Method for improving heat exchange performance and longitudinal local heat accumulation of buried pipes of ground-source heat pump

A heat transfer performance and ground source heat pump technology, applied in heat pumps, material heat development, lighting and heating equipment, etc., can solve the problem of large differences in simulation design and analysis, unfavorable promotion and use of ground source heat pumps, unfavorable operation of ground source heat pump systems, etc. problems, to achieve the effect of improving longitudinal local heat accumulation, avoiding unsatisfactory heat transfer performance, and reducing the number of buried pipes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

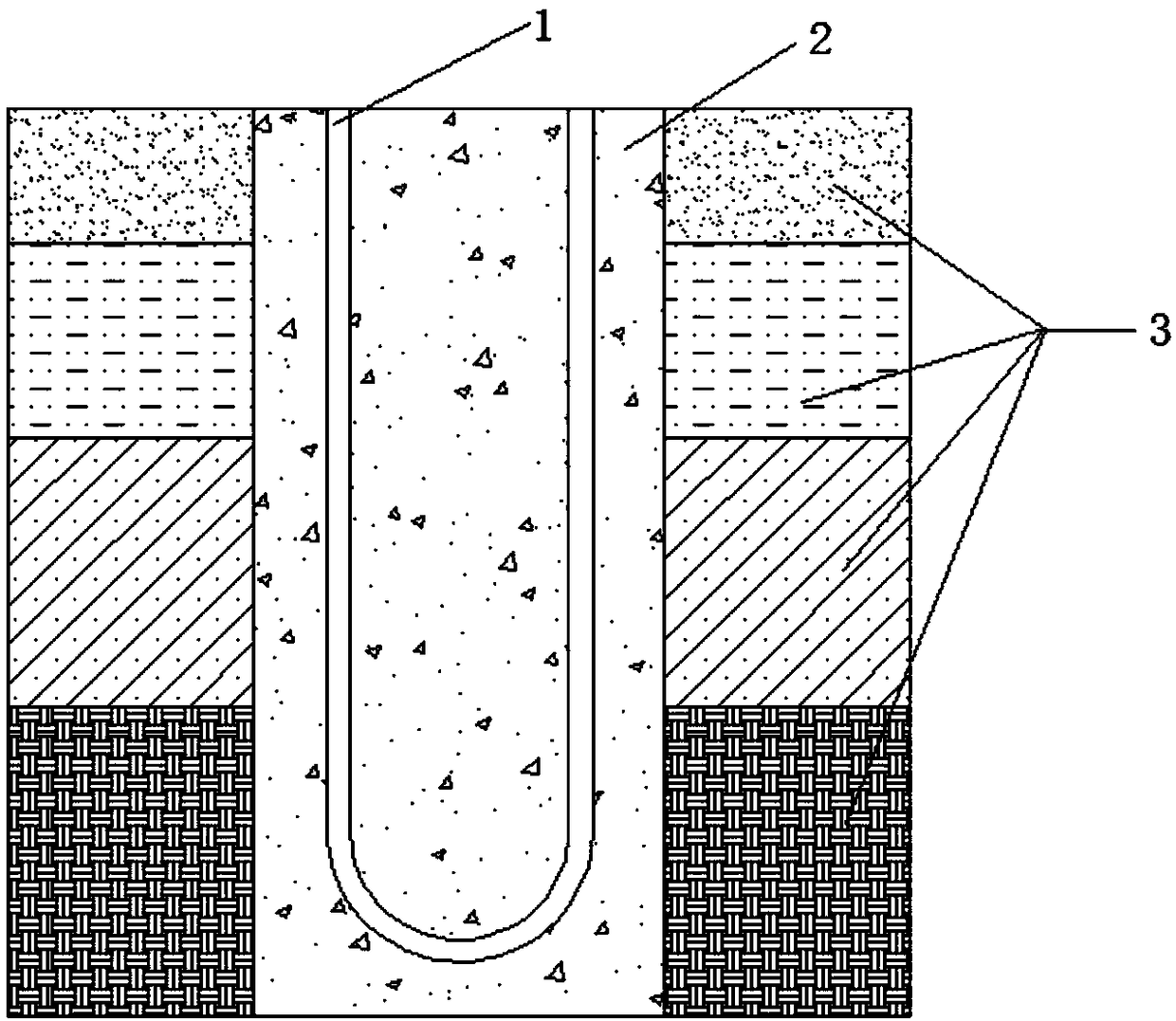

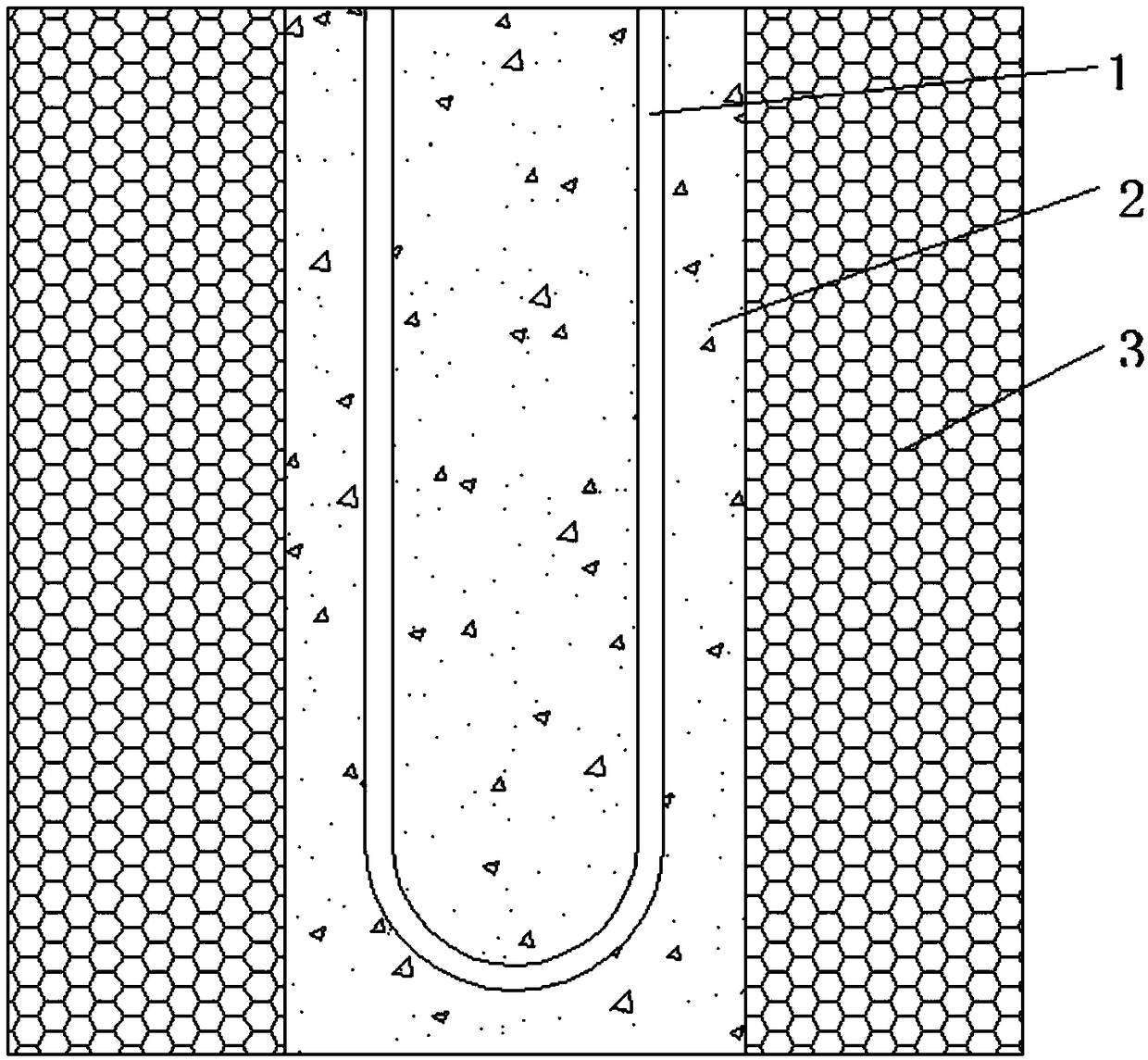

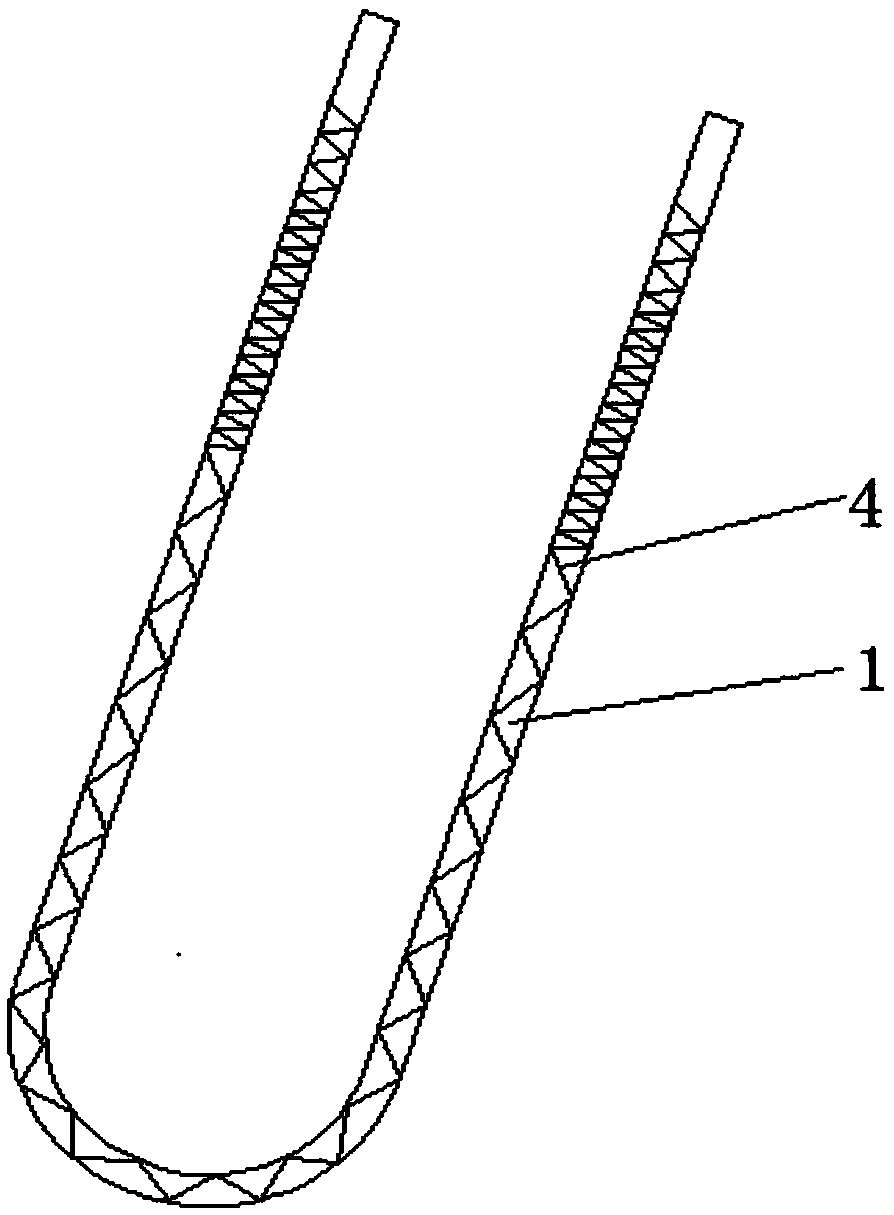

[0033] figure 1 It is a schematic diagram of the buried pipe simulation model of the present invention, figure 2 It is a schematic diagram of the buried pipe structure of the present invention, image 3 It is a schematic diagram of the wire wrapped around the buried pipe of the present invention. The present invention takes the vertical single U-shaped underground tube heat exchanger as an example to describe the solution provided by the present invention in detail. Since the vertical U-shaped tube is symmetrical, in order to reduce the amount of calculation, only half of the calculation is calculated. The invention respectively simulates the equivalent thermal conductivity of the buried pipe in the ideal state under the thermal conductivity conditions of different soil layers, wherein the inlet fluid temperature, the inlet flow velocity, the initial soil temperature, the running time and other parameters remain unchanged. The method for improving the heat transfer performa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com