Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

35results about How to "Guaranteed direction of movement" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

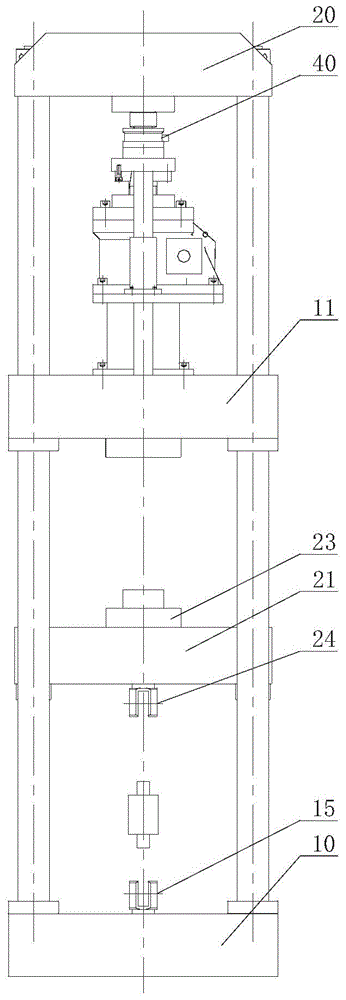

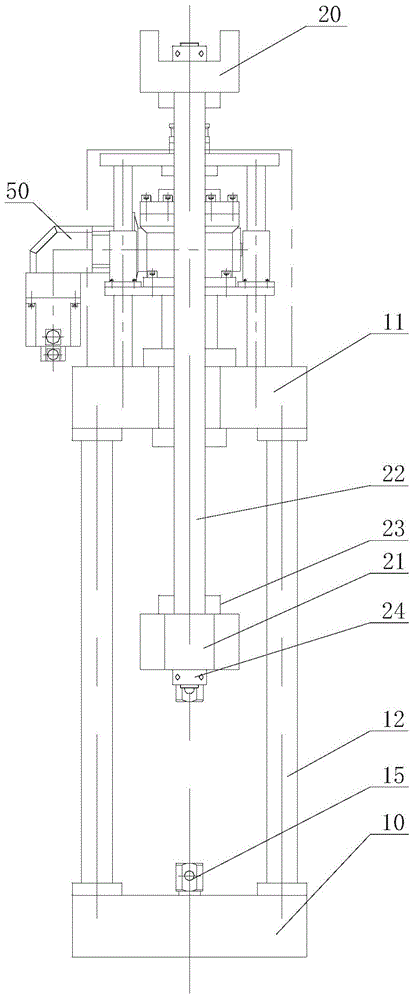

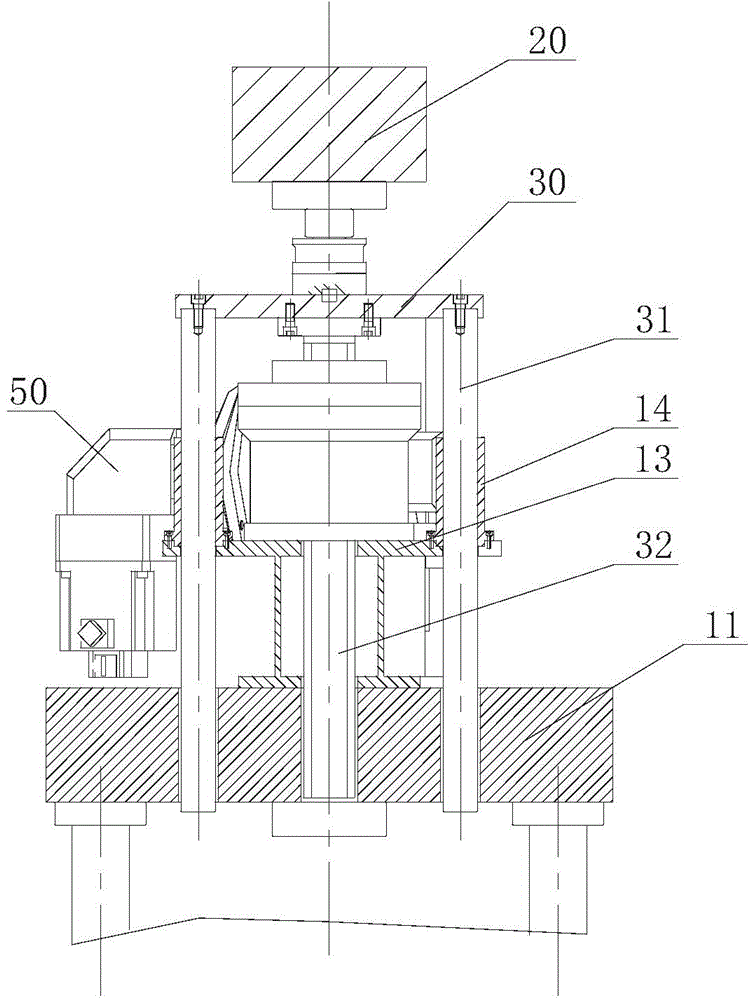

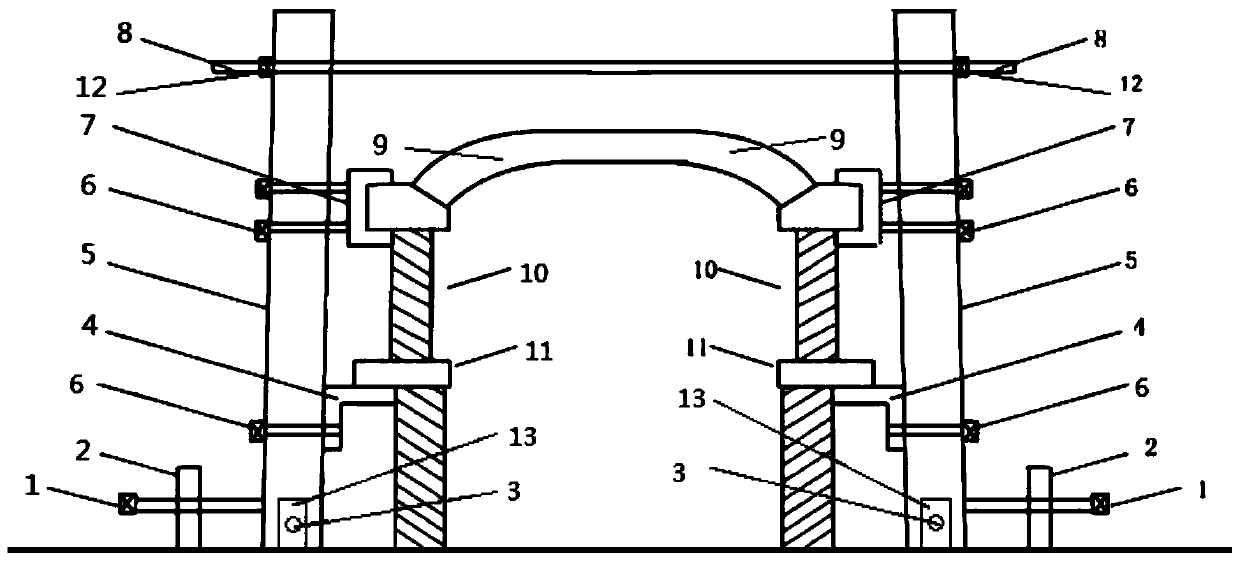

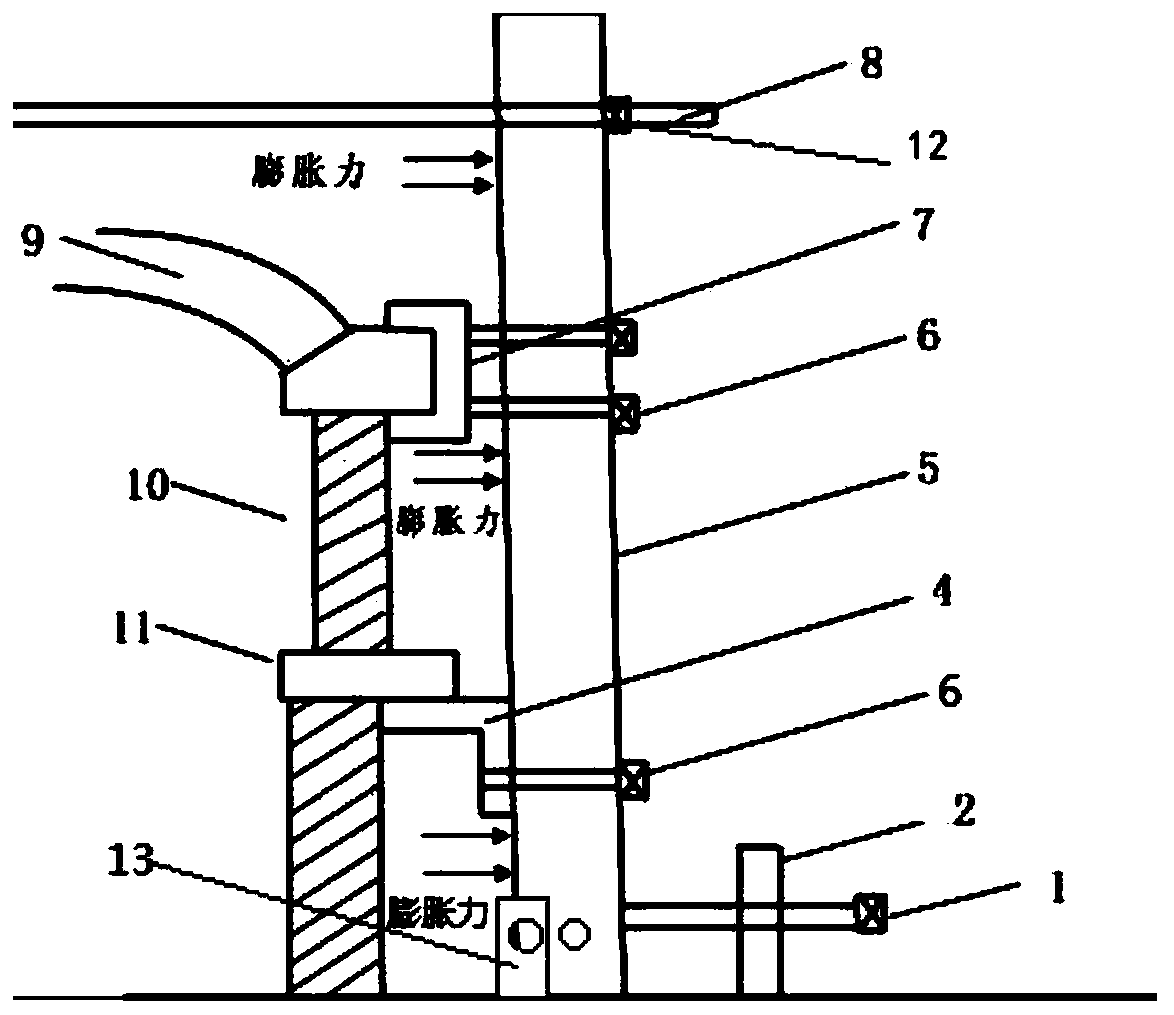

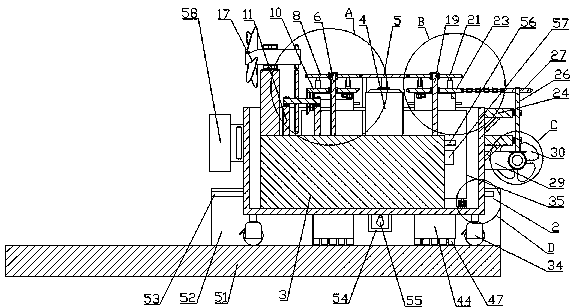

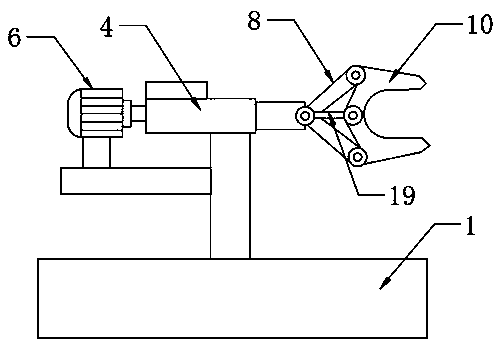

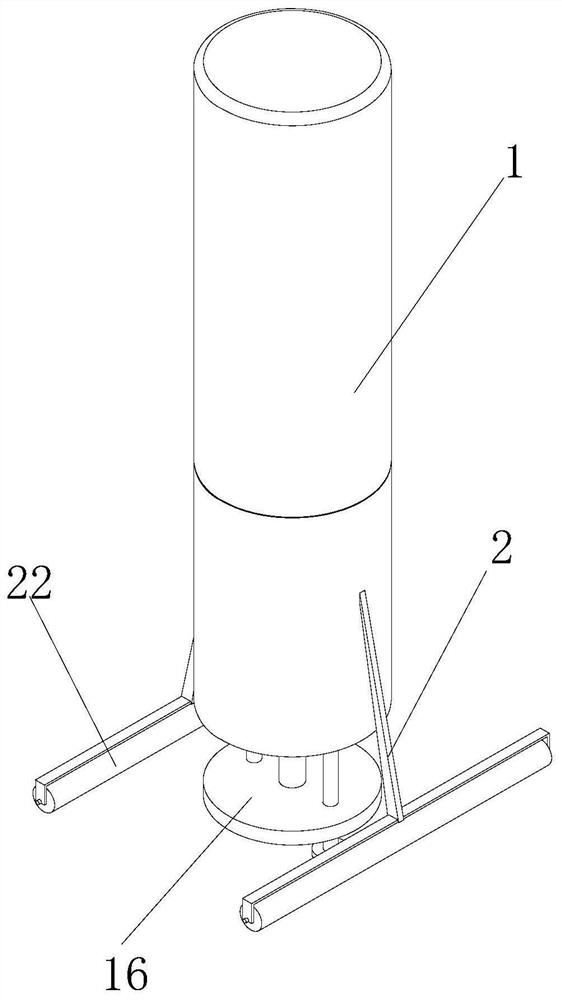

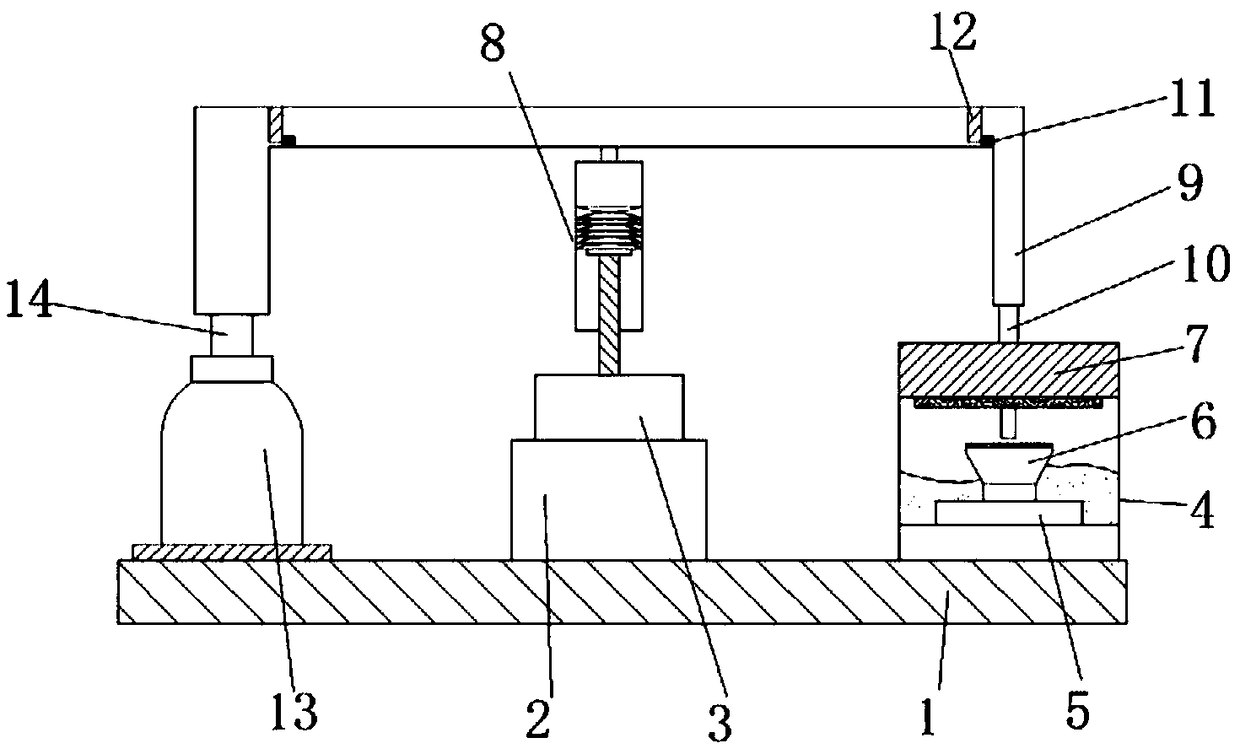

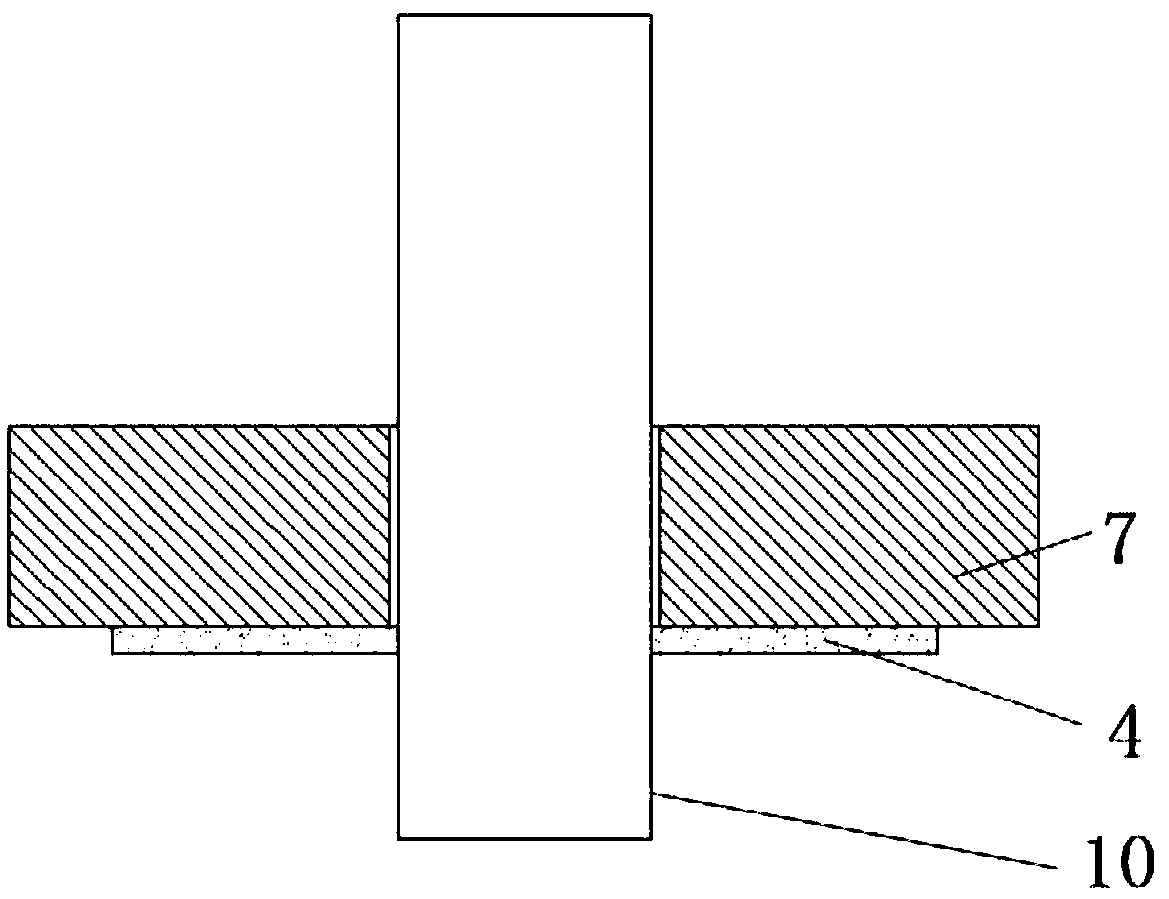

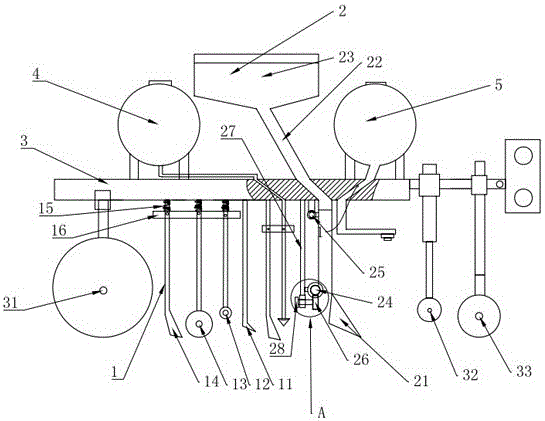

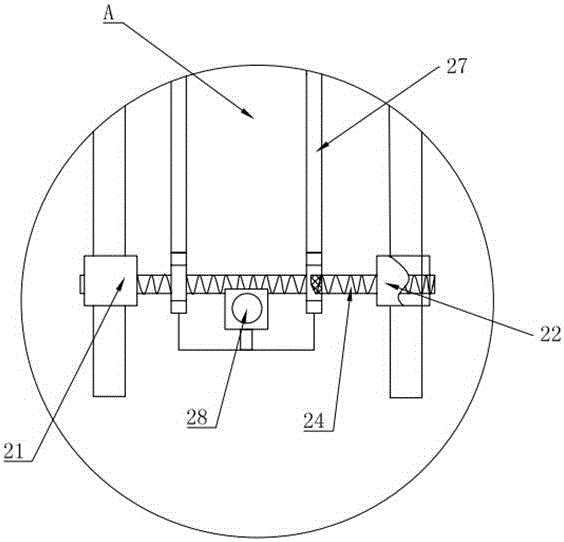

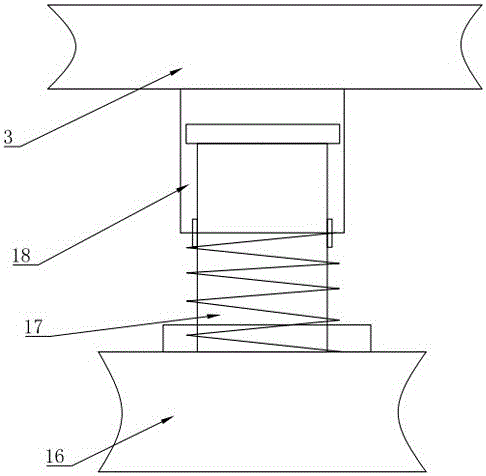

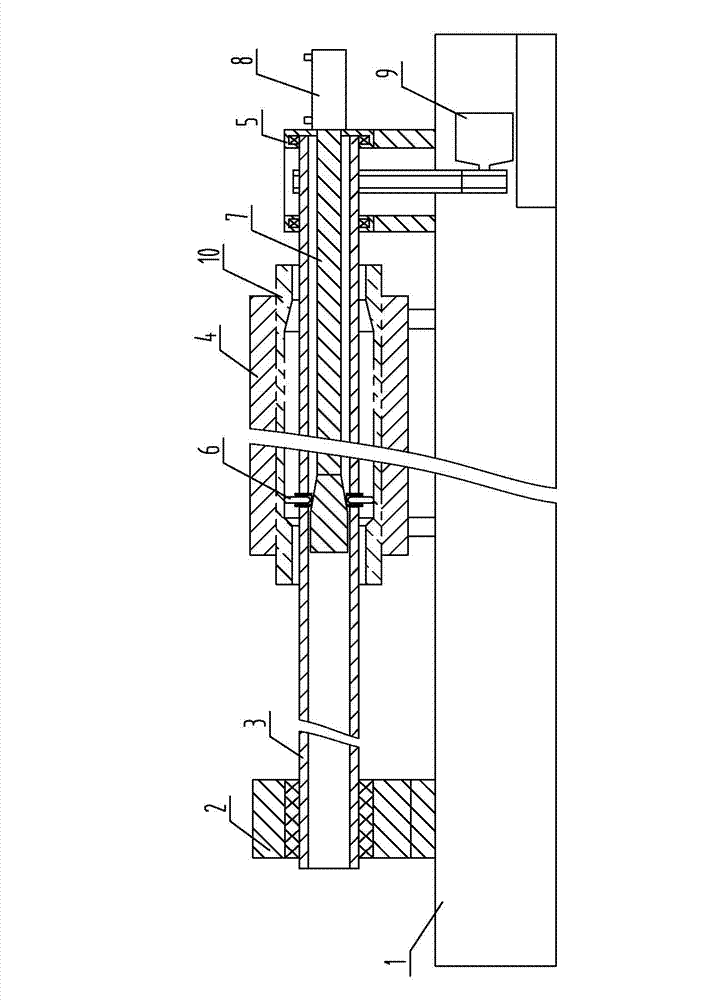

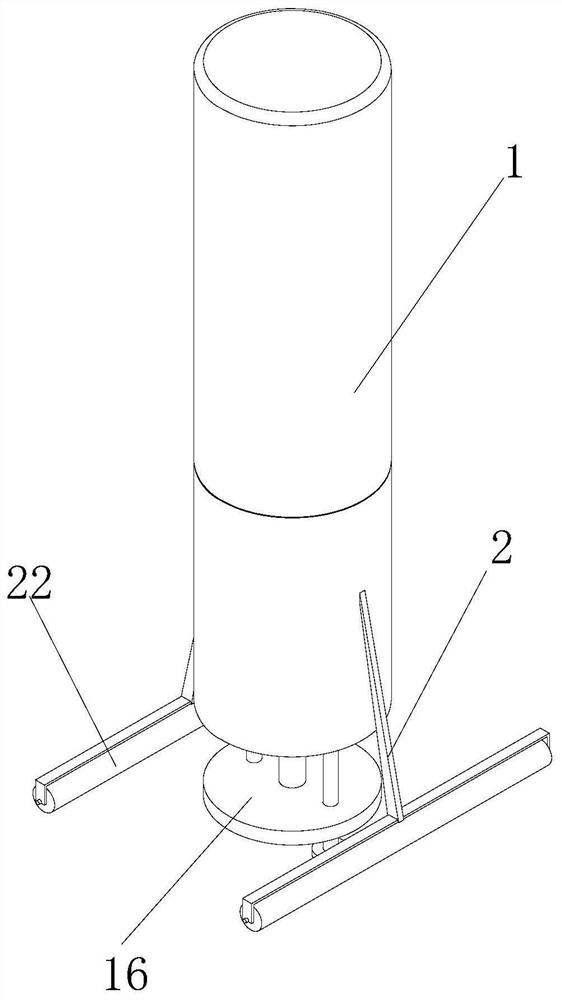

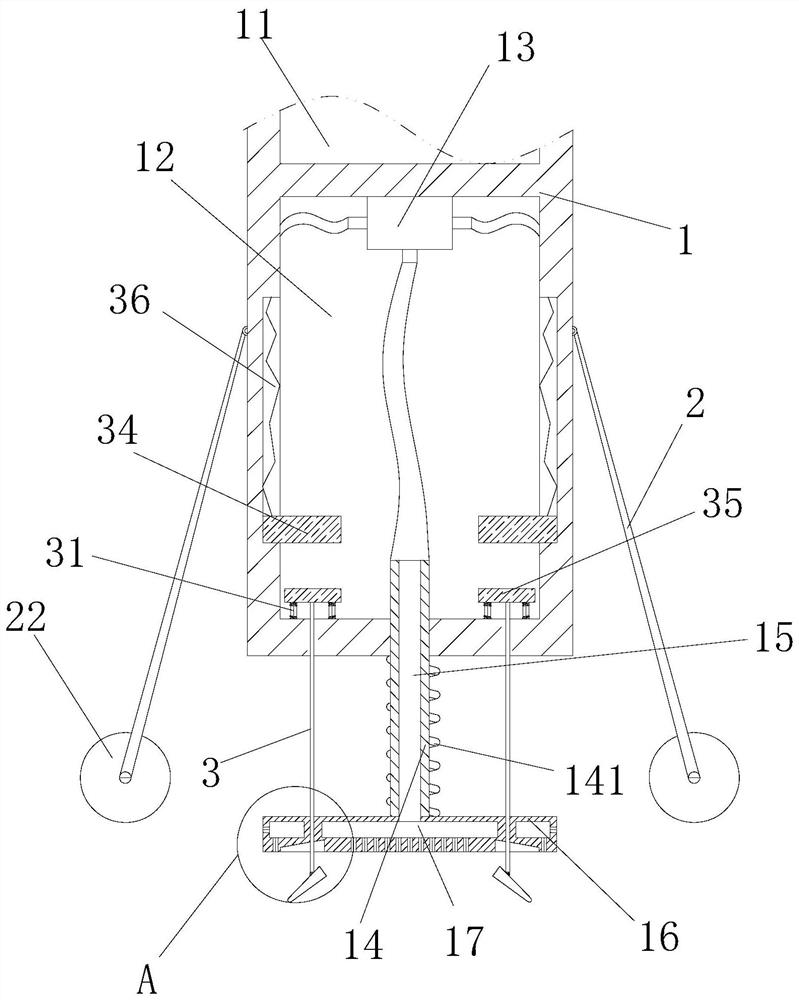

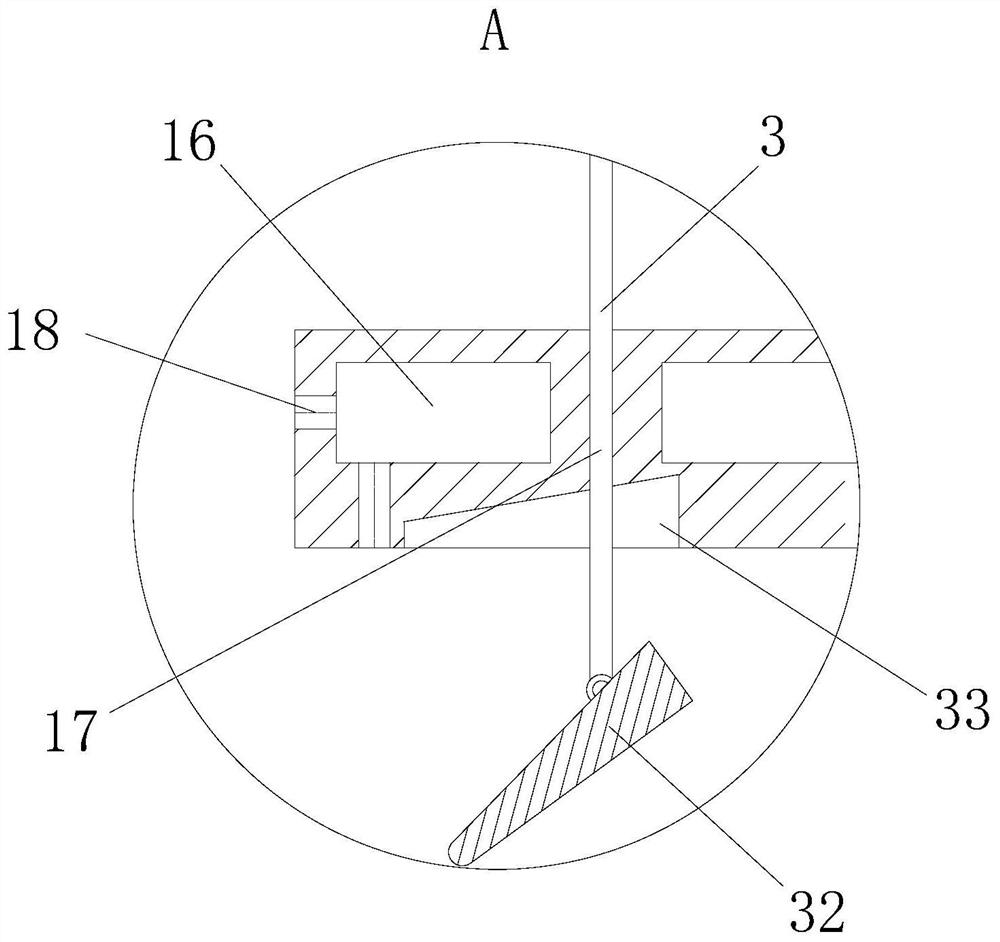

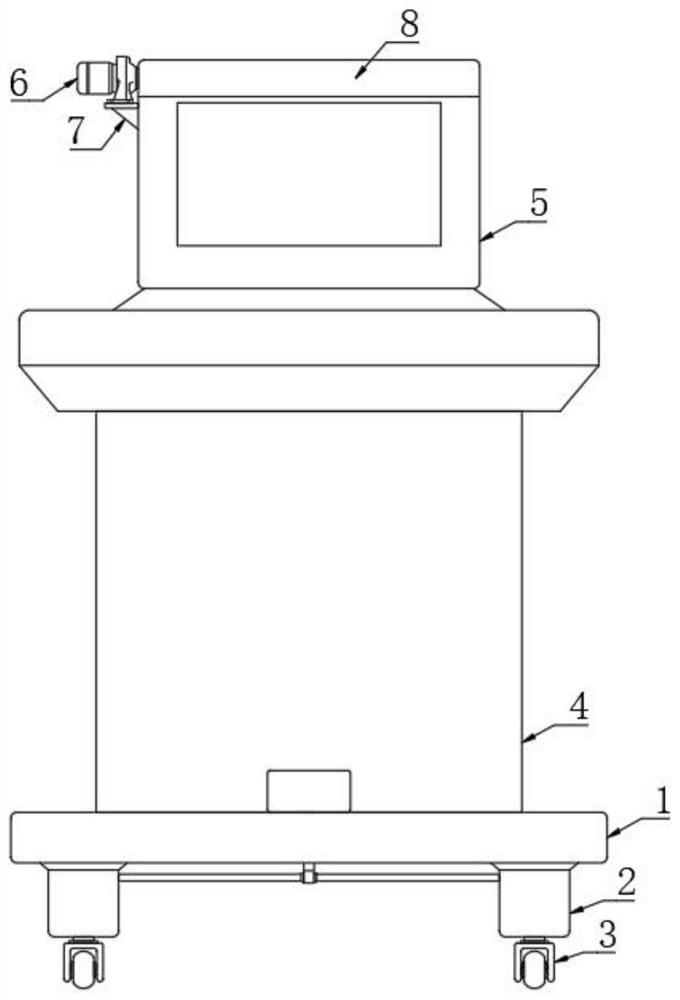

Electric cylinder loading overlapping type force standard machine

InactiveCN104807592AGuaranteed direction of movementGuaranteed accuracyForce/torque/work measurement apparatus calibration/testingBall screwPower equipment

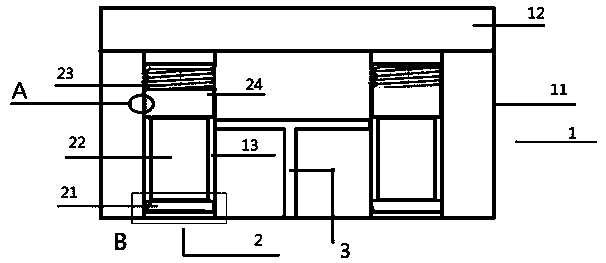

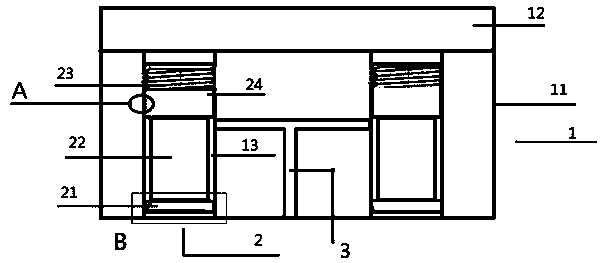

The invention discloses an electric cylinder loading overlapping type force standard machine. The electric cylinder loading overlapping type force standard machine comprises a support, a reversing frame, a connection guide piece, a standard sensor and power equipment, wherein the support comprises a base and an upper supporting seat; the reversing frame comprises a reversing frame upper beam, a reversing frame lower beam and a reversing frame connection rod; the reversing frame lower beam is arranged between the base and the upper supporting seat; the top of the reversing frame lower beam is provided with a sensor mounting seat; the connection guide piece comprises a mounting plate, a guide rod and a ball screw; the tops of the guide rod and the ball screw are arranged at the bottom of the mounting plate; the standard sensor is arranged on the mounting plate; the power equipment is arranged on the upper supporting seat. The power equipment drives a screw rod of the ball screw to rotate so that the screw moves upwards in the vertical direction, and the mounting plate is driven to move upwards to drive the reversing frame to wholly upwards move so that only electric energy needs to be consumed when pressing direction measurement is carried out on a sensor to be detected which is pressed on the upper supporting seat; the energy consumption is low and oil leakage is not caused; the electric cylinder loading overlapping type force standard machine has a simple and stable structure and high measurement precision and is easy to operate, and can be used for applying different force values according to requirements and measuring a small force value.

