Thermal expansion adjusting device and method for glass tank furnace

An adjustment device and thermal expansion technology, applied in glass furnace equipment, glass manufacturing equipment, manufacturing tools, etc., can solve problems such as support platform deformation, pool furnace structure deformation, unfavorable temperature and pressure control, etc., and achieve the effect of solving structural deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

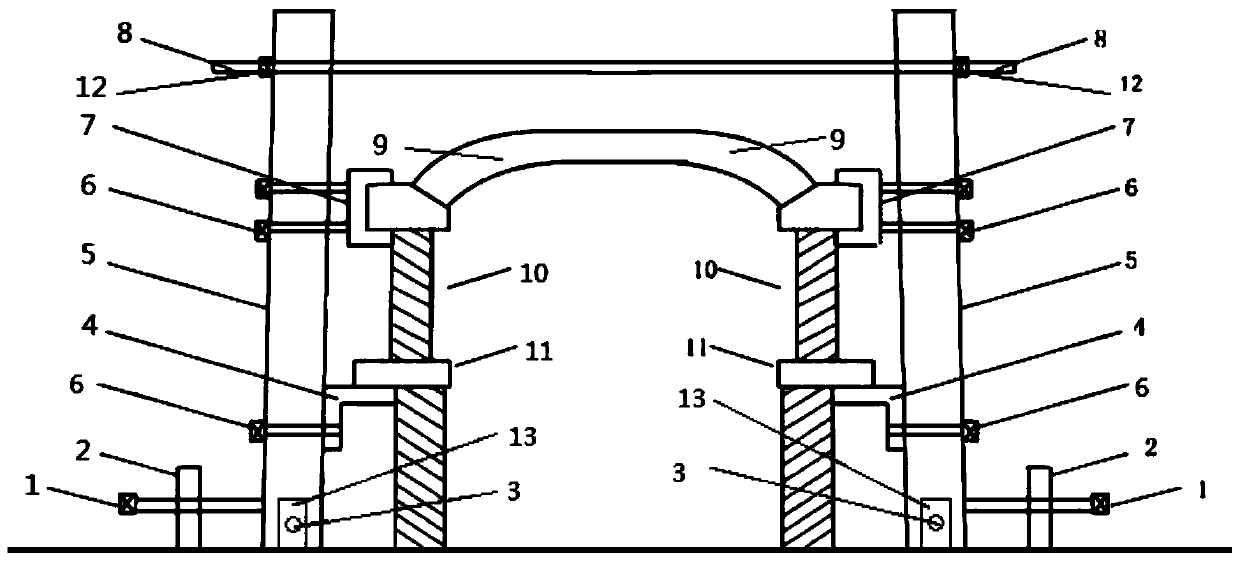

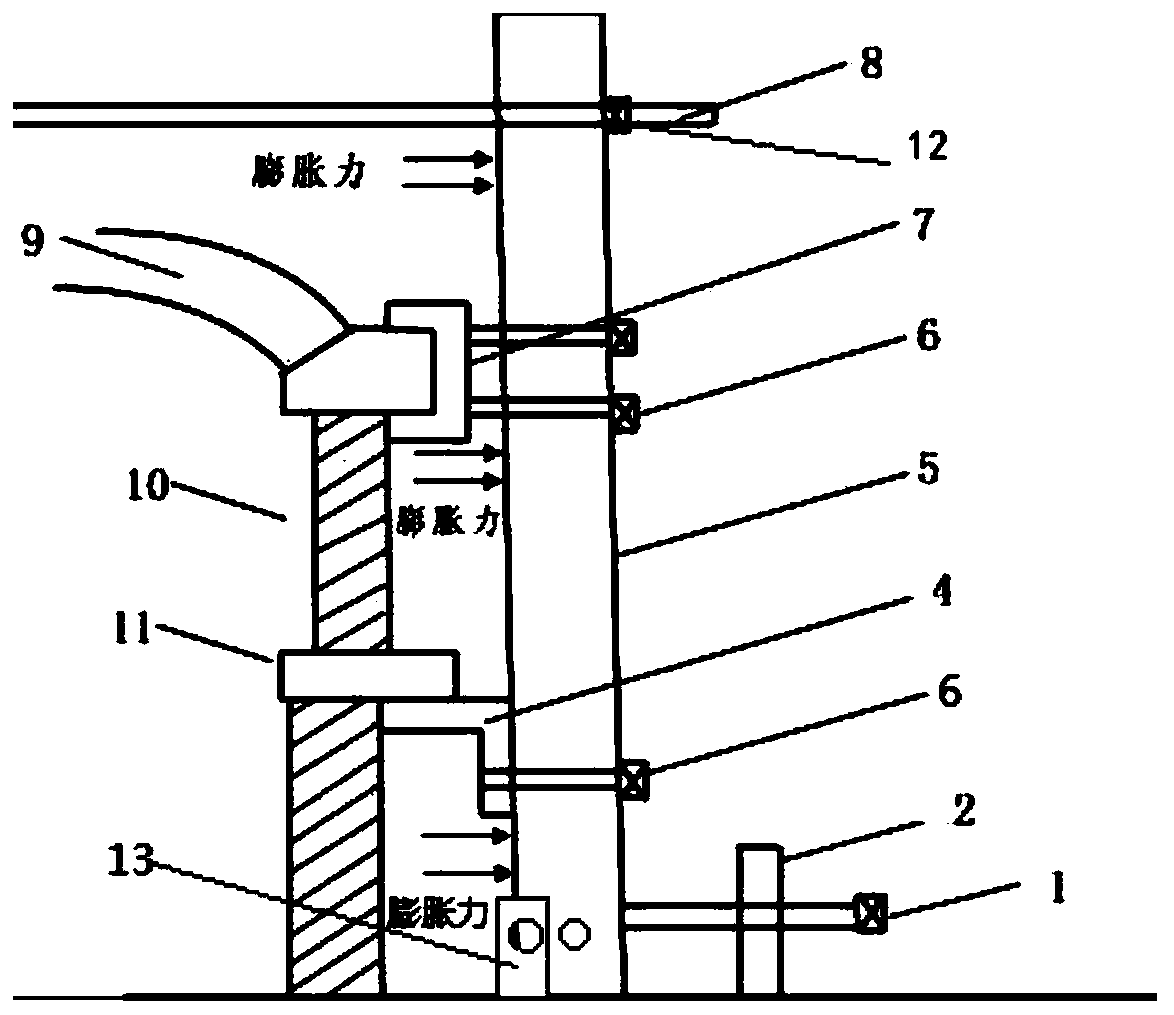

[0039] Such as figure 1 As shown, a glass pool furnace thermal expansion regulating device of the present invention, figure 1 For the fixed state of the device before the temperature of the glass pool furnace, the glass pool furnace is arranged on the bottom platform, the column 5 is symmetrically arranged on both sides of the glass pool furnace, and the bottom of the column 5 is provided with a fixed wing plate 13, and each two fixed wing plates 13 are respectively It is fixed on the bottom platform on both sides of the glass pool furnace along the thermal expansion movement direction to form a clamping warehouse, which is plugged and matched with the column 5 one by one, and the column 5 and the fixed wing plate 13 are connected and fixed on the bottom platform by the positioning bolt 3 The fixed column 2 is fixedly connected on the bottom platform of the column 5 moving direction, the middle of the fixed column 2 is provided with a threaded hole, the adjusting bolt 1 passes...

Embodiment 2

[0041] Embodiment 2: On the basis of Embodiment 1, this embodiment has made the following optimizations. The bottom of the column 5 is also provided with a bump, and the bottom platform is provided with a sliding groove, and the bump is embedded in the sliding groove so that the column 5 is along the direction of thermal expansion. move.

[0042]The bumps and sliding grooves provided at the bottom of the column 5 ensure the direction of movement during the entire thermal expansion process and improve the stability of the column 5 during the movement.

[0043] A method for adjusting the thermal expansion of a glass pool furnace in the present invention: disassemble the bottom positioning bolt 3, adjust the tightness of the adjusting screw 1 and the loosening of the tie bar 8 by rotating the adjusting bolt 1 and the adjusting nut 12, so that the upright column 5 is under the action of the expansion force down to move.

[0044] In a specific embodiment, the method for adjusting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com