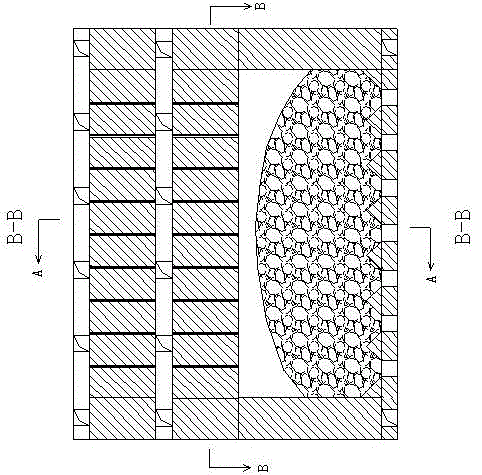

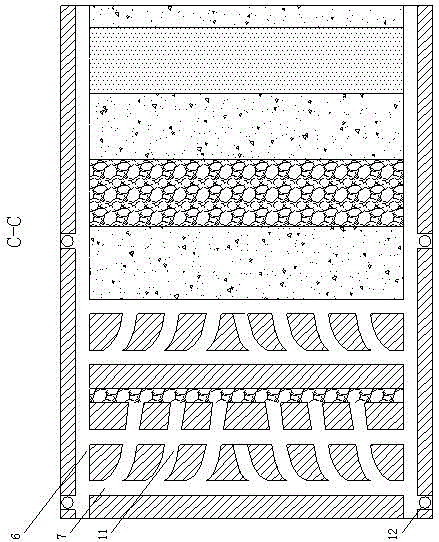

Segmented mining method

The invention discloses a segmented mining method which comprises the following steps: (1) segmenting an ore body into a panel and middle segments, dividing the panel into ore blocks, dividing the ore blocks into rooms and space pillars, dividing the ore body into middle segments along a height direction of the ore body and dividing each middle segment into sections, wherein the height of the middle segments is 50 to 60 m, the height of the sections is 14 to 20 m, the length and the width of the ore blocks are 80 to 100 m and 30 to 60 m respectively, the length and the width of the rooms in the ore blocks are 60 to 80 m and 15 to 30 m respectively, and the width of the ore pillar is 15 to 30 m; (2) stoping the units of the rooms: a step of stoping by using a segmented open-stope method and ore drawing by using a manner of bundle-hole combined funnel blasting; (3) cementing and filling mined rooms; (4) stoping the units of the space pillars, wherein stoping of a unit of the space pillars is carried out after stoping, cementing and filling of adjacent units of the rooms at two sides of the unit of the space pillars is finished; and (5) filling mined space pillars with water and sediment. The mining method can be used for large scale high efficiency mining of plateau ores.

Owner:BEIJING GENERAL RES INST OF MINING & METALLURGY

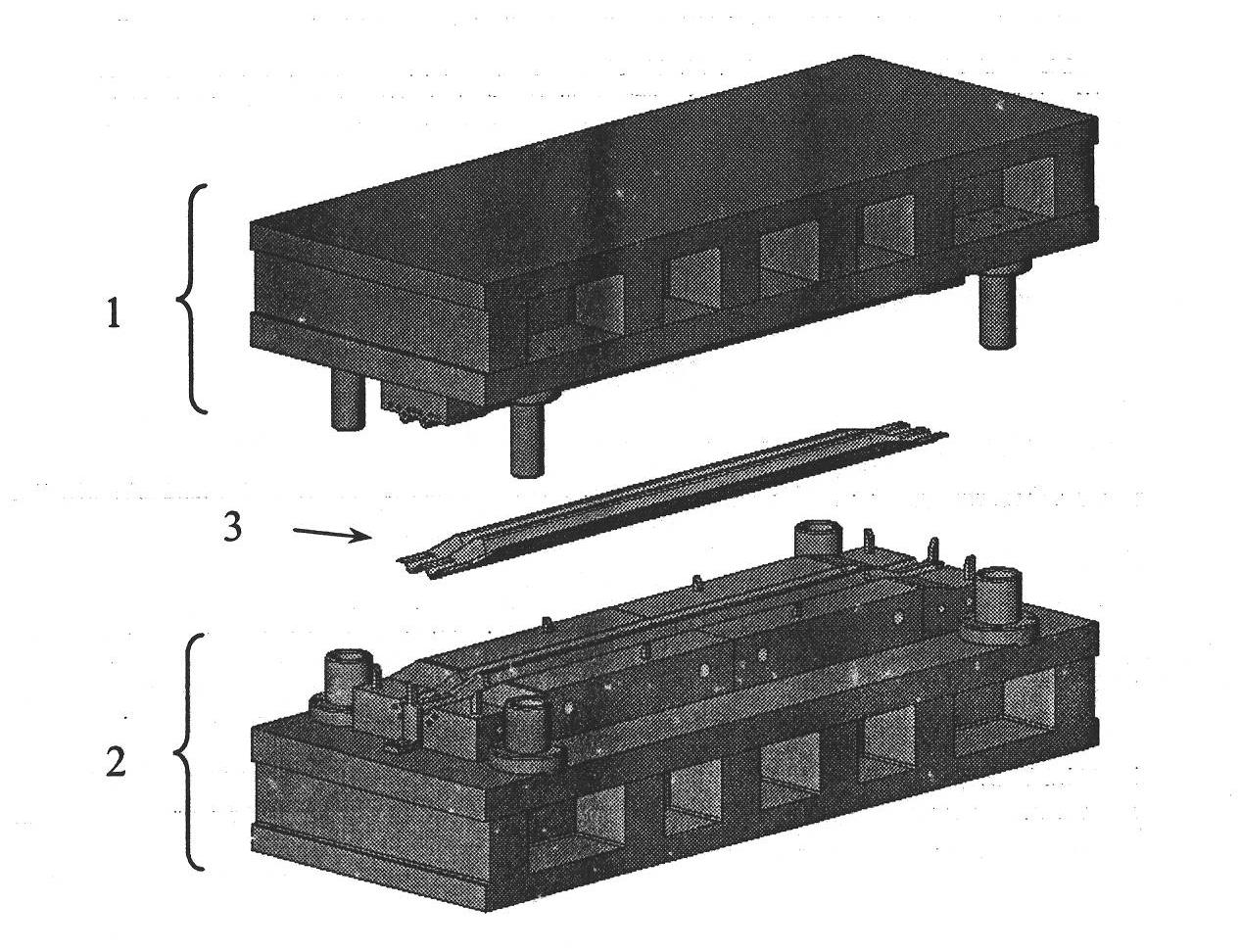

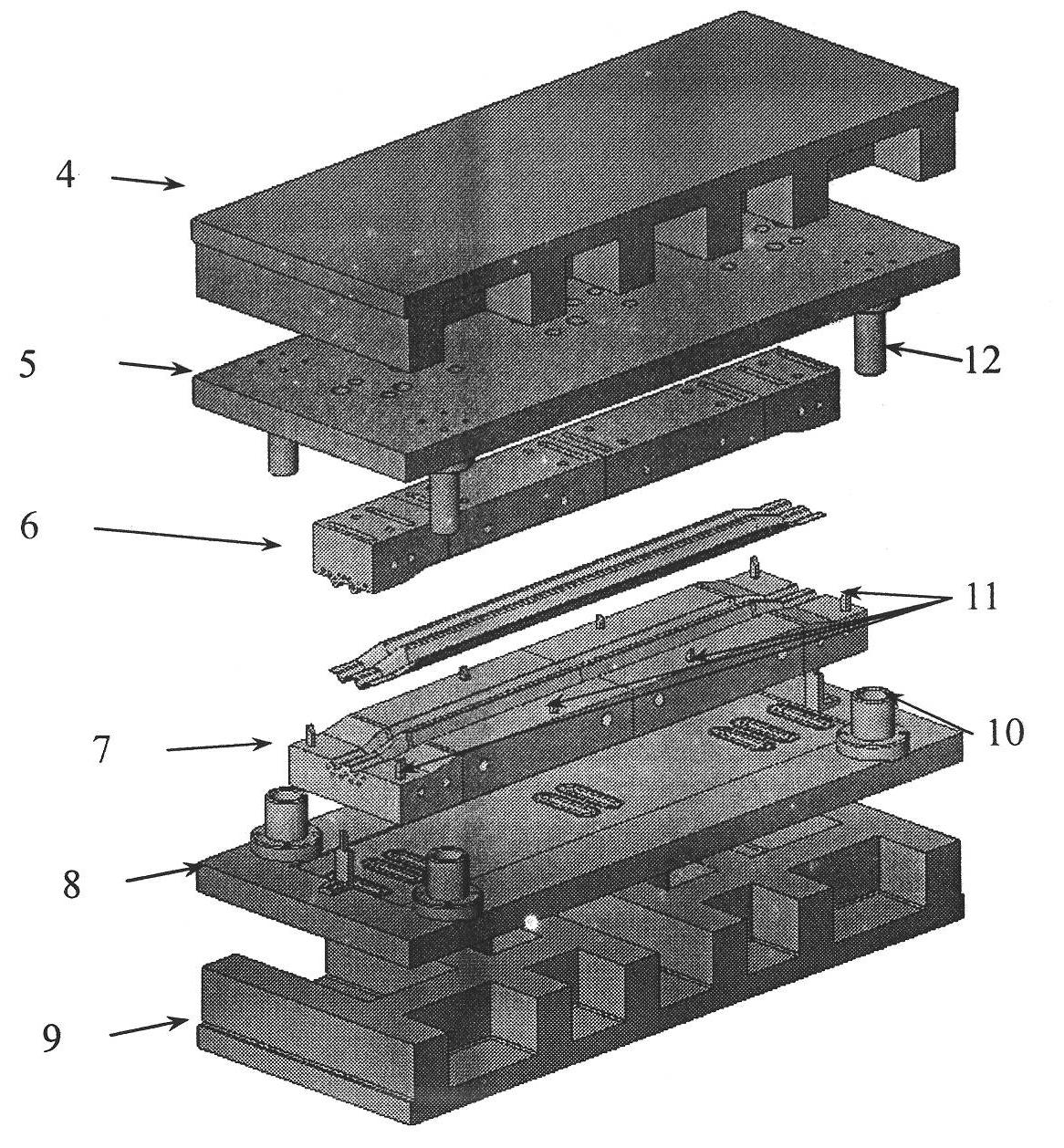

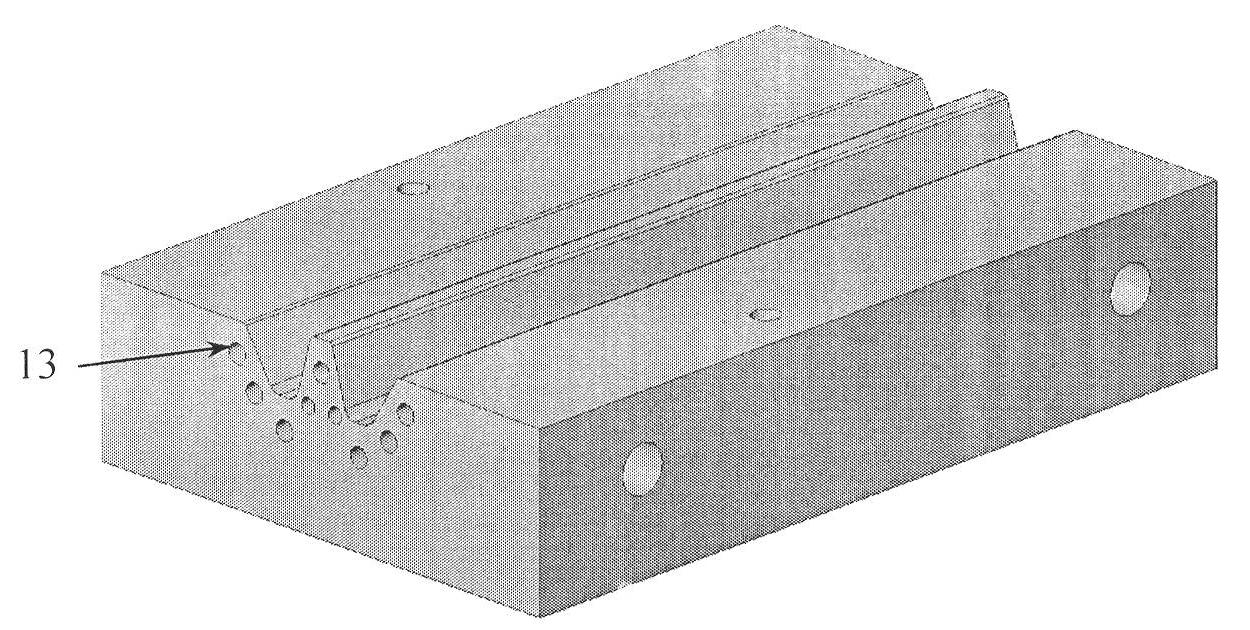

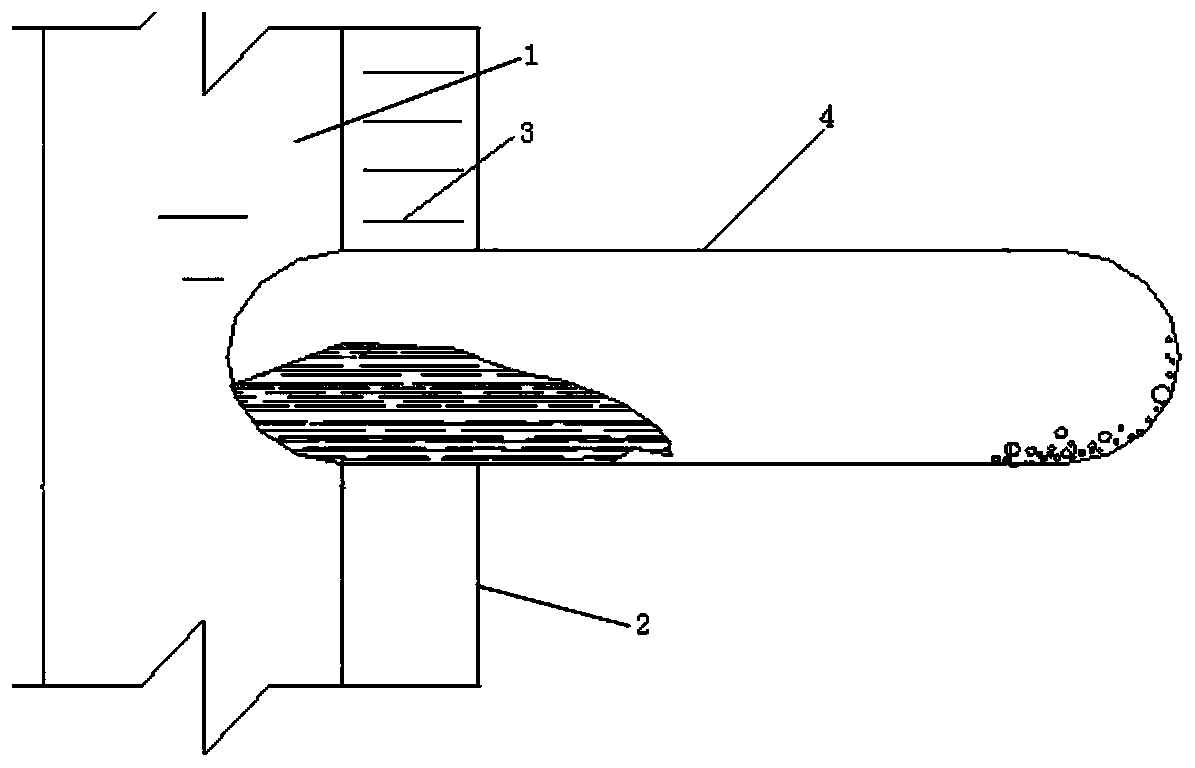

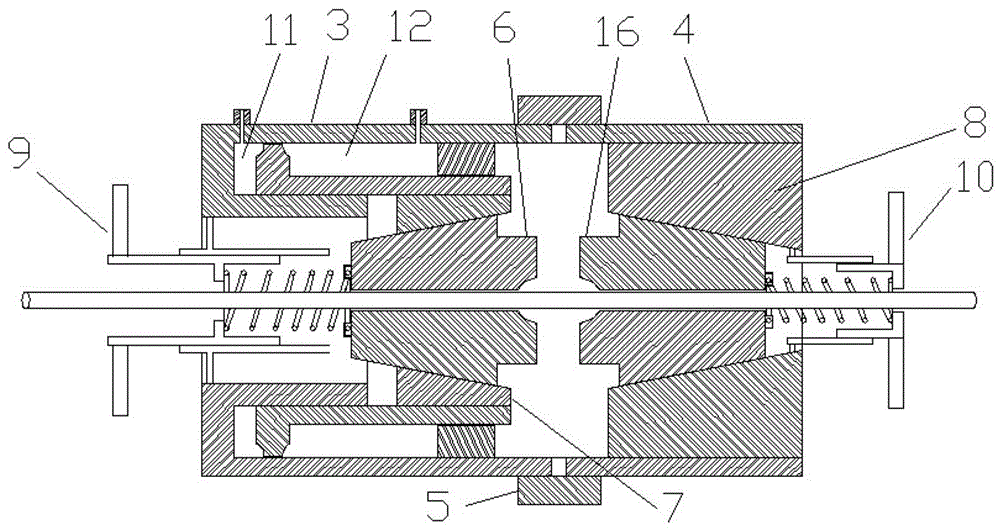

Ultra-high strength steel hot-stamping die for car door anticollision beam

InactiveCN101972814AHigh strengthReduce weightShaping toolsLoad-supporting pillarsHot stampingEngineering

The invention provides a hot-stamping die for an anticollision beam, comprising an upper die and a lower die, wherein the upper and lower dies mainly comprise combined convex / concave dies, cooling systems and a cooling seal ring. The blocks of the combined convex / concave dies avoid the corners and are staggered relatively. The cooling systems adopt drill holes, wherein the diameter of the holes is 8-30mm and the peaks of the holes are 3-10mm distant from the profiles; the two ends of the holes are sealed after hole drilling; runway type water troughs are processed near the places where the block dies are 10-50mm distant from the two end faces; the cooling water enters from one water trough and flows out of the other water trough; and seal grooves are arranged on the cooling water troughs and the cooling water troughs are provided with the seal ring and are externally connected with cooling water pipes.

