Anti-floating anchor and construction method thereof

A technology of anti-floating anchor rods and construction methods, applied in the direction of foundation structure engineering, sheet pile walls, protection devices, etc., can solve problems such as pollution and low construction efficiency, and achieve the effects of advanced technology, reduced cleaning, and shortened construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0066] The first bid section of Huasujiayuan Community Project in Chuzhou City, with a total construction area of 48,000 square meters, and a frame shear wall structure;

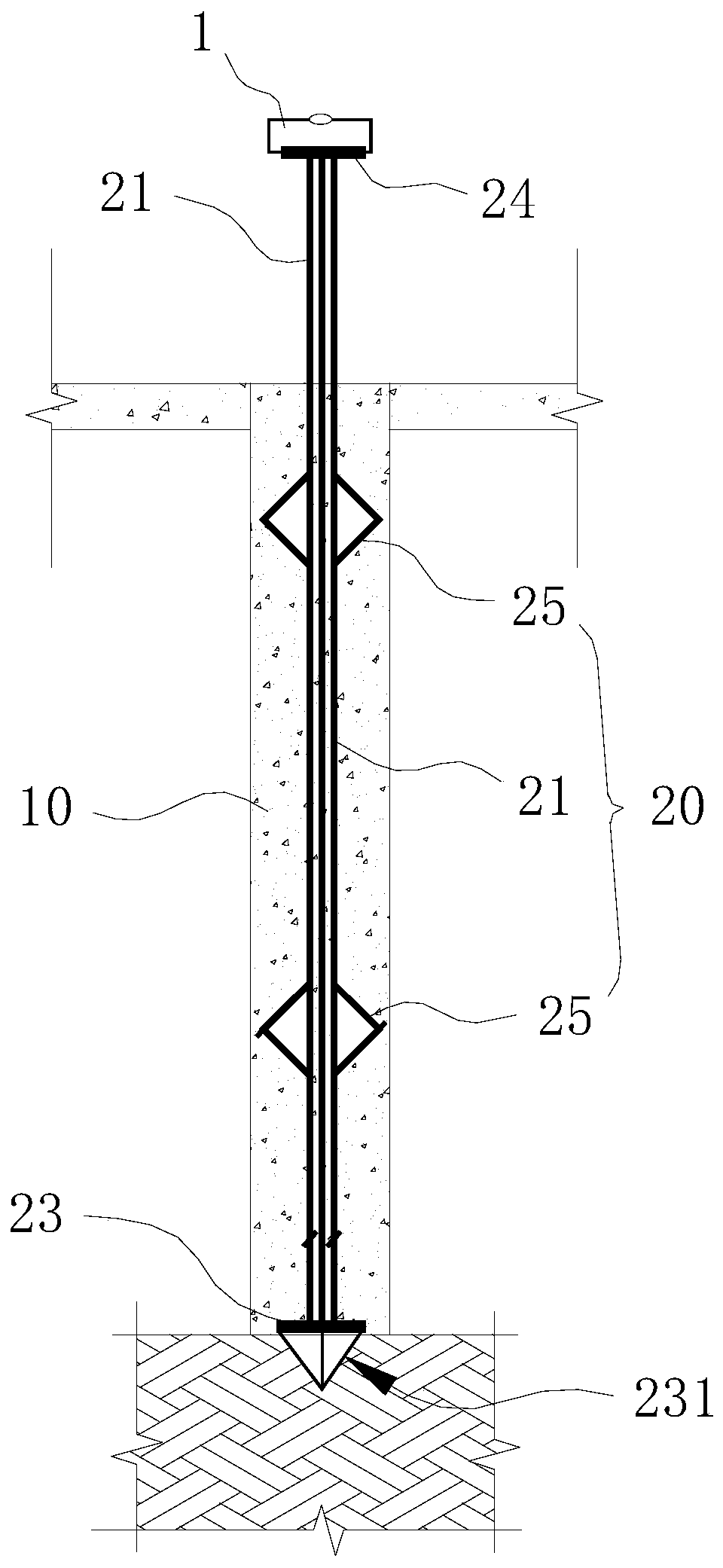

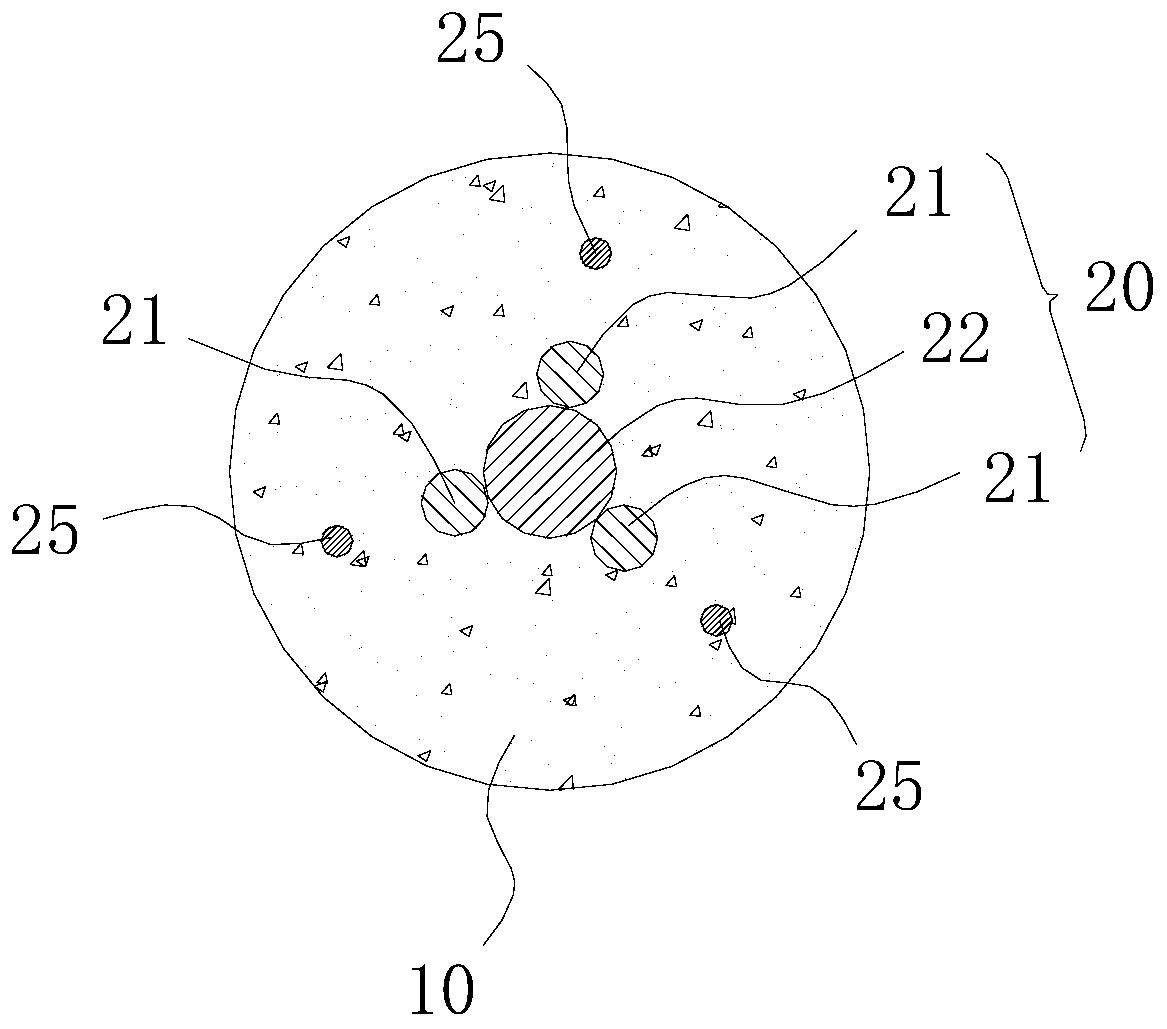

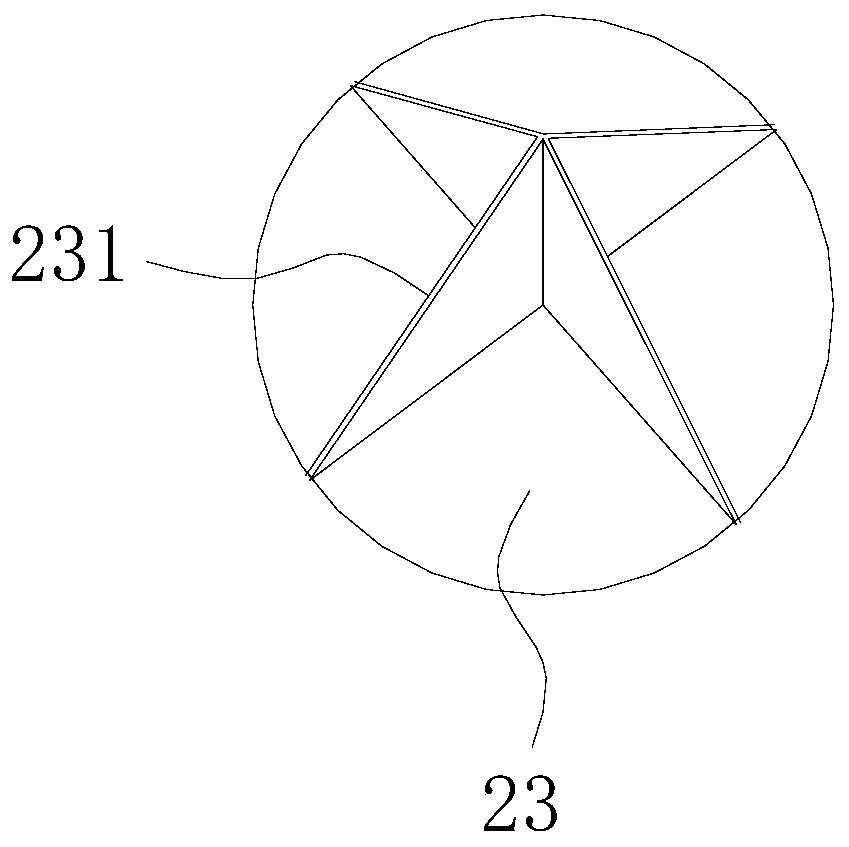

[0067] Adopt the anti-floating anchor structure provided by the present invention, specifically, the number of anti-floating anchors