A preparation method and application of a polyelectrolyte nanomaterial loaded with fe3o4

A technology for polyelectrolyte and nanomaterials is applied in the field of preparation of polyelectrolyte nanomaterials, which can solve the problems of incapability of composite adsorption of various heavy metals, incapability of desorption and reuse, complicated adsorption process, etc., and achieves wide source of raw materials, high promotion and application ability , the preparation method is simple

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

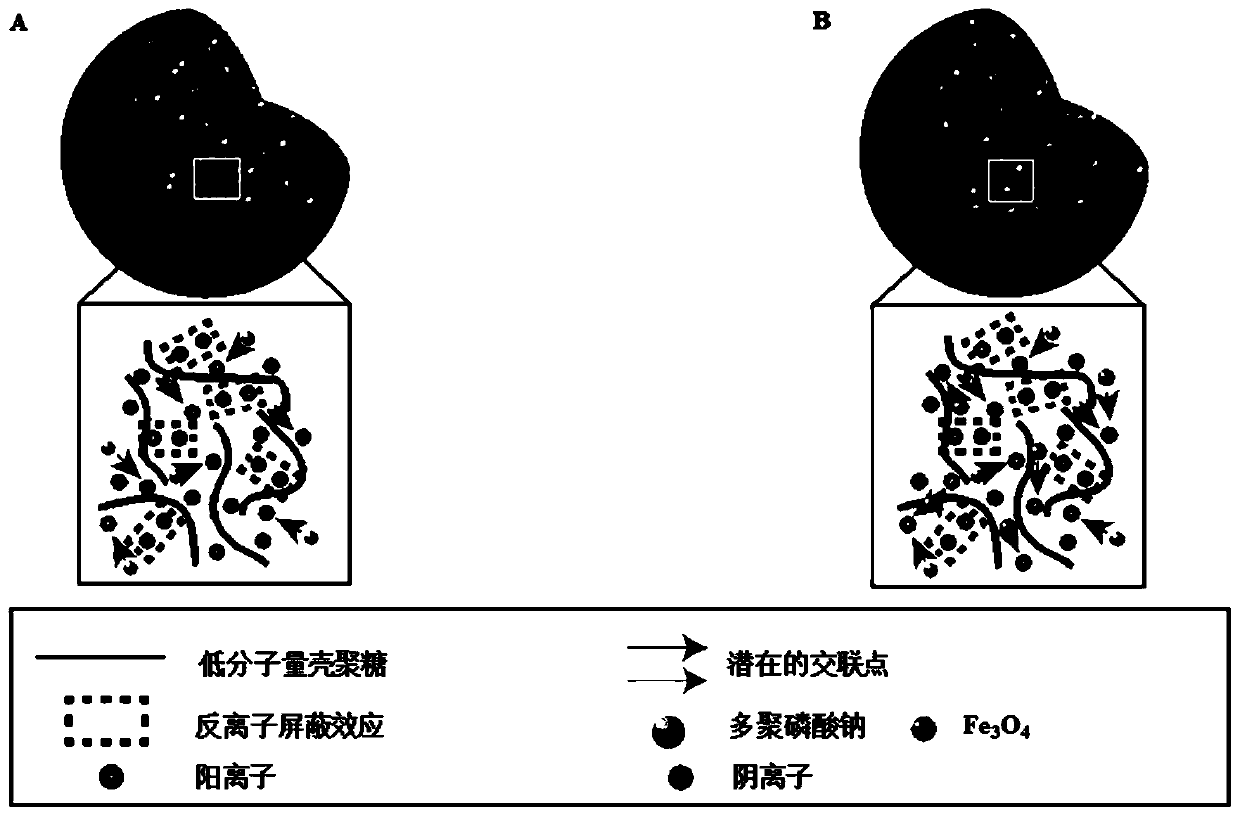

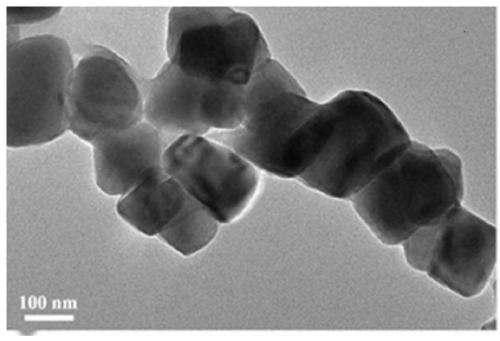

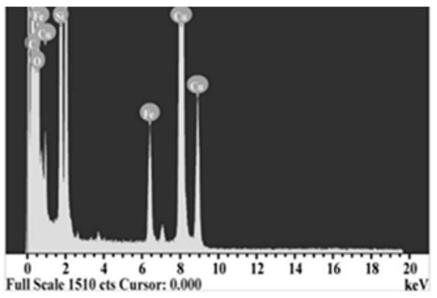

[0037] 1.1 Loading Fe 3 o 4 Preparation of Polyelectrolyte Nanomaterials

[0038] (1) Depolymerization of β-chitosan

[0039] Dissolve 30g of β-chitosan in 1,000mL of 1% acetic acid solution, stir overnight to fully dissolve, then add 3% β-chitosan cellulase (w:w), fully stir and dissolve, Put it in a water bath at 55°C and react for 7h. After the reaction, the pH of the solution was adjusted with 25% NaOH to make the pH>11. The precipitate was collected and freeze-dried to prepare β-chitosan before depolymerization. The molecular weight and degree of deacetylation of β-chitosan before depolymerization were 3500 kDa and 81.5%, and the molecular weight and degree of deacetylation of β-chitosan after depolymerization reached 150 kDa and 92%, respectively.

[0040] (2) Fe 3 o 4 Preparation of loaded polyelectrolyte nanomaterials

[0041] Weigh 150mg of depolymerized β-chitosan, stir and dissolve in 1% acetic acid solution, set the volume to 100mL, stir fully to prepare tr...

Embodiment 2

[0051] 2.1 Loading Fe 3 o 4 Preparation of Polyelectrolyte Nanomaterials

[0052] (1) depolymerization of chitosan