Owner:陶泽成

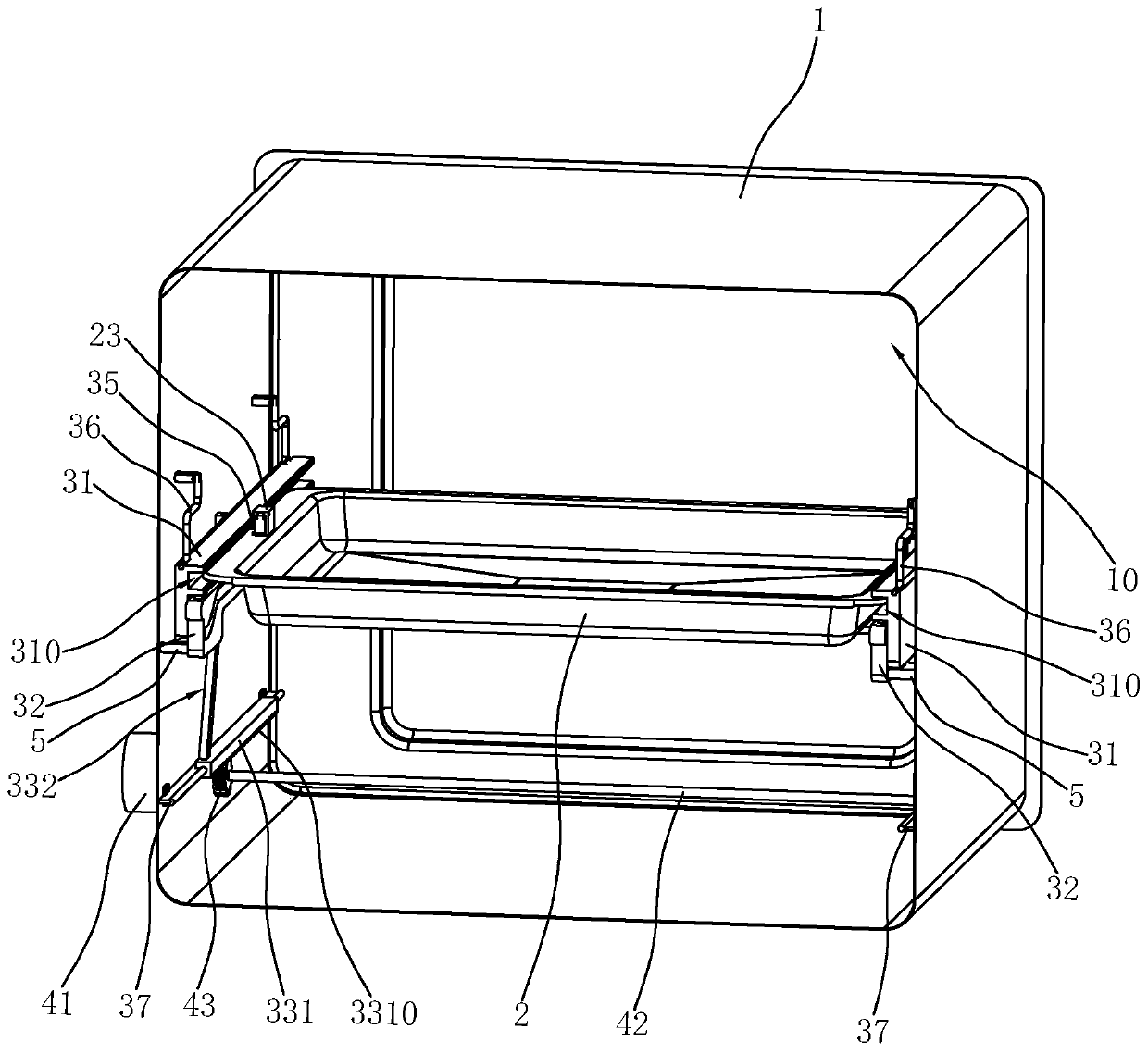

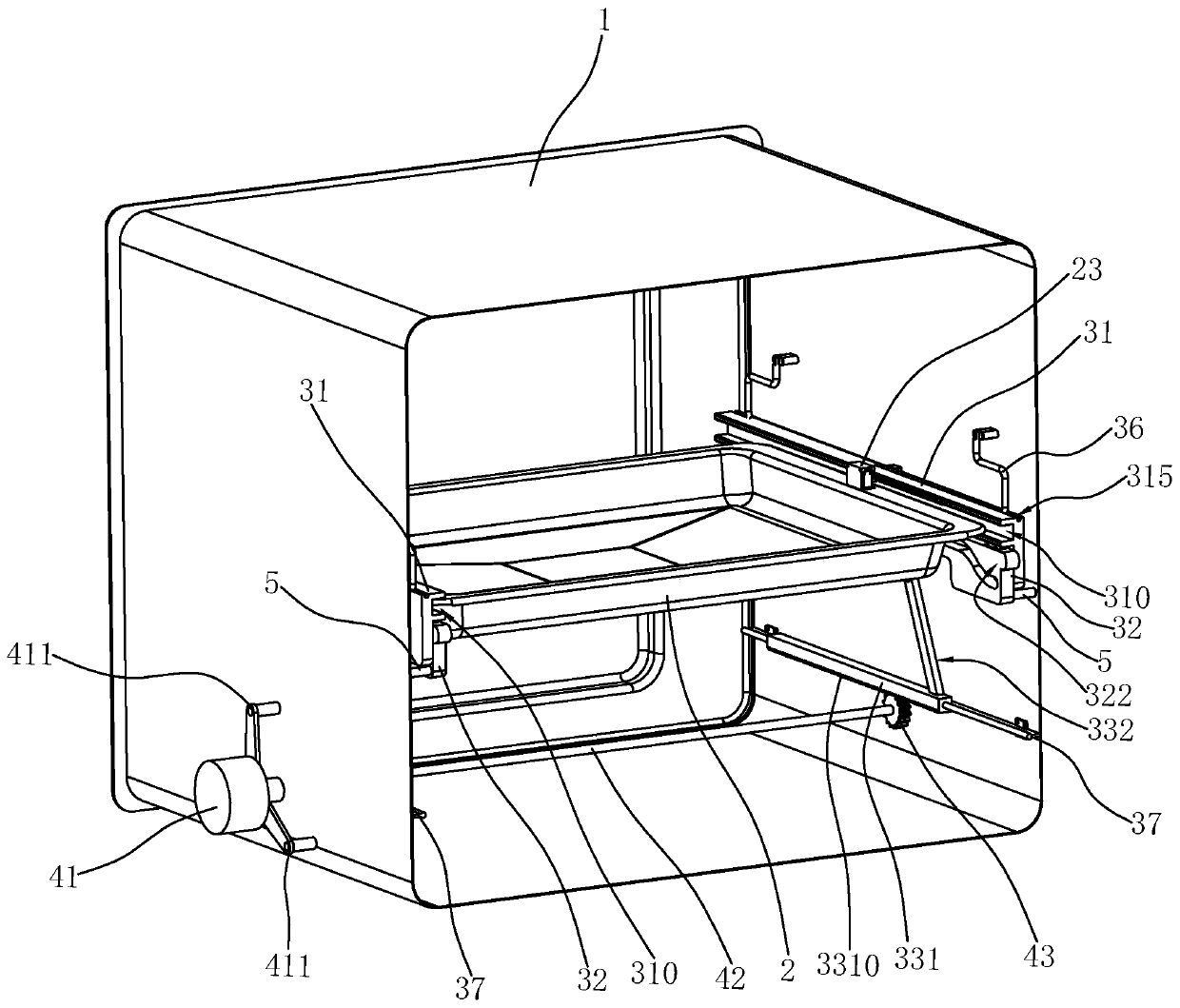

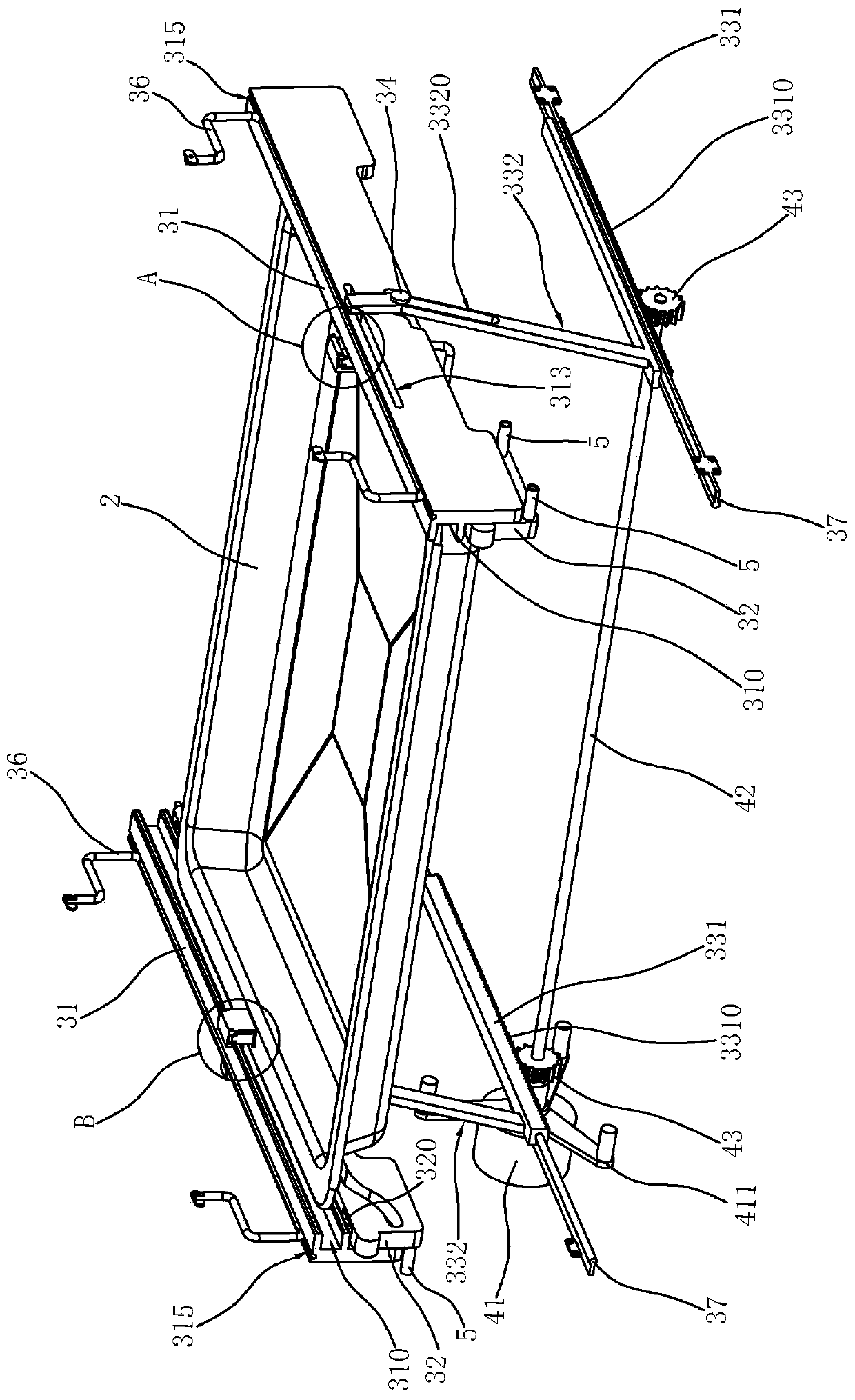

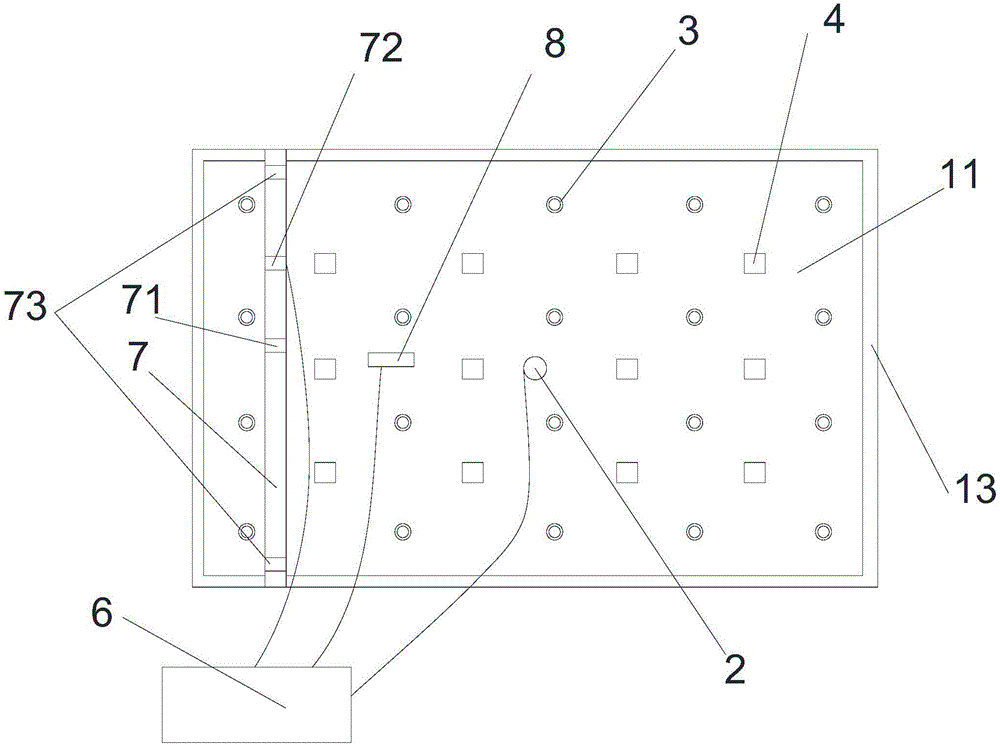

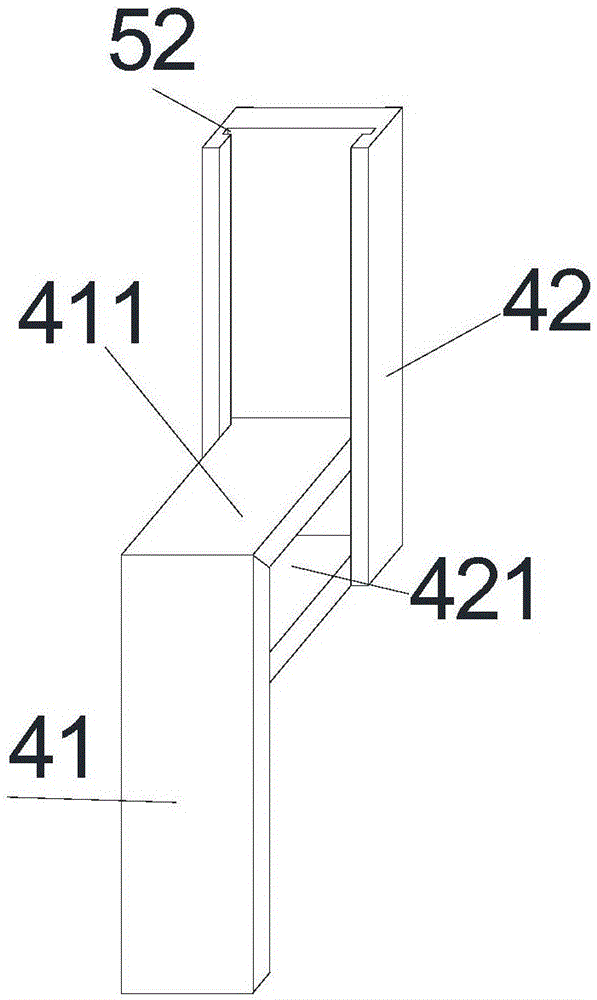

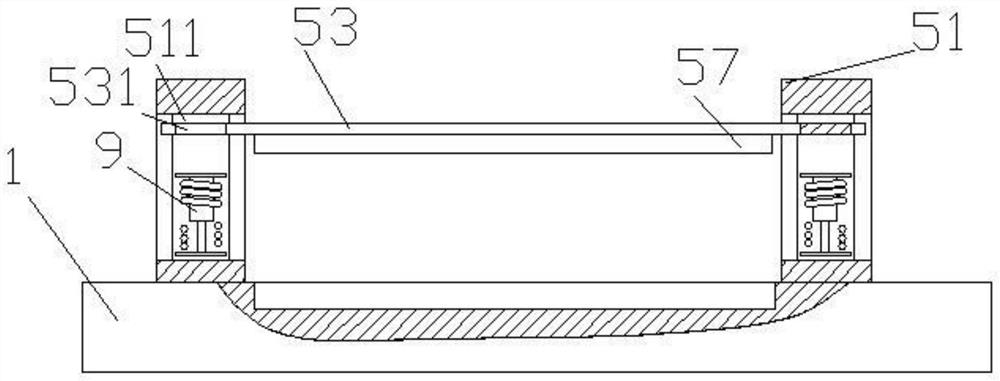

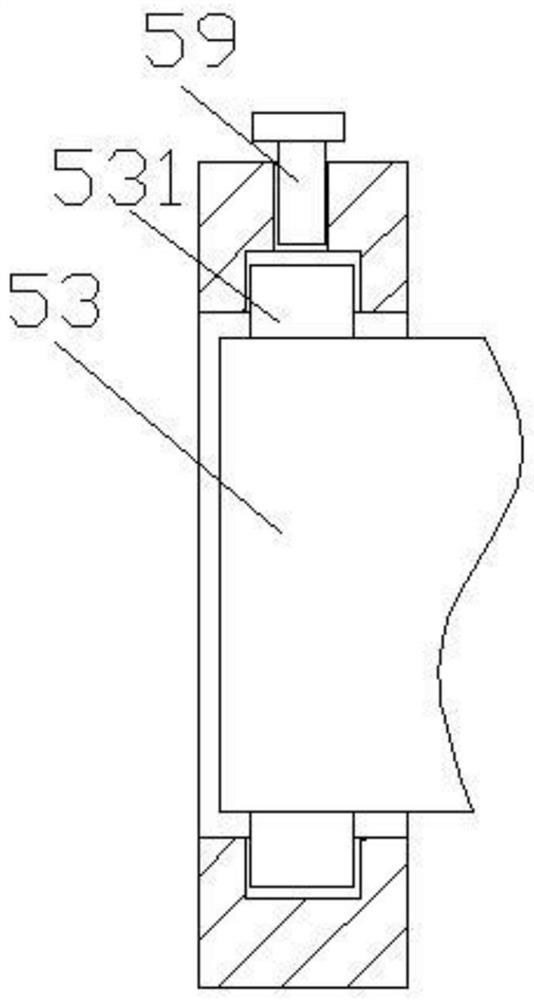

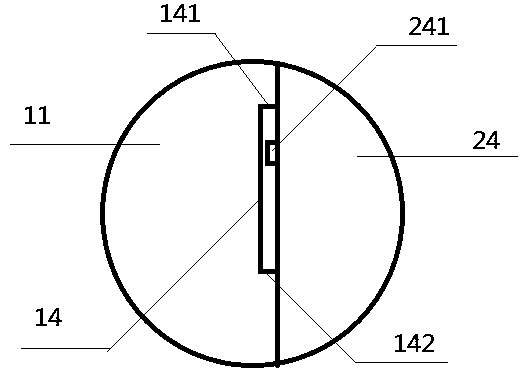

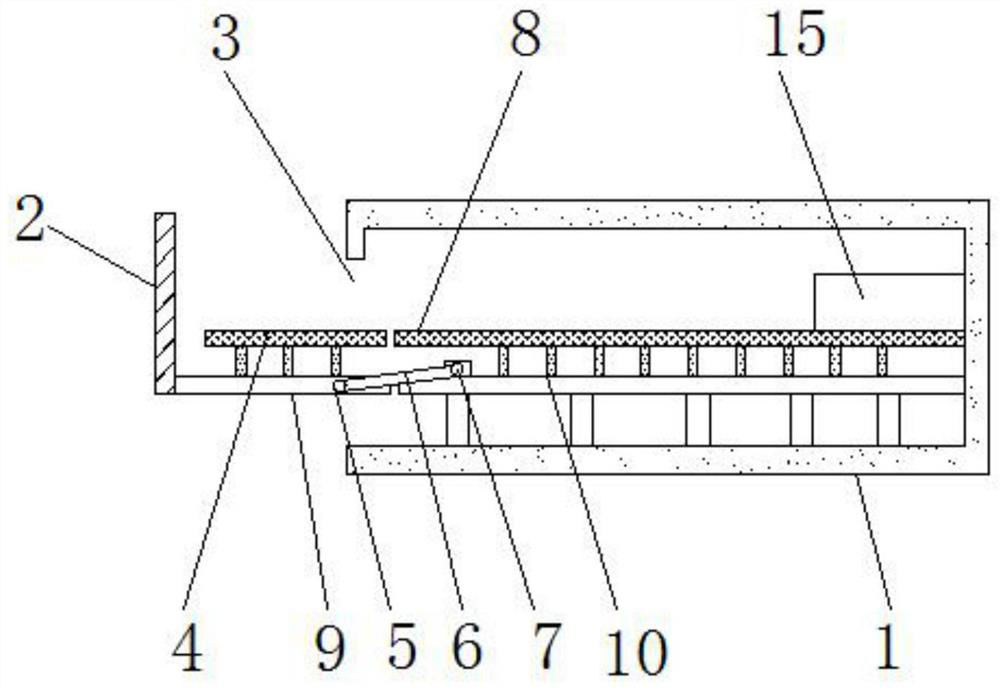

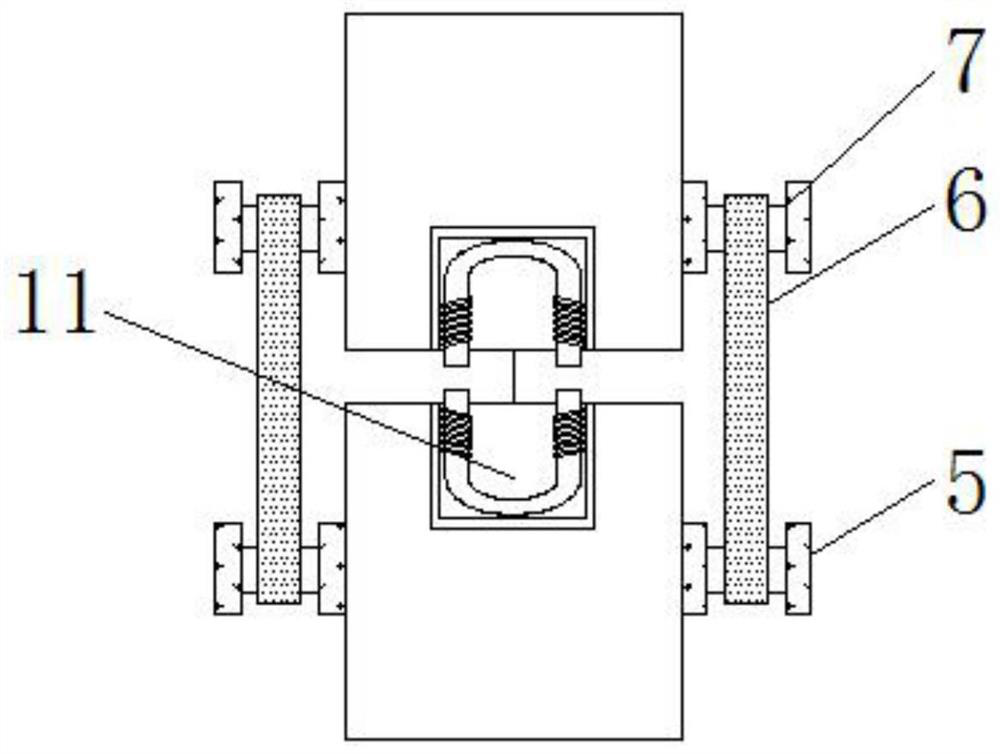

Oven realizing stable move-out of baking plate

ActiveCN110604483AGuaranteed direction of movementEnsure terminationRoasters/grillsEngineeringMechanical engineering