Owner:ADVANCED MFG TECH CENT CHINA ACAD OF MASCH SCI & TECH

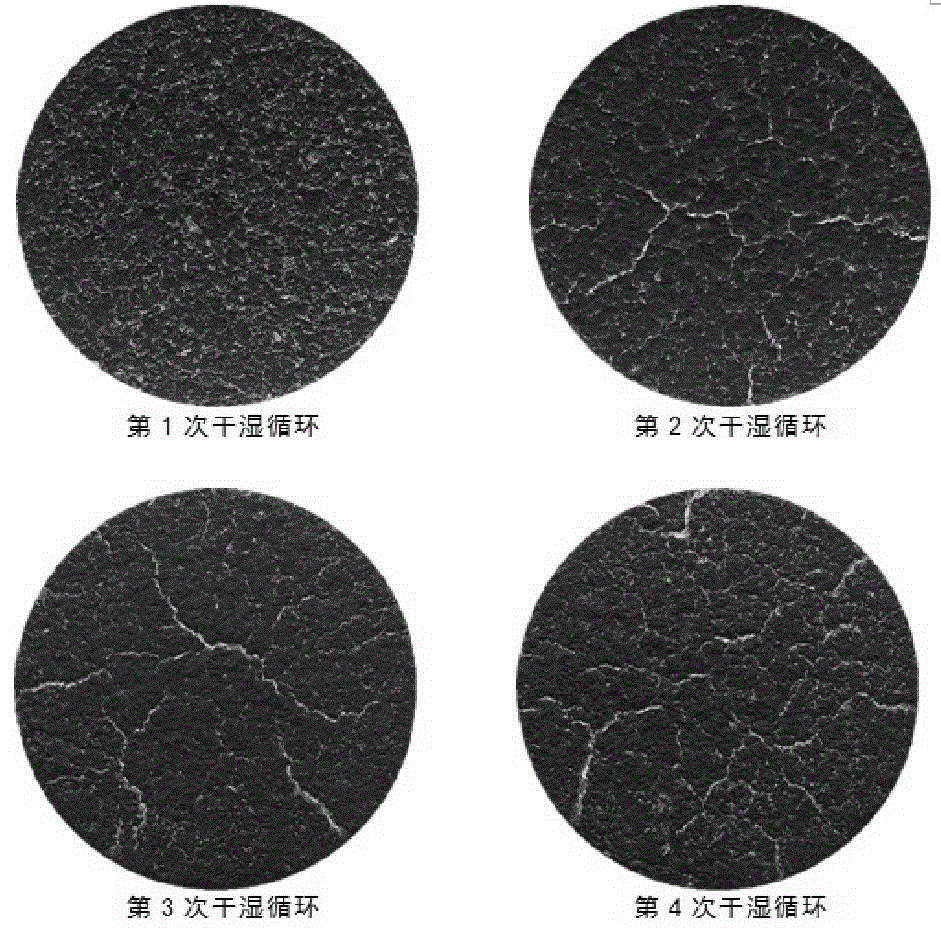

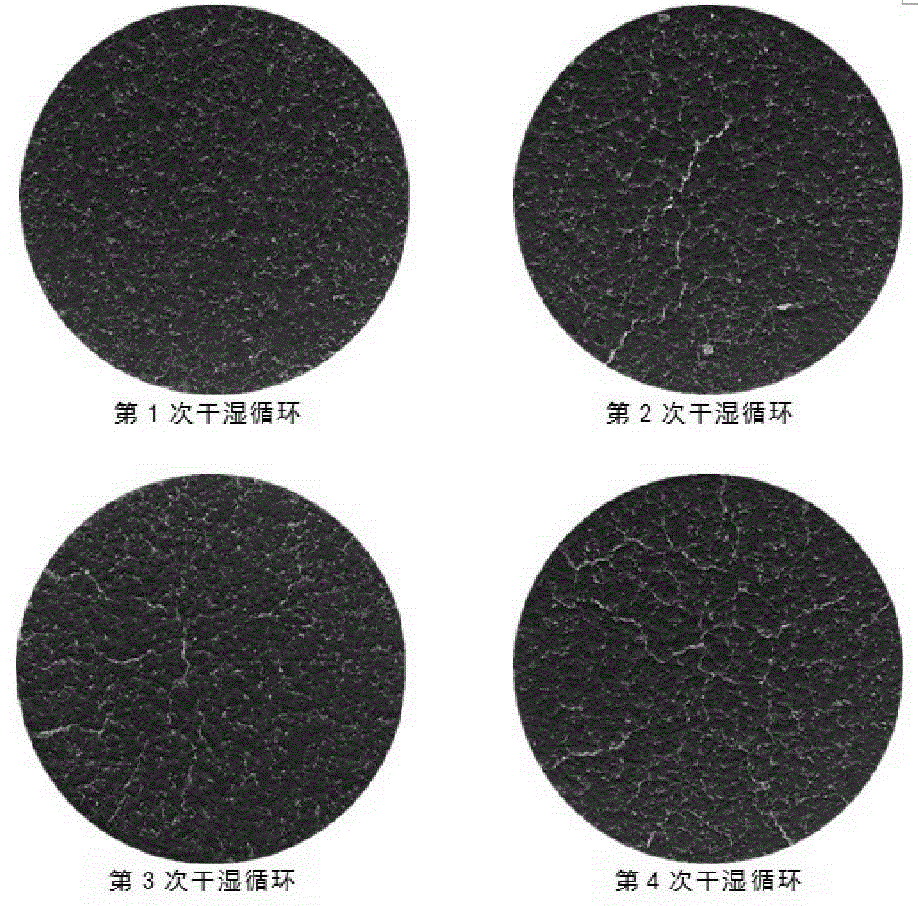

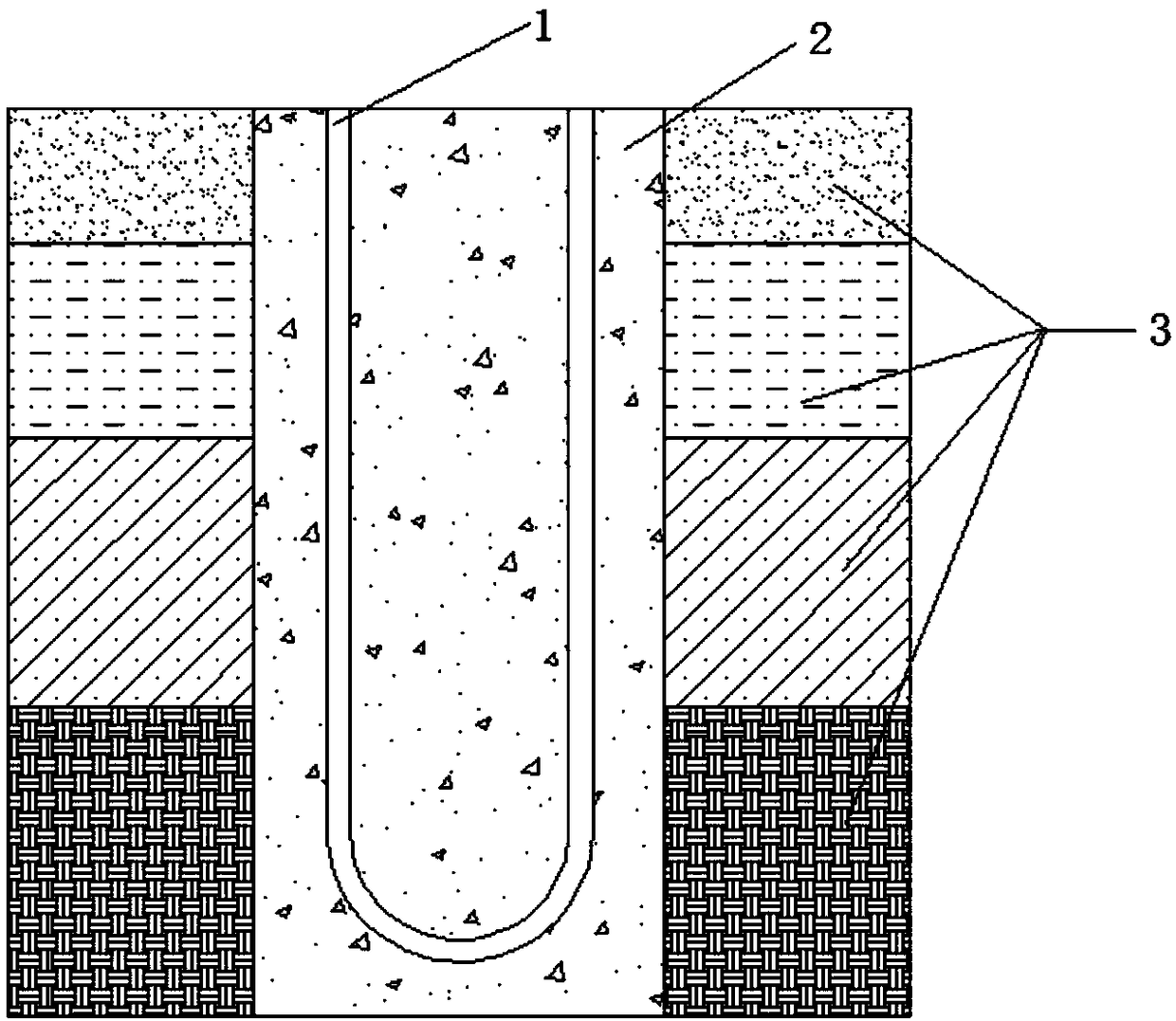

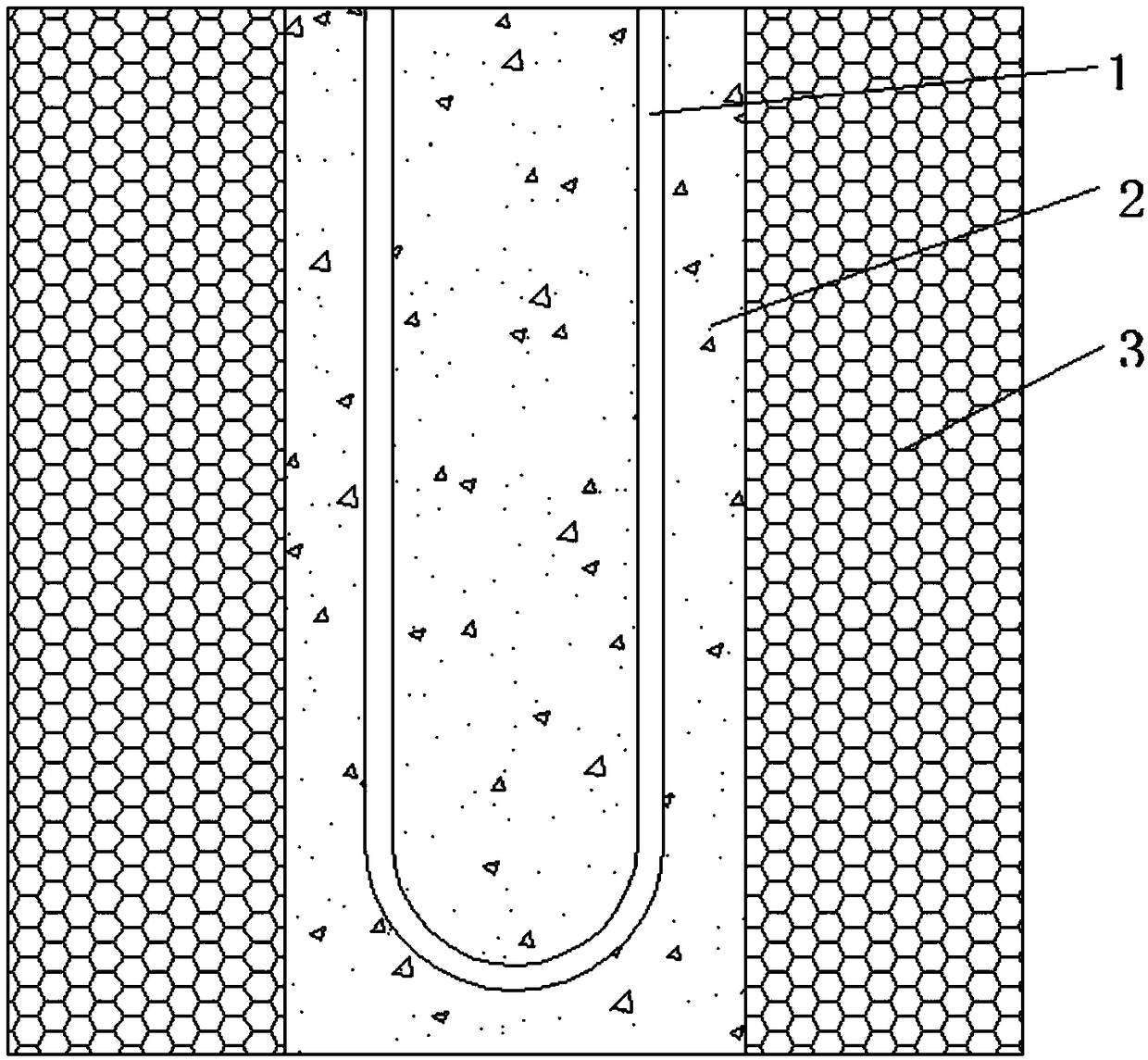

Special anti-cracking bentonite-based composite drill hole backfill material for ground source heat pump

The invention relates to a special anti-cracking bentonite-based composite drill hole backfill material for a ground source heat pump. The special anti-cracking bentonite-based composite drill hole backfill material comprises the following components in parts by weight: 200 parts of bentonite, 800 parts of quartz sand and 0.9 kg / m<3> of motar / concrete crack-resistant fibers. The special anti-cracking bentonite-based composite drill hole backfill material disclosed by the invention can be used for improving a large quantity of cracks caused by intergranular cohesion change and nonuniform expansion and contraction in the drying and wetting circulating process of a bentonite-quartz sand type drill hole backfill material and preventing the surface water from being downwards infiltrated by closely filling a drill hole. The special anti-cracking bentonite-based composite drill hole backfill material disclosed by the invention can be used for reducing the heat resistance inside the drill hole due to good engineering characteristic when adopted for filling the drill hole, and can be used for reducing the depth of the drill hole and the length of a U-shaped pipe, thus reducing the initial assembly cost of the ground source heat pump and being contribute to the popularization and application of a ground source heat pump air-conditioning system which is low in energy consumption and environmentally friendly.

Owner:SOUTHWEAT UNIV OF SCI & TECH

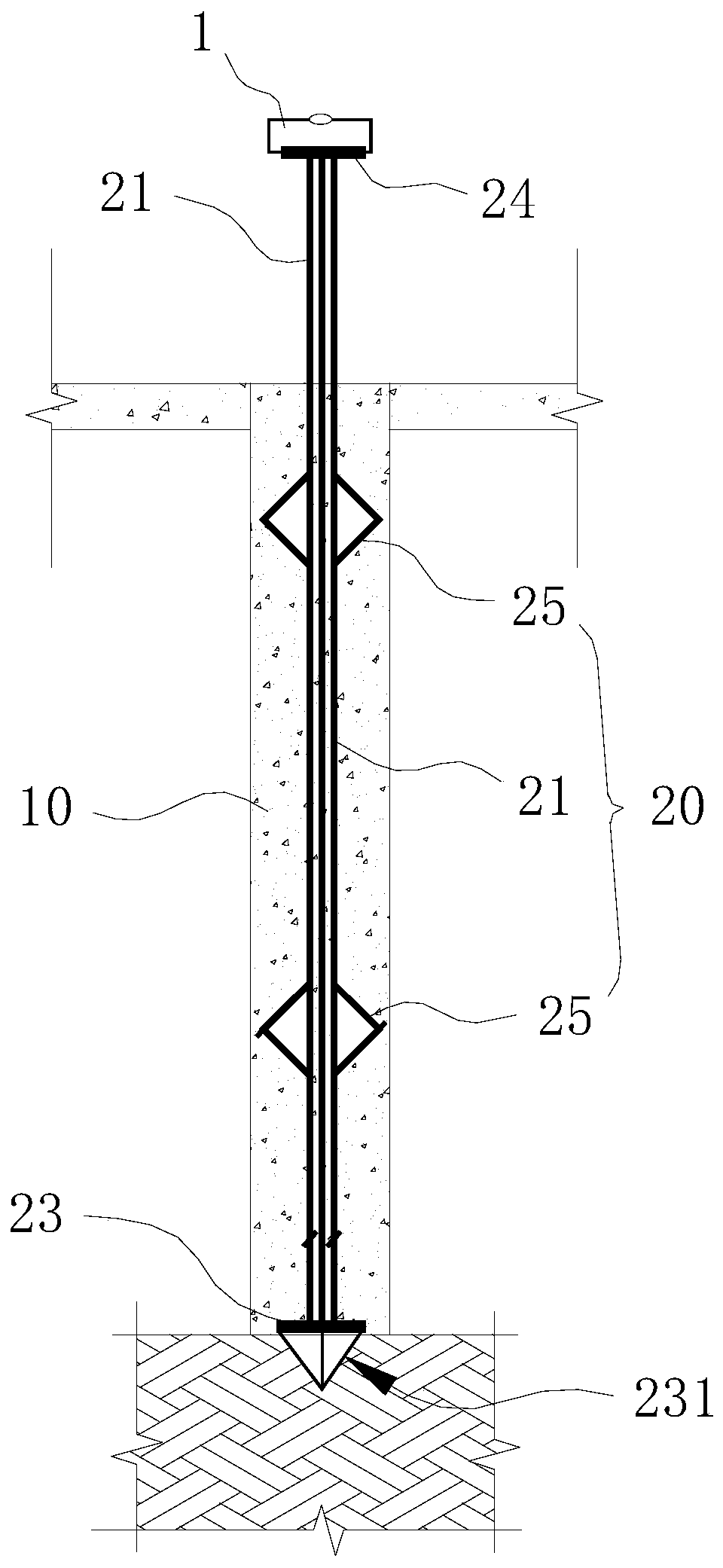

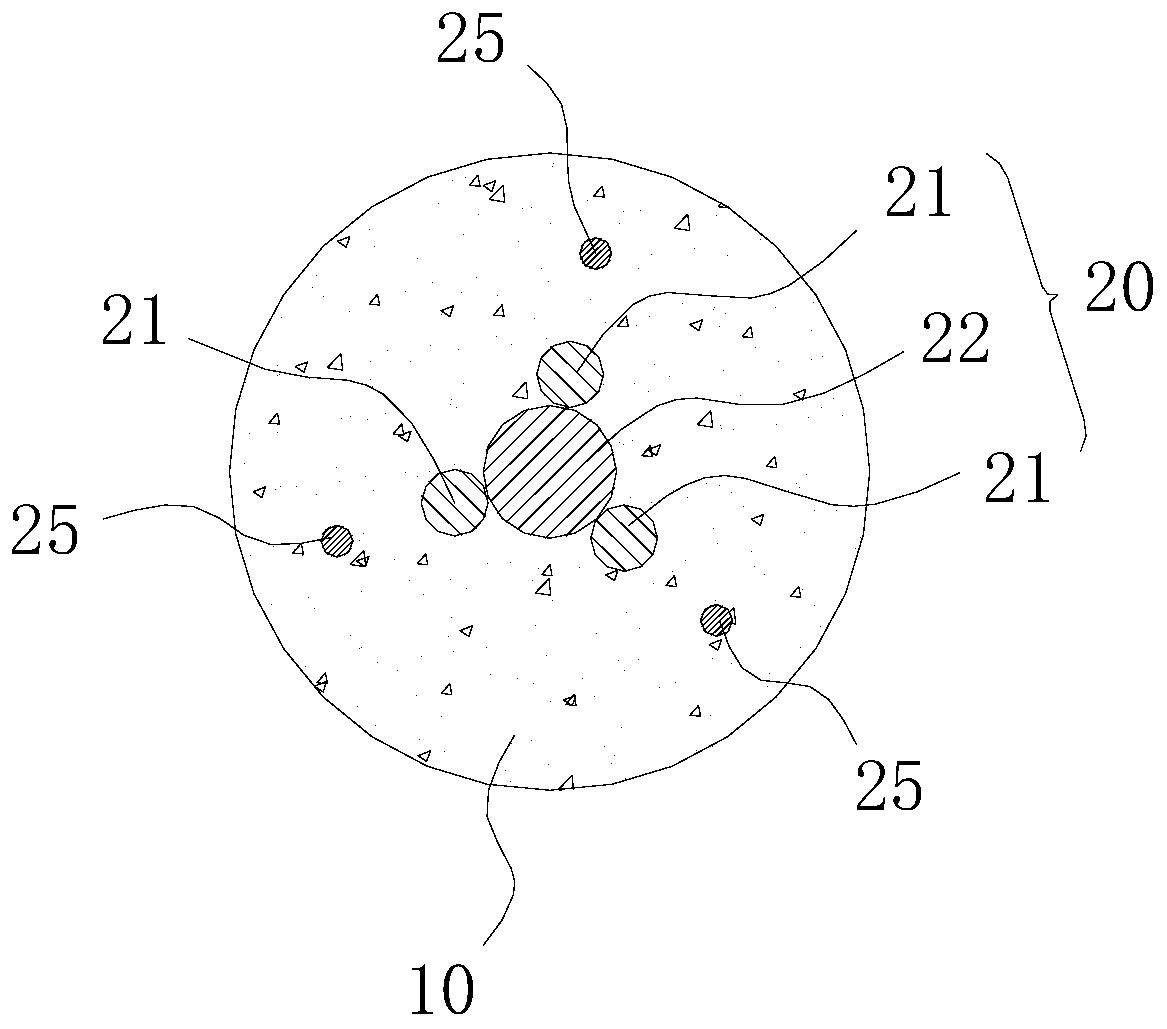

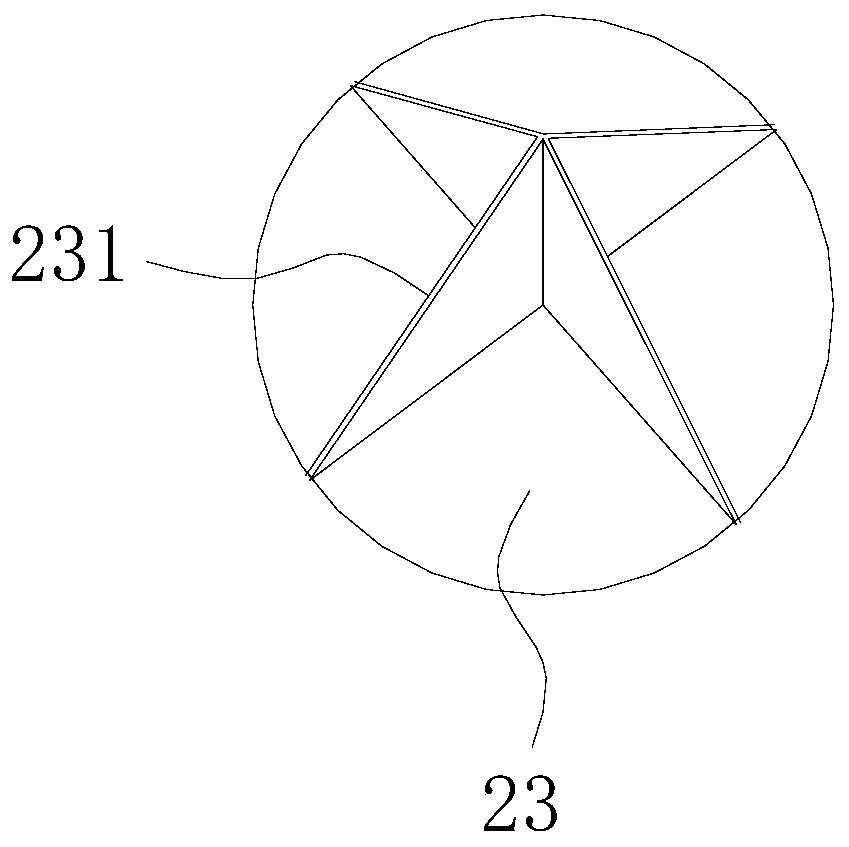

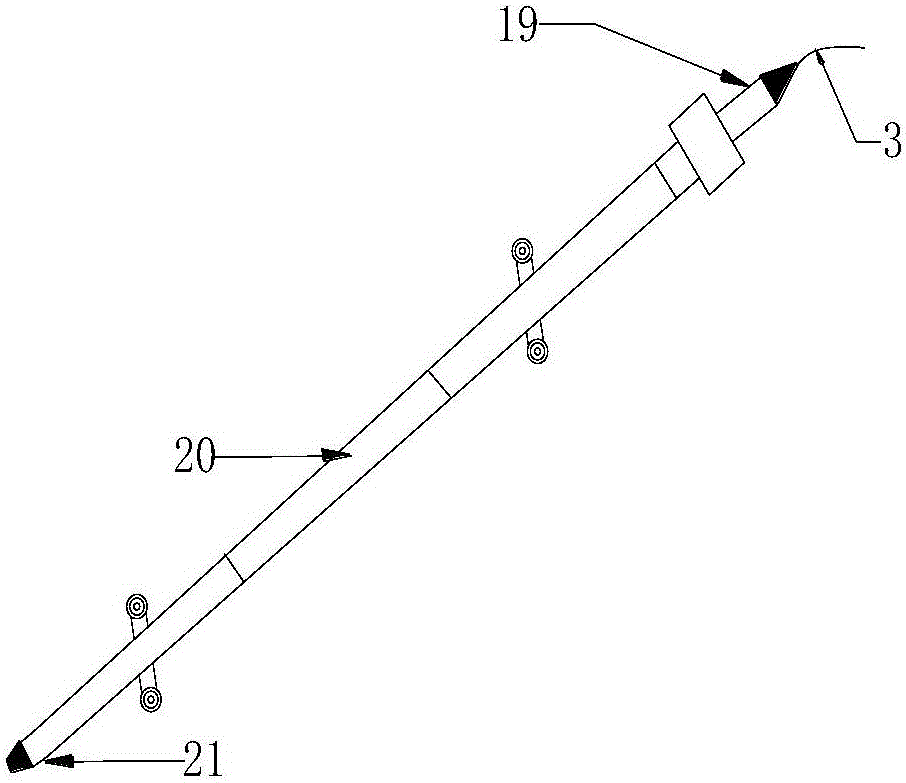

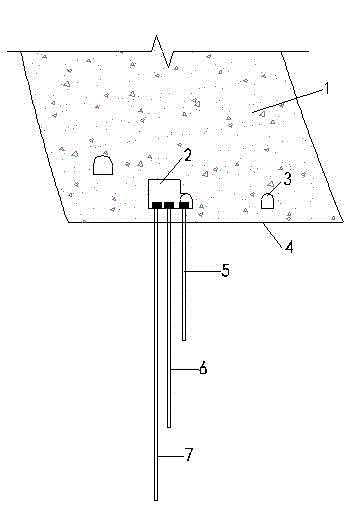

Anti-floating anchor and construction method thereof

PendingCN109944244AEasy to operateAdvanced technologyProtective foundationBulkheads/pilesEngineeringRebar

The invention belongs to the technical field of building construction structures, in particular to an anti-floating anchor and a construction method thereof. The anti-floating anchor comprises a concrete tubular pile and an anti-pull bar bundle inserted into the concrete tubular pile. The anti-pull bar bundle comprises a plurality of anti-pull main bars and short bars arranged in the length direction of the anti-pull main bars at intervals, and the bar bodies of the short bars and the bar bodies of the anti-pull main bars are welded and fixed. An end plate is arranged at the bottom of the anti-pull bar bundle, and an end tip is arranged on the plate face of the side, away from the anti-pull bar bundle, of the end plate. Compared with a traditional anti-floating anchor, the anti-floating anchor can reach the design elevation through one time of dry operation, operation is easy, the construction speed is high, and the construction period can be remarkably shortened. According to the anti-floating anchor, hole collapse and hole shrinkage can be effectively avoided, the anti-floating anchor can be suitable for filling earth, silty clay, silty-fine sand and other hole collapse soil layers, the construction quality of the anti-floating anchor is improved, and the application range of the anti-floating anchor is widened.

