Dual-U-shaped tubular heat exchanger for soil source heat pump system

A technology of soil source heat pump and U-shaped tube, which is applied in the direction of indirect heat exchangers, heat pumps, lighting and heating equipment, etc., can solve the problem of high initial investment, the heat transfer efficiency of soil source heat pumps cannot meet the design requirements, and the development and promotion of soil Unfavorable source heat pumps and other issues, to increase heat exchange efficiency, promote better work, and reduce drilling depth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

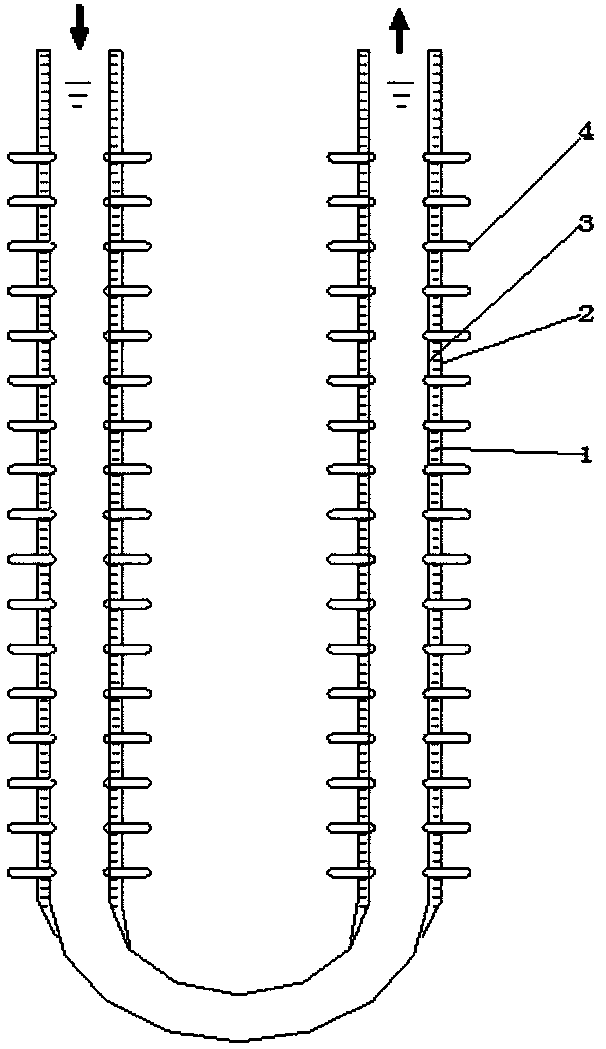

[0021] Such as Figure 1 ~ Figure 3 As shown, the outer wall of the vertical pipe in the double U-shaped pipe is covered with an oil storage pipe 2, and the upper and lower ends of the oil storage pipe are respectively sealed with the outer wall of the vertical pipe, and the gap between the oil storage pipe and the outer wall of the vertical pipe is formed. Oil storage chamber 3, the oil storage chamber is filled with heat transfer oil, the heat transfer coefficient of the heat transfer oil is 150-200w / ㎡, the heat pipe group includes several heat pipes, and several heat pipes are arranged at even intervals along the circumference of the vertical pipe. The end is inserted into the vertical pipe, and the rest is located in the soil. Several heat pipes are arranged horizontally at 90° to the vertical pipe axis of the double U-shaped pipe. In summer and winter, the heat of the medium in the double U-shaped pipe can be transferred respectively. Soil, or the heat in the soil is tran...