Owner:NINGBO FOTILE KITCHEN WARE CO LTD

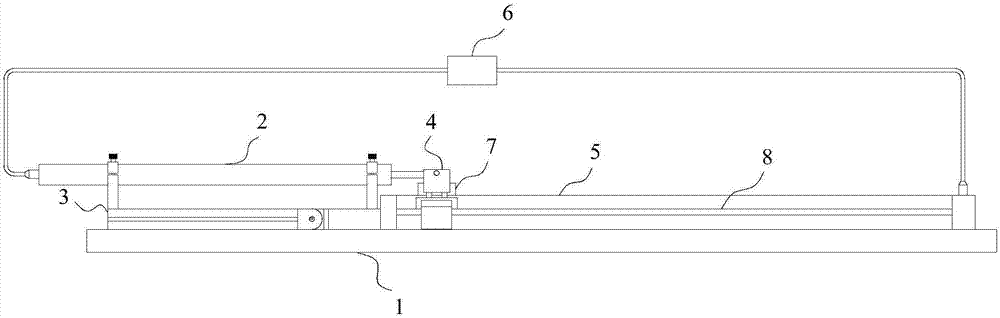

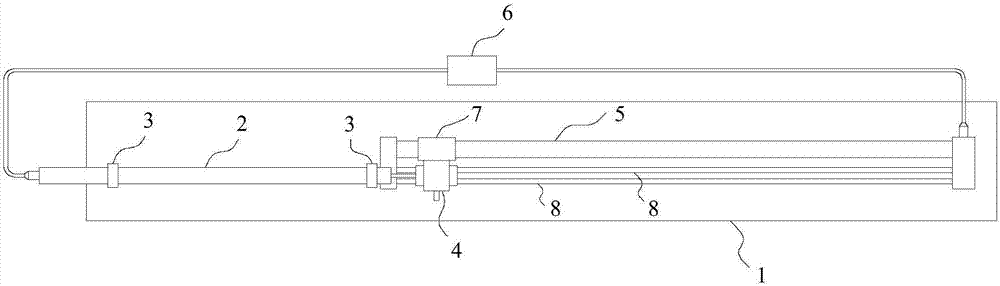

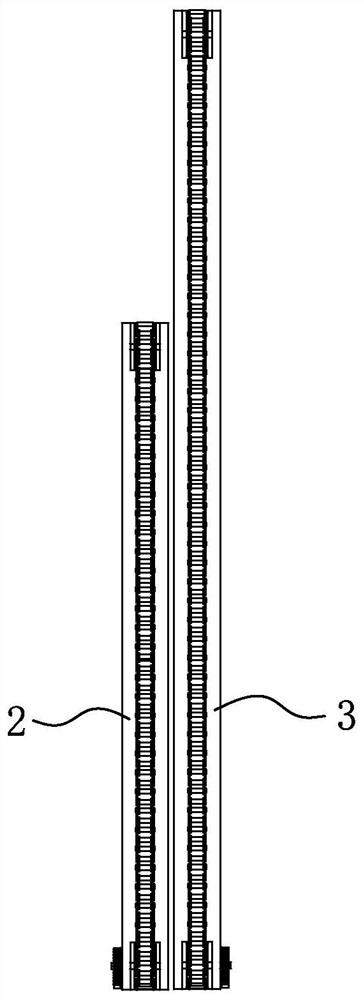

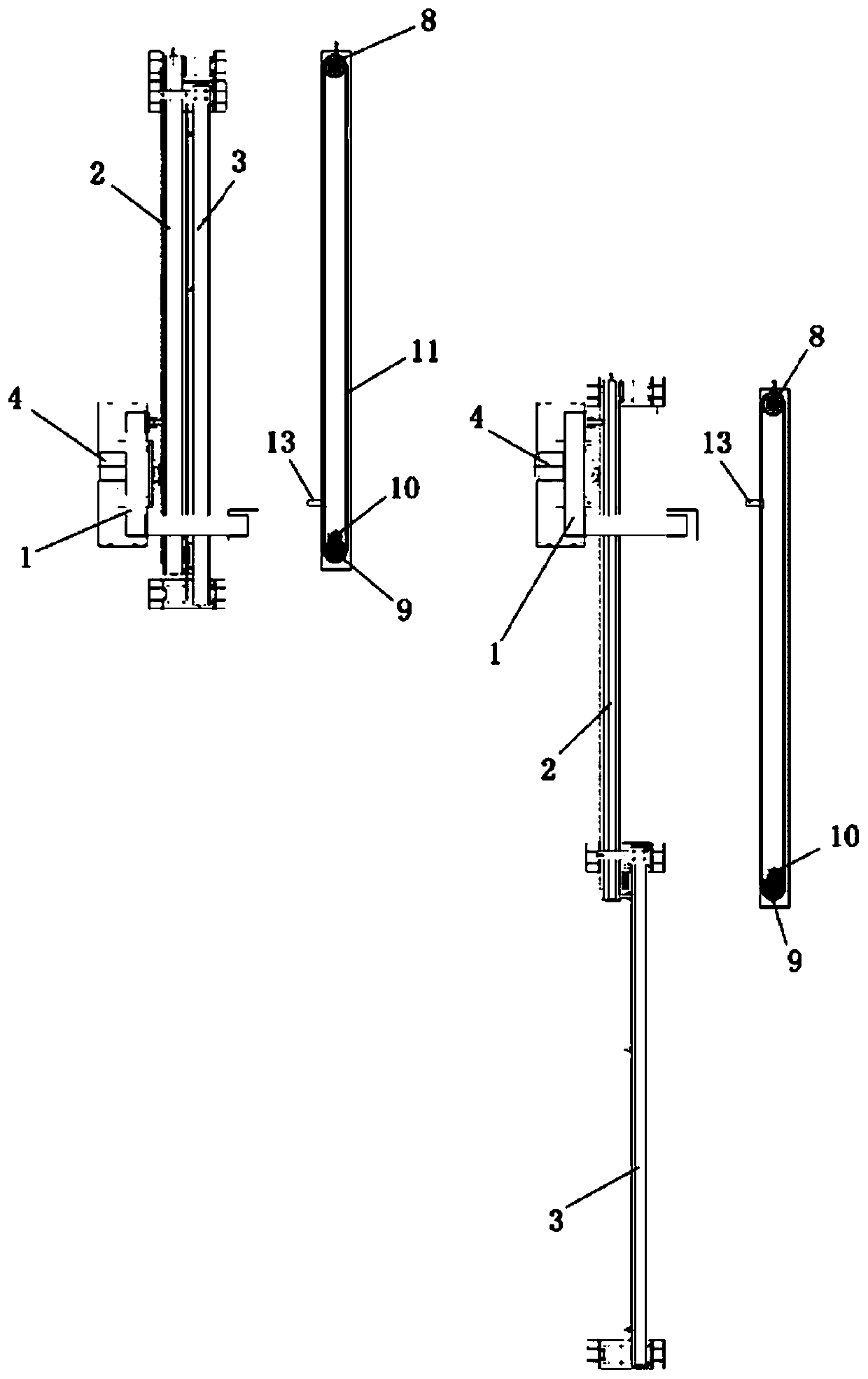

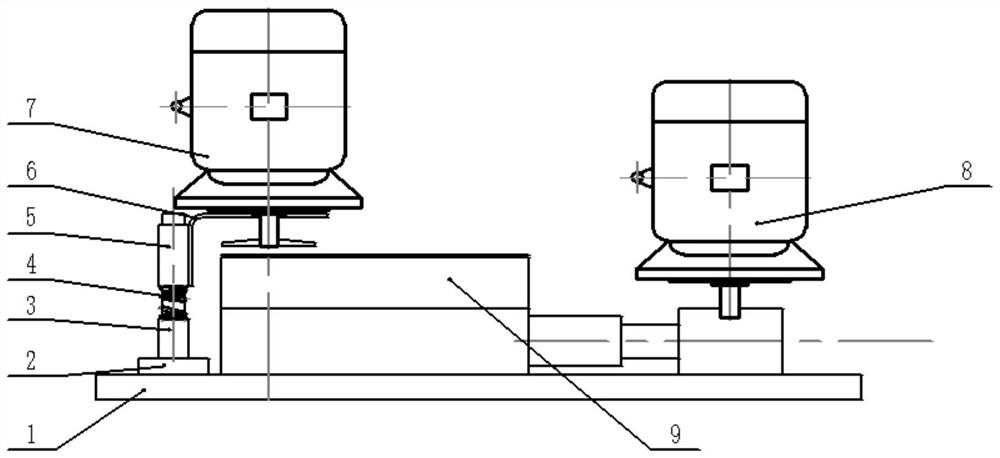

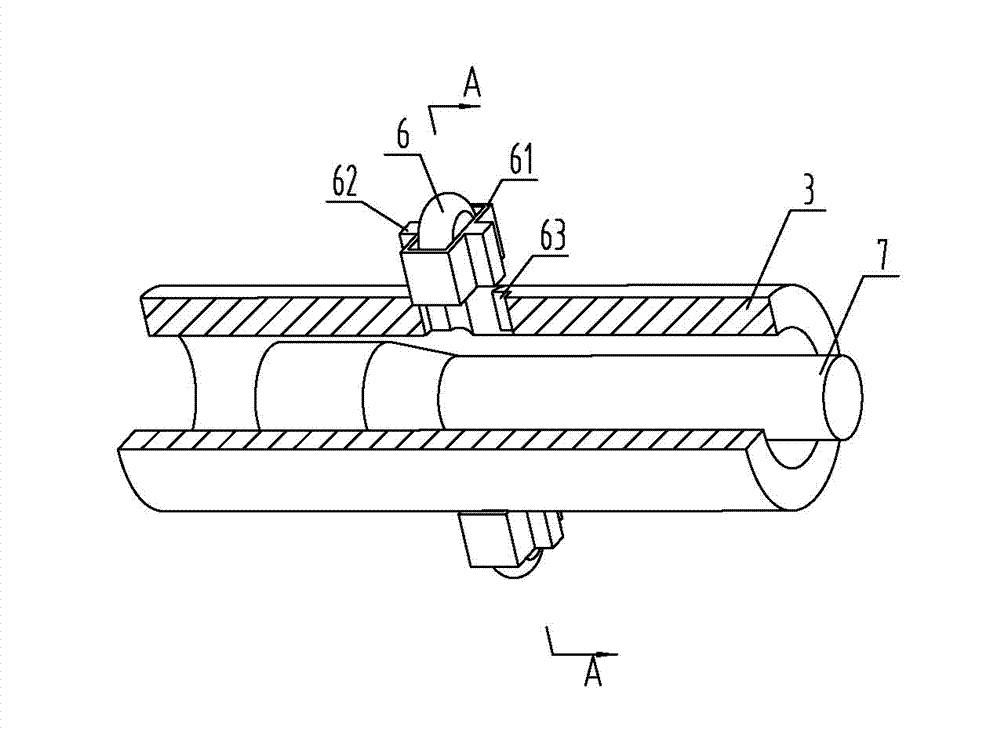

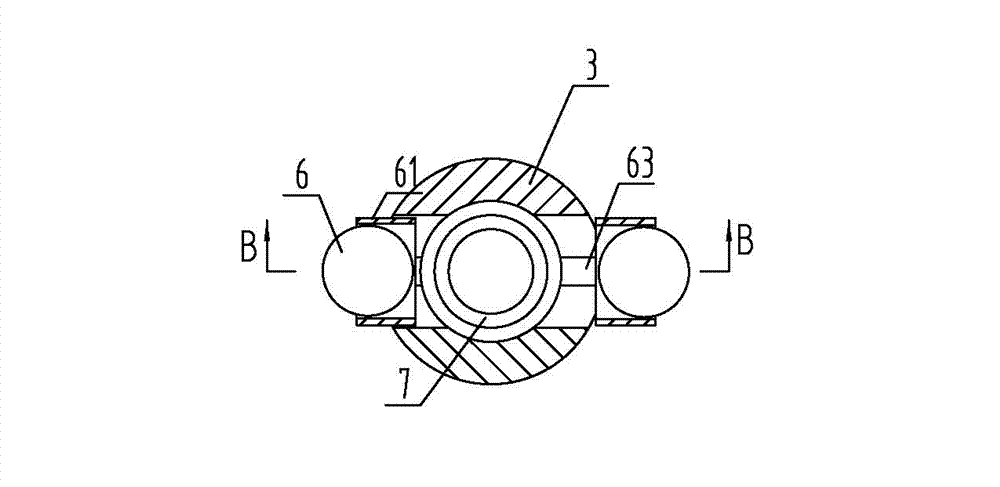

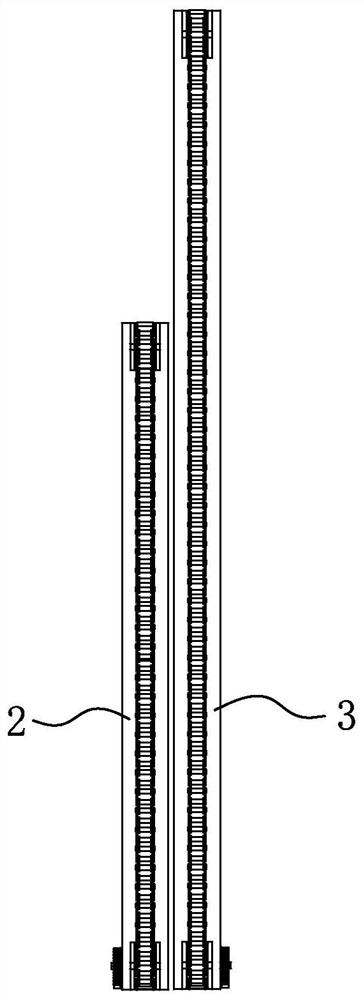

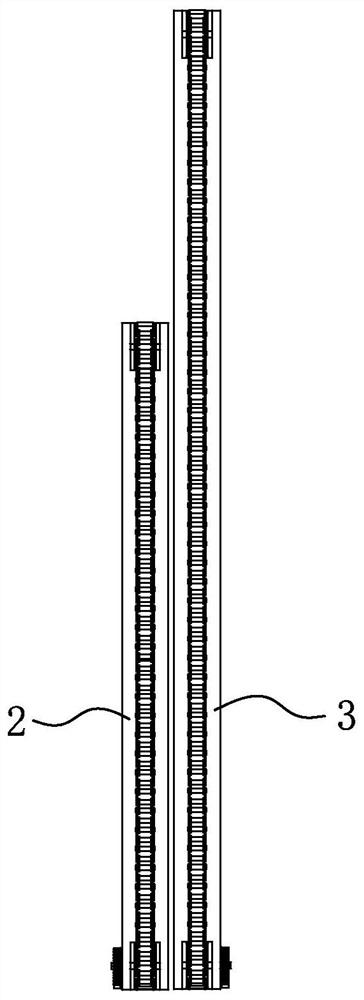

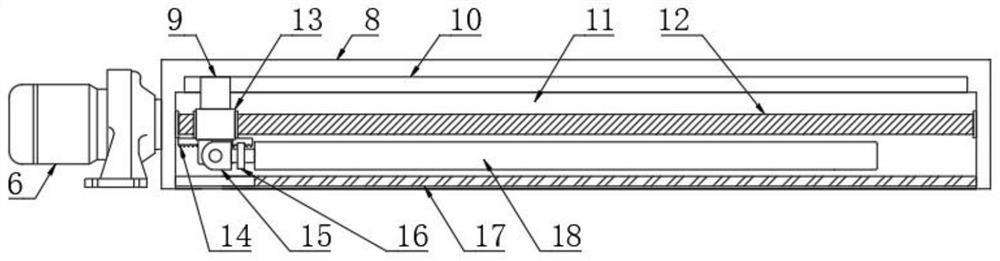

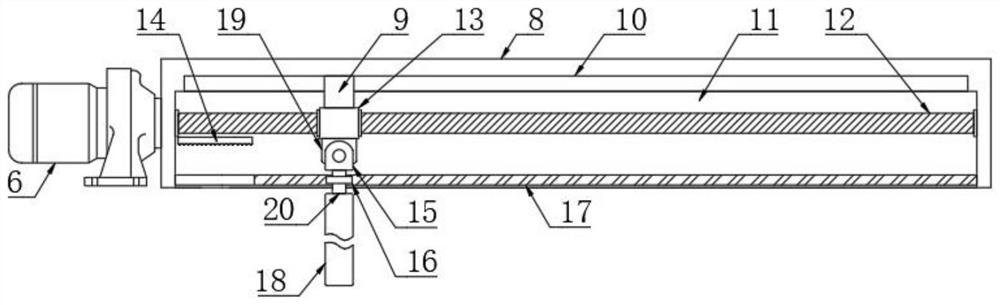

Linear displacement metering calibrator

InactiveCN107014330AHigh measurement accuracyGuaranteed accuracyUsing electrical meansUsing optical meansGratingEngineering

The invention relates to a linear displacement metering calibrator, and the calibrator comprises a substrate, a linear displacement sensor, a clamping part, a moving part, a grating ruler, and output equipment. The precision of the linear displacement sensor is less than the precision of the grating ruler, and the clamping part and the grating ruler are disposed on the substrate. The linear displacement sensor is disposed on the clamping part, and the linear displacement sensor and the grating ruler are respectively connected to the output equipment. A pull rod of the linear displacement sensor is connected with the moving part, and is parallel to the grating ruler. The moving part is fixedly connected with a measuring head of the grating ruler. The calibrator can calibrate the linear displacement sensor because the precision of the grating ruler is greater than the precision of the linear displacement sensor, improves the measurement precision of the linear displacement sensor, guarantees the accuracy of the linear displacement sensor, is simple in structure, facilitates the production, and is low in cost.

Owner:SICHUAN UNIV

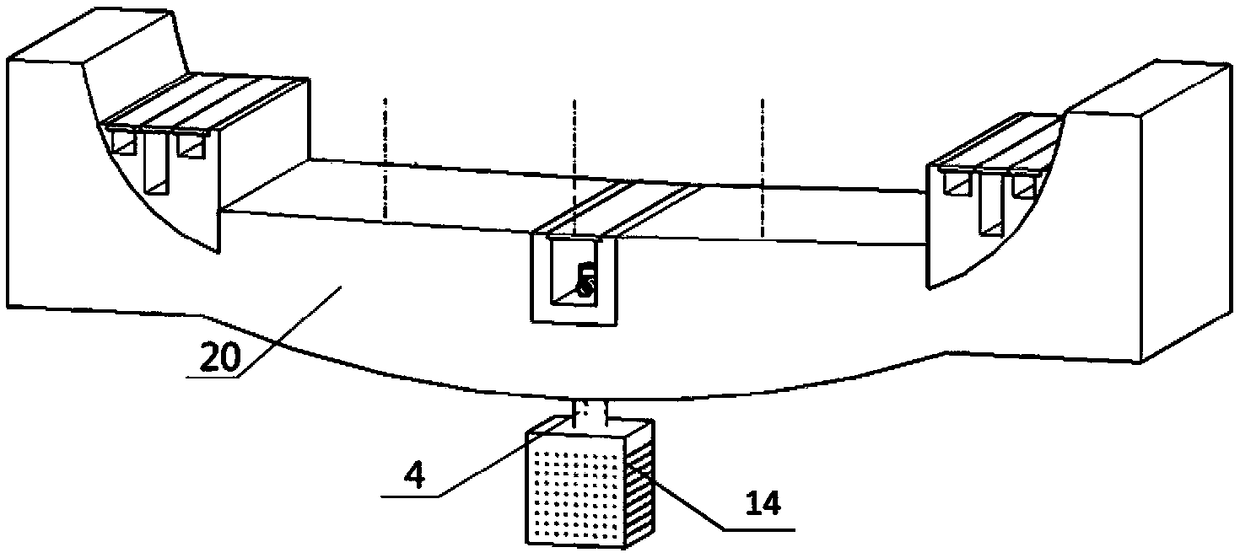

Thermal expansion adjusting device and method for glass tank furnace

PendingCN111018315ASolve structural deformationNo structural deformationGlass furnace apparatusStructural engineeringManufacturing engineering

The invention discloses a thermal expansion adjusting device for a glass tank furnace. The thermal expansion adjusting device comprises adjusting bolts, fixed columns, a release brace and adjusting nuts, wherein stand columns are symmetrically arranged on the two sides of the glass tank furnace and located and fixed to a bottom platform of the glass tank furnace through locating bolts; the fixed columns are fixedly connected to the parts, located at the outer sides of the stand columns on the two sides of the tank furnace, of the bottom platform respectively; the adjusting bolts are in threaded connection with the fixed columns, and the ends of screws abut against the bottoms of the stand columns on the same side; the two ends of the release brace are provided with threads, penetrate through the upper portions of the stand columns on the two sides of the glass tank furnace respectively and are connected with the adjusting nuts. According to the thermal expansion adjusting device for the glass tank furnace, the bottom positioning bolts are disassembled, and the tightness state of the adjusting screws and the release brace is adjusted by rotating the adjusting bolts and the adjustingnuts, so the stand columns of the glass tank furnace are continuously moved and adjusted, and structural deformation caused by expansion of the glass tank furnace is effectively solved.