Owner:ANHUI TONGJI CONSTR GRP

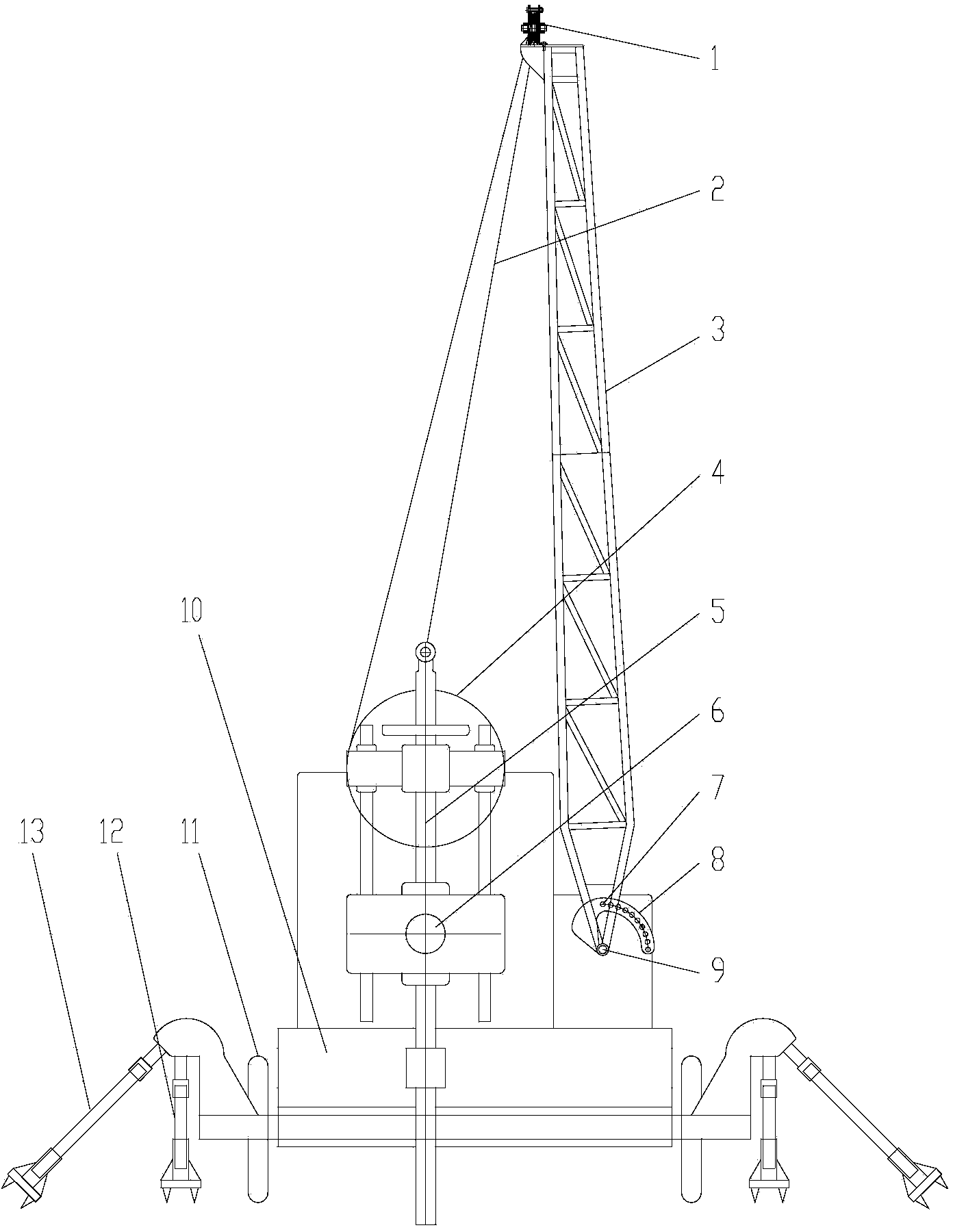

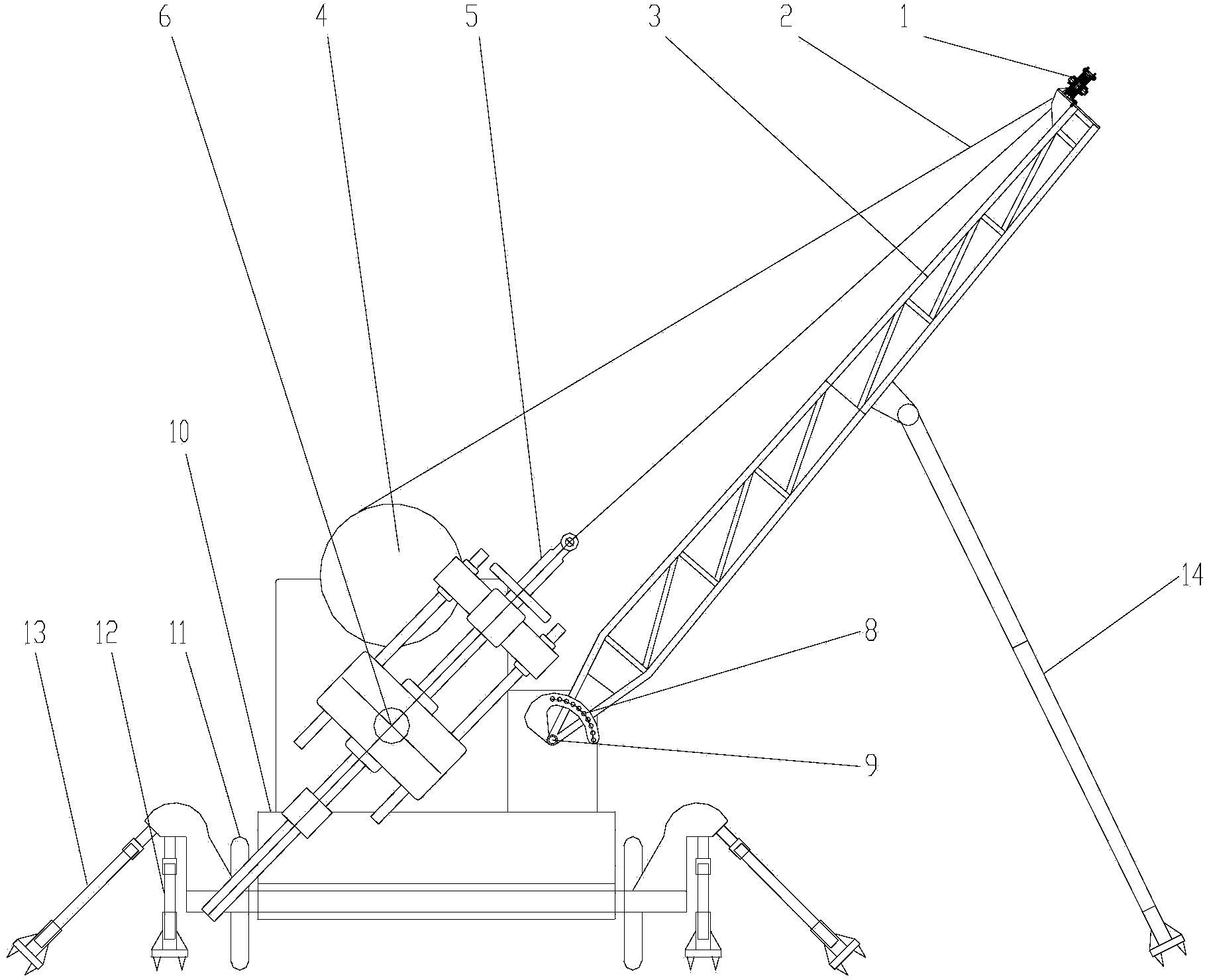

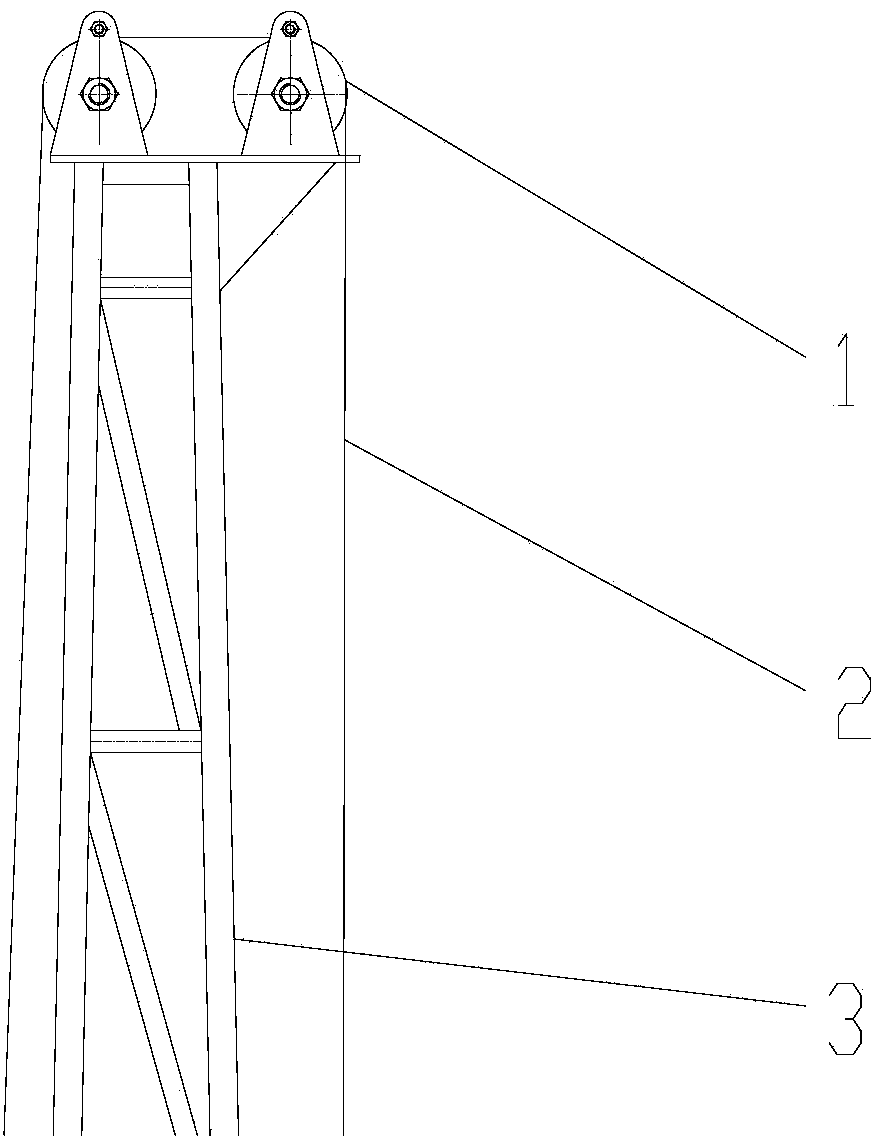

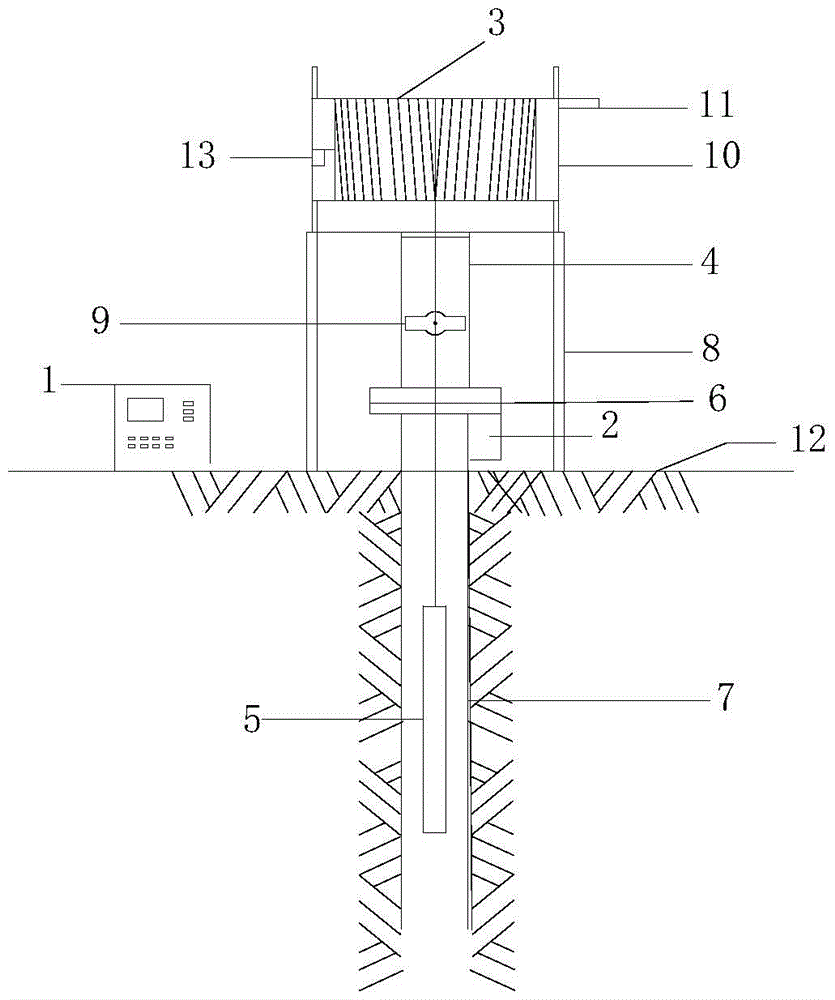

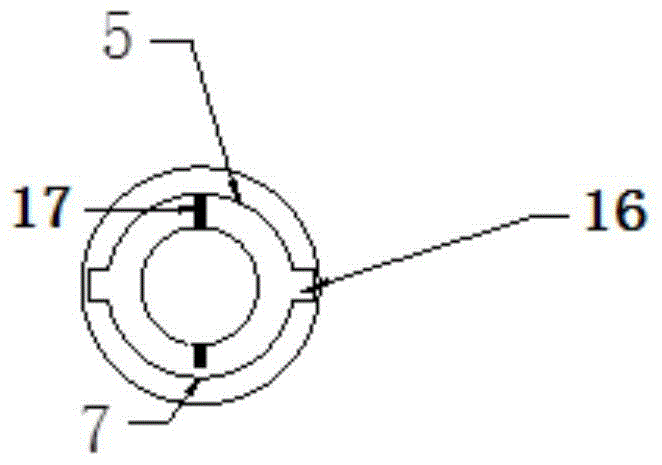

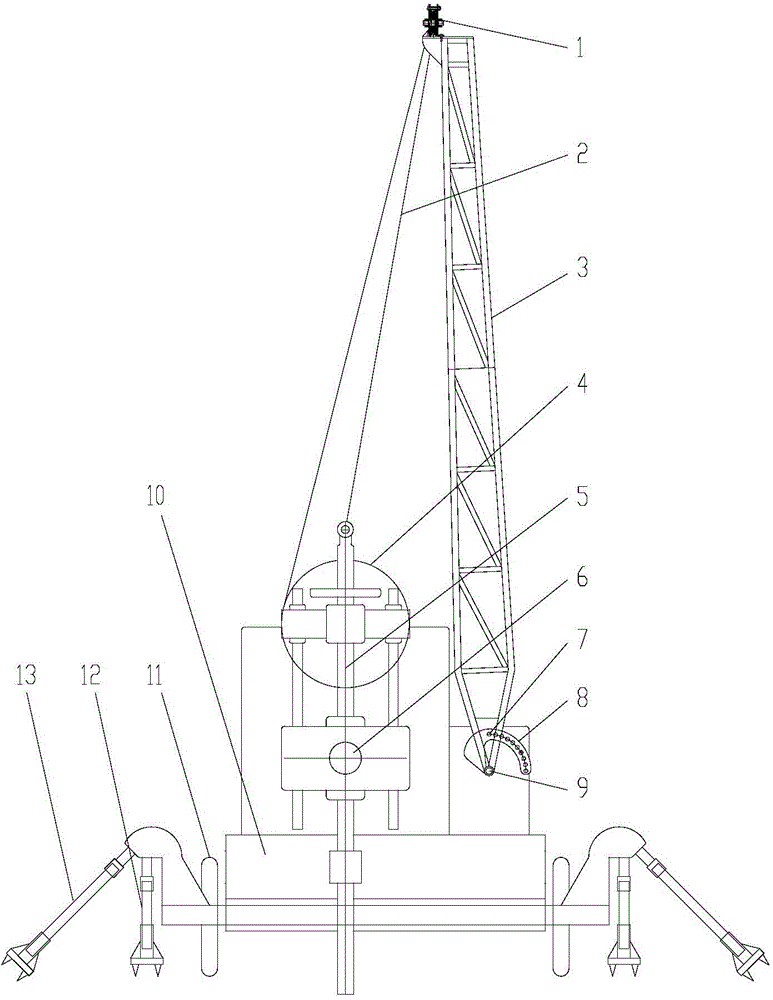

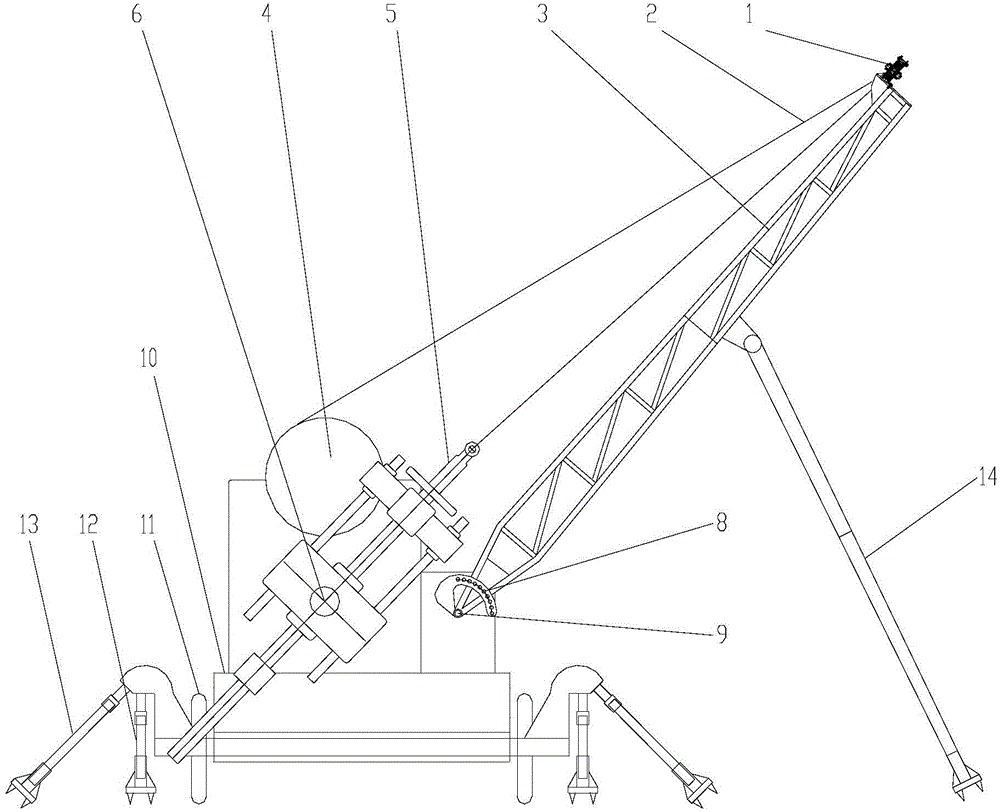

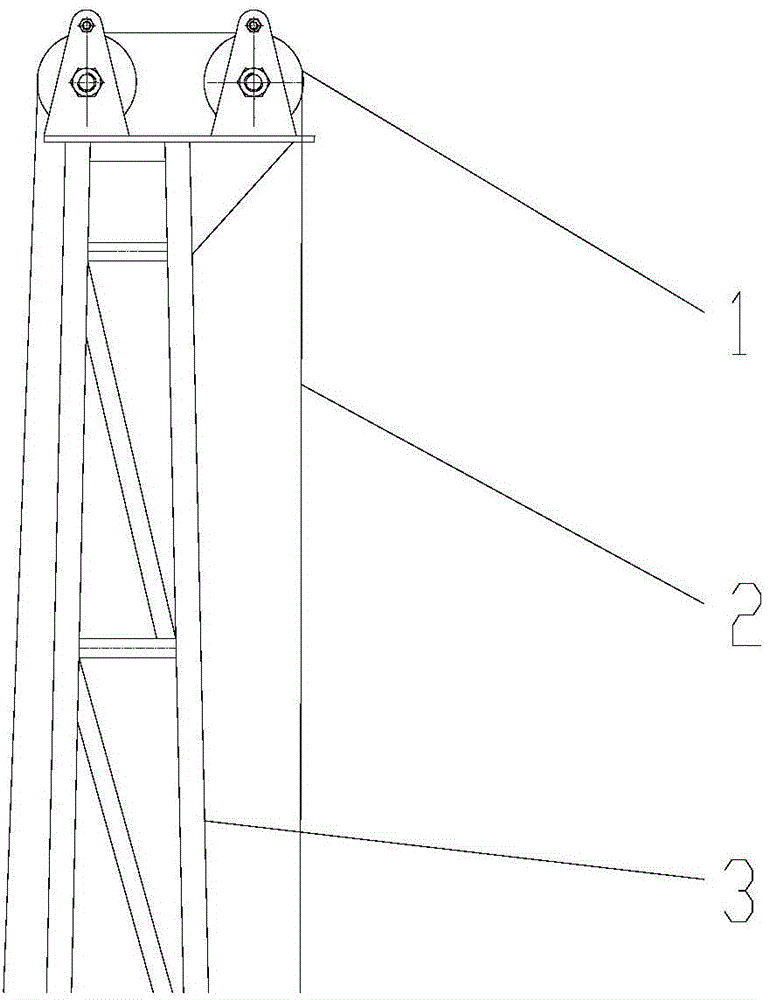

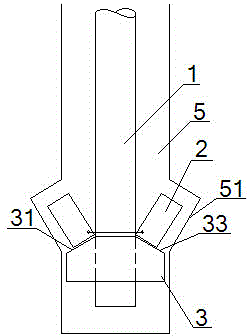

Angle-adjustable engineering geological drilling rig

ActiveCN103452479AEasy to moveGuaranteed stabilityDerricks/mastsDirectional drillingWinding machinePunching

The invention discloses an angle-adjustable engineering geological drilling rig. The engineering geological drilling rig comprises a base, a rotary tower, a winding machine and a drill rod component, wherein the bottom end of the rotary tower is hinged to the base and is provided with a tower locating device, and a fixed pulley is arranged at the top of the rotary tower; the winding machine is fixedly arranged on the base, a steel wire rope connected with the winding machine bypasses the fixed pulley and is connected with the drill rod of the drill rod component so as to realize punching promotion; the drill rod component is connected with the base through a detachable drill rotating disk, the rotating plane of the drill rod component is parallel to the rotating plane of the rotary tower, and a travelling device is arranged at the bottom of the base. According to the angle-adjustable engineering geological drilling rig, the existing engineering geological drilling rig can be improved, and the angle-adjustable engineering geological drilling rig is reasonable in structure, low in cost and high in usability; furthermore, inclined holes in any angle can be drilled by adjusting the angle between the rotary tower and the drill rod component, so that the work efficiency of the engineering geological drilling rig is greatly improved.

