Calculation method for allowable single pile bearing capacity of following drilling method railway tubular piles

A technology of allowable bearing capacity and calculation method, applied in the field of calculation of allowable bearing capacity of single piles of railway pipe piles with drilling method, can solve problems such as inconclusive results, reduce the drilling depth, improve the allowable bearing capacity of single piles, and significantly improve the bearing capacity of single piles. Economic and social benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

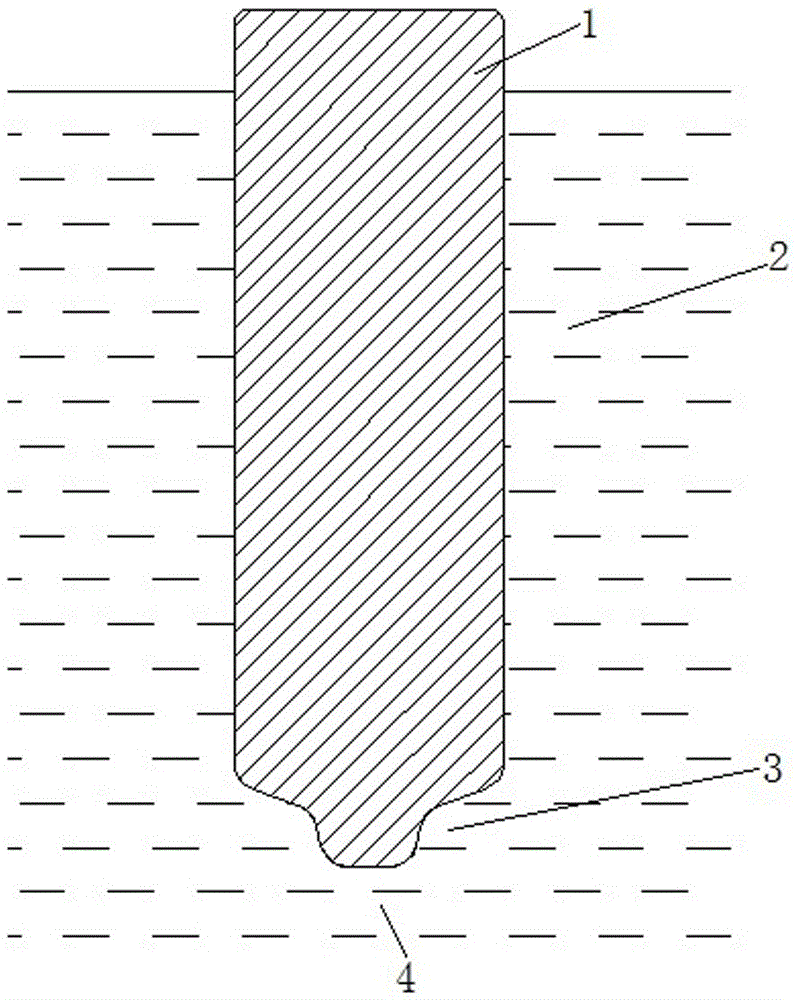

[0049] Embodiment: In this embodiment, the calculation method for the permissible bearing capacity of a single pile of the heel-drilling railway pipe pile involves the pipe pile 1, and the pipe pile 1 is set by the following construction process:

[0050] (1) Install the drill bit with a special structure on the front end of the long screw, and then penetrate into the hollow part of the special pipe pile (pile bottom notch type) for the railway heel drilling method, drill the foundation directly below the pile end, and discharge the drilled soil upwards Side-by-side continuous pile sinking, before the drill bit penetrates into the bearing layer, the diameter of the drill bit is drilled down according to the size smaller than the pile diameter;

[0051] (2) When the design bearing layer is reached, the enlarged drill wing (1.2-1.5D) larger than the pile diameter (1.2-1.5D) will be hydraulically opened (confirm the state of its expansion head through the electronic display screen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com