Owner:IRICO DISPLAY DEVICES

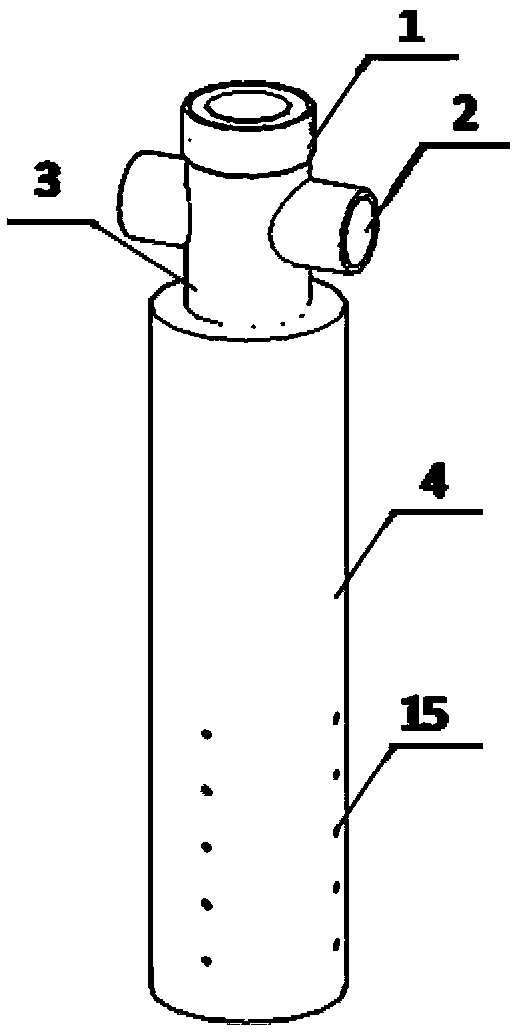

Drainage device and method for tunnel and underground structure

InactiveCN108755722AReduce water pressureInhibit deteriorationFoundation engineeringDrainageEngineeringOuter Cannula

The invention provides a drainage device and method for a tunnel and an underground structure. The drainage device comprises an outer sleeve pipe penetrating through a tunnel lining or the undergroundstructure when used, a core pipe and a drainage structure control unit placed in the core pipe, wherein the lower end of the core pipe extends into the upper end of the outer sleeve pipe, and the core pipe is in threaded connection with the outer sleeve pipe. A plurality of second water release holes are formed in the outer wall of the lower portion of the outer sleeve pipe; a bearing part is arranged at the lower end of the core pipe, and a plurality of first water release holes are formed in the outer wall of the lower portion of the core pipe; and the drainage structure control unit comprises a stabilizing block placed in the core pipe and located on the bearing part, a guiding sleeve, a guiding rod, a connecting piece, a sealing piece, a spring, a top cover and one or more transversedrainage pipes, wherein the lower end of the guiding sleeve is fixedly connected with the upper end of the stabilizing block; the lower end of the guiding rod extends into the guiding sleeve, and theguiding rod is in sliding fit with the guiding sleeve; the connecting piece is fixedly connected with the upper end of the guiding rod; the sealing piece is mounted at the upper end of the connectingpiece and is in liquid sealing fit with the inner wall of the core pipe; the spring is mounted on the guiding sleeve in a sleeving mode, and the two ends of the spring are fixedly connected with the stabilizing block and the connecting piece correspondingly; and the upper end of the core pipe is closed by the top cover.

Owner:KUNMING SURVEY DESIGN & RES INST OF CREEC

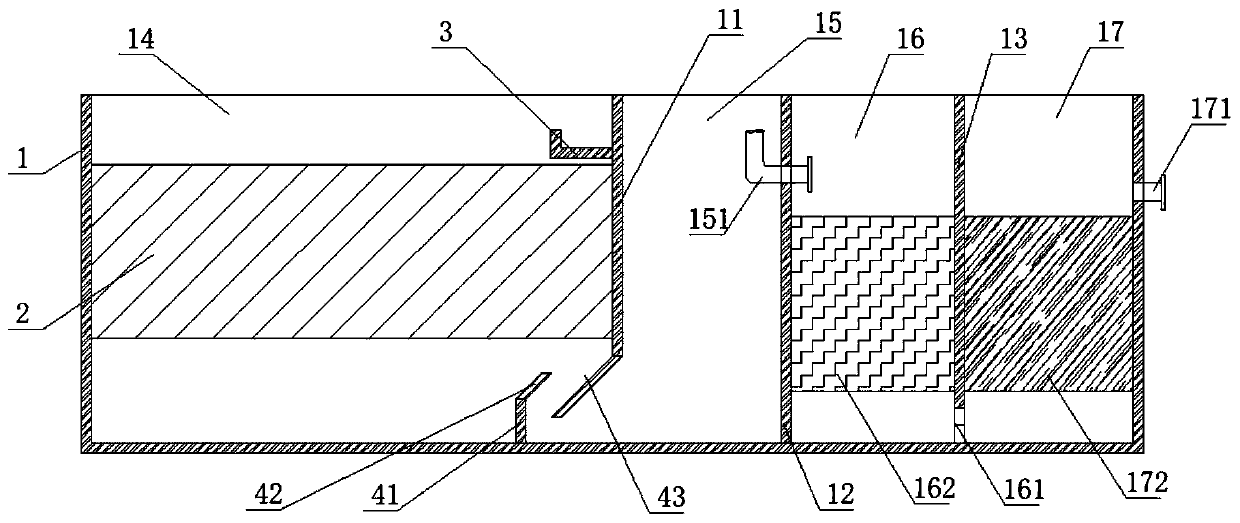

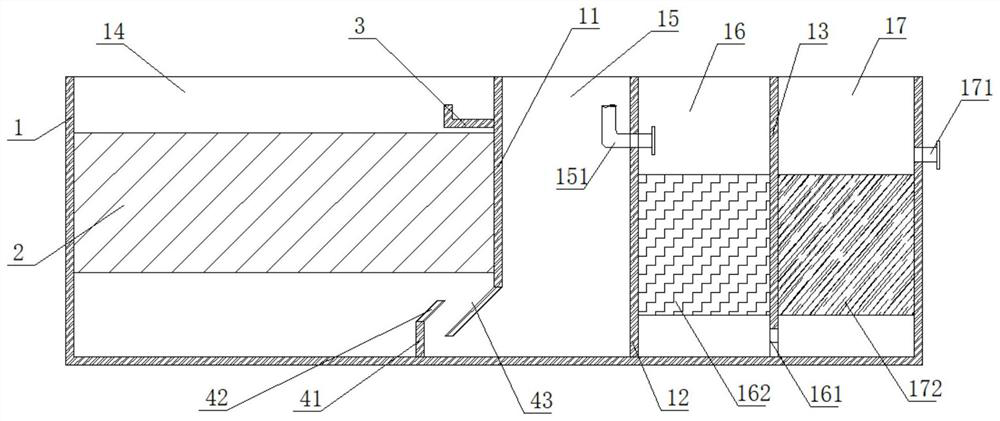

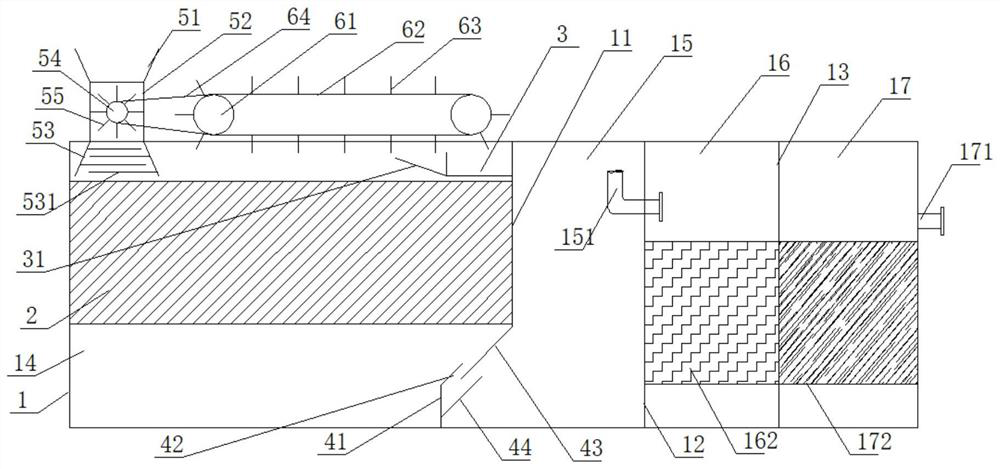

Movable integrated transformer substation accident oil tank oil-containing wastewater treatment device

ActiveCN110937704AExtended stayReduce dwell timeFatty/oily/floating substances removal devicesWater contaminantsTransformerWaste oil

The invention discloses a movable integrated transformer substation accident oil tank oil-containing wastewater treatment device which is used for treating the oil-containing wastewater in an accidentoil tank. A drainage treatment device includes: a shell, internally provided with an oil-water separation bin, a liquid level adjustment bin, a first filtering chamber and a second filtering chamber;sloping plate packing, disposed at the upper part of the oil-water separation bin; an oil storage tank, disposed in the oil-water separation bin and located above the sloping plate packing. Due to integrated design, the device can be carried by a vehicle, so that field hoisting is avoided, and the device can be manufactured out of field and regulated and operated directly on field. The device isshort in treatment time, is free of influence on normal operation of the transformer substation, can adapt the compact arrangement and stressed field occupation of the transformer substation. The device is simple in structure, allows automatic oil-water separation, is low in manual management load in operation, is convenient to maintain and can work well just by removing the waste oil at certain frequency, and is low in operation cost.

Owner:STATE GRID HUBEI ELECTRIC POWER CO LTD MAINTENANCE CO +1

Vehicle alarm device

InactiveCN106394242ALow yield ratioHigh elongationTractorsSignalling/lighting devicesSmoke detectorsControl system

The invention discloses a vehicle alarm device, and belongs to the technical field of electronics. The vehicle alarm device comprises a box body, a pressure sensor, elastic pieces and connection devices, wherein two ends of the elastic pieces and two ends of the connection devices are respectively fixed on the bottom surface and an upper cover of the box body; one end of the pressure sensor is fixed on the bottom surface of the box body; a detection air duct and a buzzer are arranged on the bottom surface of the box body; the detection air duct is provided with an air inlet and an air outlet which enable air outside the box body to get in and out; dustproof screens, a smoke fog detector and a fan are arranged in the detection air duct in a spacing manner; the dustproof screens are arranged at two ends of the detection air duct to remove dust entering the detection air duct; both the smoke fog detector and the pressure sensor are connected with the buzzer; and the buzzer is connected with a vehicle control system to realize an alarm of a vehicle. The alarm device disclosed by the invention can detect a load capacity and the concentration of smoke fog, and can sound the alarm once the load capacity and the concentration of the smoke fog exceed limited threshold values.

Owner:龙婵绘

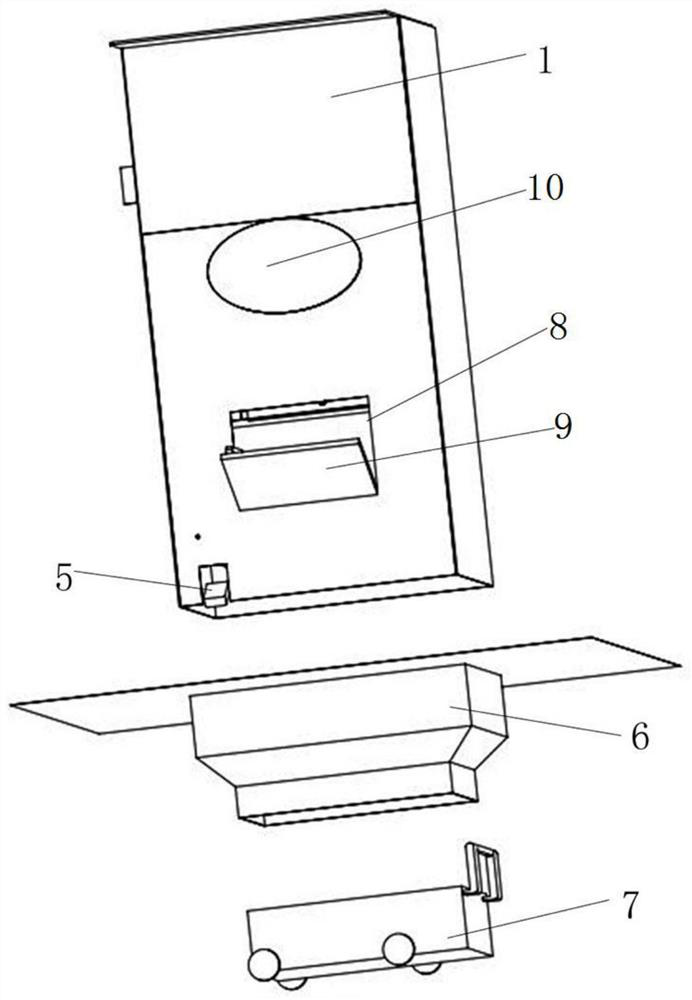

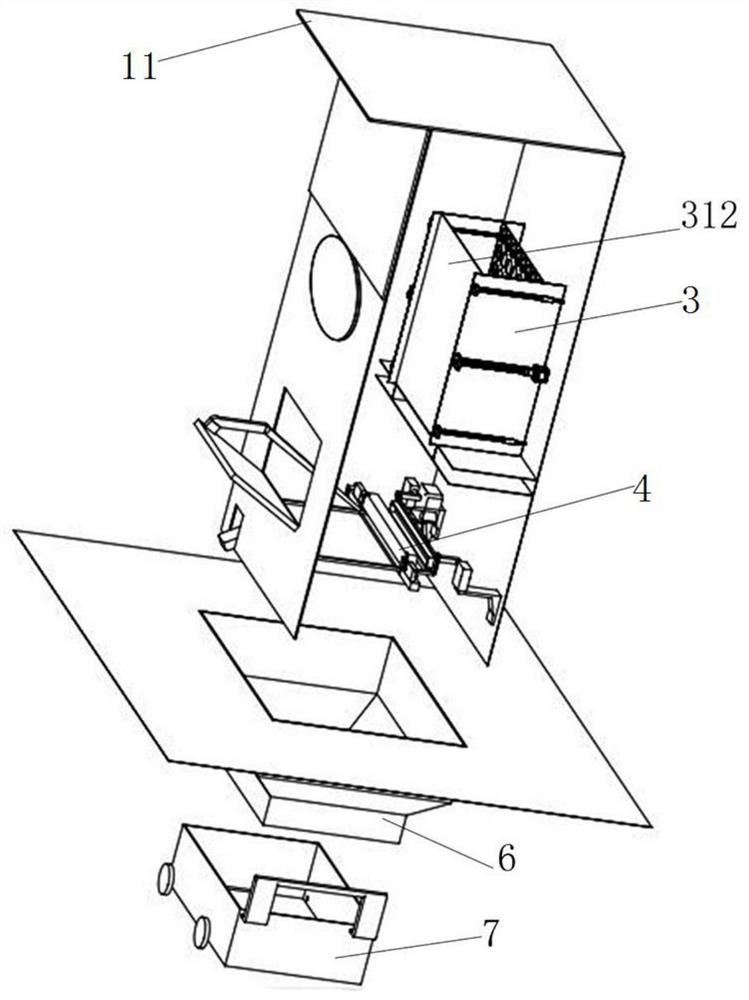

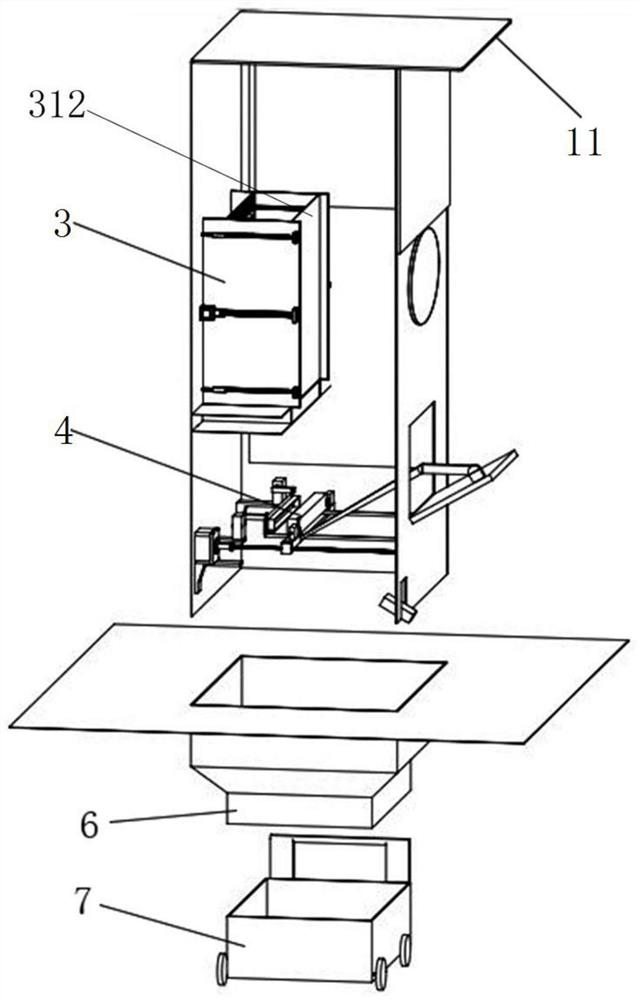

Household garbage datamation classification recycling system and classification method

PendingCN113071835AEasy to operateEasy to recycleRefuse transferringLoading/unloadingControl systemIdentification device

The invention discloses a household garbage datamation classification recycling system. The system comprises a garbage recycling system and a garbage sorting part; the garbage recycling system comprises household garbage throwing intelligent equipment and a control system; the household garbage throwing intelligent equipment comprises a garbage can body, a garbage funnel and a garbage trolley; and a display screen, a recognition device, a garbage throwing opening, a garbage door and a pedal are arranged on the garbage can body, a special garbage bag storing and delivering mechanism is arranged in the garbage can body, a set of special garbage bags are stacked in the special garbage bag storing and delivering mechanism, and a special garbage bag opening and closing and garbage throwing opening opening and closing mechanism is arranged below the special garbage bag storing and delivering mechanism. The method has the advantages that the operation is simple, the garbage is convenient to recycle, the use method and the control mode are simple and practical, the classification method for decayed, burnt and dyed and transformed garbage is provided, the classification method is simple and efficient in management, and meanwhile, the user is promoted to accurately classify the garbage in a reward income mode.