Owner:HUNAN CHENZHOU MINING CO LTD

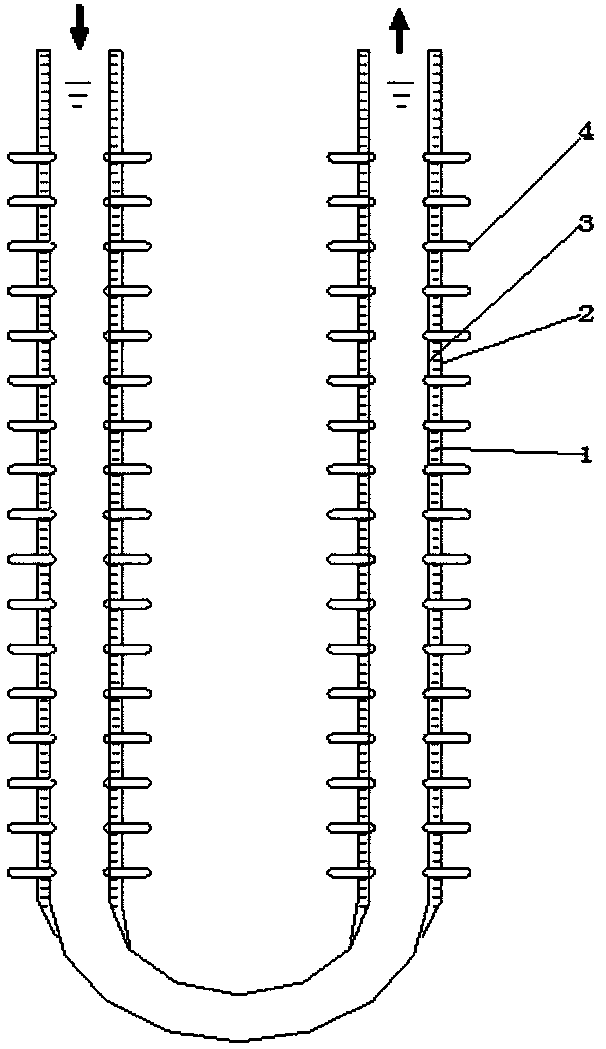

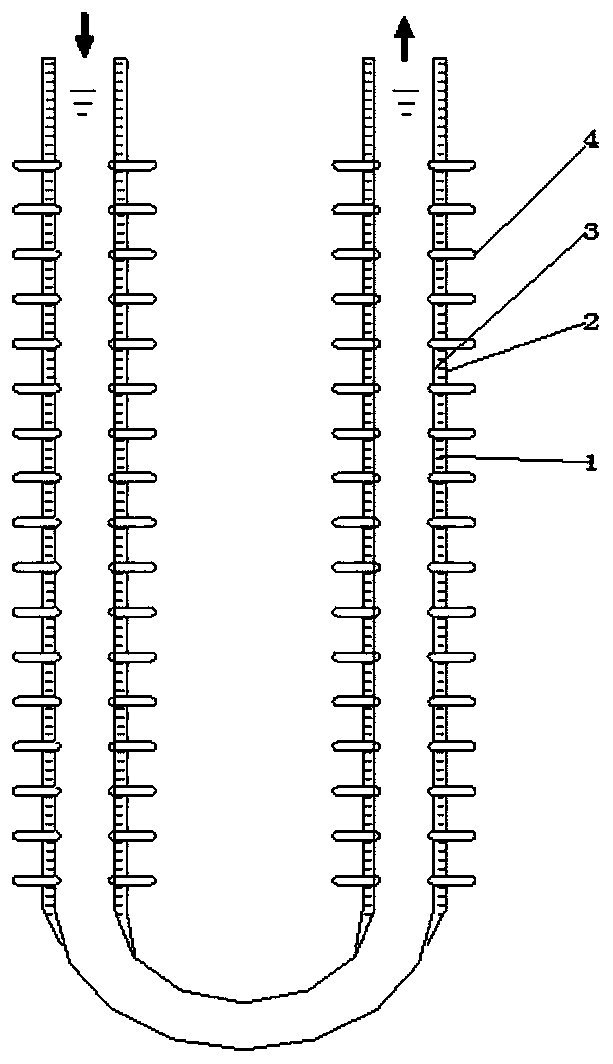

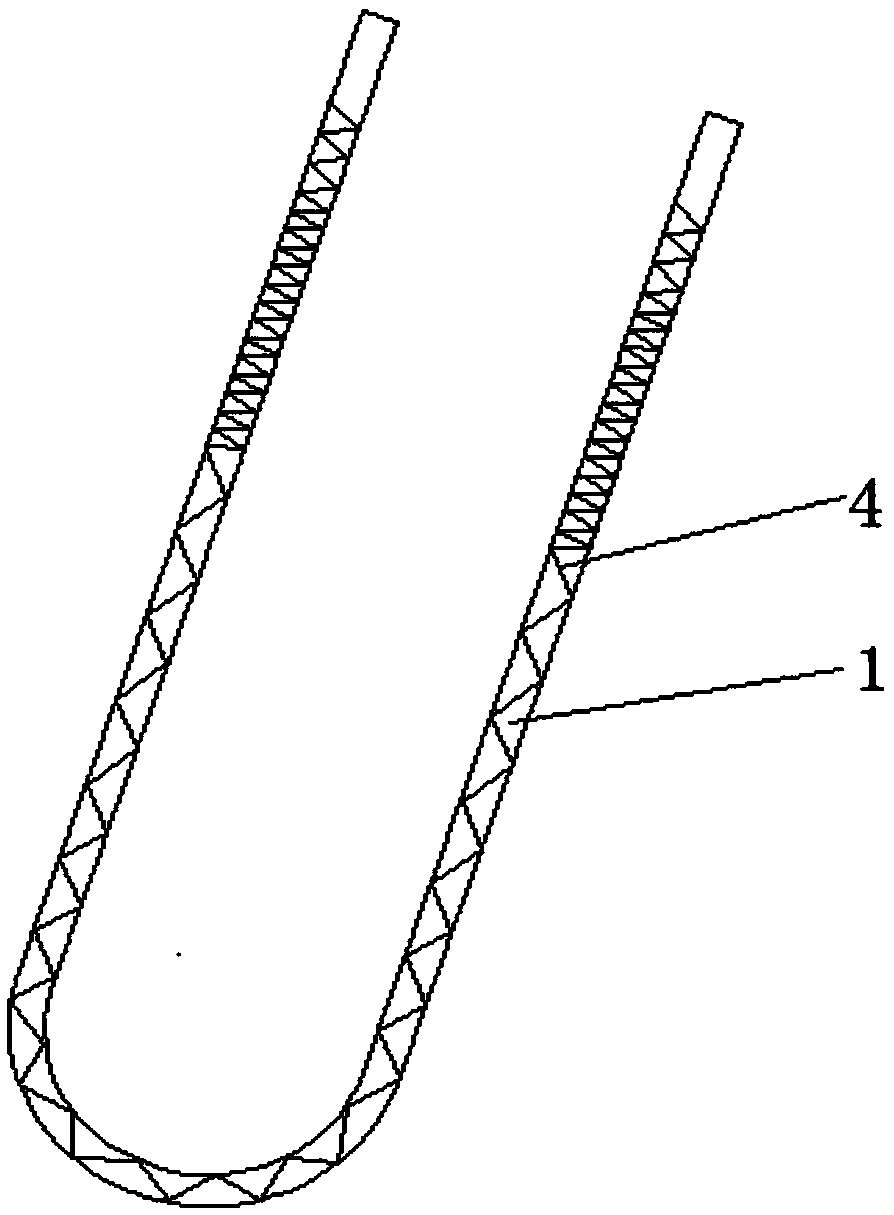

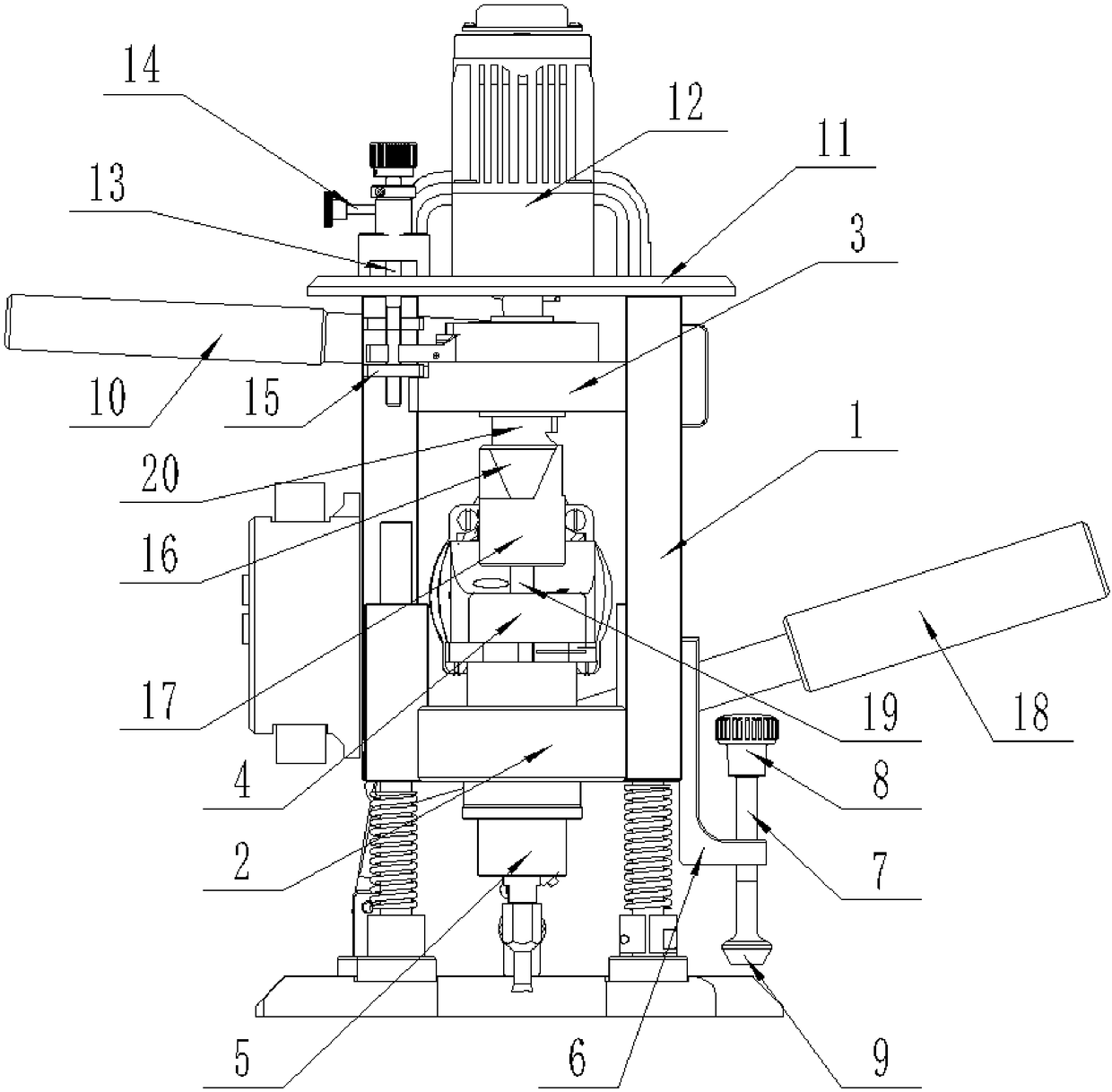

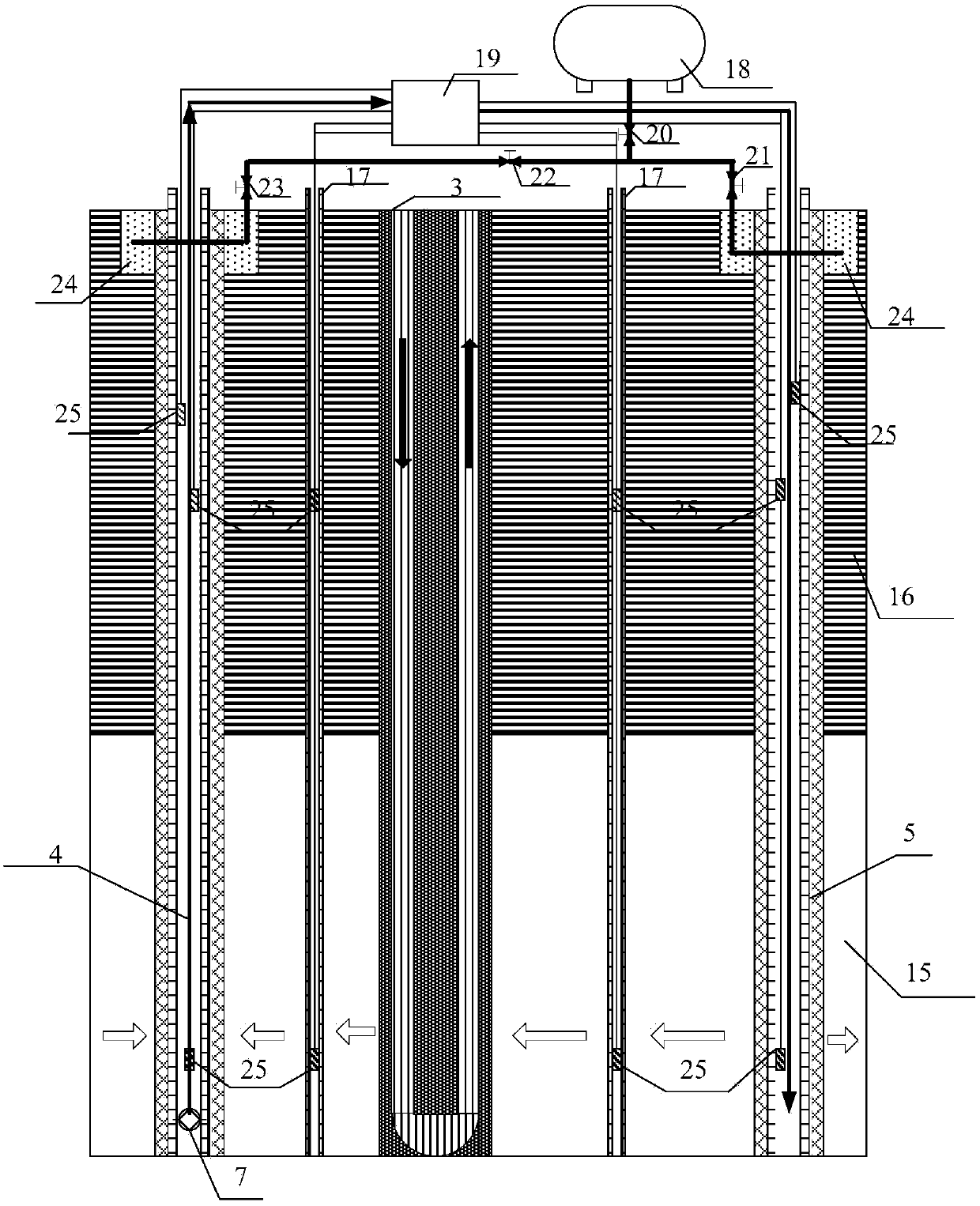

Dual-U-shaped tubular heat exchanger for soil source heat pump system

ActiveCN107741170AImprove the coefficient of performanceSolve the problem that the coefficient of performance is difficult to meet the design standardHeat pumpsIndirect heat exchangersVertical tubeEngineering

The invention provides a dual-U-shaped tubular heat exchanger for a soil source heat pump system. The dual-U-shaped tubular heat exchanger comprises a dual-U-shaped tube, multiple layers of heat tubeassemblies are axially and evenly arranged on the outer all of each vertical tube of the dual-U-shaped tube at intervals, the inner side ends of the heat tube assemblies penetrate through the outer walls of the vertical tubes to be inserted into the vertical tubes, and sealing treatment is conducted on the joints of the inner side ends of the heat tube assemblies and the outer walls, wherein annular heat tubes or multiple heat tubes can be adopted as the heat tube assemblies. According to the dual-U-shaped tubular heat exchanger for the soil source heat pump system, heat exchange between a medium in the U-shaped tube and soil is strengthened through the good heat conduction property of the heat tubes, the heat exchange efficiency is obviously improved, therefore, the drilling depth can bedecreased, then investment is reduced, and most of the heat exchange process is completed in the shallow stratum.

Owner:中南建筑设计院股份有限公司

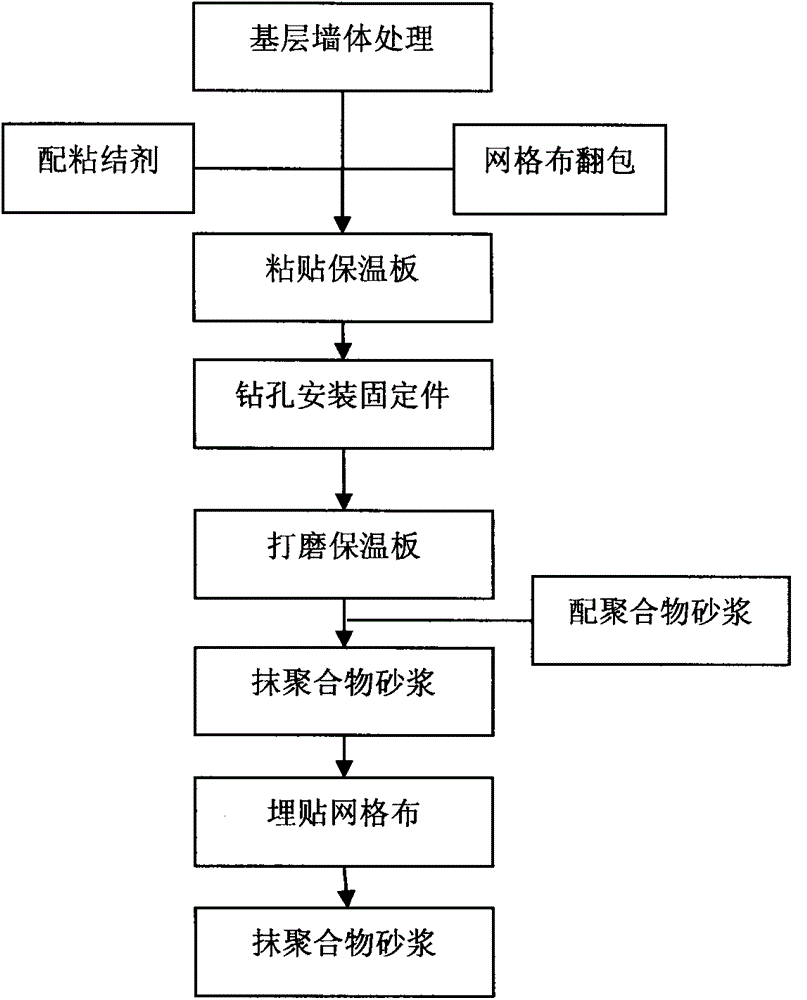

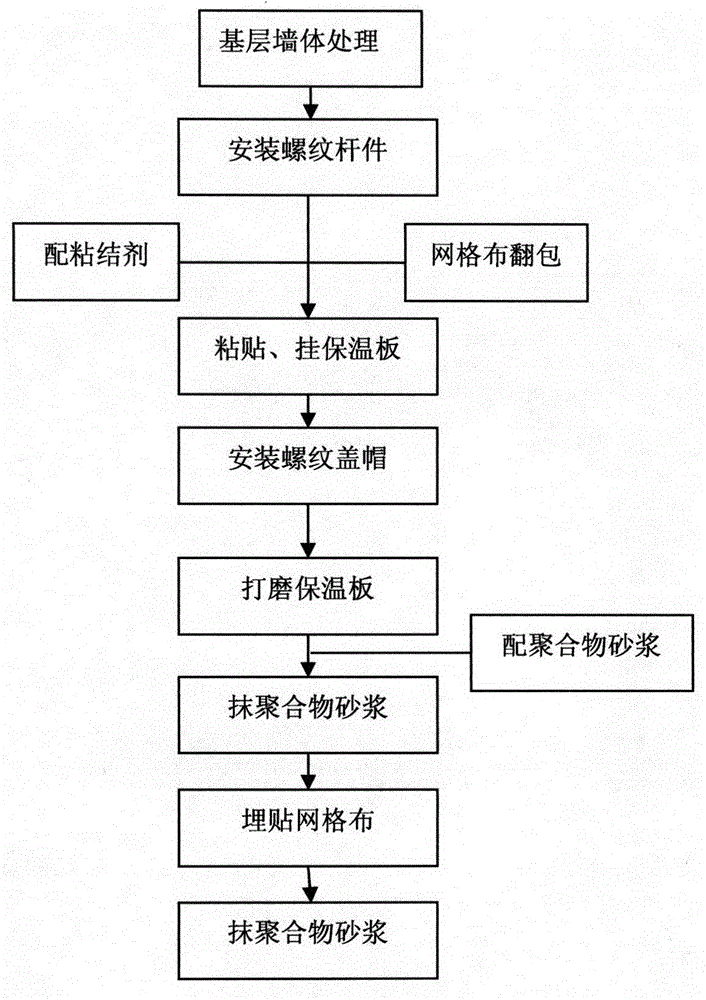

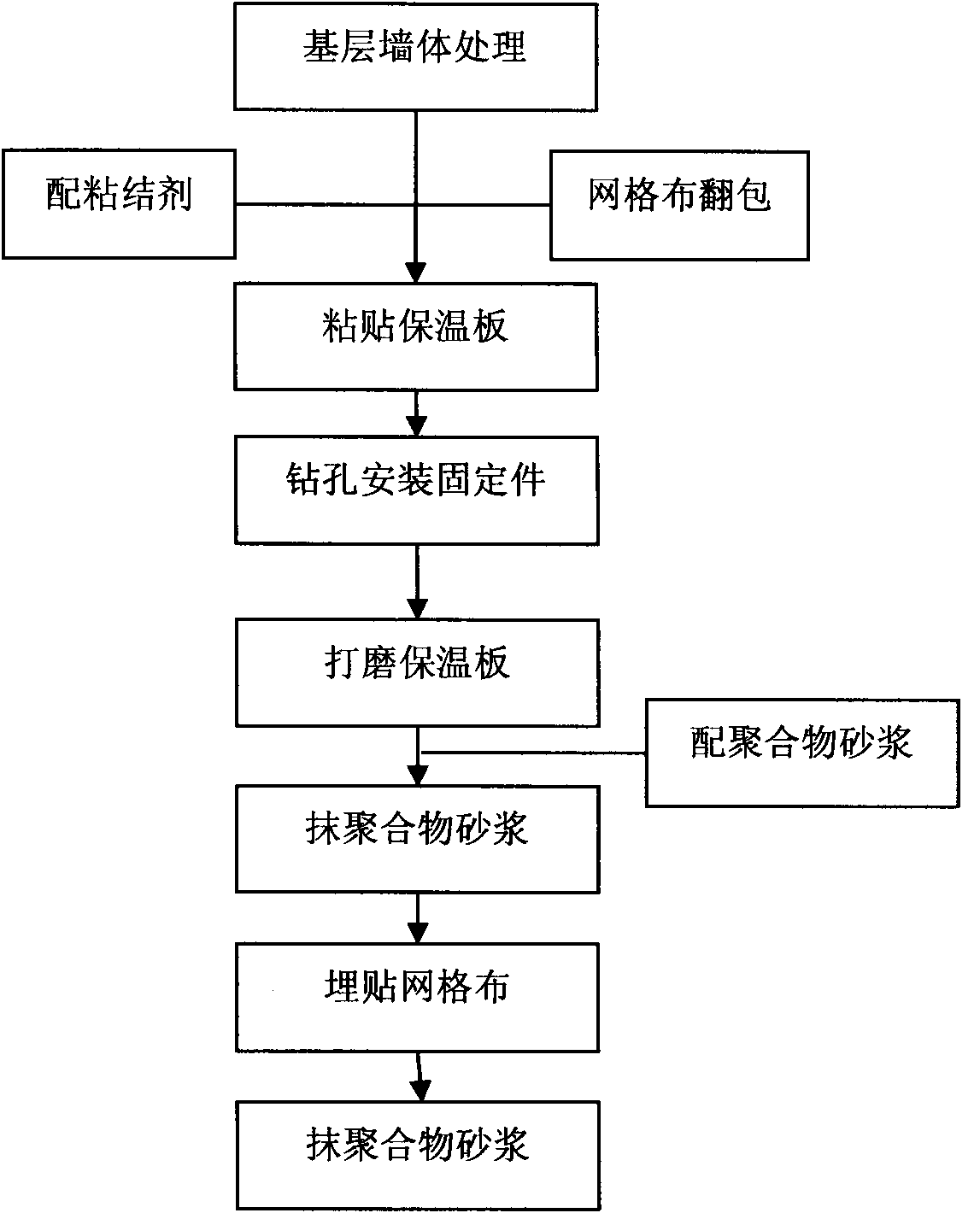

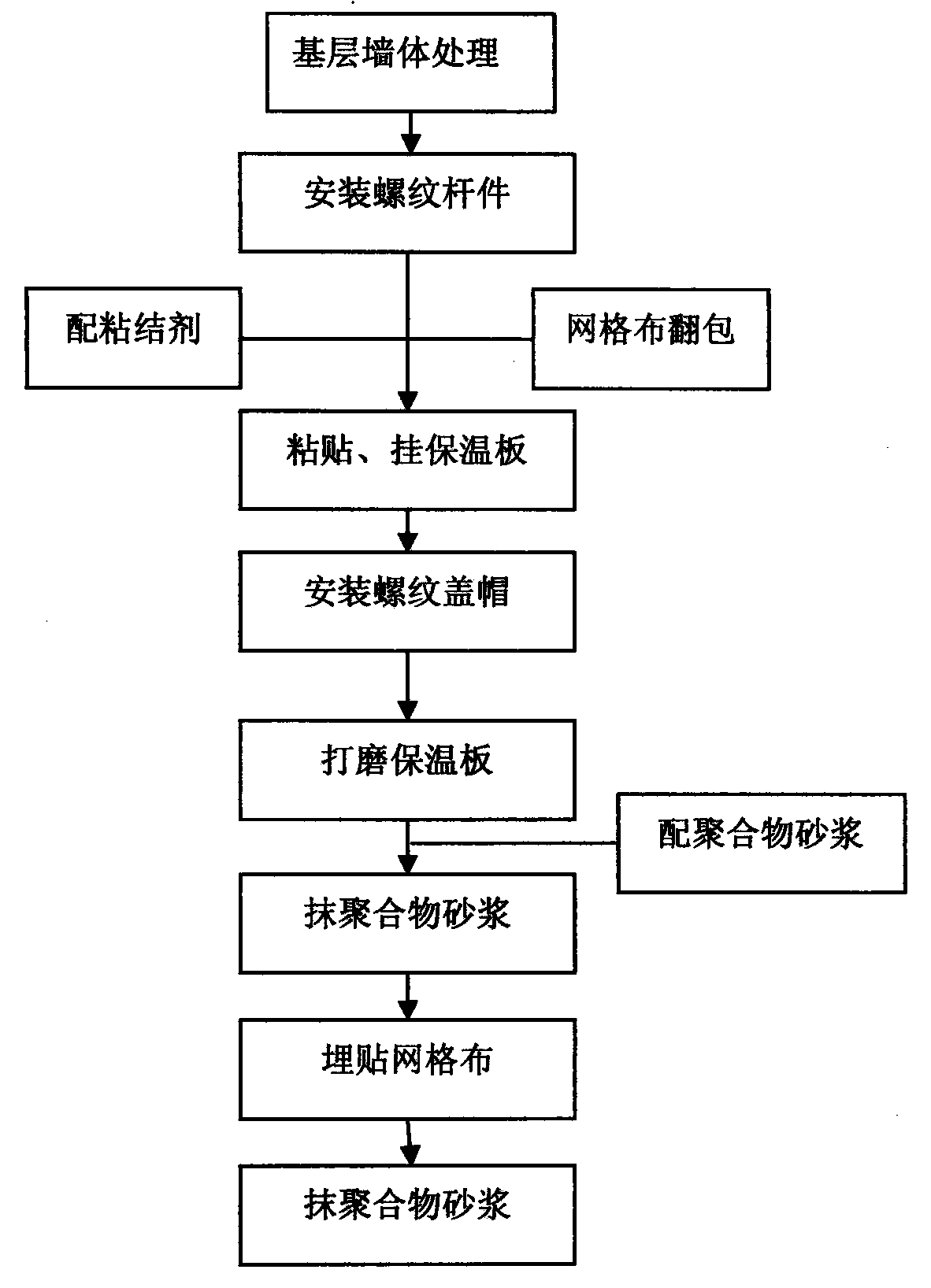

Pre-fixed plate system wall insulation system construction technology

ActiveCN104975658AShorten the lengthReduce drilling depthHeat proofingArchitectural engineeringInsulation system

The invention relates to the building wall insulation system construction technology, and specifically refers to a pre-fixed plate system wall insulation system construction technology; the core of the technology is to use a drilling, pre-buried or bonding mode to lead out vertical outward thread rod from a base wall; the thread rods are bonded or hung with one or more layers of insulation plates; an outer side of the insulation plate is provided with thread caps in a screwing or knocking mode, thus firmly fixing the insulation plates on the base wall; then later polishing-plastering netting steps are followed. The pre-fixed plate system wall insulation system construction technology solves seepage and virtual fixation disadvantages of the conventional technology, optimizes a construction flow, ensures engineering quality, reduces construction cost, and has wide application in civil building and cold storage engineering.

Owner:JIANGSU WONIUSHAN THERMAL INSULATION & WATERPROOF TEHNOLOGY

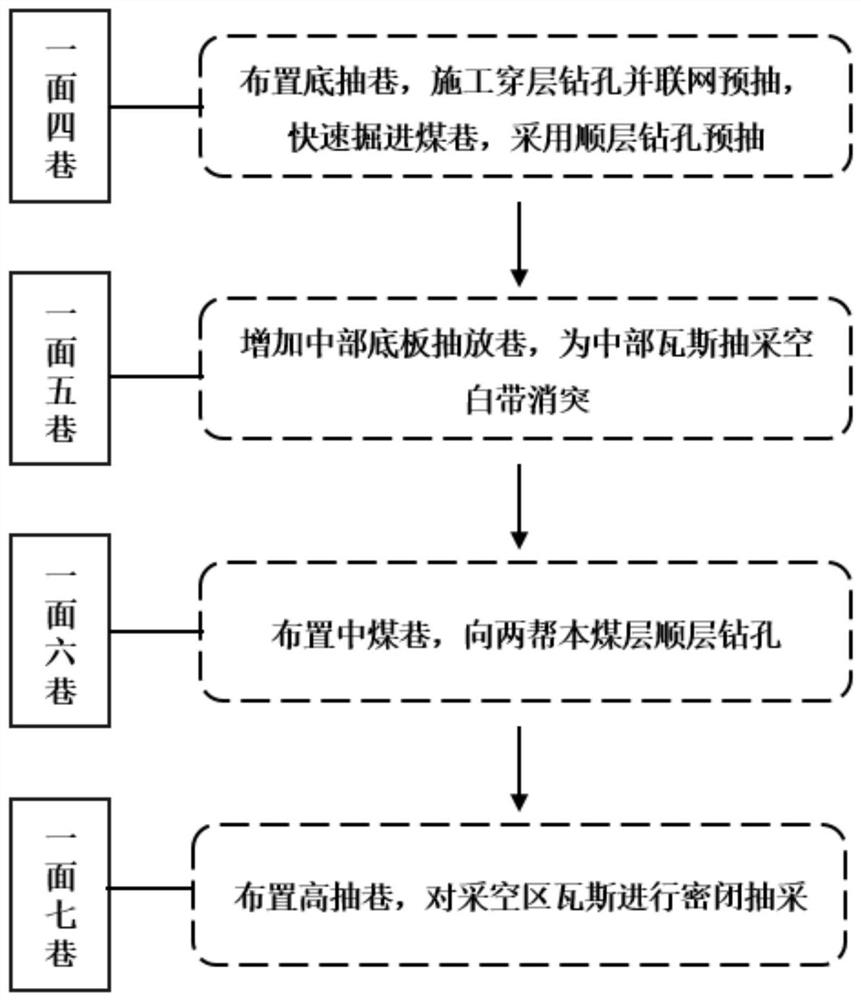

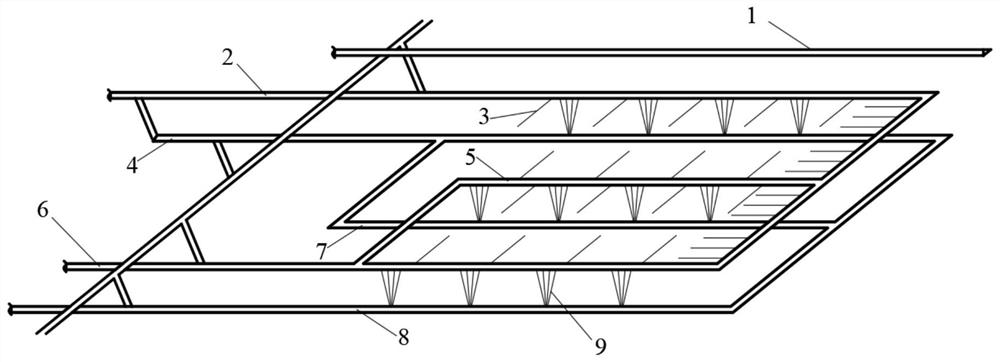

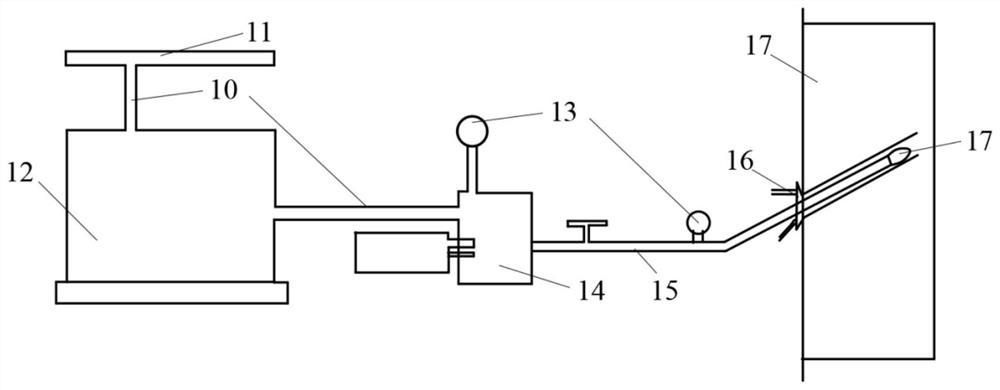

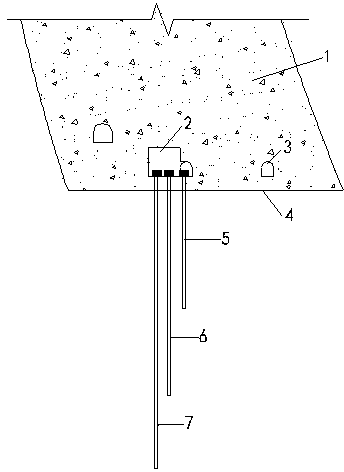

One-face multi-roadway gas control method for large-mining-height large-mining-length working face

InactiveCN111810223AShort governance cycleReduce sampling blanksGas removalMining engineeringMechanical engineering

The invention relates to a one-face multi-roadway gas control method for a large-mining-height large-mining-length working face, and belongs to the field of gas development and utilization. The methodcomprises the steps that a bottom drainage roadway and a coal roadway are arranged, gas pre-drainage is conducted in manners of bottom drainage roadway cross-layer drilling and coal roadway bedding parallel drilling, and a one-face four-roadway pattern is formed; a middle bottom plate drainage roadway is additionally arranged, cross-layer drilling is executed, outburst elimination is conducted ona gas drainage blank zone in the middle of the working face, and a one-face five-roadway pattern is formed; a middle coal roadway is arranged, bedding drilling is conducted on two coal seams, and a one-face six-roadway pattern is formed; and high drainage roadways are arranged in the coal mining working face in a staggered manner, and finally a one-face seven-roadway pattern is formed. Accordingto the one-face multi-roadway gas control method for the large-mining-height large-mining-length working face, the middle drainage roadway and the middle coal roadway are additionally arranged on a traditional one-face four-roadway gas drainage pattern, the coal seam gas drainage blank zone is reduced, the drilling depth is decreased, and the gas control period can be greatly shortened.