Embodiment 2

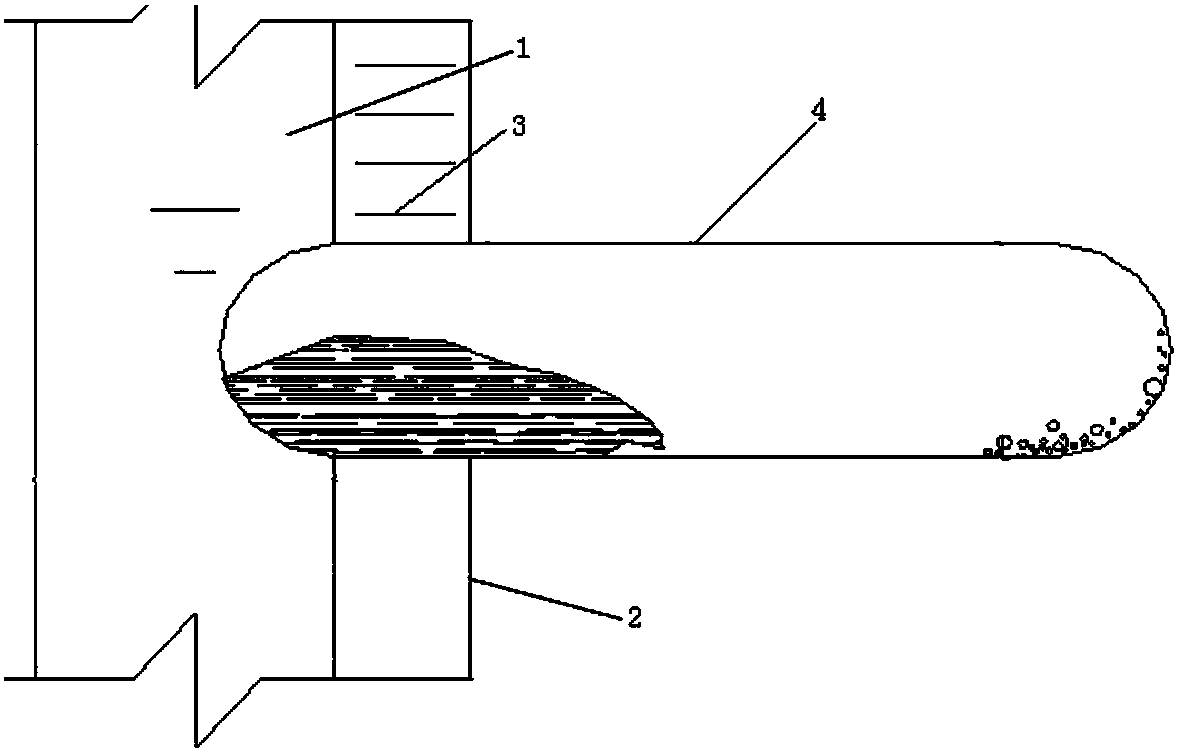

[0024] Such as Figure 4 As shown, the heat pipe group is an annular heat pipe, the outer wall of the vertical pipe in the outer wall of the annular heat pipe and the double U-shaped pipe, and the inner ring end of the annular heat pipe is inserted into the inside of the vertical pipe to increase the working length of the heat pipe and further increase the heat exchange efficiency of the heat pipe. In areas with better soil heat transfer characteristics, or areas with abundant geothermal resources, oil storage pipes are not required, which makes the structure simpler and more convenient to manufacture.

Embodiment 3

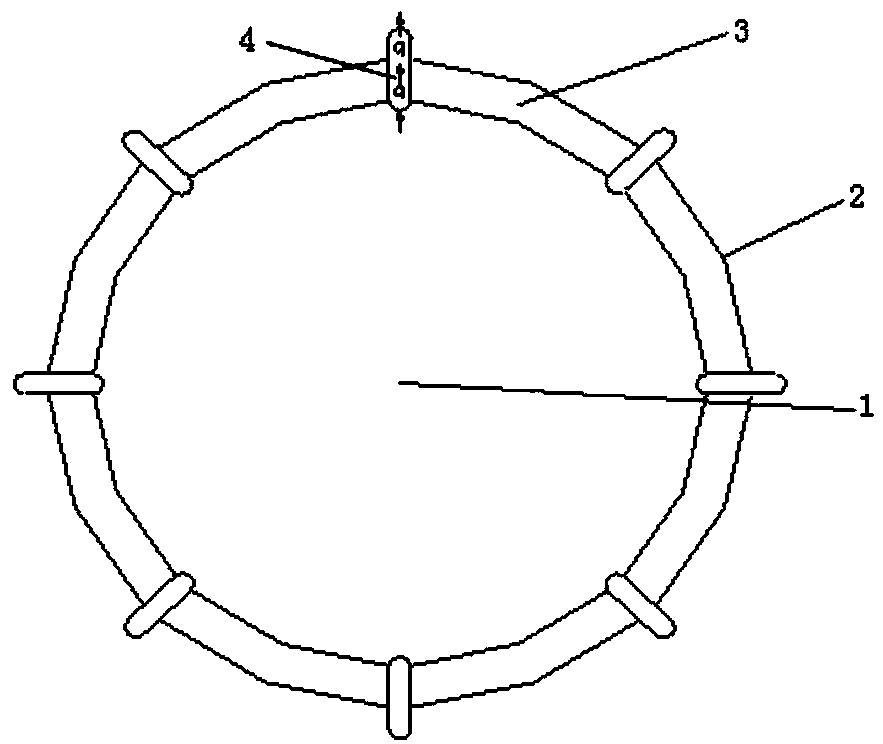

[0026] Such as Figure 5 As shown, as the optimization scheme of Embodiment 1, the adjacent two heat pipes are moved up and down by a certain angle, because the angle of the heat pipe has a great influence on the heat exchange efficiency of the heat pipe, so the downwardly inclined heat pipe can be It is used in winter conditions, while the upward-sloping heat pipe can be used in summer conditions, and the heat conduction direction of the two heat pipes is the same under any working condition. Downslope heat pipes play a secondary role.

[0027] Both the oil storage pipe and the double U-shaped pipe in the present invention are made of polyethylene material, and the heat pipe group is made of carbon steel.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com