Owner:申建为

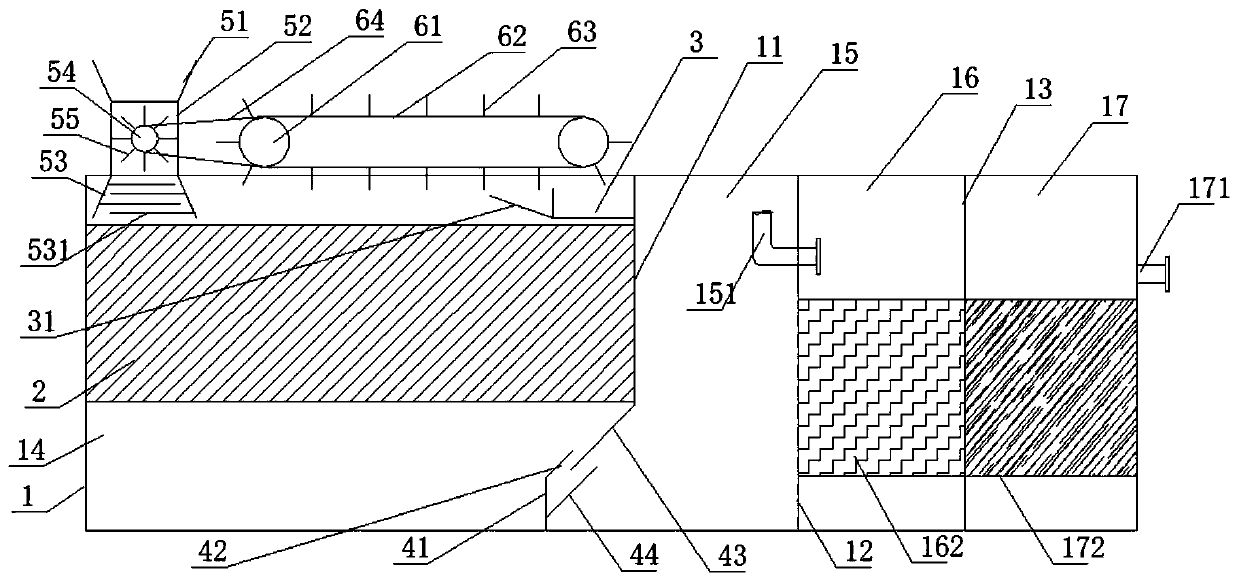

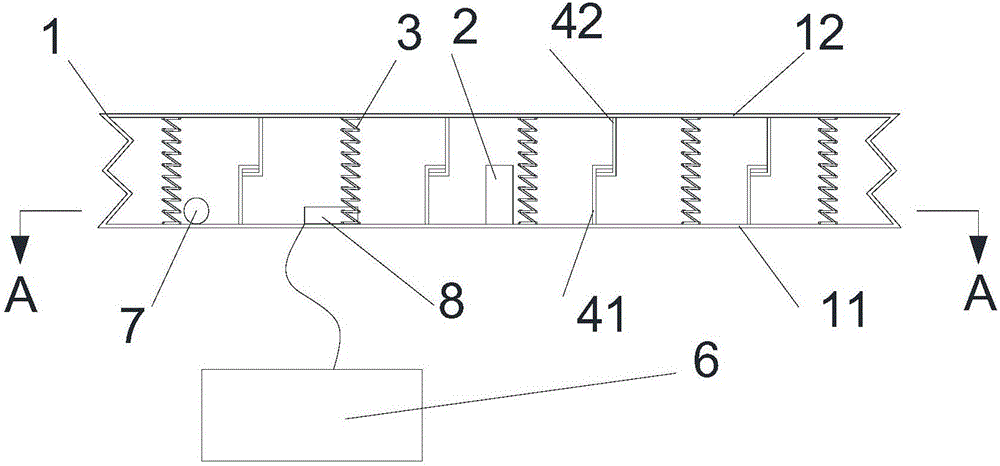

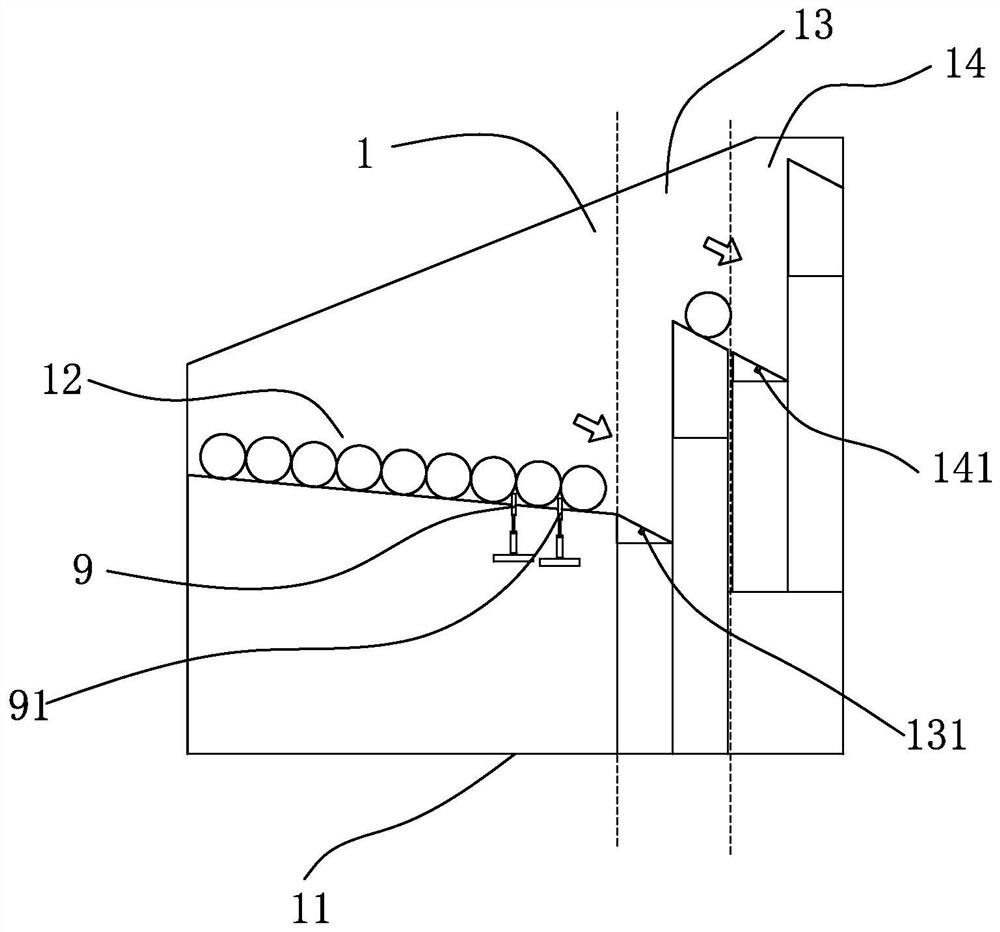

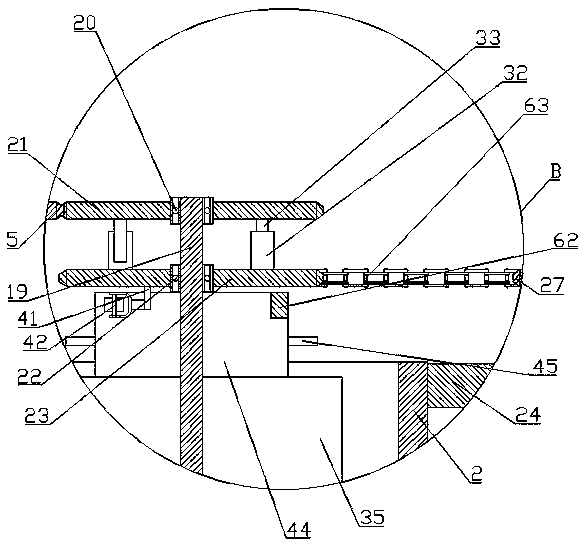

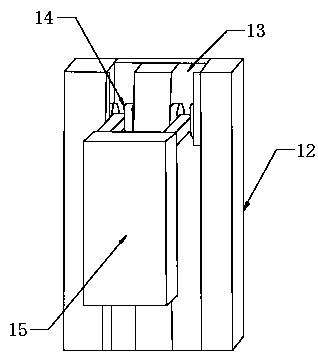

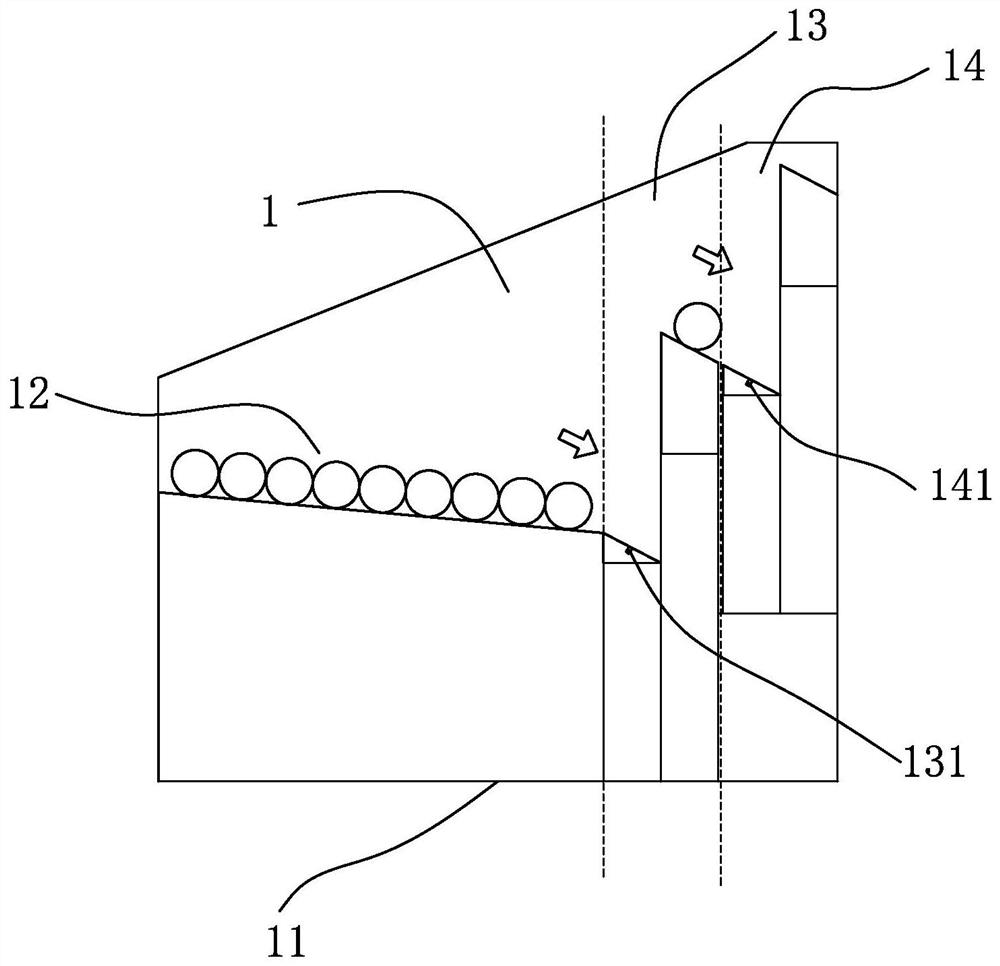

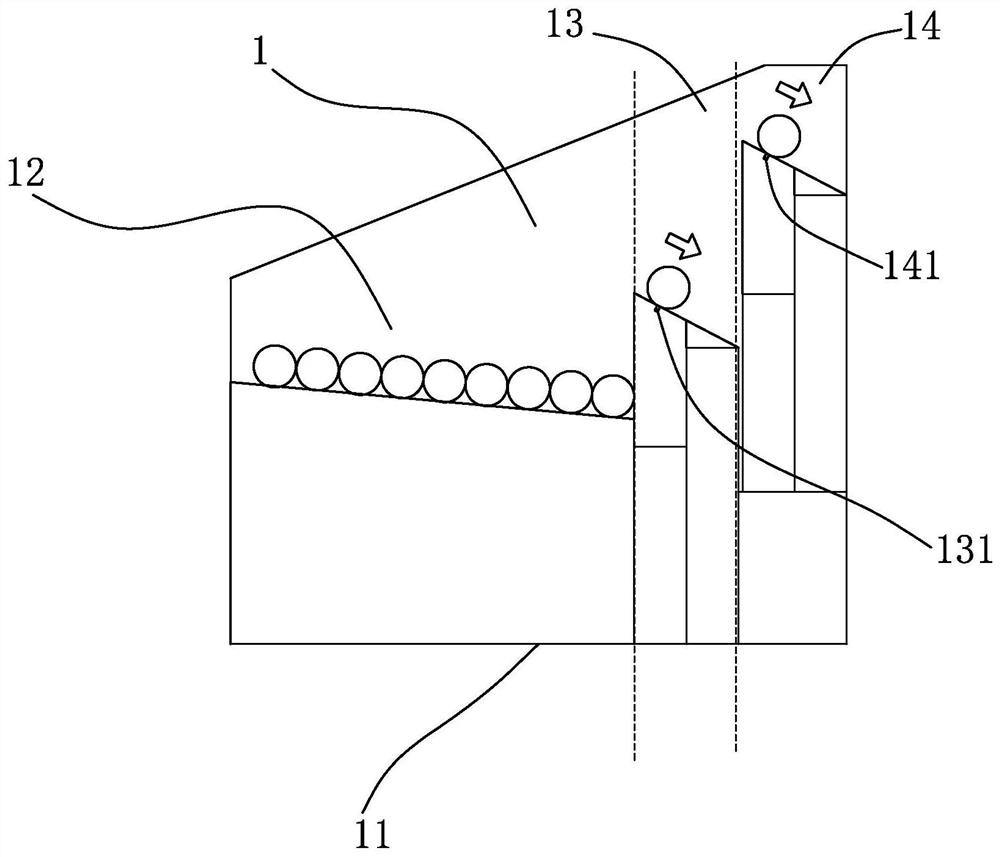

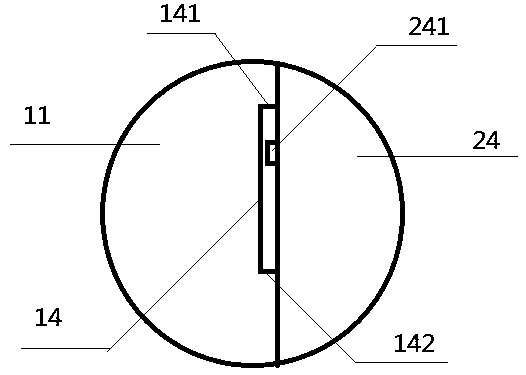

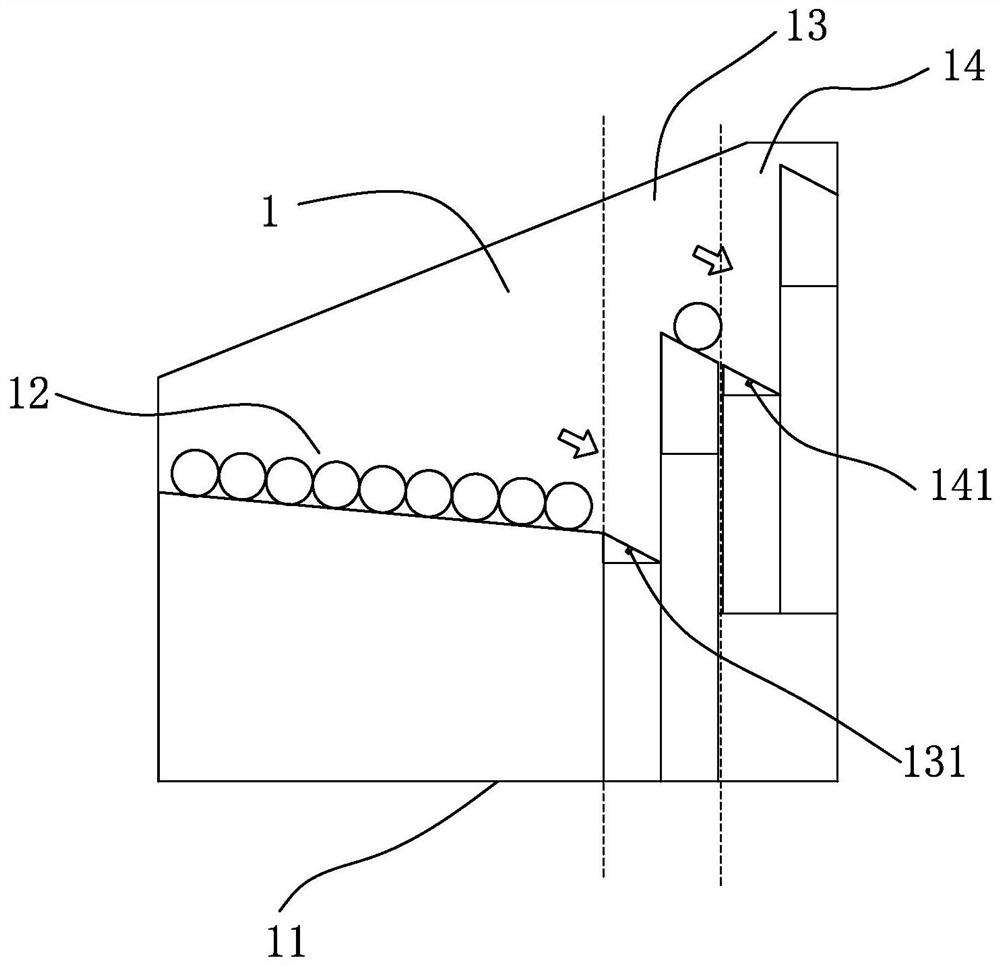

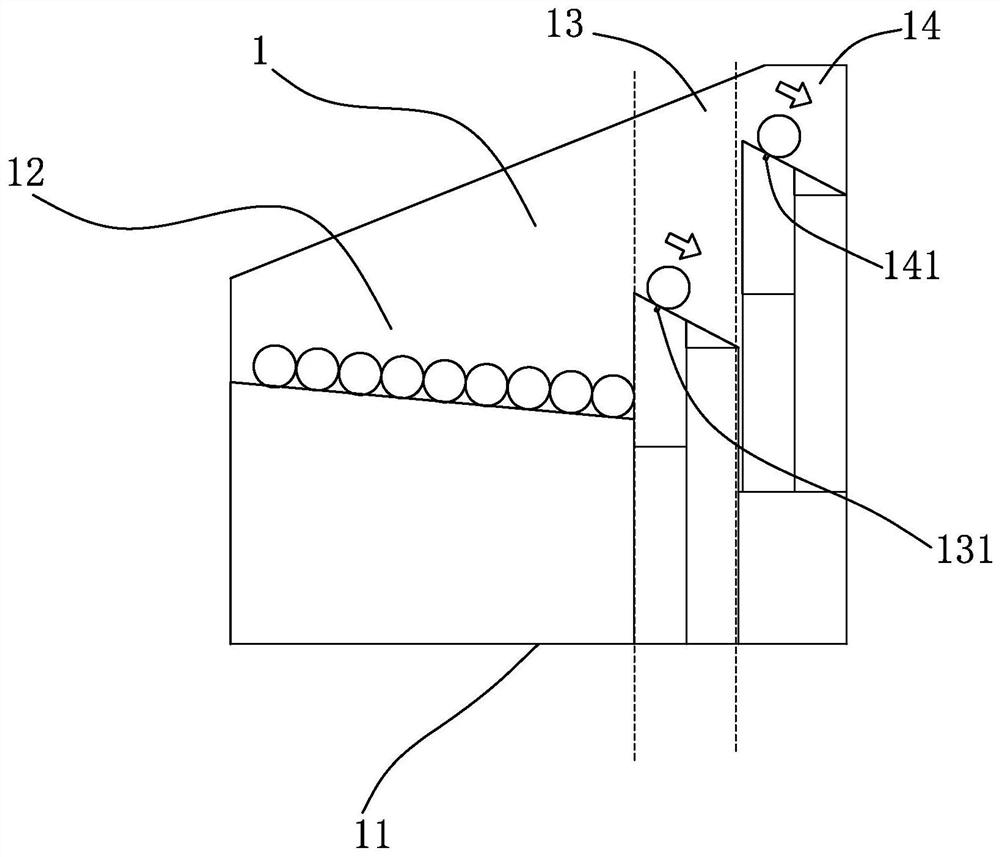

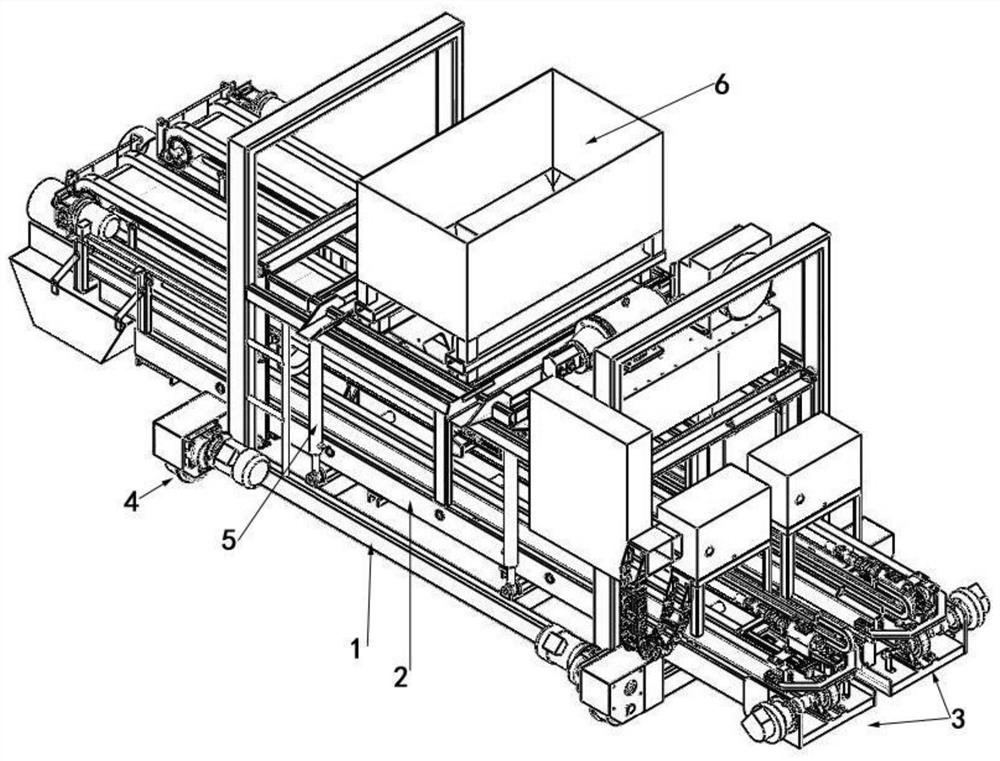

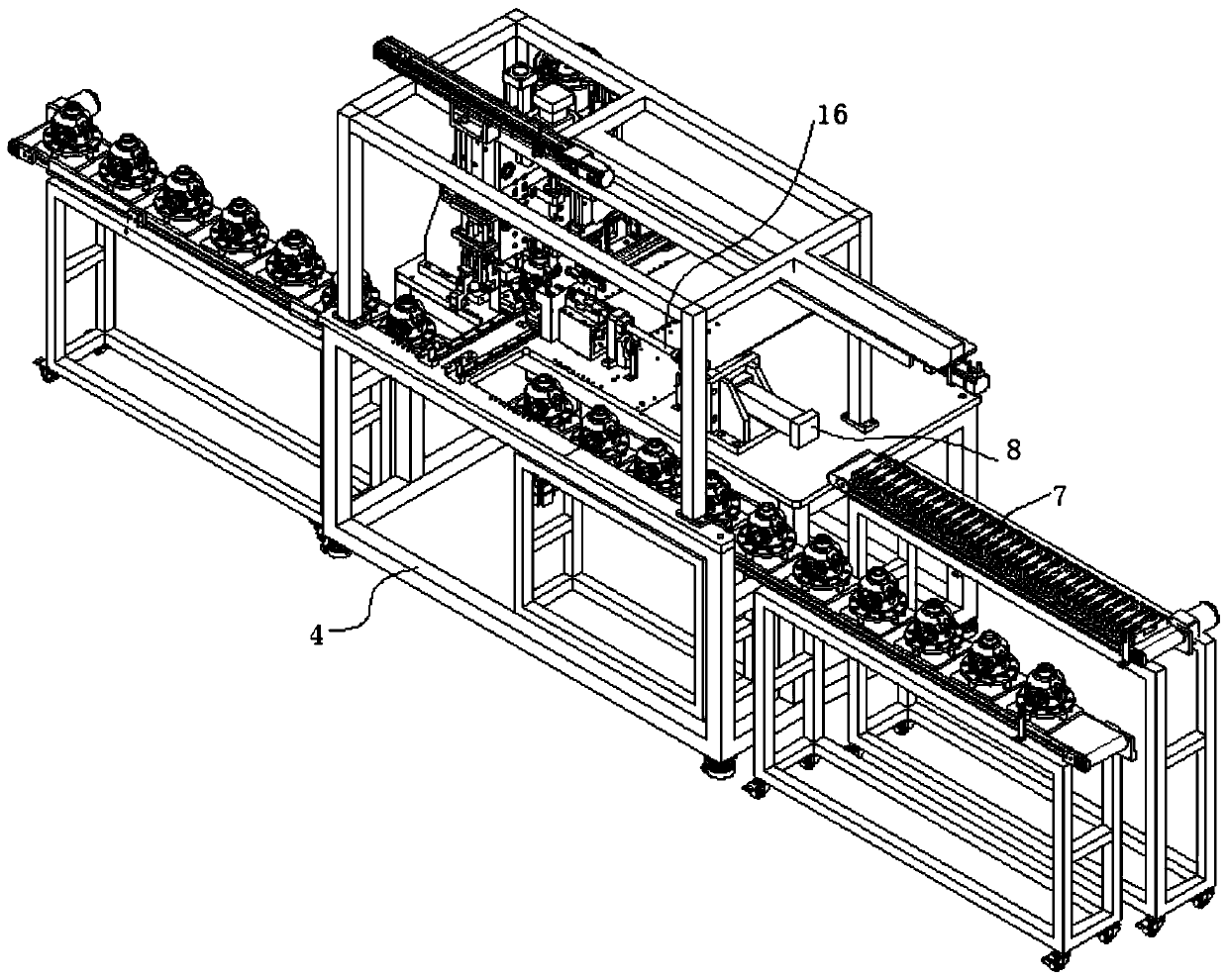

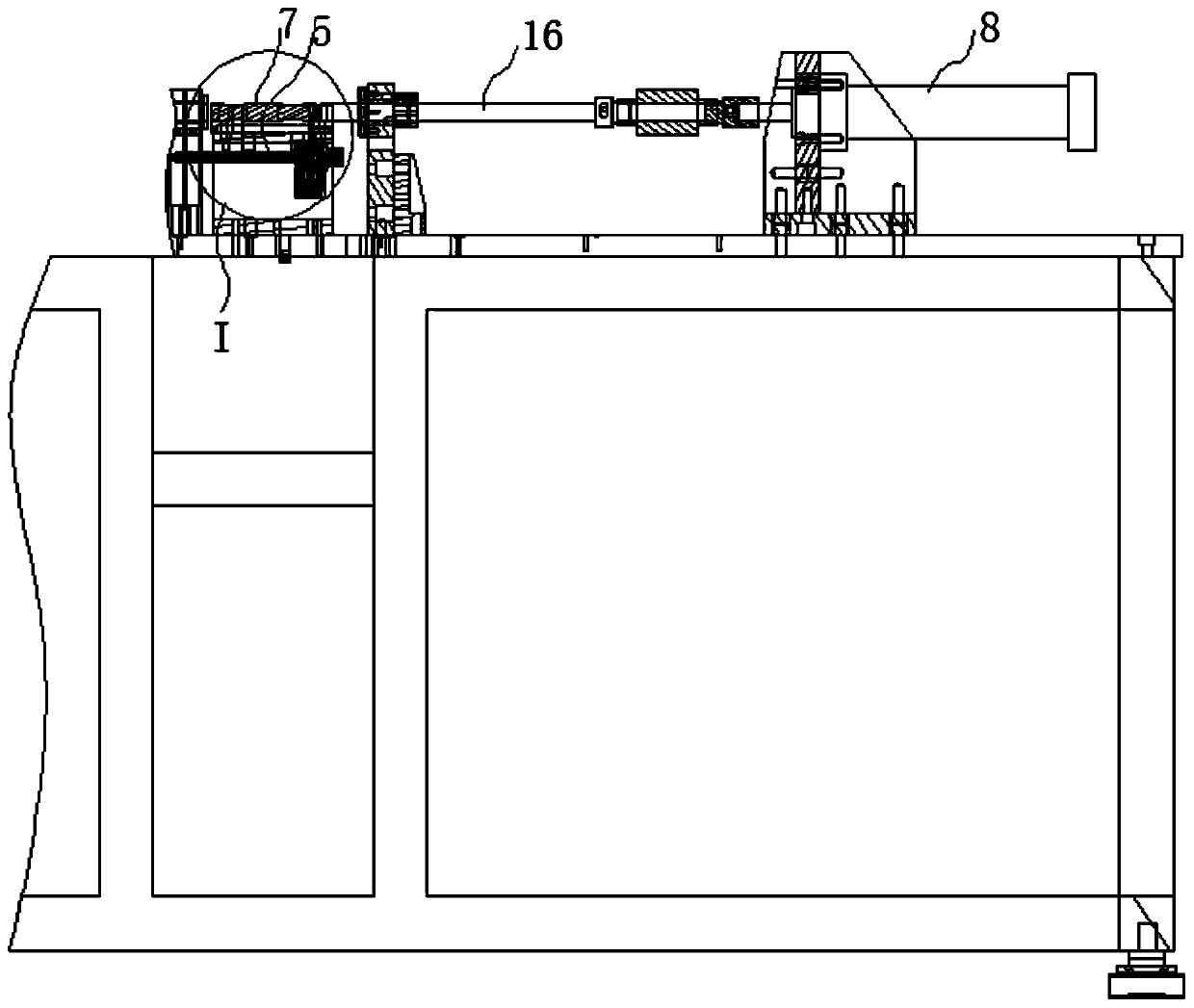

Feeding device for drill rod production and feeding method thereof

InactiveCN113460669AEnsure consistencyAvoid leaningConveyorsControl devices for conveyorsStructural engineeringManufacturing engineering

The invention discloses drill rod machining equipment, and particularly relates to a feeding device for drill rod production and a feeding method thereof. The feeding device comprises a drill rod box and a stepped feeding mechanism, the drill rod box stores raw materials, and the stepped feeding mechanism lifts the raw materials in the drill rod box upwards for feeding. The drill rod box is obliquely arranged towards the stepped feeding mechanism, the raw materials in the drill rod box can automatically roll towards the stepped feeding mechanism under the action of gravity, a first movable plate and a second movable plate are arranged in the drill rod box, the first movable plate can be arranged between the penultimate raw material and the antepenultimate raw material, and the second movable plate can be arranged between the penultimate raw material and the last raw material, so that the raw materials can be temporarily blocked by the first movable plate and the second movable plate, the sequence of the raw materials can be ensured when the raw materials roll to the stepped feeding mechanism, and the feeding efficiency is ensured.

Owner:王建中

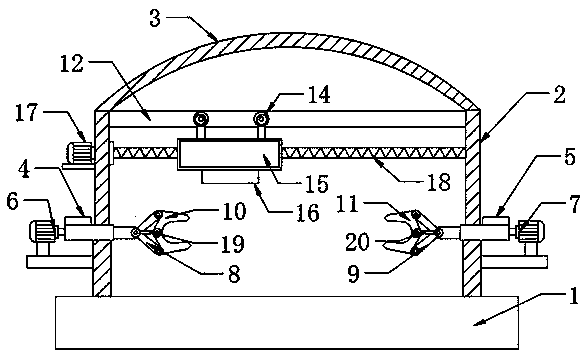

Forest fire monitoring device based on hot air balloon

PendingCN111091675AAvoid offsetEasy to moveForest fire alarmsFire alarm radiation actuationElectric machineEngineering

The invention discloses a forest fire monitoring device based on a hot air balloon. The forest fire monitoring device comprises a solar hot air balloon, wherein a holding mechanism is provided below the solar hot air balloon, a positioning monitoring mechanism is provided below the solar hot air balloon, a fixing mechanism is provided below the solar hot air balloon, a moving mechanism is providedon the solar hot air balloon, and a limit mechanism is provided below the moving mechanism. The invention has the beneficial effects of using the hot air balloon to fly in the air to monitor forest fires and reduce energy consumption, using solar energy as an energy source to reduce own weight and increase the sustainability of flight with no need to carry fuel through electric heating, heating the air in the hot air balloon before the flight, retracting a limit lever by the reverse rotation of a motor when the hot air balloon can fly to facilitate the hot air balloon to rise, making the hotair balloon advance and steer in the air through the positive and negative rotation of the motor, and positioning by a GPS locator to easily ensure the monitoring range of the hot air balloon.