Owner:河南平宝煤业有限公司 +1

Dam foundation deformation depth monitoring method

ActiveCN103821187AMonitor Deformation DepthDeformation depth implementationFoundation testingMeasuring instrumentEngineering

Owner:POWER CHINA KUNMING ENG CORP LTD

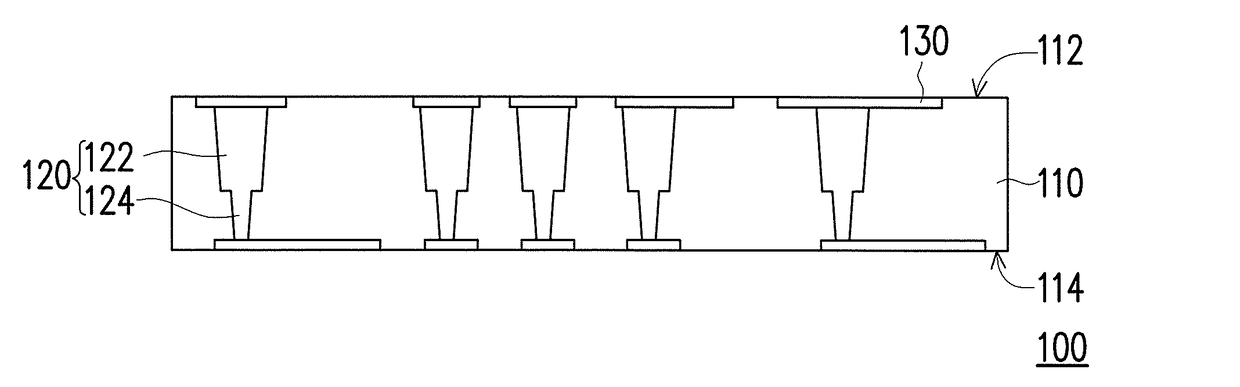

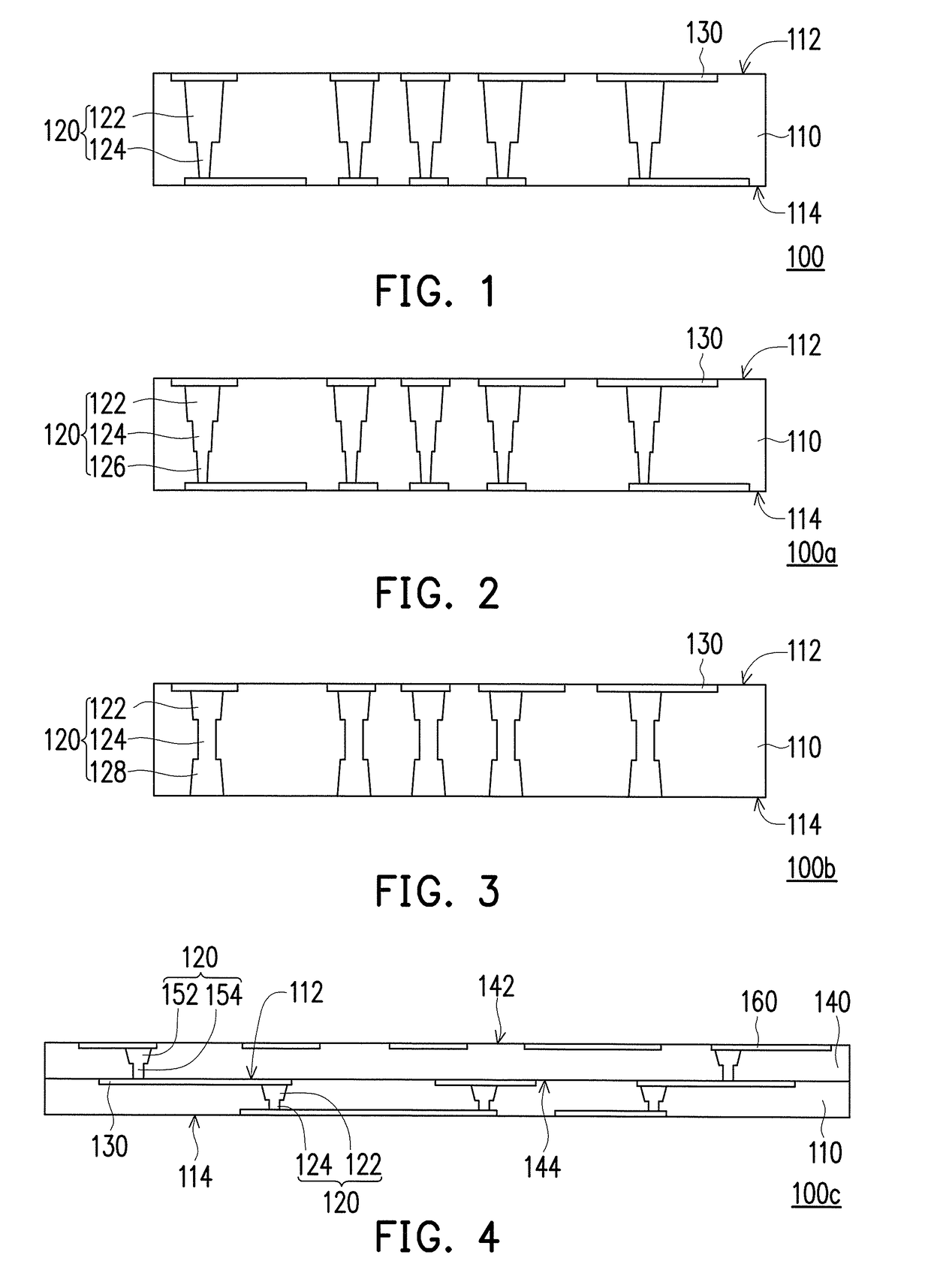

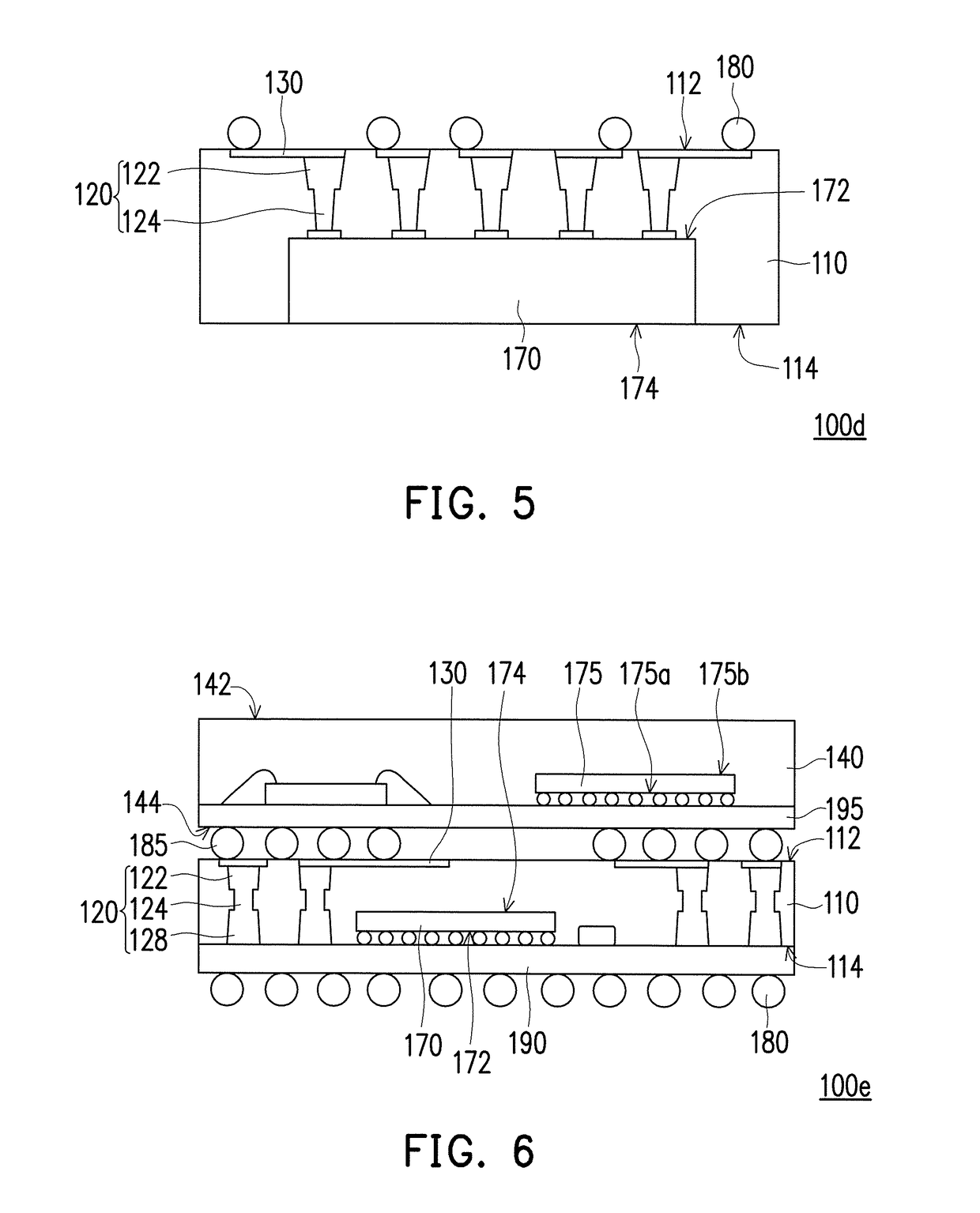

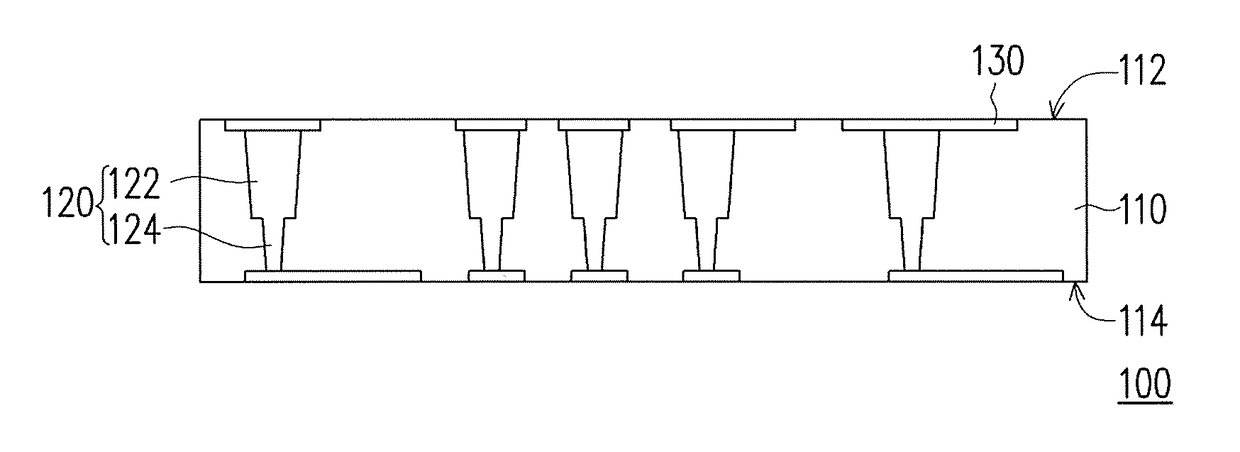

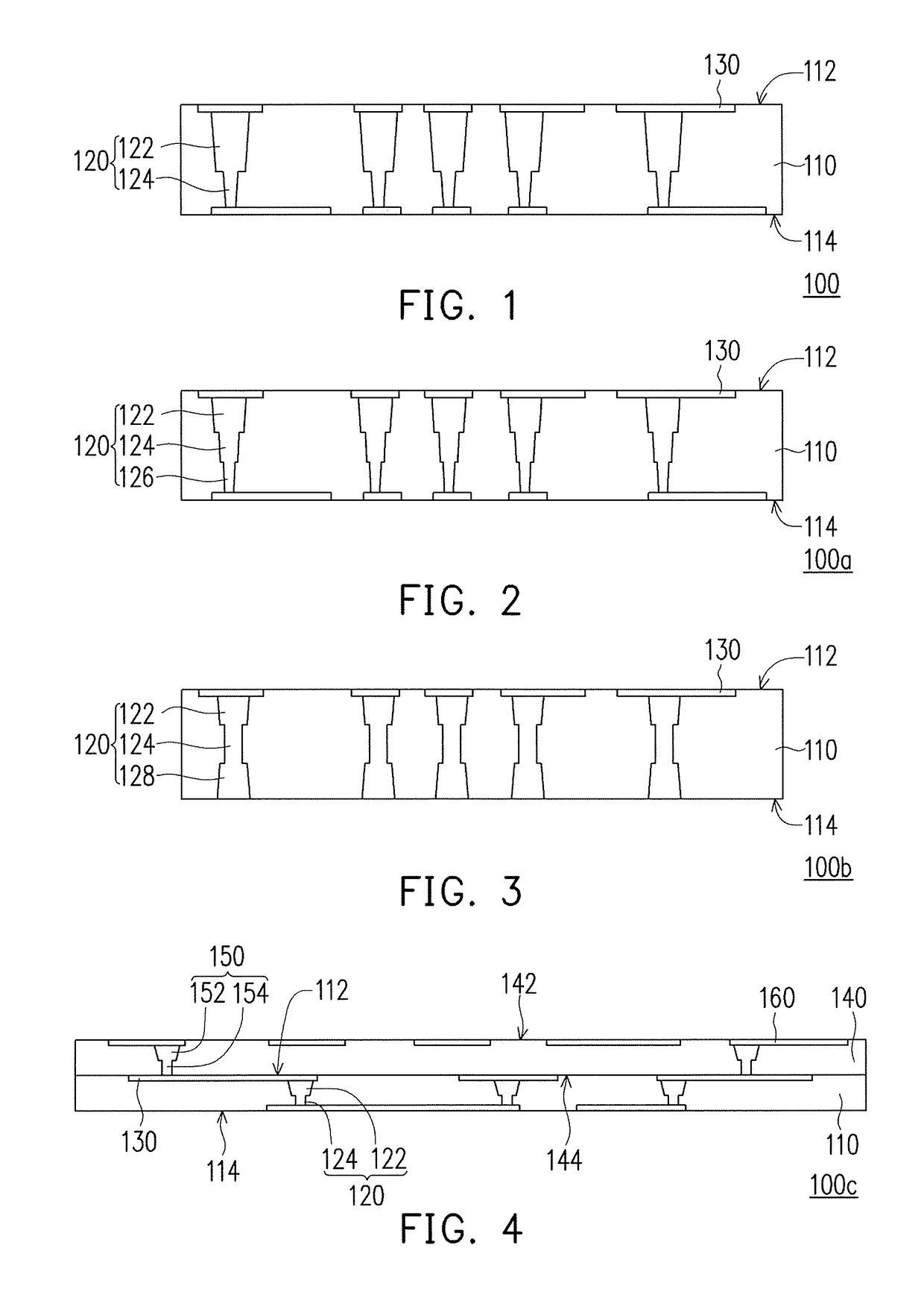

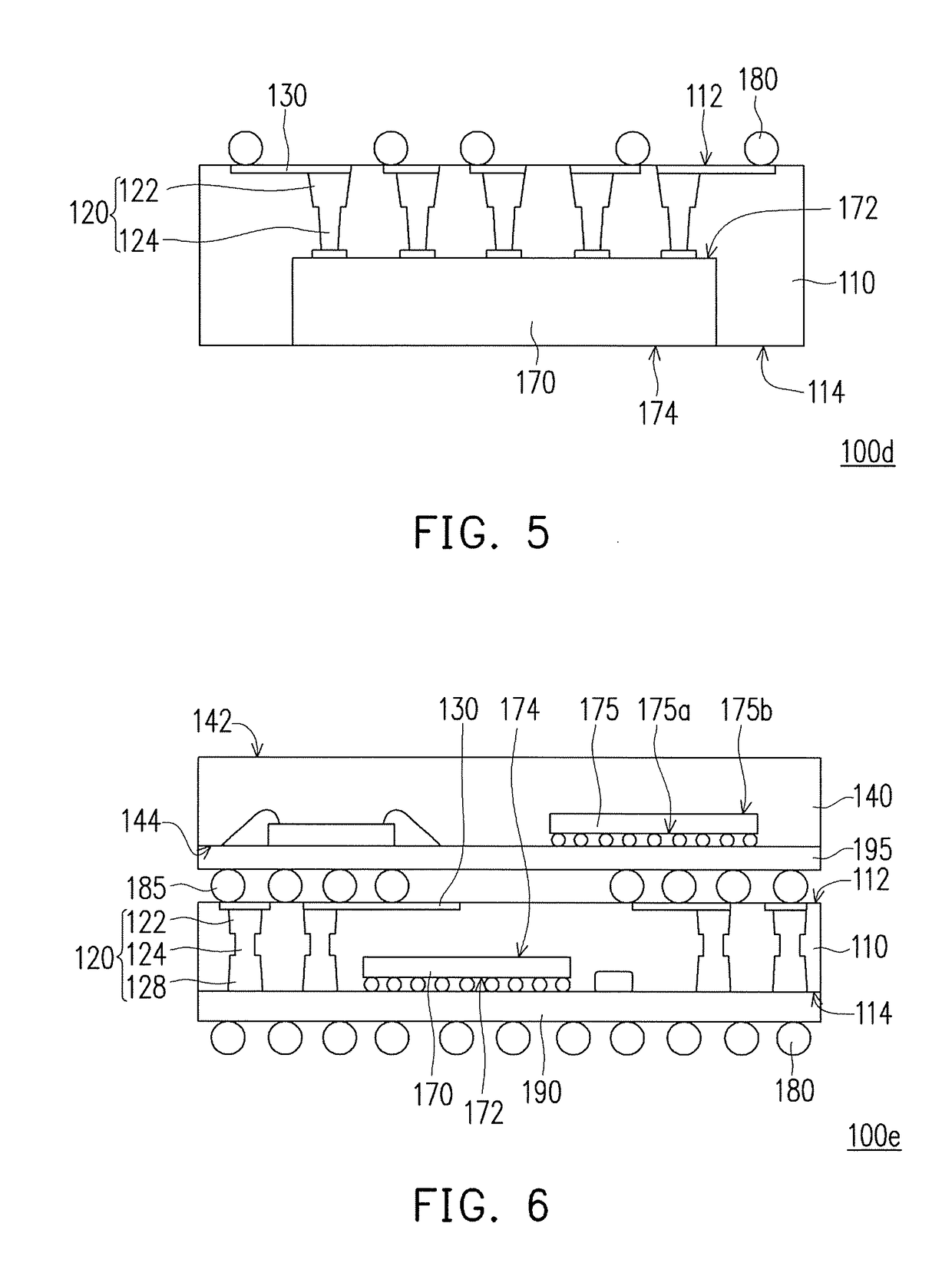

Semiconductor structure

InactiveUS20170077045A1Improve reliabilityEffectively reduces diameterSemiconductor/solid-state device detailsPrinted circuit aspectsSemiconductor structureMaximum diameter

A semiconductor structure includes an insulating layer, a plurality of stepped conductive vias and a patterned circuit layer. The insulating layer includes a top surface and a bottom surface opposite to the top surface. The stepped conductive vias are disposed at the insulating layer to electrically connect the top surface and the bottom surface. Each of the stepped conductive vias includes a head portion and a neck portion connected to the head portion. The head portion is disposed on the top surface, and an upper surface of the head portion is coplanar with the top surface. A minimum diameter of the head portion is greater than a maximum diameter of the neck portion. The patterned circuit layer is disposed on the top surface and electrically connected to the stepped conductive vias.

Owner:IBIS INNOTECH

A double u-shaped tube heat exchanger for soil source heat pump system

ActiveCN107741170BImprove the coefficient of performanceSolve the problem that the coefficient of performance is difficult to meet the design standardHeat pumpsIndirect heat exchangersVertical tubePlate heat exchanger

Owner:中南建筑设计院股份有限公司

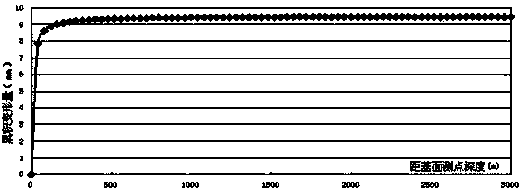

Method for improving heat exchange performance and longitudinal local heat accumulation of buried pipes of ground-source heat pump

InactiveCN108956947AReasonable designReduce drilling depthHeat pumpsMaterial heat developmentAnalytic modelSoil model

The invention provides a method for improving heat exchange performance and longitudinal local heat accumulation of buried pipes of a ground-source heat pump. Heat conductivity of a plastic pipe can be improved by winding a common plastic pipe with metal wire that is low in cost and high in heat conductivity coefficient. By analyzing the thermophysical parameter of soil in a pipe burying zone, thesoil in the pipe burying zone is reasonably layered, and analytic models for the soil layers are established on ANSYS software; optimum equivalent heat conductivity coefficient of the composite plastic pipe in each layer of the soil model then is determined, and the required length of the metal wire, the distance between metal wires, and the winding number of the metal wires on the buried pipes in each layer of the soil model are then calculated; and according to the calculated distance between metal wires, the plastic pipe is winded with the metal wires to obtain the composite buried pipe having optimum heat conductivity. The method can simply and effectively improve the heat exchange performance of the buried pipes and also can solve the problem of local heat accumulation since the thermophysical parameters of soil in the layers are different due to soil layering. The method is low in manufacturing cost, has extensive application range and can be extensively promoted.

Owner:CHONGQING JIAOTONG UNIVERSITY

PCB non-drilling-through solving method

InactiveCN109788647AReduce drilling depthReduce single work timePrinted circuit manufactureDrill cuttingsMultiple layer

The invention relates to a PCB non-drilling-through solving method. The method comprises the steps that S1, the thickness of a multilayer board is measured, and a drill bit with appropriate length isselected according to the thickness of the multilayer board; S2, the multilayer board is divided into multiple layers according to the thickness of the multilayer board for drilling, wherein the thicknesses of all the drilling layers are equal; S3, a drilling machine is used to perform drilling operation on the multilayer board, wherein in the drilling process, drilling operation is performed on the uppermost drilling layer according to data on a drilling tape first, and drilling cuttings in holes are cleared up after drilling is completed; and S4, drilling operation is performed on the next drilling layer according to the drilling tape, the drilling cuttings in the holes are cleared up after drilling is completed, and the process is repeated till the multilayer board is drilled through. Through the method, the situation that the drill bit is broken and cannot drill through the multilayer board can be effectively prevented.