is 623, and each anti-floating anchor includes concrete pipe piles and pull-out steel tendons inserted in the concrete pipe piles; anti-floating anchors Rod diameter is 200mm, effective anchorage length is 12m;

[0068] The concrete used for the concrete pipe pile formed by pressure filling is C30 fine stone concrete;

[0069] Described pull-out steel tendon adopts three (Grade 3) as the main steel bar for pullout resistance;

[0070] Short bars are used (Level 3), set the spacing on the pullout main reinforcement to 1500mm;

[0071] fine steel bars (Level 3), set the spacing on the pullout main reinforcement to 1.5m;

[0072] The standard value of the pullout force ...

Embodiment 2

[0075] Wuhu Yunding International City 1#-4# building and basement project:

[0076] The construction area is 160,000 m 2 , is a first-class high-rise office building, the 4# building office building is divided into A, B, four-story podium, the ground floor area is 65147.5m 2 , two floors underground, for civil air defense garages and equipment rooms, the roof is the superior roof, and the building height is 99.1 meters. In order to solve the anti-lifting problem of the basement of this project, the anti-floating anchor rod provided by the present invention is used as the foundation.

[0077] The number of anti-floating anchor rods actually constructed is 1361, and the diameter of the final hole is 200mm. Pressure grouting adopts commercial fine stone concrete with strength grade C30.

[0078] Described pull-out steel tendon adopts three (Grade 3) as the main steel bar for pullout resistance;

[0079] Short bars are used (Level 3), set the spacing on the pullout main r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com