Handheld back holt punching machine

A punching machine, handheld technology, applied in the direction of work accessories, manufacturing tools, stone processing equipment, etc., can solve the problem of difficulty in adjusting and changing the drilling depth, the size of the support hole, uneven drilling accuracy, and the roundness of the drilling Large deviation and other problems, to achieve the effect of complete functions, easy operation and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

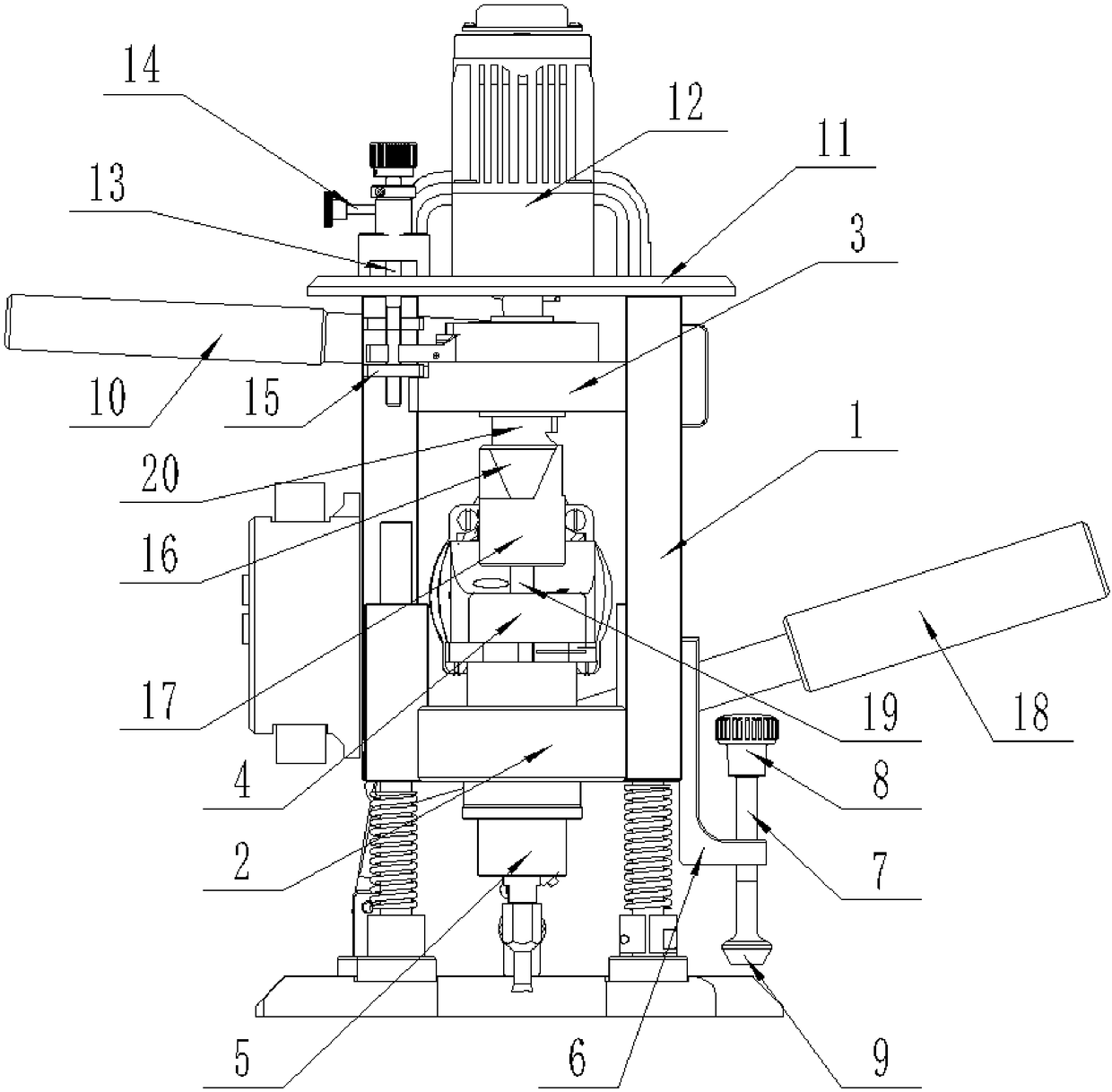

[0015] Such as figure 1 As shown, this specific embodiment adopts the following technical solutions: a hand-held back bolt punching machine, including a bracket 1, a lower slider 2, an upper slider 3, a drilling angle mold machine 4, a drill bit 5, and an L-shaped frame 6 , limit screw 7, limit knob 8, limit block 9, yaw link handle 10, top cover 11, drilling motor 12, adjusting screw 13, locking knob 14, limit rod 15, upper oblique cutting block 16. The lower oblique cutting block 17, the drilling link handle 18, the power transmission rod 19 and the boring driving rod 20; the inner lower end of the support 1 is slidingly connected with a lower slider 2; the lower slider 2 is connected with A drilling link handle 18; the upper end of the bracket 1 is slidably connected with an upper slider 3; the upper slider 3 is connected with a yaw link handle 10; the top of the lower slider 2 is fixed A drilling angle mold machine 4 is connected; a drill bit 5 is fixedly connected to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com