One-face multi-roadway gas control method for large-mining-height large-mining-length working face

A working face and gas technology, applied in gas discharge, mining equipment, earthwork drilling and mining, etc., can solve problems such as inability to effectively drain gas in blank areas, poor gas control effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The specific technical solutions of the present invention are described in conjunction with the accompanying drawings.

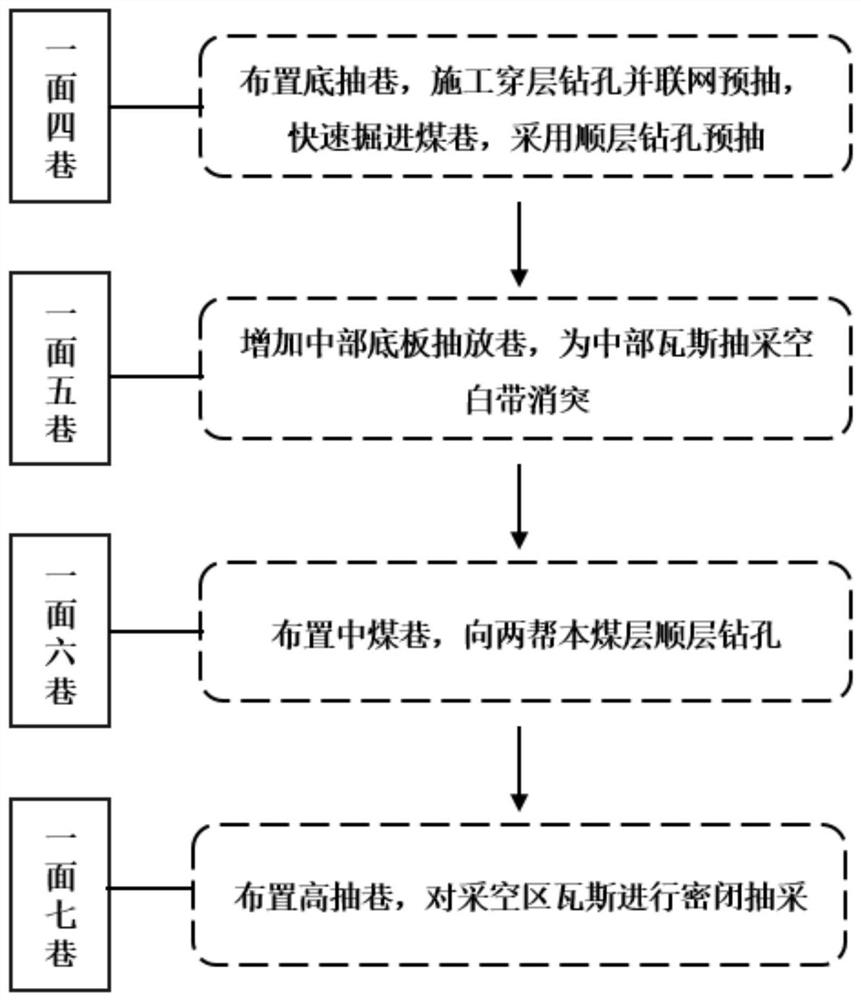

[0025] refer to figure 1 It can be seen that a "one side and multiple lanes" gas control method for a large mining height and large mining length working face includes the following specific implementation steps:

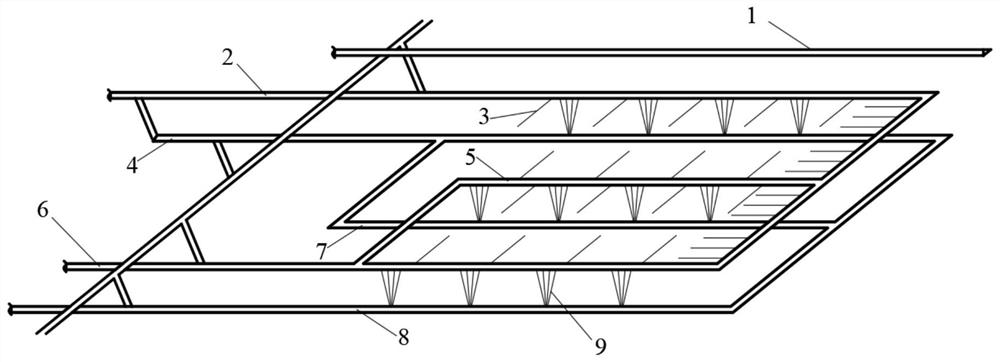

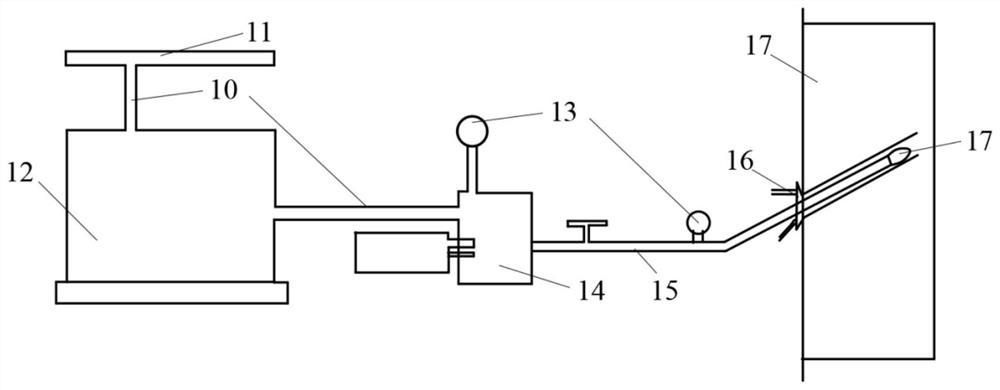

[0026] S1: Arrange the bottom pumping roadway along the coal line marking layer 10m away from the coal seam floor and 200-300mm in thickness, establish a gangue discharge system, realize the separate transportation of coal and gangue, and form a rock roadheader-belt-working face gangue bin-belt-mining area gangue Warehouse-mine car-auxiliary well-ground dedicated gangue discharge route, at the same time, if figure 2 As shown in the figure, 9 drill holes are drilled through the layers and networked to pre-extract coal seam gas. The distance between the drill hole groups is 4.8m, and each group is constructed with 11 drill holes, which are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com