Owner:中科星控(河北)信息技术有限公司

Rotary electroplating device for roll

InactiveCN108754560AEasy to shrinkEasy to openElectrolysis componentsEngineeringMechanical engineering

The invention discloses a rotary electroplating device for a roll. The rotary electroplating device comprises a base, wherein two support legs are fixedly arranged at the two sides of the upper end surface of the base; a protective plate is fixedly arranged at the upper end surface of each support leg; a first push rod motor and a second push rod motor are movably arranged on each support leg; a first motor and a second motor are fixedly arranged at the end surface of one side of each support leg by installation brackets; two first movable rods and two second movable rods are respectively movably arranged at the telescopic ends of the first push rod motor and the second push rod motor; a first jaw and a second jaw are respectively arranged at the other end of each of the first movable rodsand the second movable rods through pin shafts, and are connected by a pin shaft; a transverse plate is fixedly arranged at the end surfaces of the two sides of each support leg, and is provided withtwo sliding grooves. The rotary electroplating device has the advantages that the structure is simple, and the operation is convenient; the roll is electroplated in an omnibearing way, the electroplating effect is good, and the practicality is higher.

Owner:于婷婷

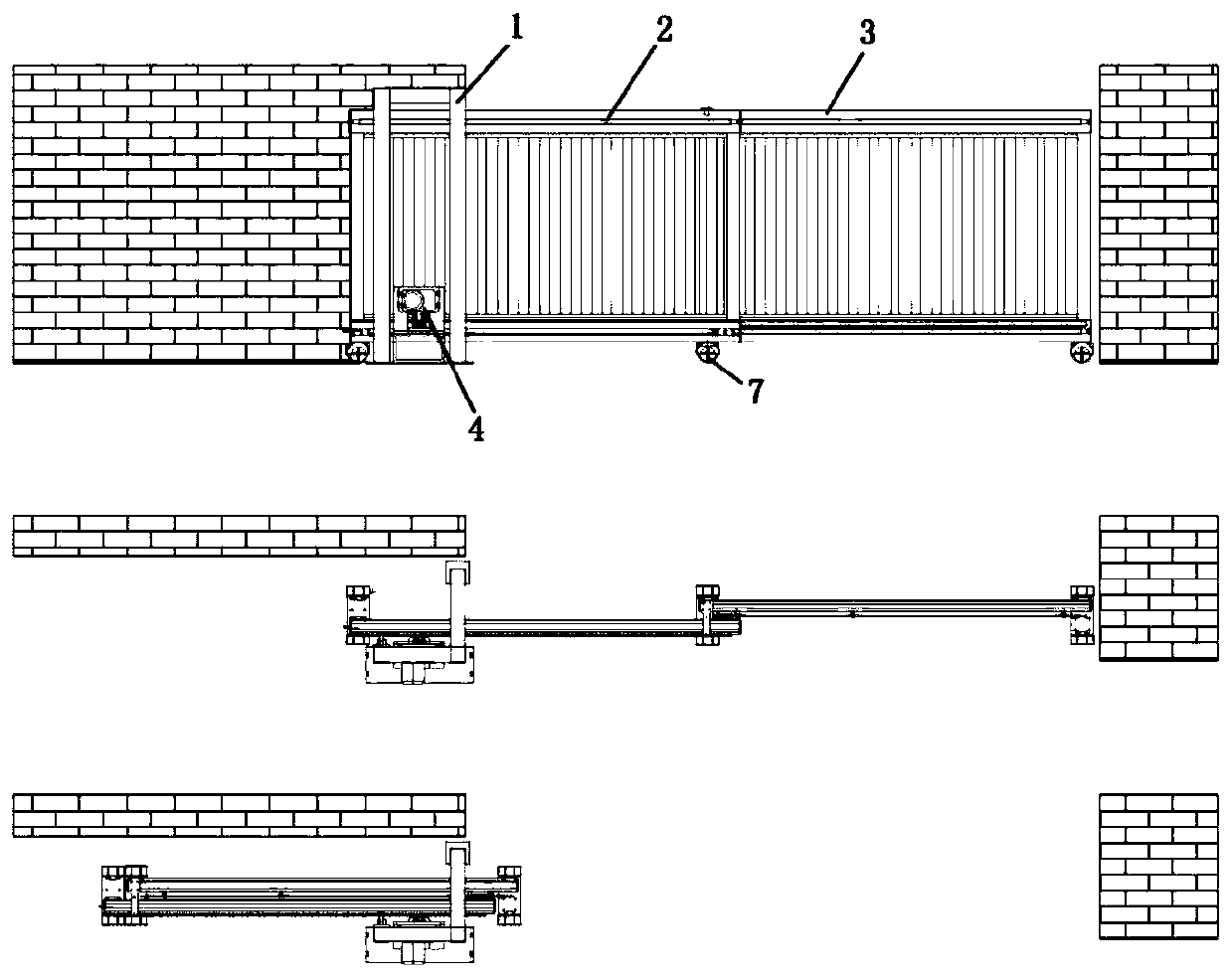

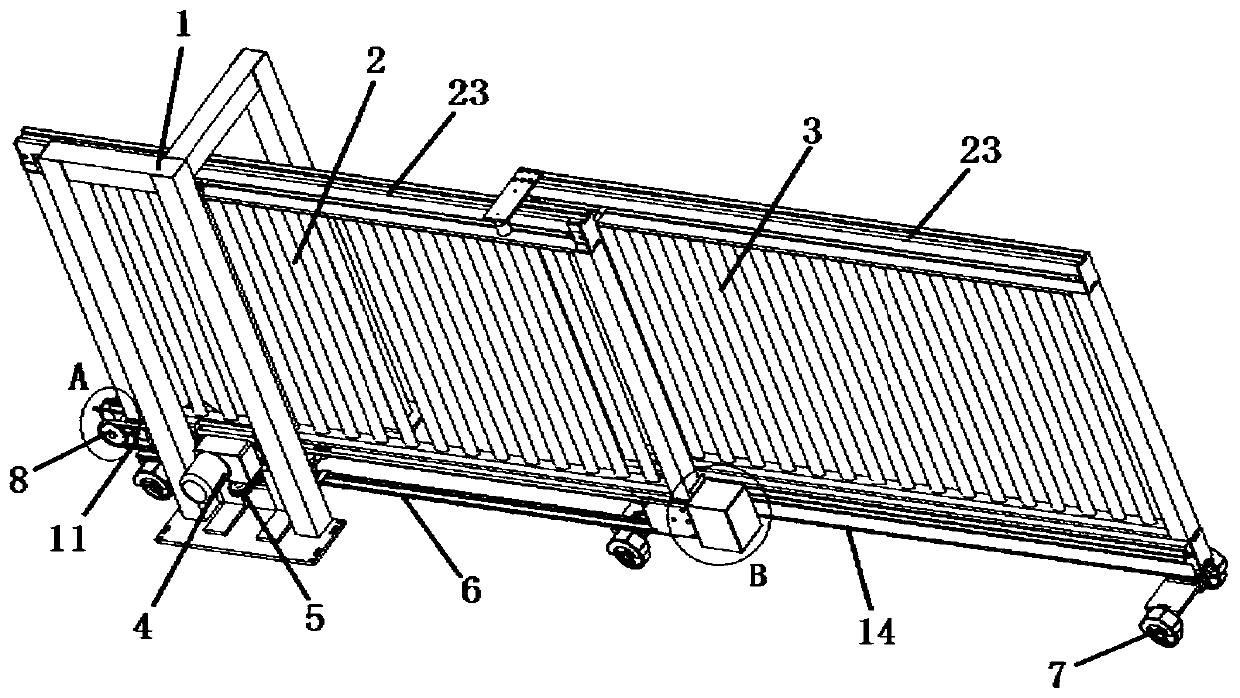

a sliding door

ActiveCN108756713BAdjustable elasticAdjustable tightnessGates/doorsPower-operated mechanismGear driveGear wheel

The invention provides a sliding door. A driving gear is driven through a motor, and the driving gear meshes with a first rack, so that a driving door is driven to move. A first flexible connecting piece is arranged on the driving door to drive a first gear and a second gear to rotate when the driving door moves through fixing a point of the first flexible connecting piece; the second gear and a third gear are arranged on a first transmission shaft to drive a first driven door to move through meshing of the third gear and a second rack, so that the opening and closing speed of the sliding dooris improved without laying cables, the structure is simple, and the maintenance is easy; the driving door and the first driven door both adopt gear drive, so that the movement of the driving door andthe first driven door is compact, slipping is avoided, the distance between the first gear and the second gear is adjustable, the tightness of the first flexible connecting piece can be adjusted, theproblem that the first flexible connecting piece becomes looser with the use time being longer is avoided, the sliding door is not required to be removed for replacement, the service life of the first flexible connecting piece is prolonged, and the operation quality of the sliding door is always unaffected.