Owner:GUANGDONG CHAMPION ASIA ELECTRONICS CO LTD

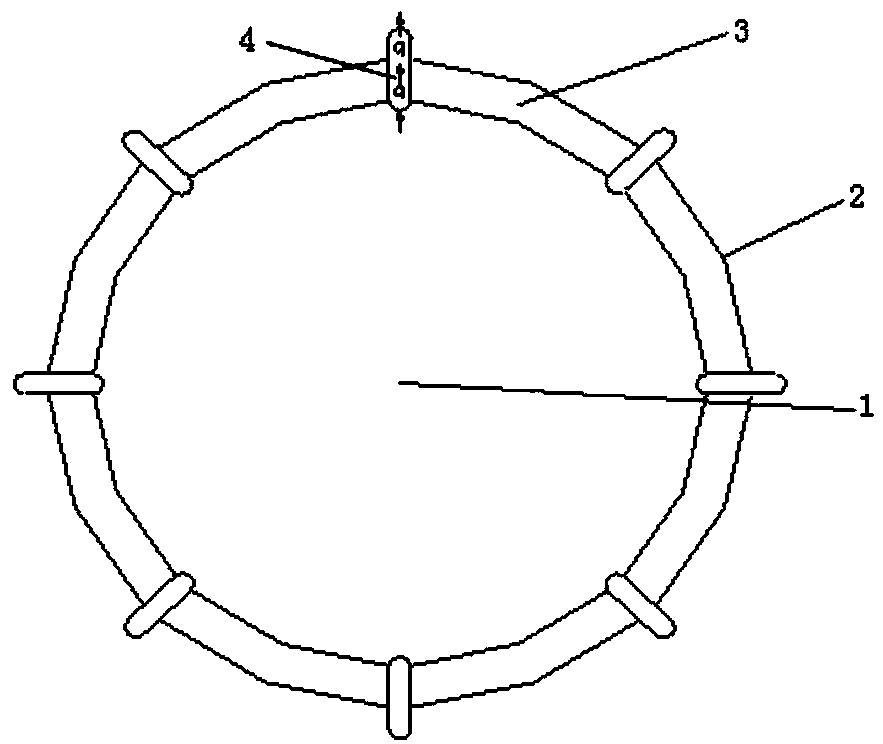

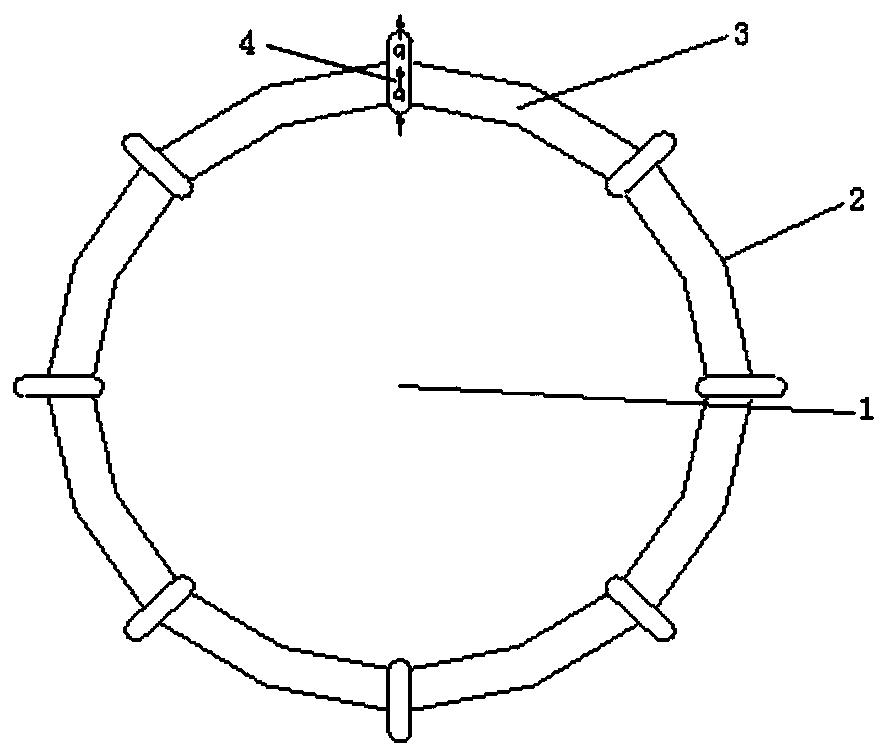

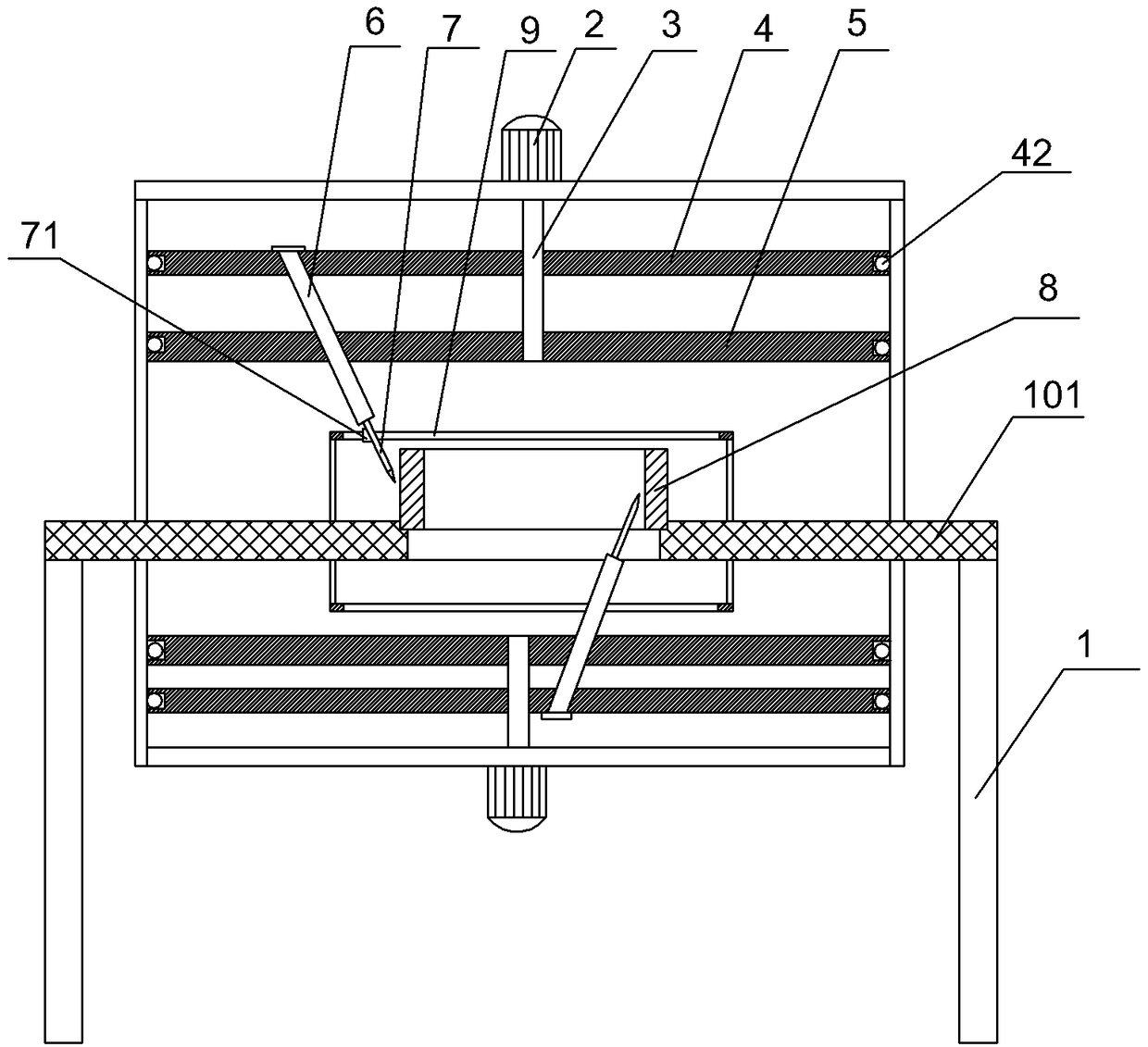

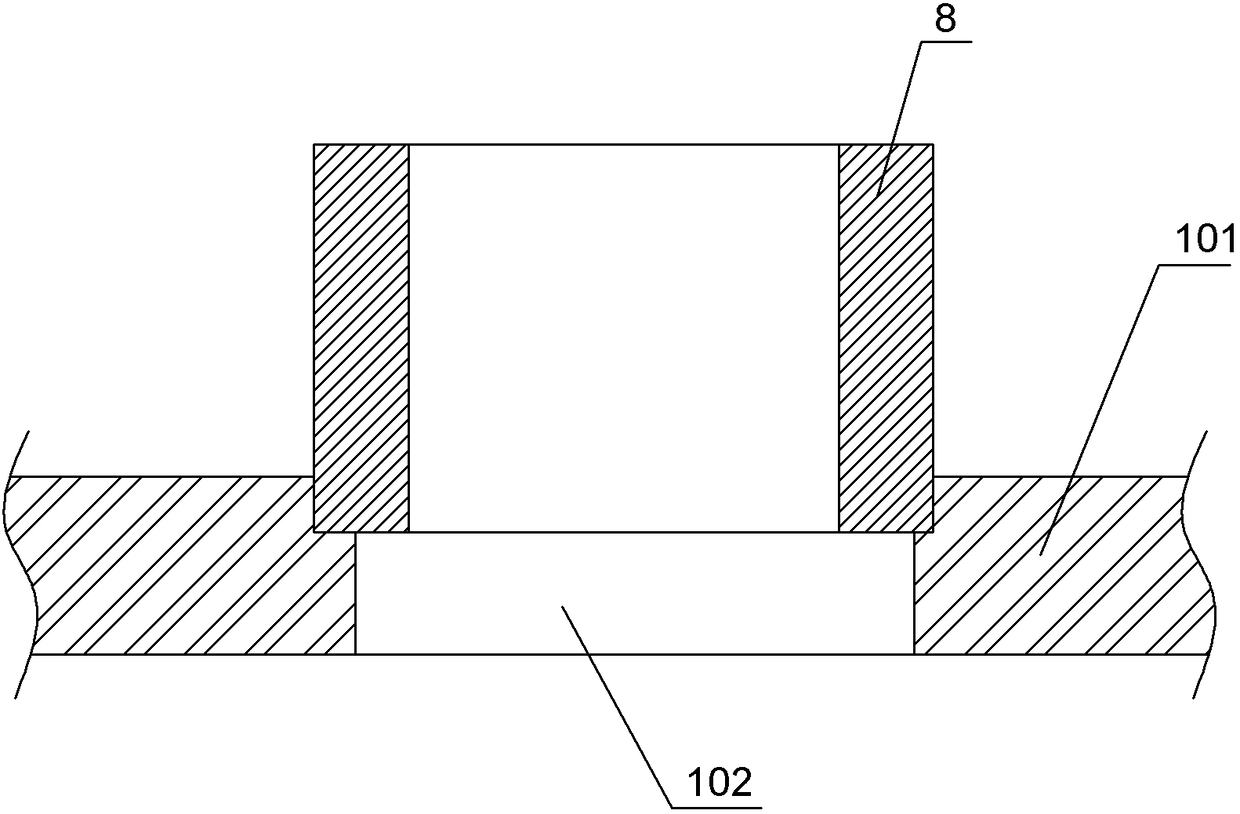

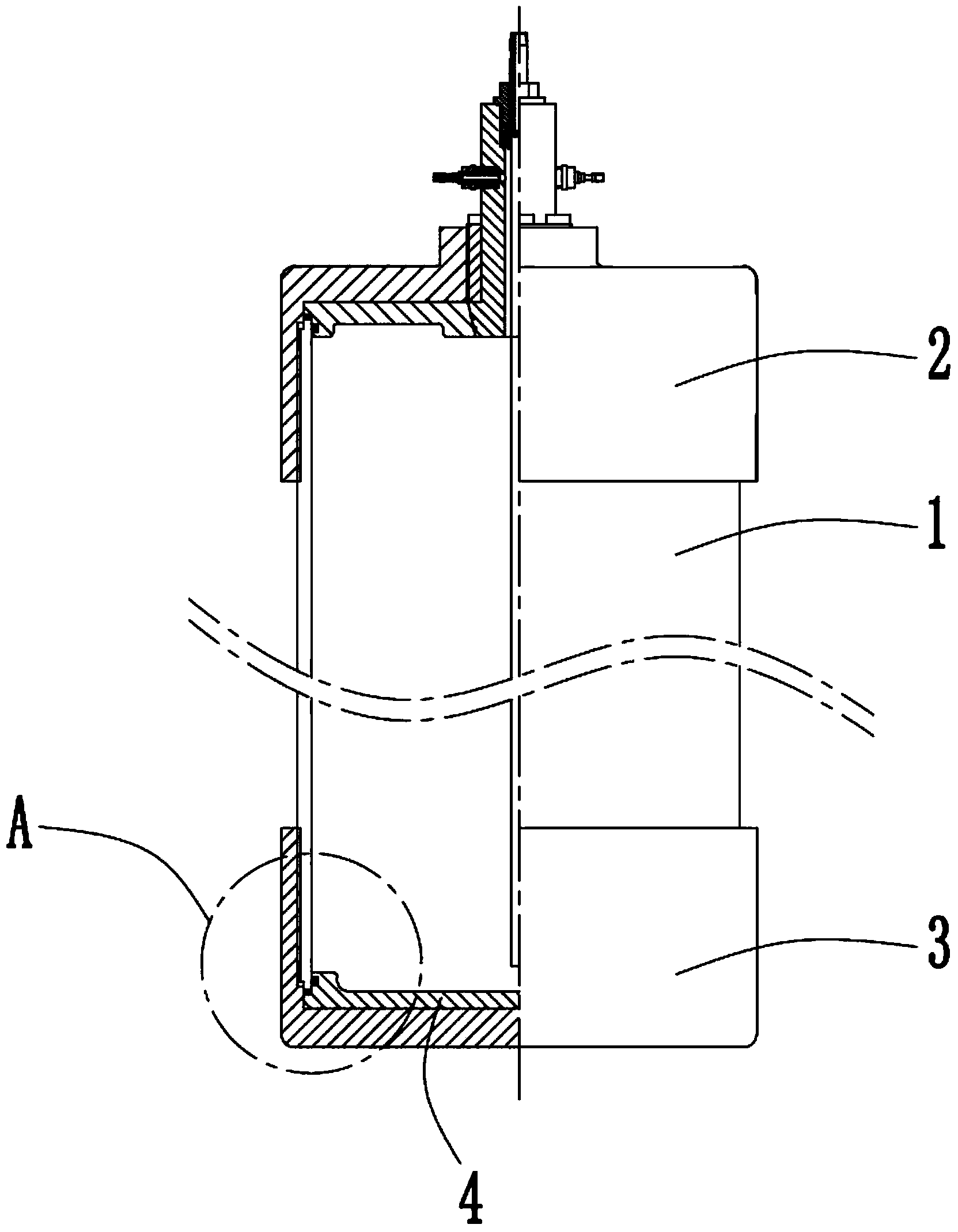

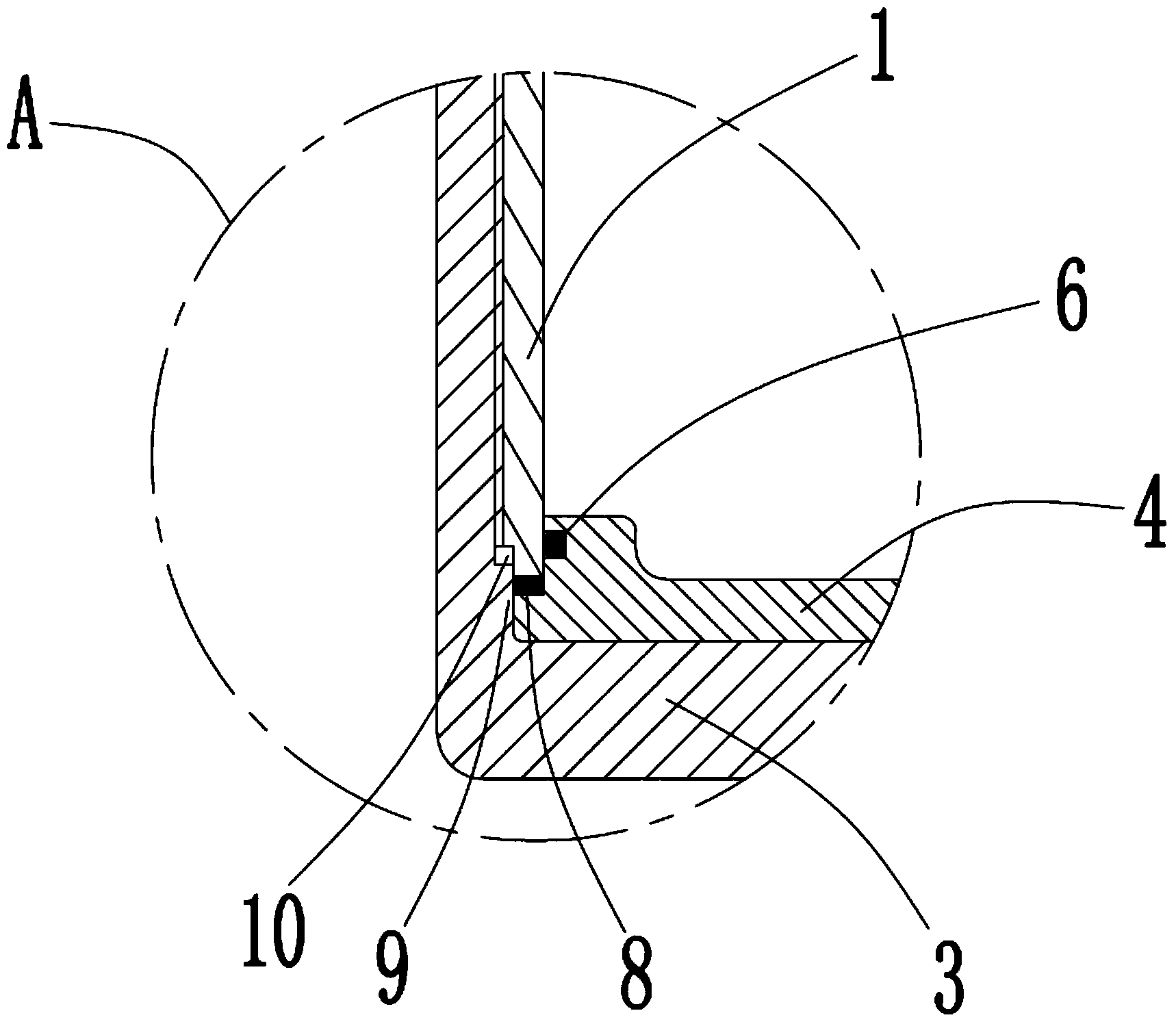

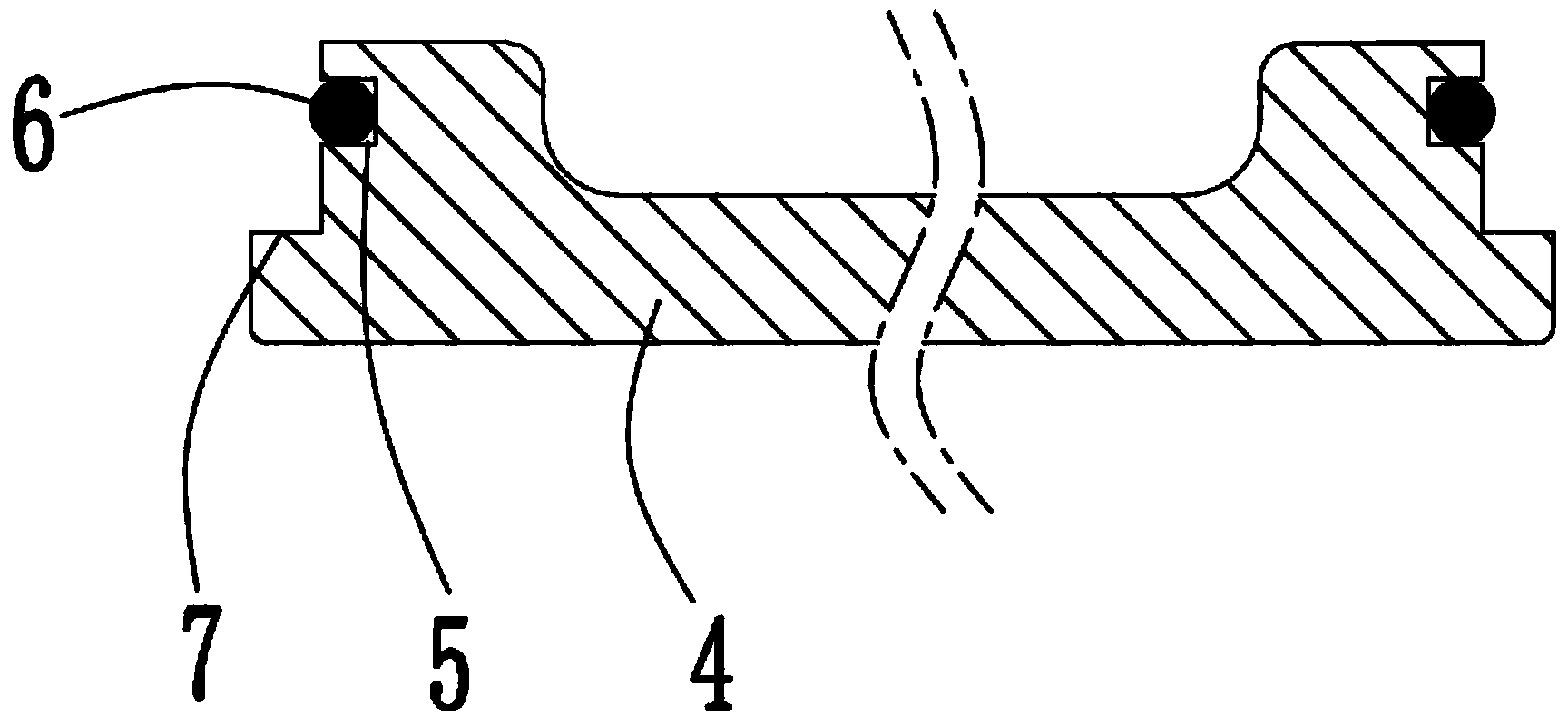

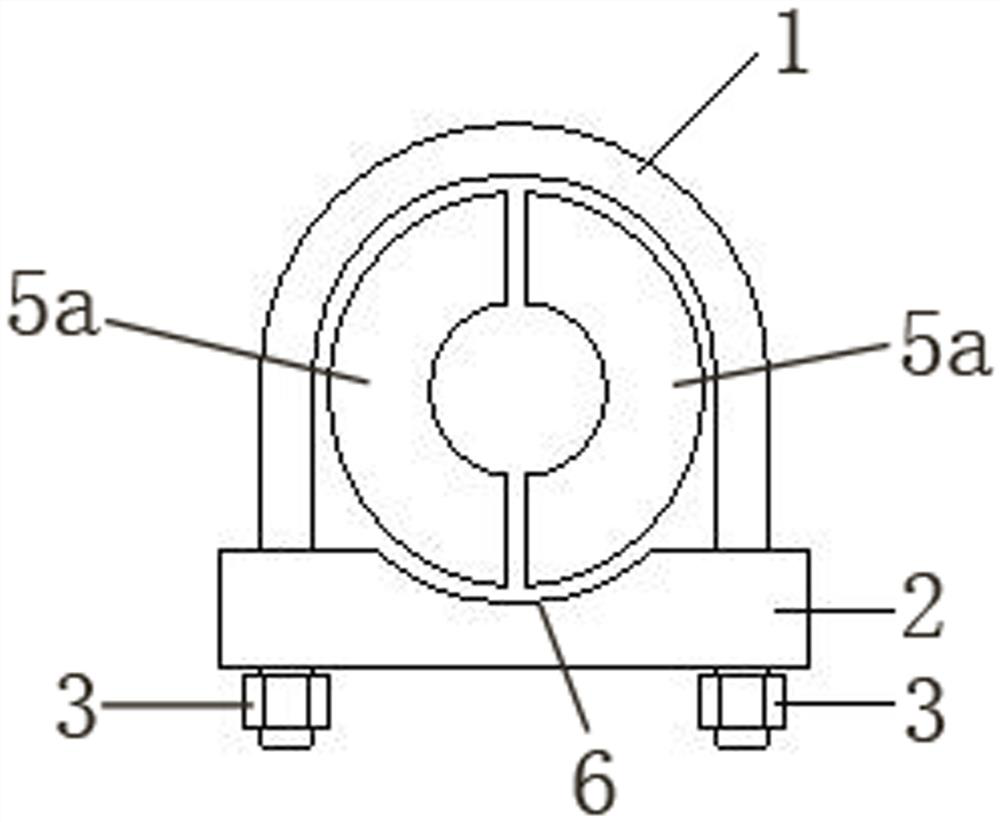

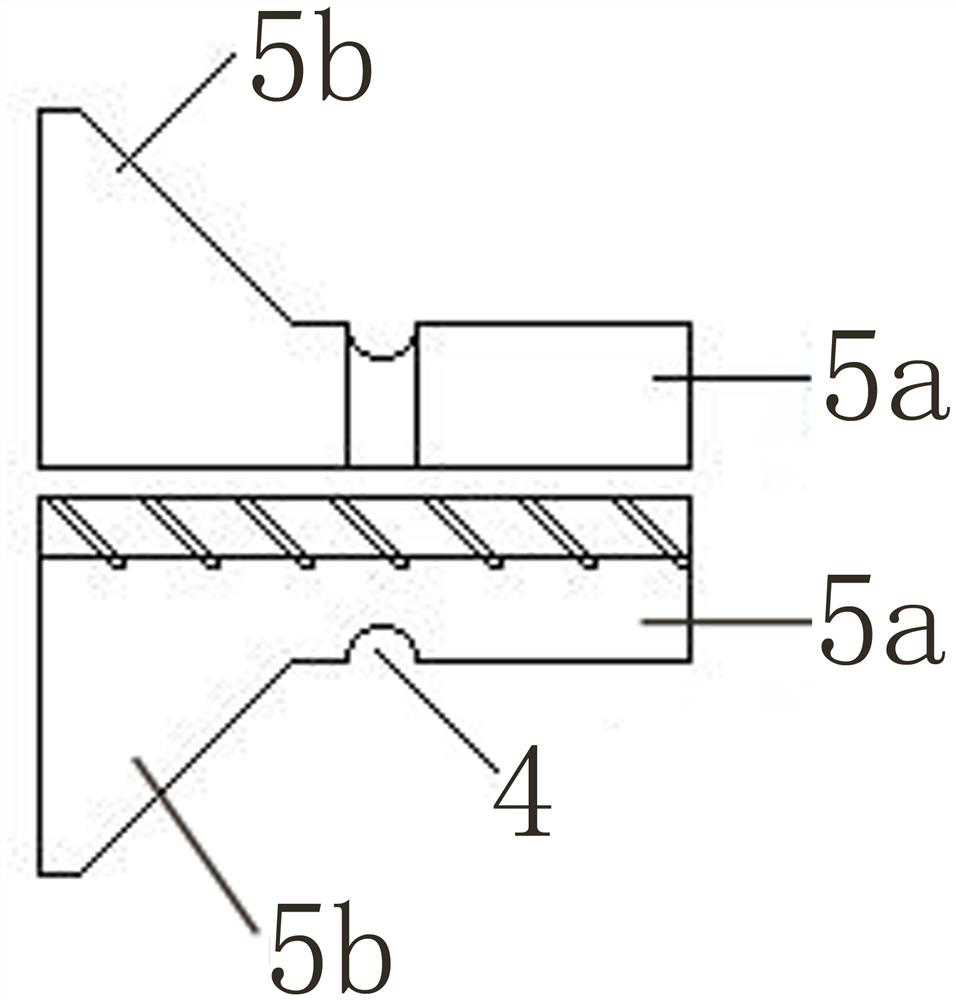

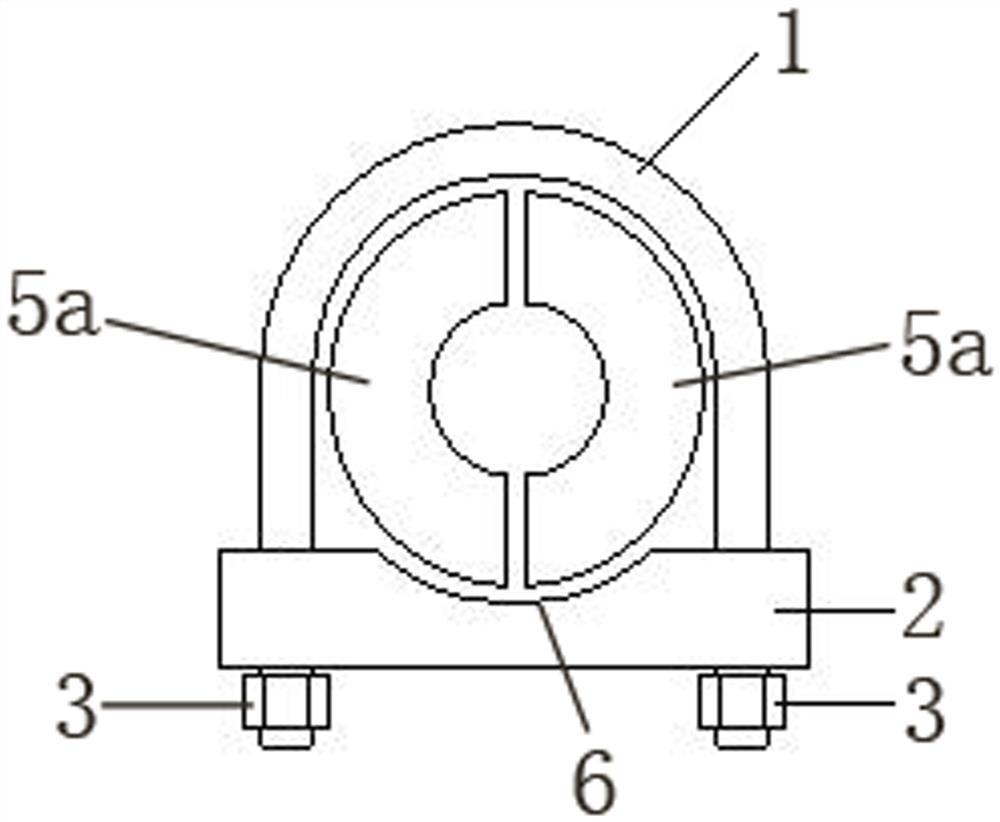

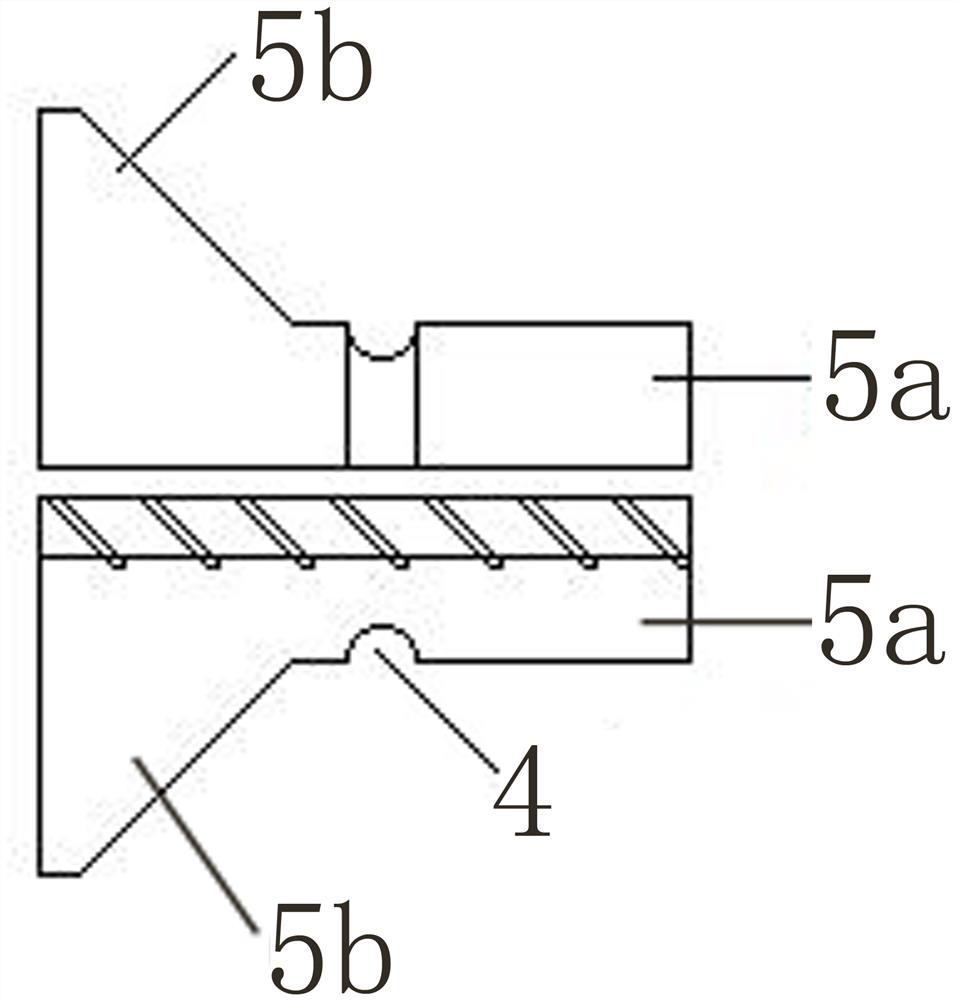

Bearing Ring Slant Oil Hole Processing Tooling

ActiveCN107511506BGuarantee directionReduce processing difficultyBearing componentsBoring/drilling machinesEngineeringMachine tool

The invention belongs to the technical field of bearing machining, and discloses a bearing ring inclined oil hole machining tool. The bearing ring inclined oil hole machining tool comprises a rack, a step hole is formed in a table top of the rack, the table top of the rack is an electromagnetic chuck, and a rotating mechanism and a drilling mechanism are arranged above and below the table top of the rack; the rotating mechanism comprises a first rotary disc and a second rotary disc which are rotationally connected to the rack, rotating centers of the first rotary disc and the second rotary disc are coincident with a center shaft of the step hole, a first through hole is formed in the first rotary disc, a second through hole is formed in the second rotary disc, and the turning radius of the first through hole is larger than the turning radius of the second through hole; the drilling mechanism comprises a rotating rod and electric drills, the two electric drills are staggered in the circumferential direction of a bearing ring, and the sum of the drilling depths of the two electric drills is equal to the depth of a bearing ring inclined oil hole; and the rack is further provided with a rotating parking mechanism which comprises a plurality of microswitches and trigger blocks. When the bearing ring inclined oil hole machining tool is used for machining the bearing ring inclined oil hole, positioning is accurate, and the machining difficulty is small.

Owner:重庆市合川区云天机械制造有限公司

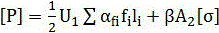

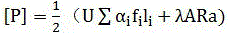

Calculation method for allowable single pile bearing capacity of following drilling method railway tubular piles

InactiveCN105926689AIncreased allowable bearing capacity of single pileShorten pile lengthFoundation testingSocial benefitsEconomic benefits

The invention relates to the field of railway bridges, in particular to a calculation method for the allowable single pile bearing capacity of following drilling method railway tubular piles. The calculation method is characterized by at least including the steps of calculating the allowable bearing capacity of each of soil around the tubular piles, soil around expansion head piles and soil on the bottoms of hole expansion piles, and combining the allowable bearing capacity for obtaining the allowable single pile bearing capacity of the following drilling method railway tubular piles. The calculation method has the advantage of realizing calculation of the allowable single pile bearing capacity of the following drilling method tubular piles. Compared with bored piles, the tubular piles have the advantages that the allowable single pile bearing capacity of the tubular piles can be effectively increased through the method, the pile length can be greatly reduced, the drilling depth can be reduced, the construction progress can be quickened, and the foundation construction period can be shortened. The economic benefit and the social benefit are remarkable.

Owner:CHINA RAILWAYS CORPORATION +1

Large-diameter gas storage well

InactiveCN103591451AShorten the lengthMeet the requirements of large gas storage capacityNon-pressured vesselsPressure vesselsNational standardYard

The invention discloses a large-diameter gas storage well which comprises a shaft, wherein the outer diameter of the shaft is greater than 273.1mm. The well employs the larger-diameter shaft; the diameter of the shaft exceeds the maximum shaft diameter of 273.1mm in the current national standards; requirements on high gas storage capability are met; when the gas storage capability is definite, the shaft is shortened, so that the whole gas storage well can be fabricated and assembled in a plant and then transported to a site for mounting; the assembly quality is ensured; an assembly yard is not required to be arranged on the site; since the shaft is short, the drilling depth is reduced; and the cost and the construction period are further saved.

Owner:SICHUAN PETROLEUM & NATURAL GAS SCI & TECH CORP

Semiconductor structure

InactiveUS10090256B2Improve reliabilityEffectively reduces diameterSemiconductor/solid-state device detailsPrinted circuit aspectsSemiconductor structureMaximum diameter

A semiconductor structure includes an insulating layer, a plurality of stepped conductive vias and a patterned circuit layer. The insulating layer includes a top surface and a bottom surface opposite to the top surface. The stepped conductive vias are disposed at the insulating layer to electrically connect the top surface and the bottom surface. Each of the stepped conductive vias includes a head portion and a neck portion connected to the head portion. The head portion is disposed on the top surface, and an upper surface of the head portion is coplanar with the top surface. A minimum diameter of the head portion is greater than a maximum diameter of the neck portion. The patterned circuit layer is disposed on the top surface and electrically connected to the stepped conductive vias.

Owner:IBIS INNOTECH

Backfill material for buried pipe of ground-source heat pump system, and backfilling method thereof

InactiveCN103396036AImprove heat transfer efficiencyImprove thermal conductivityEmbankmentsHeat conductingSuper absorbent

