Modified asphalt concrete

A technology for modifying asphalt and concrete, applied in the field of building materials, can solve problems such as poor workability and influence, and achieve the effects of improving viscoelasticity and ductility, increasing specific surface area, and changing physical characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] A preparation method of modified asphalt concrete includes:

[0026] (1) After mixing sand, crushed stone, hydrotalcite, coconut shell activated carbon, and slag powder, stir it evenly;

[0027] (2) Add gel material and modified asphalt to the mixture in (1), and mix well;

[0028] (3) Add admixtures and auxiliary agents to the mixture in (2), stir evenly, and let stand for 15-20 minutes;

[0029] (4) Add water to the mixture in (3) at a water-cement ratio of 0.436, stir for 3-4 hours, and cure for 10 days in a humid environment at 21°C to obtain the concrete of the present invention.

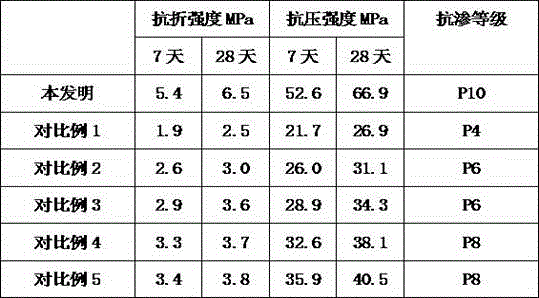

[0030] The performance test of concrete is as follows:

[0031]

[0032] Table 1

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com