[0053] Dissolve 40g of β-chitosan in 1,000mL of 1% acetic acid solution, stir overnight to fully dissolve, then add β-chitosan 4% (w:w) cellulase, fully stir and dissolve, Put it in a water bath at 60°C and react for 7 h. After the reaction, the pH of the solution was adjusted with 25% NaOH to make the pH>11. The precipitate was collected and freeze-dried to prepare β-chitosan before depolymerization. The molecular weight and degree of deacetylation of β-chitosan before depolymerization are 3500kDa and 81.5%, and the molecular weight and degree of deacetylation of β-chitosan after depolymerization reach 300kDa and 95% respectively.

[0054] (2) Fe 3 o 4 Preparation of loaded polyelectrolyte nanomaterials

[0055] Weigh 200mg of low molecular weight β-chitosan, stir and dissolve in 1% acetic acid solution, set the volume to 150mL, stir fully to prepare tr...

Embodiment 3

[0064] 3.1 Loading Fe 3 o 4 Preparation of Polyelectrolyte Nanomaterials

[0065] (1) depolymerization of chitosan

[0066] Dissolve 50g of β-chitosan in 1,000mL of 1% acetic acid solution, stir overnight to fully dissolve, then add 3.5% of β-chitosan cellulase (w:w), fully stir and dissolve, Put it in a water bath at 60°C and react for 6h. After the reaction, the pH of the solution was adjusted with 25% NaOH to make the pH>11. The precipitate was collected and freeze-dried to prepare β-chitosan. The molecular weight and degree of deacetylation of β-chitosan before depolymerization are 3500kDa and 81.5%, and the molecular weight and degree of deacetylation of β-chitosan after depolymerization reach 260kDa and 93% respectively.

[0067] (2) Fe loading 3 o 4 Preparation of Polyelectrolyte Nanomaterials

[0068] Weigh 200mg of low molecular weight β-chitosan, stir and dissolve it in 1% acetic acid solution, set the volume to 100mL, stir fully to prepare a transparent β-ch...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com