A Construction Method for Improving the Pullout Performance of Threaded Reinforcement Anchor

A technology of threaded steel bars and construction methods, applied in excavation, infrastructure engineering, construction, etc., can solve the problems of labor and time, waste of resources, etc., and achieve the effects of preventing displacement, speeding up construction progress, and reducing construction costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

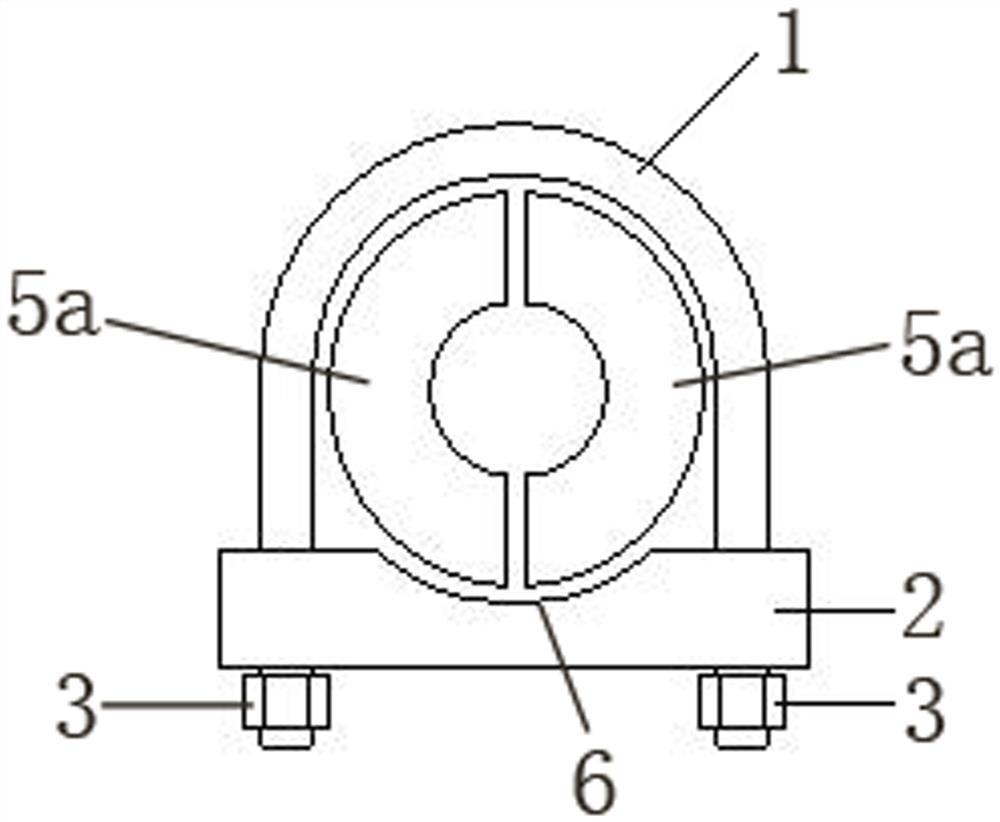

[0024] A construction method for improving the pullout resistance of a threaded steel bar anchor, the method comprising the following steps:

[0025] S1: A number of vertical rib-column grooves are vertically opened on the surrounding rock wall, and the rock mass in each vertical rib-column groove is eliminated;

[0026] S2: Drill several bolt holes on the bottom wall of each vertical rib column slot, and clean up each bolt hole;

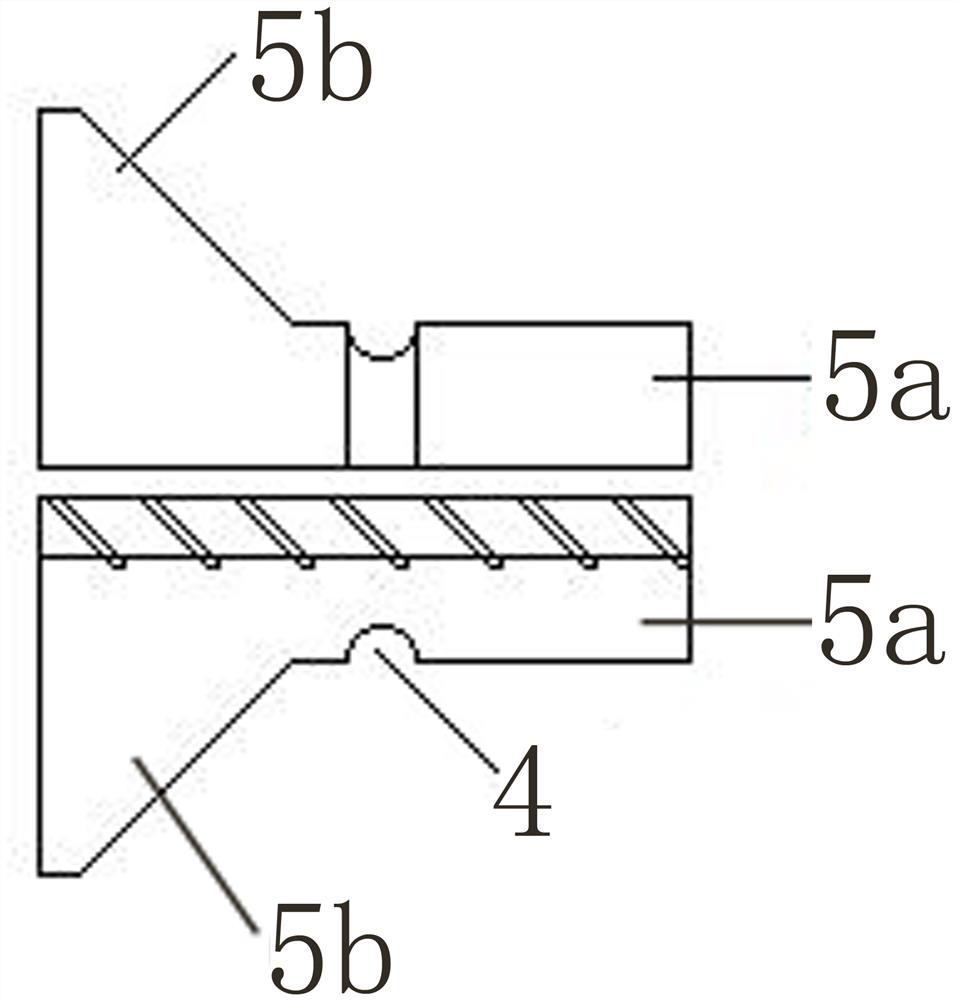

[0027] S3: Install several anti-pull resistance blocks on the anchoring section of each threaded steel anchor; the installation process is realized by the following steps: a. Screw the sleeve on the anchoring section of the threaded steel anchor; the sleeve The barrel includes a straight barrel located at the head and a conical barrel integrated end-to-end with the straight barrel, and the diameter of the head end of the conical barrel is smaller than the diameter of the rear end; b. Install the sleeve on the sleeve with the opening facing down and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com