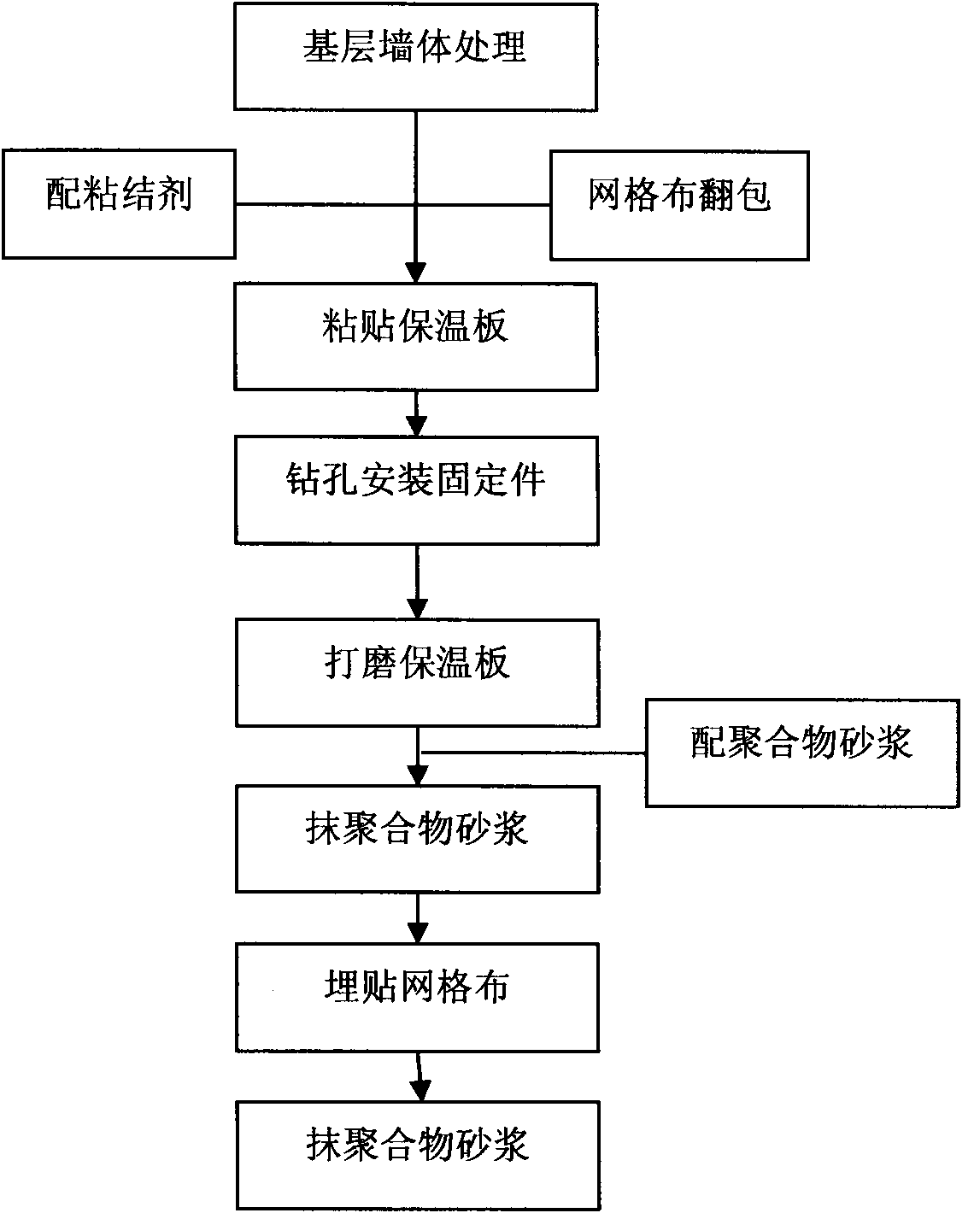

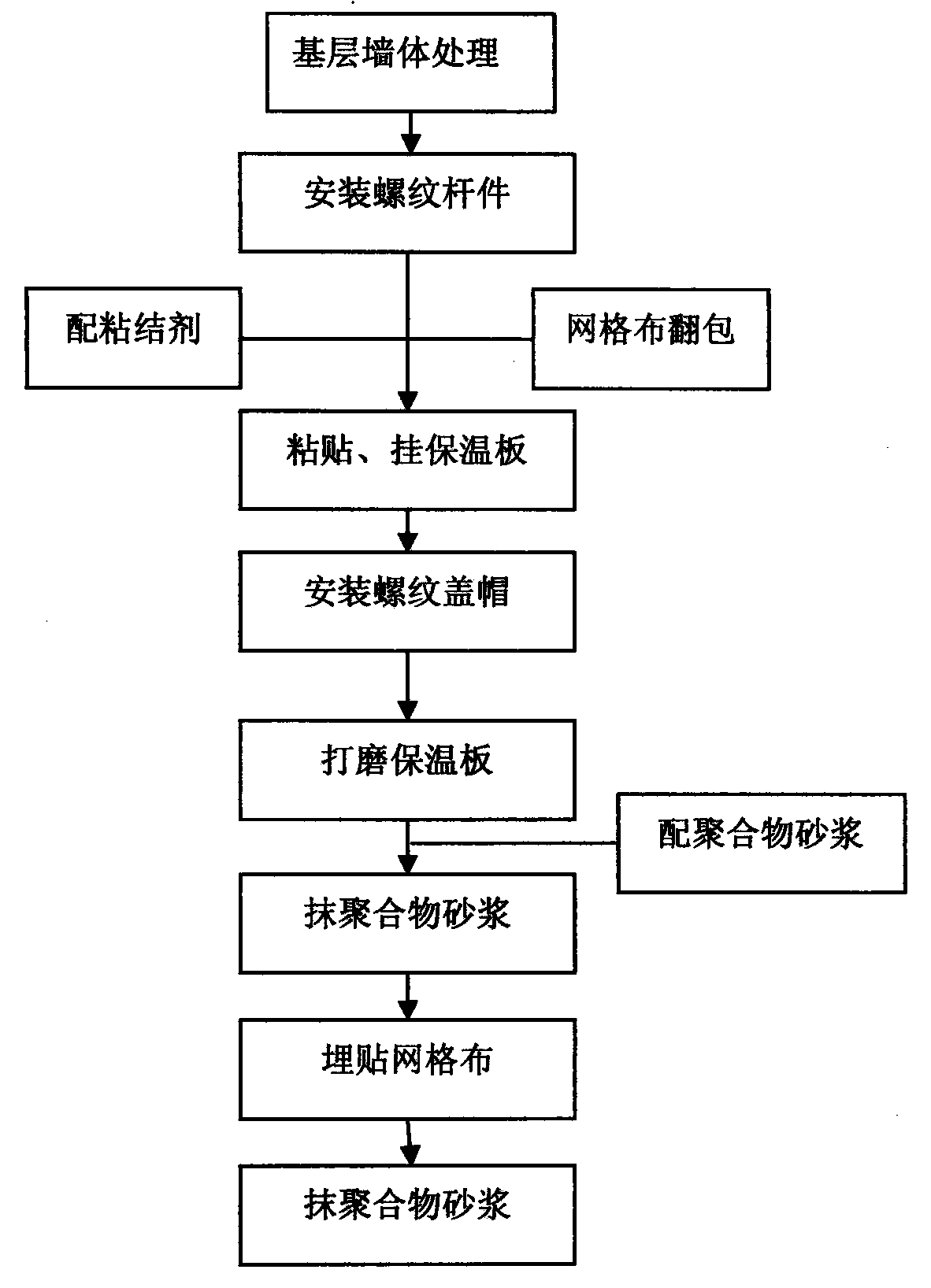

Construction technology of pre-fixed board system wall insulation system

A technology of thermal insulation system and construction process, applied in thermal insulation, building components and other directions, can solve the problems of affecting the bonding strength, affecting the progress, increasing costs, etc., to prevent insufficient drilling depth, save costs and construction periods, and save construction periods and costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Implementation example 1:

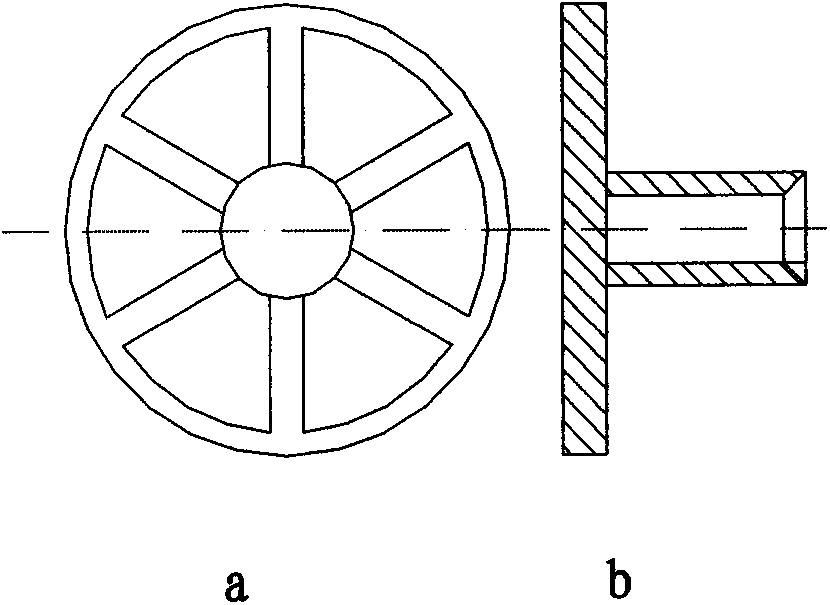

[0028] For masonry walls, when plastering the leveling layer, put image 3 The threaded cap is embedded in the leveling mortar layer with the plane facing inward. After the mortar is solidified, the threaded rod of the length corresponding to the thickness of the insulation board ( Figure 5 ) Connected to the embedded threaded cap ( image 3 ) With the tip facing outward, and then paste or hang the insulation board (one or more layers) on the threaded rod, and then use image 3 The threaded cap shown is tightened and fixed with the flat surface facing outward, and then a series of processes such as grinding-applying polymer mortar-embedding mesh cloth are carried out.

[0029] Implementation example 2:

[0030] For masonry walls, pre-buried in the leveling mortar layer as Figure 4 The threaded rod with cap shown, the cap is in the mortar layer, and the threaded rod is perpendicular to the wall facing outward. After the mortar is cured, paste and h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com