The invention discloses a backfill material for buried pipe of ground-source heat pump system and a backfilling method of the backfill material. The backfill material is prepared by steps of mixing normal sands and non-degradable polymer type polyacrylic acid series super absorbent resin according to a volume ratio of 10:1-15:1, stirring and standing. The method comprises the following steps of: firstly determining the type of normal sands according to the type of rock and soil body of a soil source, then, according to the moisture content and the thermal conductivity of the soil source, mixing the normal sands and the non-degradable polymer type polyacrylic acid series super absorbent resin according to the volume ratio of 10:1-15:1, stirring and standing, and finally backfilling. The backfill material provided by the invention has short thermal storage time and low heat transfer time coefficient, so that the heat conducting effect of the backfill material is improved. According to the method, when the normal sands are mixed with the super absorbent resin, the water penetrability is improved, the mobility of water in gaps of sands is promoted, and the heat transfer efficiency of the backfill material is enhanced.

Owner:HUNAN ZHONGBO ENERGY TECH

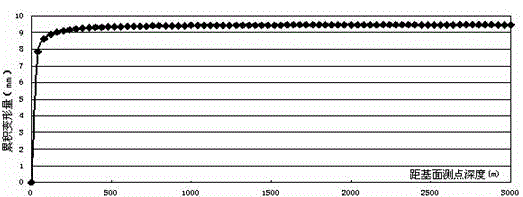

Method for measuring horizontal displacement of stratum by using movable inclinometer and movable inclinometer

InactiveCN105444738BSimple structureEasy to operateSurveying instrumentsIncline measurementHydrologyGps positioning

The invention discloses a method for measuring horizontal displacement of a stratum through a movable inclinometer. The movable inclinometer is used for measuring total horizontal displacement and horizontal shift displacement, and the horizontal displacement of the stratum is calculated according to measurement numerical values. The invention further discloses the movable inclinometer. The movable inclinometer comprises a measurement reader, a GPS position finder, an inclinometer tube, an inclinometer cable, a cable support and a GPS position finder connecting sleeve. The measurement reader is located on one side of the inclinometer tube, the measurement reader and the inclinometer tube are independently arranged, the inclinometer cable is installed on the cable support, the GPS position finder connecting sleeve is fixed to the upper end of the inclinometer tube, one end of the inclinometer cable penetrates through the GPS position finder connecting sleeve and is connected with a movable probe in the inclinometer tube, at least one GPS position finder is arranged on the GPS position finder connecting sleeve, and the cable support is provided with Bluetooth used for transmitting signals received by the inclinometer cable to the measurement reader. By means of the method for measuring the horizontal displacement of the stratum through the movable inclinometer and the movable inclinometer, the drilling depth can be effectively reduced, economic cost can be reduced, the measurement data can better conform to field reality, and a more reliable base is provided for slope and foundation pit retaining and protection construction.

Owner:SHANDONG UNIV OF SCI & TECH

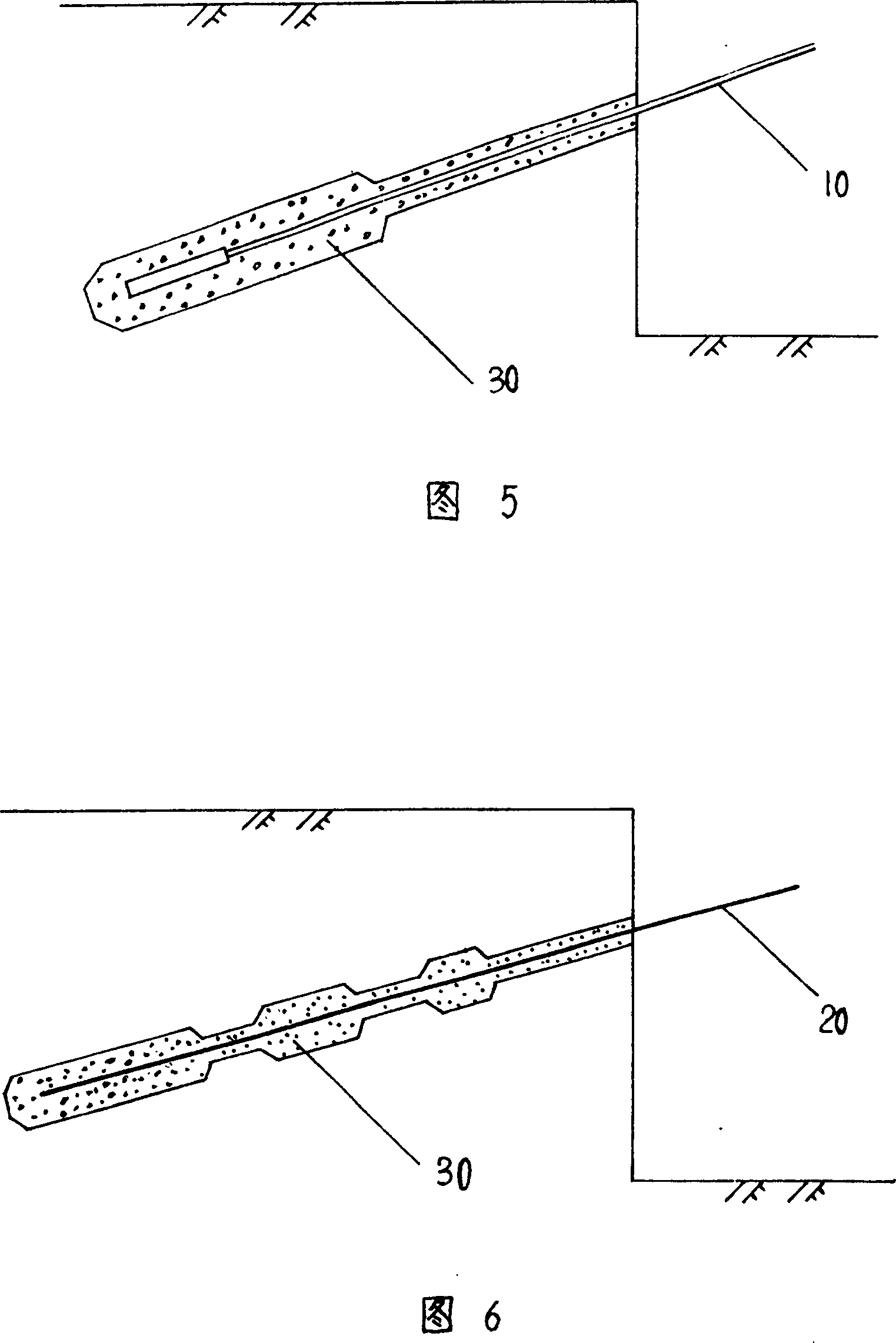

Construction method for improving pulling resistance of twisted steel anchor rod

ActiveCN112431199AImprove pullout resistanceIncrease resistance areaExcavationsBulkheads/pilesArchitectural engineeringRebar

The invention particularly relates to a construction method for improving the anti-pulling performance of a twisted steel anchor rod. The problems that when an existing construction method of the twisted steel anchor rod is applied, the length of an anchoring section exceeds the actual requirement by a large amount, resources are wasted, and labor and time are wasted are solved. The construction method for improving the anti-pulling performance of the twisted steel anchor rod comprises the following steps that S1, a plurality of vertical rib column grooves are vertically formed in the wall ofsurrounding rock; S2, a plurality of anchor rod holes are drilled in the bottom wall of each vertical rib column groove; S3, a plurality of anti-pulling resistance blocks are installed on the anchoring section of each twisted steel anchor rod; S4, the twisted steel anchor rods are placed into the anchor rod holes, and cement mortar is poured into the anchor rod holes; S5, steel bars of vertical rib columns and panels are bound, formwork erecting is conducted, and concrete is poured; and S6, the ends of the twisted steel anchor rods are sealed and anchored on the outer sides of the panels. Theconstruction cost is reduced, the construction progress is accelerated, and the method can be suitable for stone excavation high slope stability protection engineering and can be applied and popularized in similar engineering.

Owner:中铁十七局集团第五工程有限公司

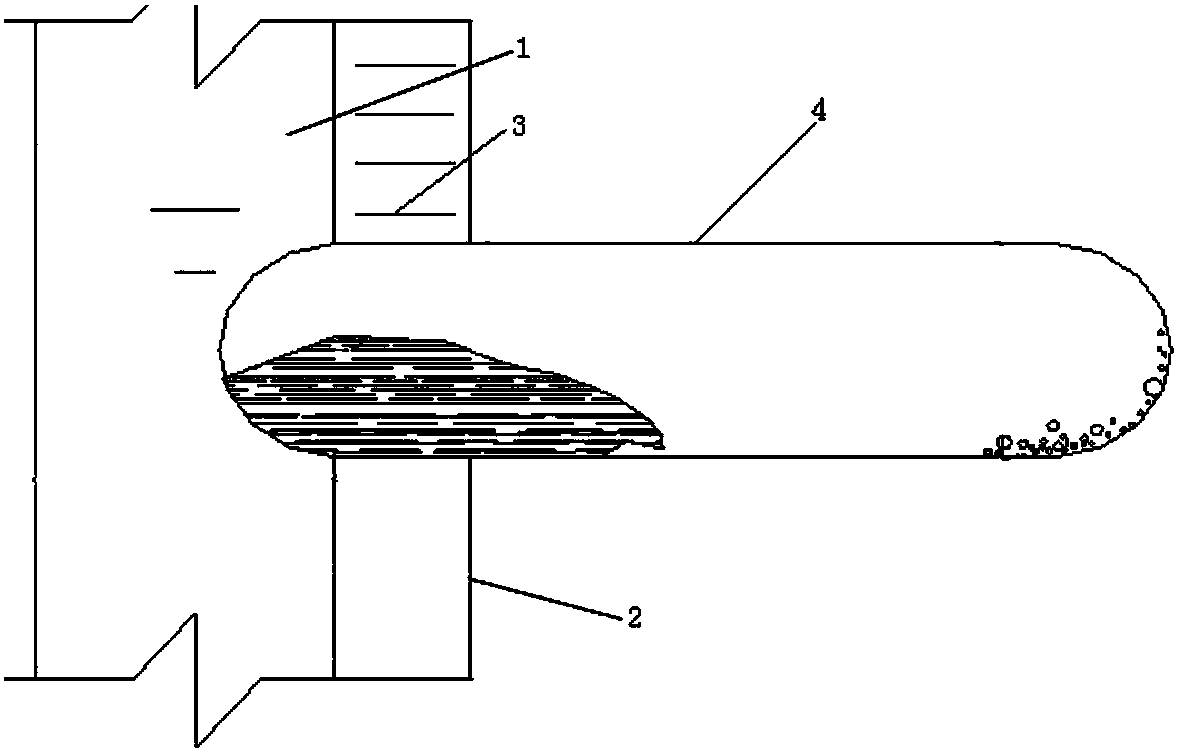

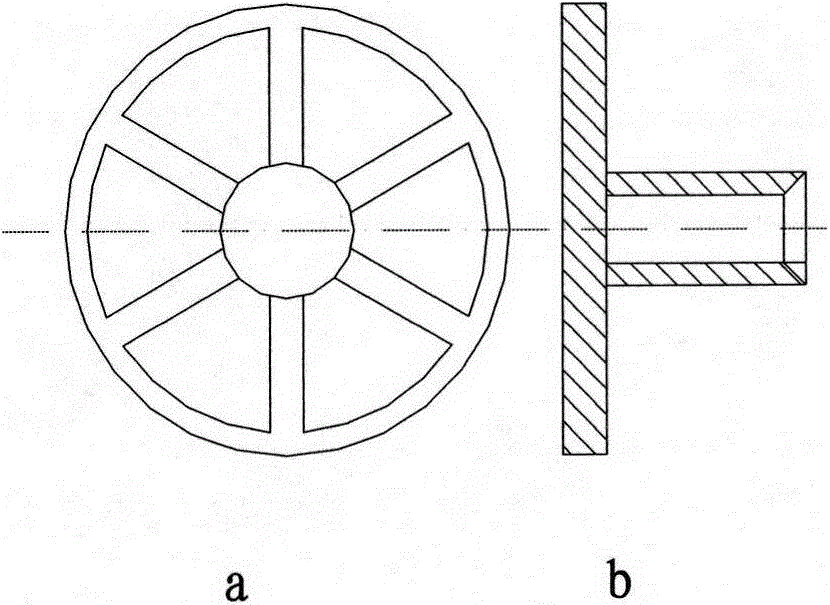

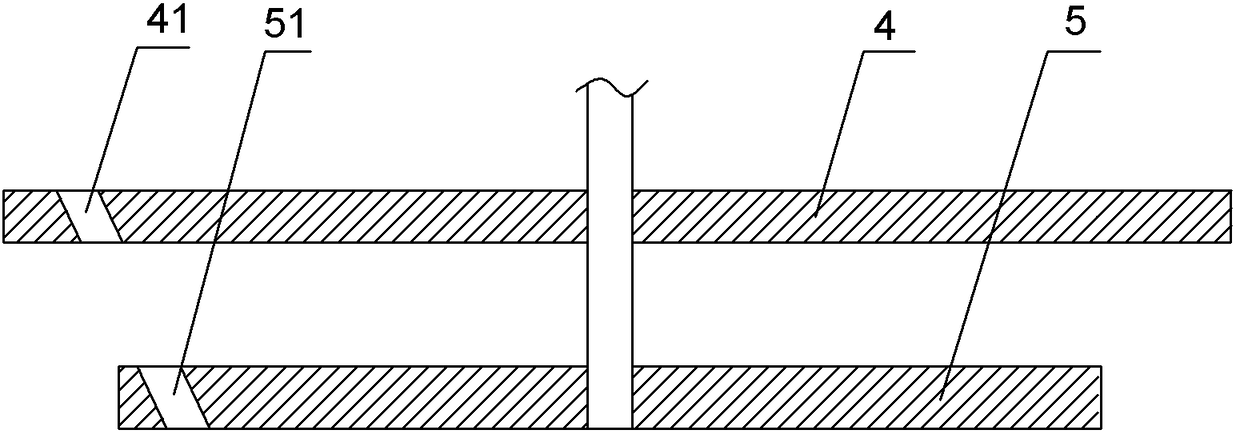

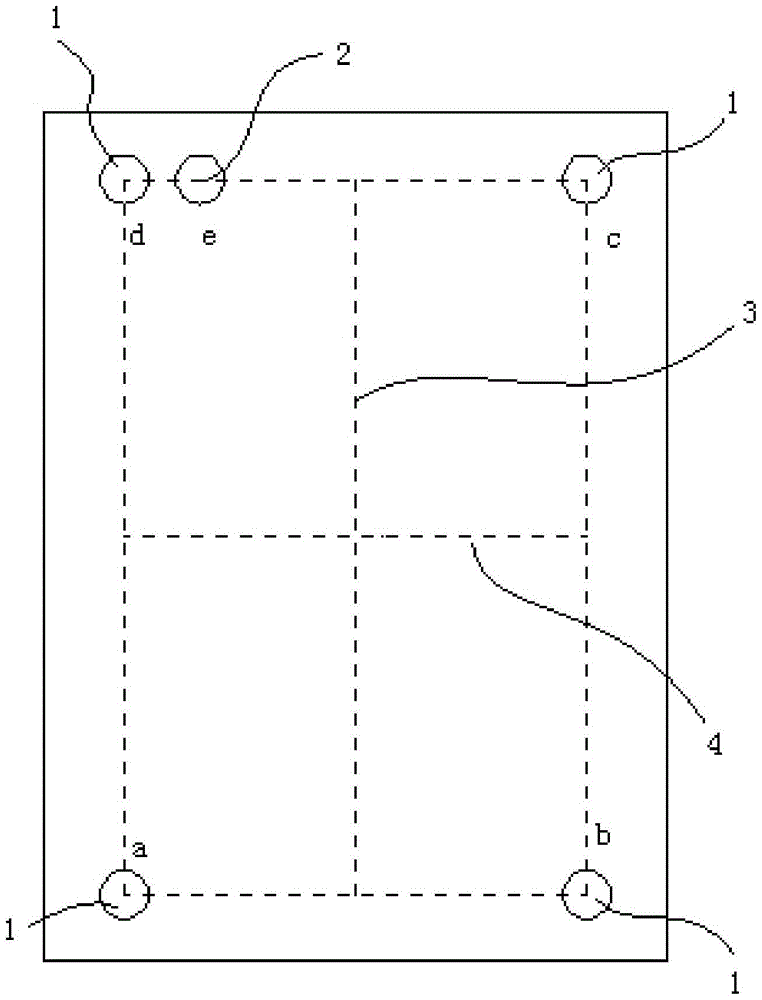

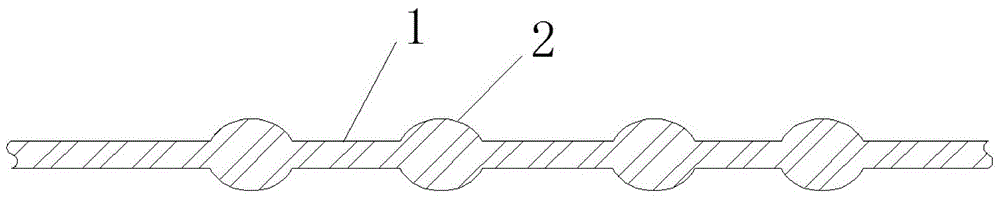

Drilling method of circuit board

ActiveCN103752882BReduce drilling depthReduce depthPrinted circuit manufactureDiameter ratioHole drilling method

A drilling method for a circuit board, comprising the following steps: arranging positioning targets (1) and a direction target (2) on a circuit board, and drilling positioning holes at the positioning targets (1) and a direction hole at the direction target (2), using the direction hole to identify the direction of the circuit board; drilling respectively from the front side and the rear side of the circuit board, so that the drill holes of the front side and the rear side form through holes. The present drilling method can achieve drilling of a circuit board with a high thickness to diameter ratio, and can obtain high accuracy hole positions.

