Wedge type inner anchor head

An inner anchor head and wedge type technology, which is applied in construction, sheet pile wall, infrastructure engineering and other directions, can solve the problems of aging resistance and single anchoring force, and achieves reduced drilling depth, good durability, and guaranteed The effect of anchoring force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

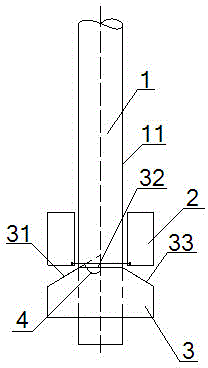

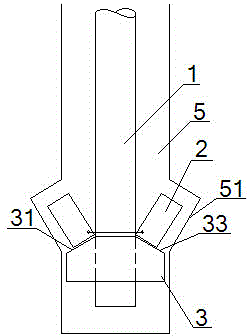

[0017] See figure 1 , figure 2 , A wedge-type inner anchor head, the inner anchor head includes an anchor rod 1, a plurality of wedges arranged around the outer wall 11 of the anchor rod 1, a wedge seat 3 sleeved outside the anchor rod 1, so The side of the bottom of the wedge block 2 near the outer wall 11 is hinged with the anchor rod 1. The wedge block seat 3 is located below the wedge block 2, and its top surface includes the No. 1 inclined plane 31, the horizontal plane 32, and the No. 2 inclined plane 33 connected in sequence. , And the first slope 31 and the second slope 33 are symmetrically arranged on both sides of the horizontal plane 32, the angle 4 formed by the first slope 31, the second slope 33 and the axis of the anchor rod 1 is an acute angle, and the anchor rod 1 passes through The horizontal plane 32 passes through the wedge seat 3 and extends to the outside of the wedge seat 3.

[0018] When assembling, first drill a straight hole in the rock with a drilling...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com