Partially upset high-strength steel wire and its preparation method

A high-strength steel wire and upsetting technology, which is applied in the direction of building reinforcements, structural elements, building components, etc., can solve the problems of limiting the application range and inconvenient installation of other components, so as to expand the application range, enhance corrosion resistance, and improve anchorage strength Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

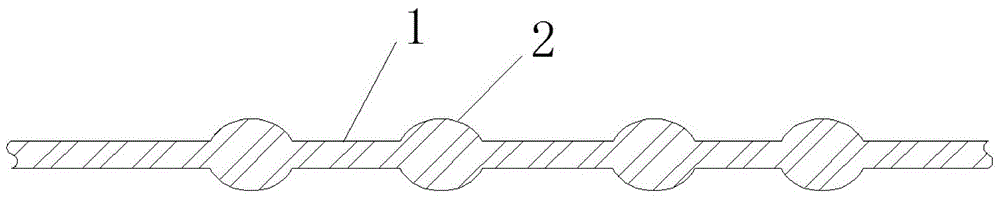

[0016] exist figure 1 , the schematic diagram of the longitudinal section of the local upsetting high-strength steel wire shows the high-strength steel wire (1) and the local upsetting (2).

[0017] The diameter of the high-strength steel wire (1) is larger than 5.0mm.

[0018] The maximum lateral dimension of the local upsetting (2) is greater than or equal to 1.5 times the diameter of the high-strength steel wire (1).

[0019] The shape of the local upsetting (2) can be spherical, ellipsoidal or other polygonal, and the corresponding longitudinal section shape is circular, elliptical or other polygonal.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com