Owner:GUANGZHOU FASTPRINT CIRCUIT TECH +2

A Construction Method for Improving the Pullout Performance of Threaded Reinforcement Anchor

ActiveCN112431199BImprove pullout resistanceIncrease resistance areaExcavationsBulkheads/pilesRebarCement mortar

Specifically, the invention is a construction method for improving the pullout resistance of threaded steel anchors, which solves the problem that the length of the anchoring section exceeds the actual requirement when the existing construction method for threaded steel anchors is applied, resulting in waste of resources, labor and time. A construction method for improving the pullout resistance of threaded steel bar bolts, the method comprising the following steps: S1: vertically opening several vertical rib column grooves on the surrounding rock wall; Drill several anchor holes; S3: install several pullout resistance blocks on the anchoring section of each threaded steel anchor; S4: put the threaded steel anchor into the anchor hole, and pour cement mortar into the anchor hole ; S5: Bind the steel bars of the vertical rib column and the panel, set up the formwork, and pour the concrete; S6: Seal the end of the threaded steel bar anchor on the outside of the panel. The invention reduces the construction cost and speeds up the construction progress, is applicable to the high slope stability protection project of stonework excavation, and can also be popularized and applied in similar projects.

Owner:中铁十七局集团第五工程有限公司

Angle-adjustable engineering geological drilling rig

ActiveCN103452479BEasy to moveGuaranteed stabilityDerricks/mastsDirectional drillingWinding machinePunching

Owner:HUNAN CHENZHOU MINING CO LTD

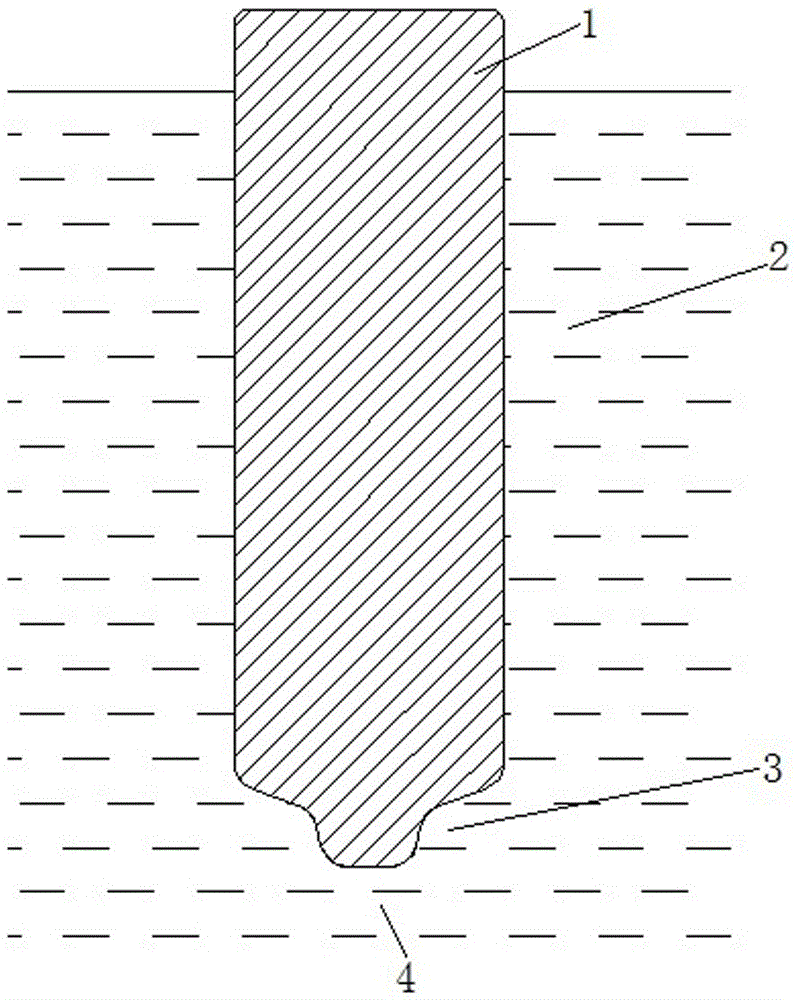

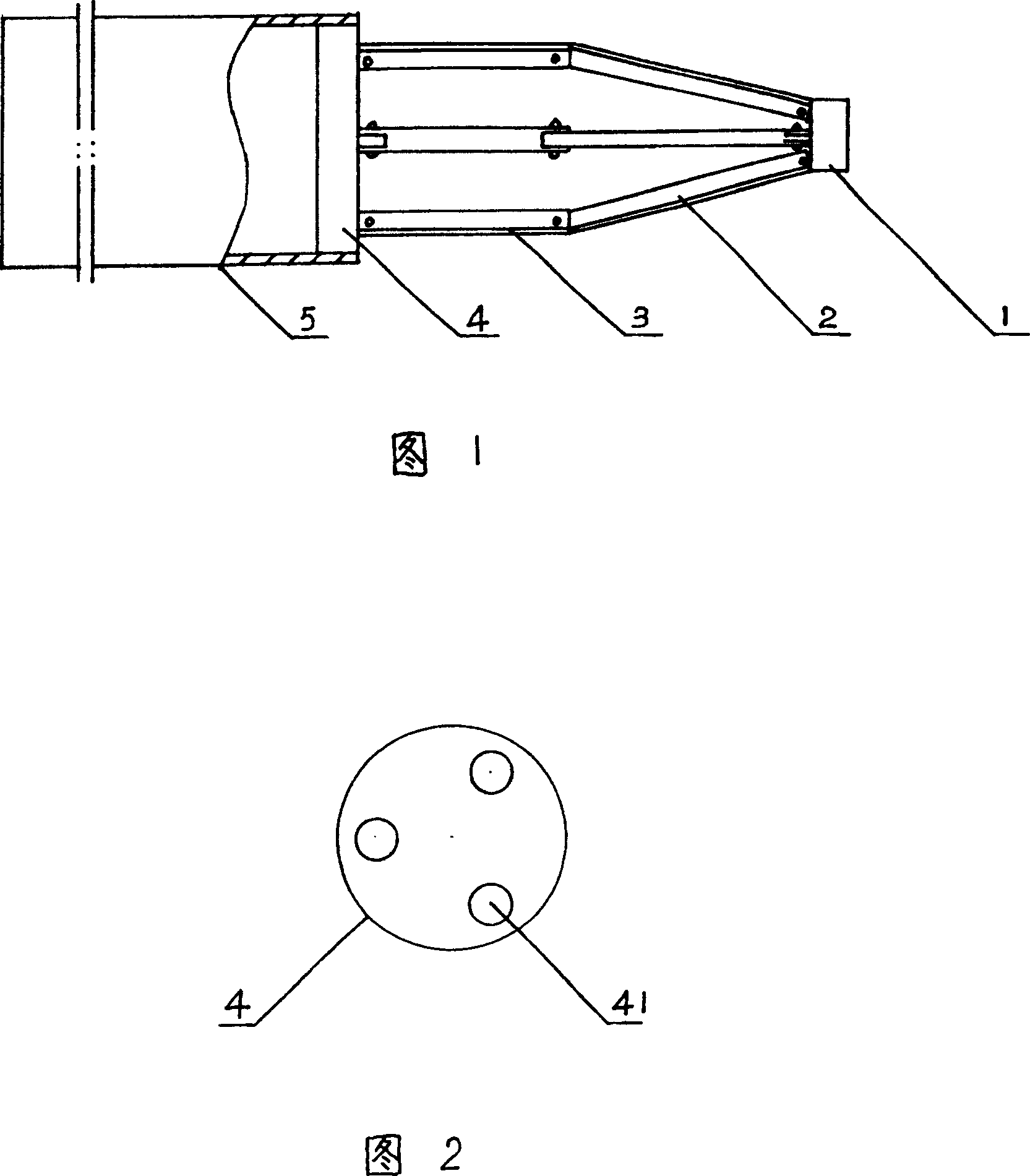

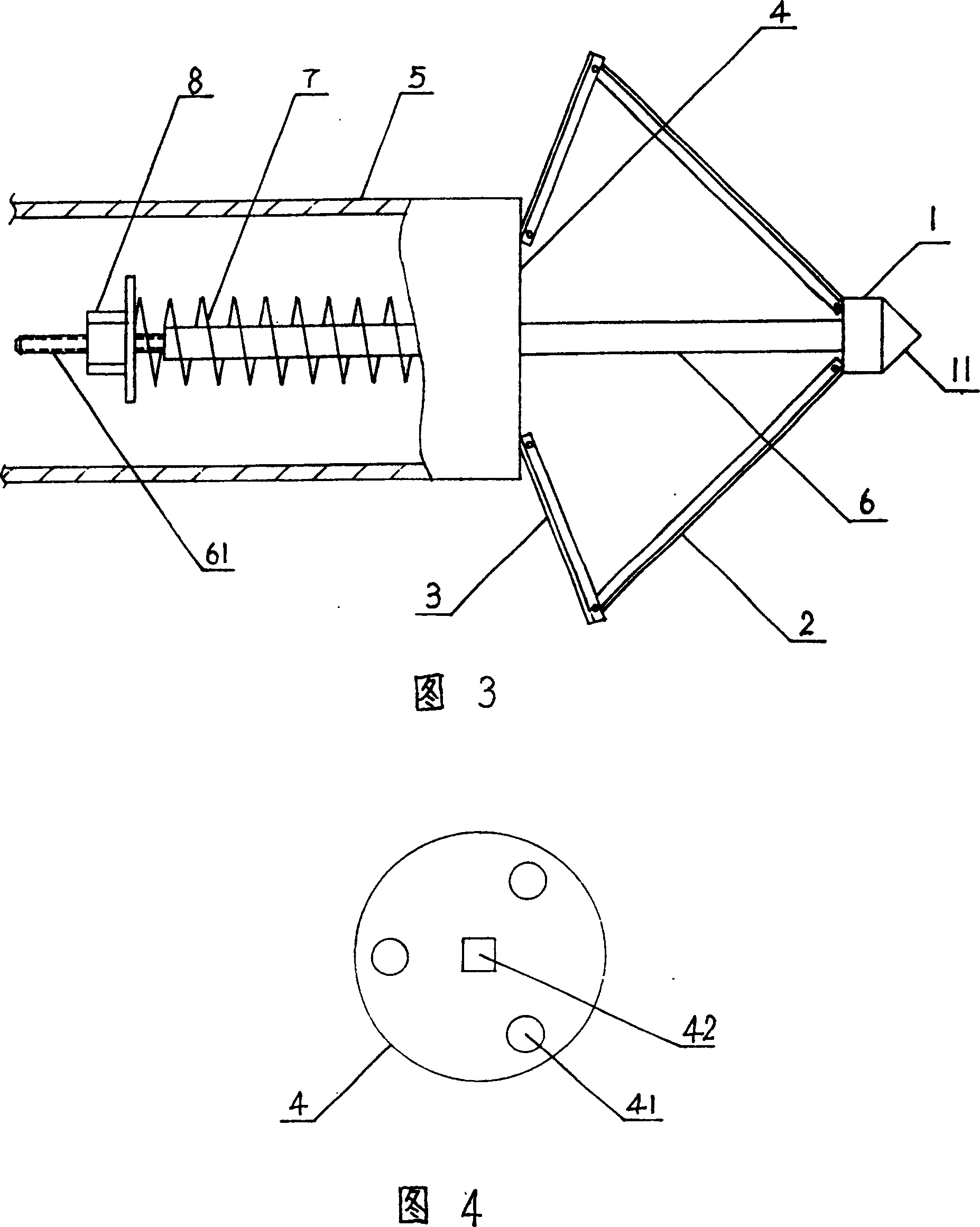

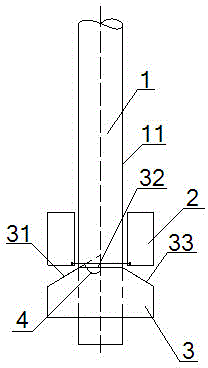

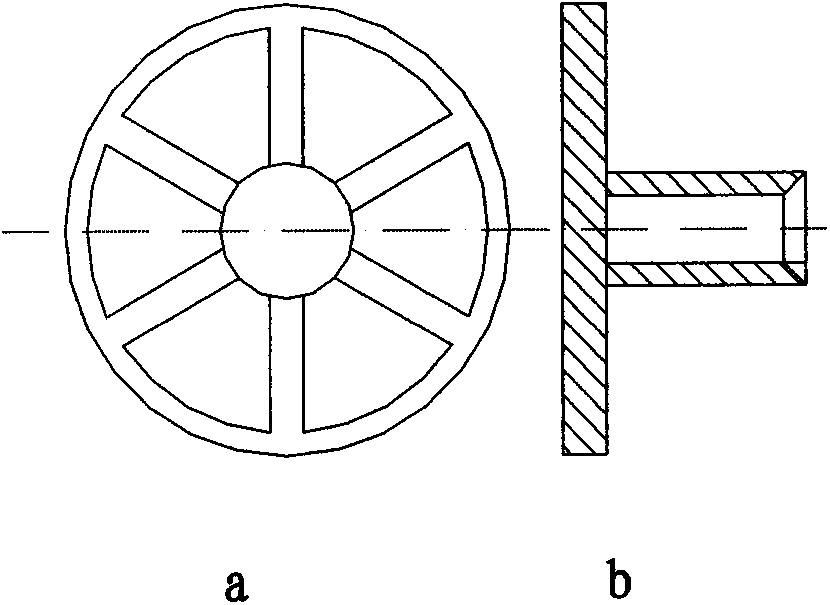

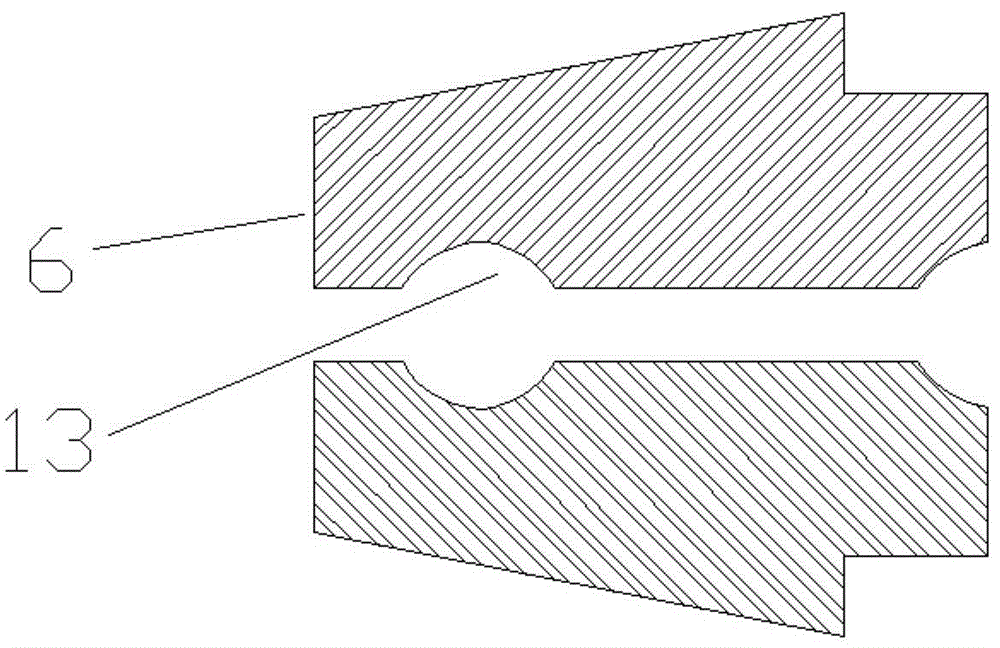

Drill expanding aiguille of anchor shaft, anchor cable, stake and drill expanding technology

The present invention discloses a reaming bit for anchor rod, anchor rope and pile in civil engineering and its reaming method. It is aimed at providing a reaming bit for anchor rod, anchor rope and pile in civil engineering which has firm structure, extensive application range and easy operation and maintenance. Said bit is characterized by that between end shaft sleeve and rear shaft sleeve of the bit the front and rear drill blades are uniformly distributed, hinge and arranged, and centrifugal force produced by rotating drilling rod and pressing force subjected by end shaft sleeve can make the bit which is rotated for drilling hole be outwards expanded so as to obtain the goal of reaming hole.

Owner:陆观宏

Wedge type inner anchor head

Owner:WUDA JUCHENG STRUCTURE CO LTD

Handheld back holt punching machine

InactiveCN108422563ASimple and reasonable structureReduce manufacturing costWorking accessoriesStone-like material working toolsEngineeringDrill bit

The invention discloses a handheld back bolt punching machine. A drilling angle die machine rotates to drive a drill bit to rotate, a limiting knob is rotated, the distance between a limiting block atthe lower end of a limiting screw and a punching face is adjusted, and therefore the punching depth is adjusted. A drilling connecting rod handle is downwards pressed, the drill bits conducts punching, and a hole expanding motor is a speed reducing motor. An upper oblique cutting block is driven, the engagement depth of the upper oblique cutting block and a lower oblique cutting block determinesthe deflection range, and the deeper the engagement is, the smaller the deflection is. The deflection hole expanding technology is completed by adjusting the engagement depth of the upper oblique cutting block and the lower oblique cutting block, the limiting depth of an adjusting rod is adjusted by rotating an adjusting screw, and the adjusting screw is locked through a locking knob after adjustment is completed. A deflection connecting rod handle is downwards pressed so that the engagement depth of the upper oblique cutting block and the lower oblique cutting block can be reduced, the drillbit is driven to do deflection movement, and the hole expanding effect is achieved. The engagement depth of the upper oblique cutting block and the lower oblique cutting block is adjusted through thedeflection connecting rod handle, and therefore the function of controlling the hole expanding diameter is achieved.

Owner:司索智能工程(上海)有限公司

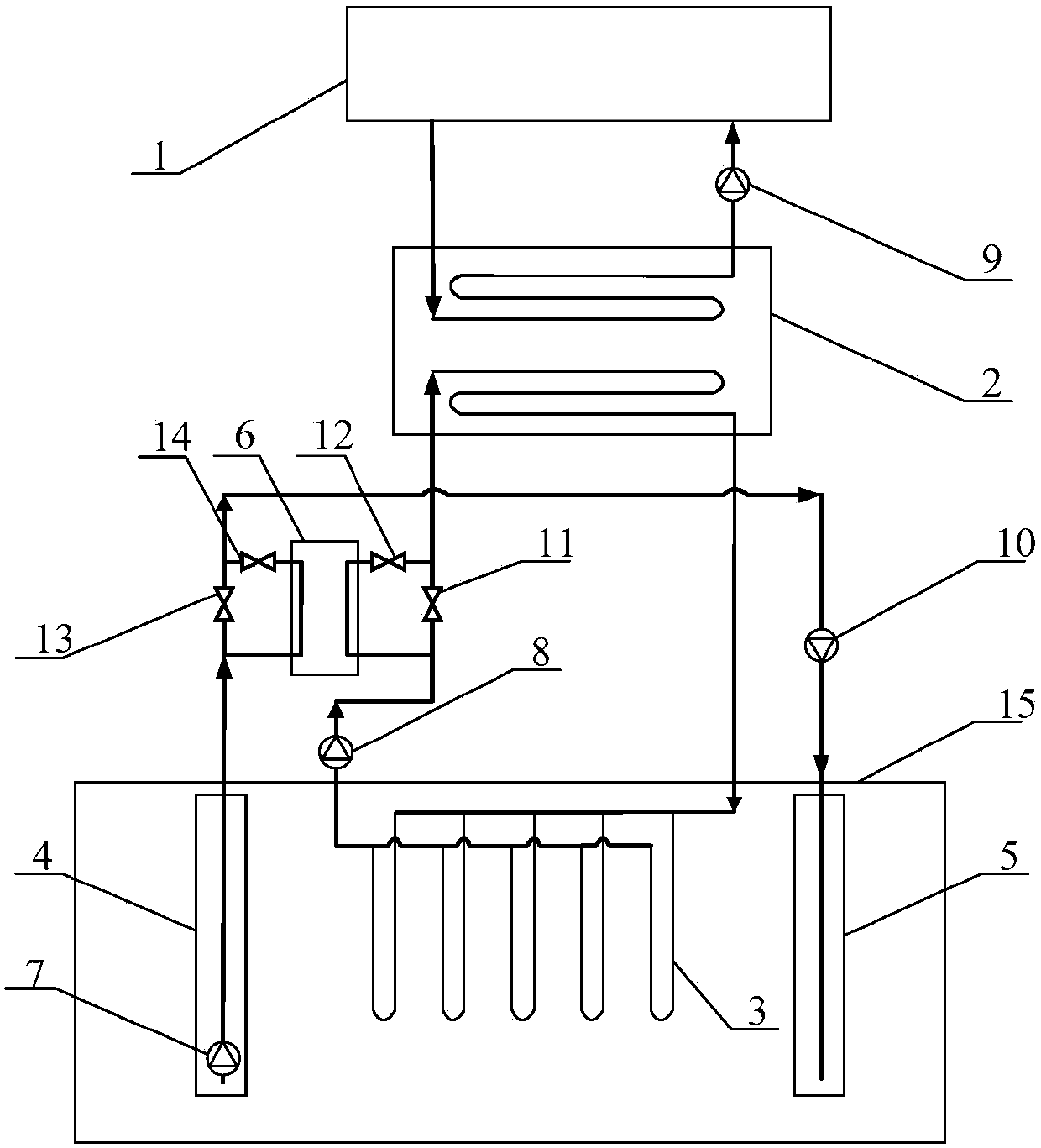

Coupling saltwater layer forced convection well type soil source heat pump system and its operation method

ActiveCN105865085BTroubleshoot Thermal ImbalancesIncrease heat exchange intensityHeat pumpsEfficient regulation technologiesOperation modeForced convection

The invention provides a coupled saline water layer forced convection well type ground-source heat pump system and an operation method. The heat pump system forms a heat pump unit user side heat supply and cool supply circulation loop, a heat pump unit ground-source side heat supply and cool supply circulation loop, and a saline water layer pumping and injection well forced convection circulation loop, and various operation modes are achieved through the operation method. The coupled saline water layer forced convection well type ground-source heat pump system and the operation method have the effects that the heat exchange intensity of a buried pipe is increased, the phenomena of heat short-circuiting and heat disturbance of a buried pipe heat exchanger are avoided, and the problem of soil heat imbalance caused by seasonal disproportion of building loads in the low laying land around the Bohai Sea is solved. A heat exchanger is additionally arranged in a saline water circulation system and conducts heat exchange with circulation solutions in the buried pipe, and the building load peak is effectively adjusted while the underground heat exchange of the buried pipe is enhanced. The application fields of the ground-source heat pump system as shallow geothermal energy in improvement and modification of environment-friendly buildings are developed, and then energy supply and carbon dioxide emission of the buildings are reduced.

Owner:TIANJIN CHENGJIAN UNIV

Construction technology of pre-fixed board system wall insulation system

ActiveCN104975658BShorten the lengthReduce drilling depthHeat proofingArchitectural engineeringInsulation system

Owner:JIANGSU WONIUSHAN THERMAL INSULATION & WATERPROOF TEHNOLOGY

Partially upset high-strength steel wire and its preparation method

InactiveCN105013984BHigh strengthImprove corrosion resistanceBuilding reinforcementsUltimate tensile strengthPrecast concrete

Owner:ZHENGZHOU UNIV

A monitoring method for dam foundation deformation depth

ActiveCN103821187BMonitor Deformation DepthDeformation depth implementationFoundation testingMeasuring instrumentDeformation monitoring

Owner:POWER CHINA KUNMING ENG CORP LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com