Owner:广东启功实业集团有限公司

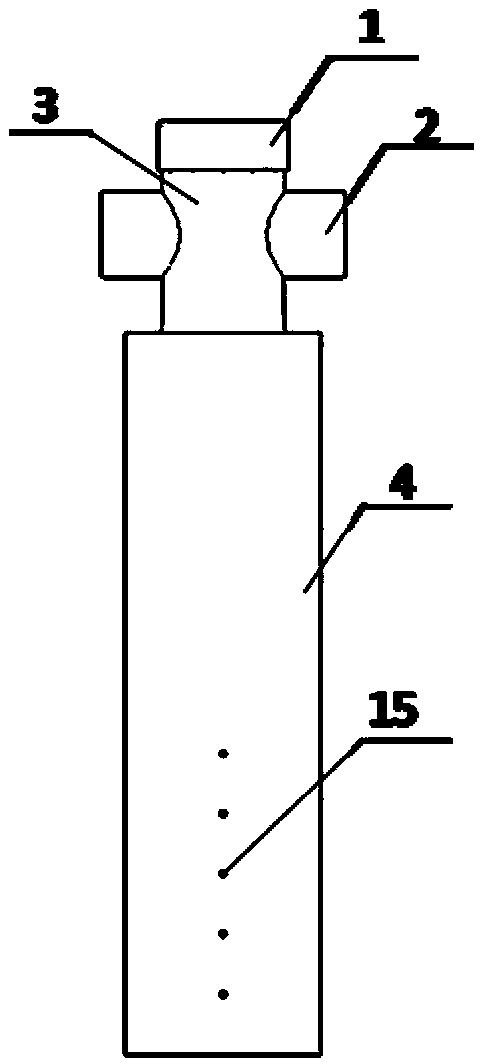

A kind of fast lamination equipment and lamination method of sensor cable gasket

ActiveCN112917114BShorten lamination timeGuaranteed bonding efficiencyLaminationLamination apparatusEngineeringBattery cell

The invention belongs to the field of gasket technology, and specifically relates to a fast lamination device and a lamination method for sensor cable gaskets, including a housing; a battery cavity and a first cavity are opened in the housing; the The battery cavity is opened directly above the first cavity; the top of the housing is provided with a switch; the bottom of the housing is provided with a first connecting post; the first connecting post is provided with a first through hole; The bottom end of the first connecting column is fixedly connected with a suction cup; a second cavity is opened in the suction cup; suction holes are provided on the bottom end and the side wall of the suction cup; the first through hole, the first cavity and the The suction hole is in a connected state; the invention provides a quick bonding device and bonding method for the sensor cable gasket to solve the problem of manual bonding when the sponge gasket is placed on the sensor cable. , but due to the small size of the sponge gasket itself, tweezers and pressing sheets are generally used for operation, and the bonding speed is slow, and the bonding quality cannot be guaranteed.

Owner:深圳市磐锋精密技术有限公司

Industrial oil filling device

InactiveCN108639407AMake sure it's sealedGuaranteed direction of movementLiquid materialFuel tankEngineering

The invention discloses an industrial oil filling device which comprises a base and a connecting pipe, wherein the top of the base is fixedly connected to a mounting seat through a screw; a hydraulicbox is mounted on the mounting seat; a hydraulic push rod is extracted from the top of the hydraulic box; the hydraulic push rod extends vertically upward and the top of the hydraulic push rod is connected to an air cylinder; an oil tank is placed on the base; an electric lifting table is mounted on the inner wall of the bottom of the oil tank; an oil holding hopper is mounted on the top of the electric lifting table; a sealing cover is mounted on the top of the oil tank; a vertical through hole is formed in the sealing cover; an oil inlet pipe is inserted into the through hole; the end, far from the oil tank, of the oil inlet pipe is mounted on a connecting pipe; the connecting pipe is provided with a main pipeline and two branches; and the two branches are located on two sides of the main pipeline. The industrial oil filling device disclosed by the invention is simple in structure, guarantees precise and reliable filling amount of industrial oil of a plant, lowers the production cost, and meanwhile, improves the production efficiency and is practicality.

Owner:吴超

Lossless mirror surface grinding device for sheet for high-temperature rapid bonding of PE tape connector

PendingCN112518539ASingle chip grindingImprove performanceGrinding drivesGrinding machinesCircular discEngineering

The invention relates to a lossless mirror surface grinding device for a sheet for high-temperature rapid bonding of PE tape connector. The lossless mirror surface grinding device comprises a grindingdisc and a grinding head; the grinding disc is in a horizontally-arranged disc shape, a plurality of special-shaped clamping grooves are evenly distributed on the grinding disc in the circumferentialdirection and used for installing the sheet; the grinding disc can axially rotate around the vertical axis of the grinding disc, and the grinding head is located above the grinding disc and can axially rotate around the vertical axis of the grinding disc; and the rotating directions of the grinding disc and the grinding head are opposite, the grinding head can move up and down and be positioned,and the grinding range of the grinding disc is within the rotating track of the clamping grooves. According to the lossless mirror surface grinding device for the sheet provided by the invention, full-automatic lossless mirror surface grinding is achieved on the sheet, single-sheet grinding and multi-sheet grinding can be achieved, the surface of the ground sheet is smooth like a mirror surface, materials of a sheet body cannot be removed, rapidness and convenience are achieved, the performance is more stable and consistent, and the production requirement is better met.

Owner:唐山三友集团兴达化纤有限公司

Plastic film mulching machine used for planting of agricultural products

InactiveCN106376401AIncrease volumetric heat capacityEasy to adjust the temperature difference between day and nightClimate change adaptationWatering devicesAgricultural engineeringSheet mulching

The invention relates to the field of agricultural machinery, in particular to a plastic film mulching machine used for planting of agricultural products. The plastic film mulching machine comprises a rack, a traveling wheel, a film mulching mechanism and a sowing mechanism, wherein the rack is connected with the traveling wheel by virtue of a wheel axle, the film mulching mechanism comprises a film covering component, a film pressing component, a film mulching component, a vibration damping component and a first ditching device; the vibration damping component has vibration damping effect, the sowing mechanism comprises a soil covering device, a sowing device, a second ditching device and a pitch adjusting component; and the pitch adjusting component can adjust sowing width according to width of a ridge through worm drive. The plastic film mulching machine achieves the technical effects of easy operation, adjustment of the sowing width according to the width of the ridge and vibration damping.

Owner:湖南角山米业有限责任公司

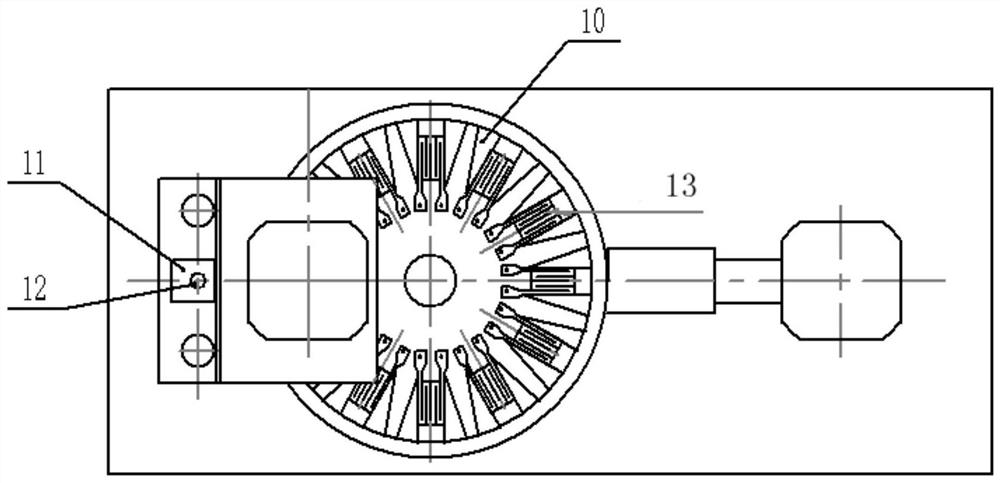

Apparatus for processing body of internally-thickened alumium alloy drill pipe

ActiveCN102814355AGuaranteed continuous transitionAvoid the disadvantages of uncontrollable deformationPipe fittingEngineering

The invention discloses an apparatus for processing a body of an internally-thickened alumium alloy drill pipe, belonging to the technical field of drilling equipment. The apparatus comprises an operation platform and is characterized in that a front support seat, an outer support pipe and a rear support seat are sequentially arranged on the operation platform back and forth; a pipe fitting is erected between the front and rear support seats, penetrates through the outer support pipe and is coaxial with the outer support pipe; a rolling head is mounted on the wall of the pipe fitting and connected with a control mechanism which enables the rolling head to move in the radial direction; the pipe fitting is driven by a motor to rotate in the front and rear support seats; and the outer support pipe is connected with a first servo power device which enables the outer support pipe to move back and forth along the operation platform. The processing apparatus is capable of clamping the equal-diameter alumium alloy pipe to be processed in the outer support pipe, the opening of the rolling head is controlled by the control mechanism, the rolling head rolls the inner wall of the body of the alumium alloy pipe, and simultaneously, the outer support tube drives the body of the alumium alloy pipe to move back and forth, so that the body of the alumium alloy pipe is formed through once rolling, the continuous transition of the sections with different wall thicknesses of the alumium alloy pipe is guaranteed, and simultaneously, the shortcoming of uncontrollable deformation caused by heading is overcome.

Owner:淄博斯壮铝业有限公司

Novel low-pressure casting mold

The invention provides a novel low-pressure casting mold. The novel low-pressure casting mold comprises mold lower mold bodies arranged on a workbench. The mold lower mold bodies comprise the fixed lower mold body and the sliding lower mold body arranged below the fixed lower mold body. A sliding groove is formed in the side face of each fixed seat. A limiting rod arranged on the outer portion of each fixed seat penetrates the corresponding sliding groove to be fixedly connected with the sliding lower mold body. The other ends of the limiting rods are connected with hydraulic cylinders through fixed rods. Multiple through holes are formed in each limiting rod. Sliding rails are arranged on the workbench. An adjustable cleaning device is in sliding connection to the sliding rails. According to the novel low-pressure casting mold, replacement of rapid wear parts and mounting and demounting of water cooling pipes are facilitated; cost waste is reduced; universality is high; machining is facilitated; it is guaranteed that a casting hole can be cleaned while quick water cooling is achieved; the quality of finished products is guaranteed; only local portions are replaced for different workpieces; and the machining cost is reduced.

Owner:大川精工(朝阳)有限公司

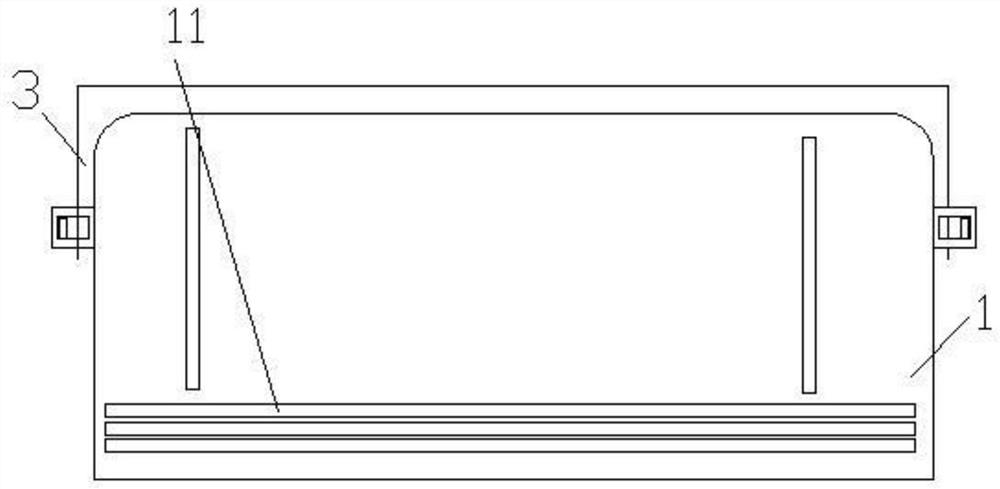

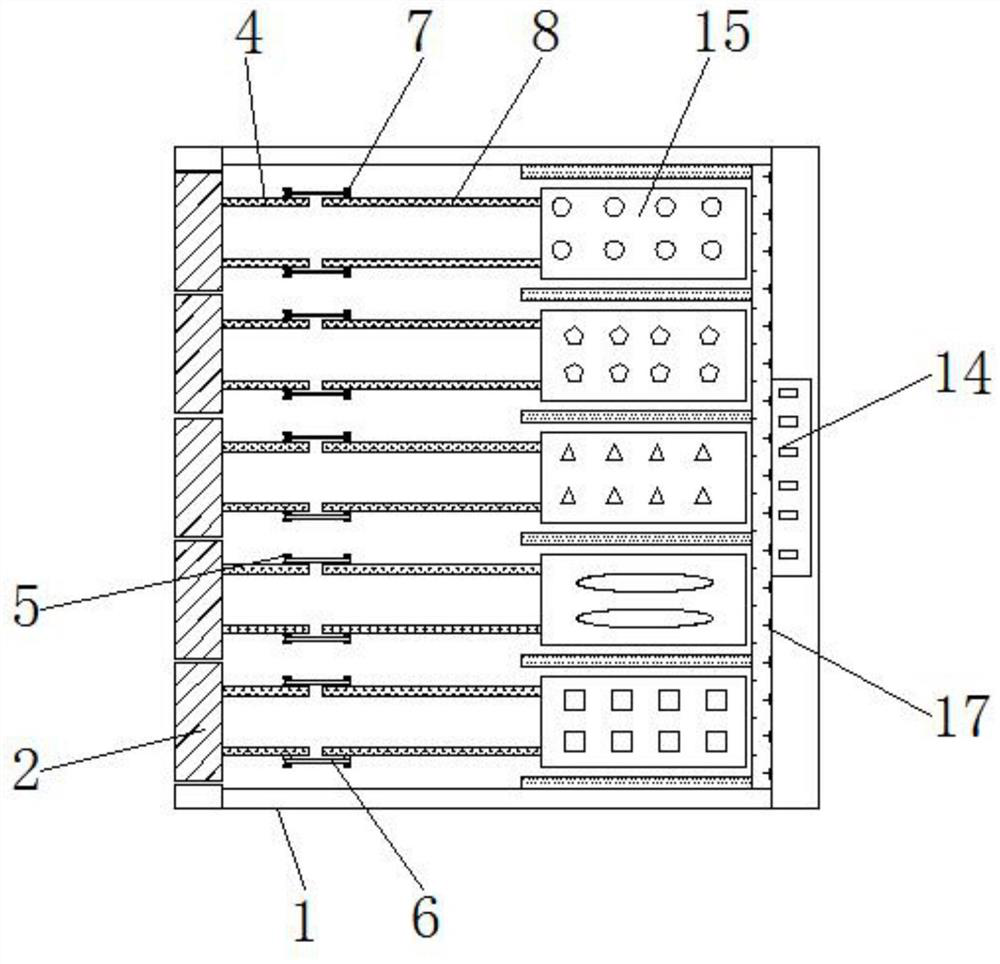

Full-intelligent air conditioner filter screen replacement equipment

PendingCN114738988AGuaranteed direction of movementQuick resetMechanical apparatusLighting and heating apparatusGratingEngineering

The invention provides full-intelligent air conditioner filter screen replacing equipment, and relates to the field of air conditioners, the full-intelligent air conditioner filter screen replacing equipment comprises an air conditioner outer shell, and the air conditioner outer shell is hung on a wall; the air conditioner air outlet grille is arranged on the surface of the air conditioner outer shell; the protection block is arranged on the top surface of the air conditioner outer shell; the positioning pieces are symmetrically arranged on the end face of the air conditioner outer shell, each positioning piece comprises positioning plates, the positioning plates are symmetrically arranged on one end face of the outer shell, and the positioning plates are fixedly connected with the air conditioner outer shell; the pressing plates are arranged between the positioning plates on the same side in a sliding manner; and the fixed bolt is rotationally arranged on the side face of the positioning plate, and after the pressing plate moves downwards by a certain distance, the fixed bolt is rotated to position the pressing plate. The problem that no matter in the heating or refrigerating process, the topmost part of the air conditioner and the air outlet of the air conditioner are kept in an open state, and dust falls into the grating in the working process is solved.

Owner:安徽美博智能电器集团有限公司

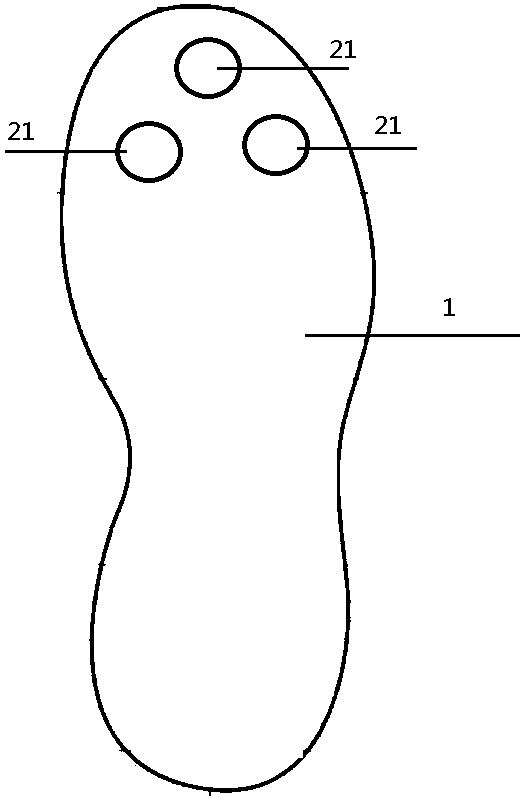

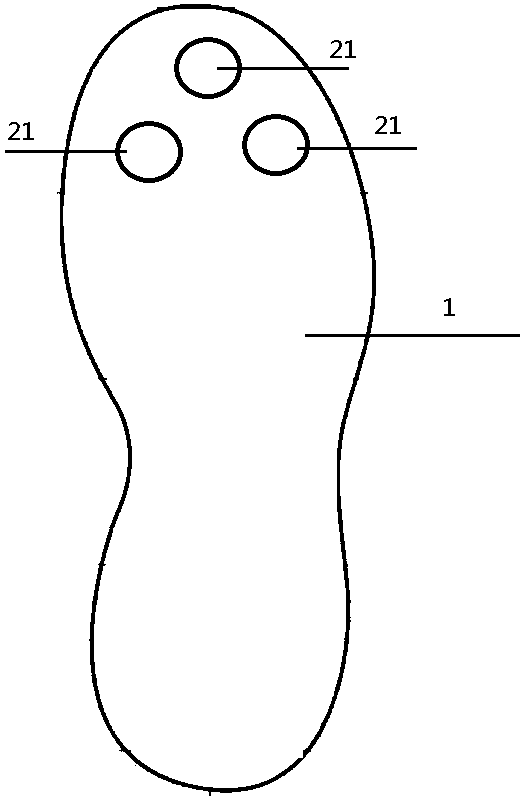

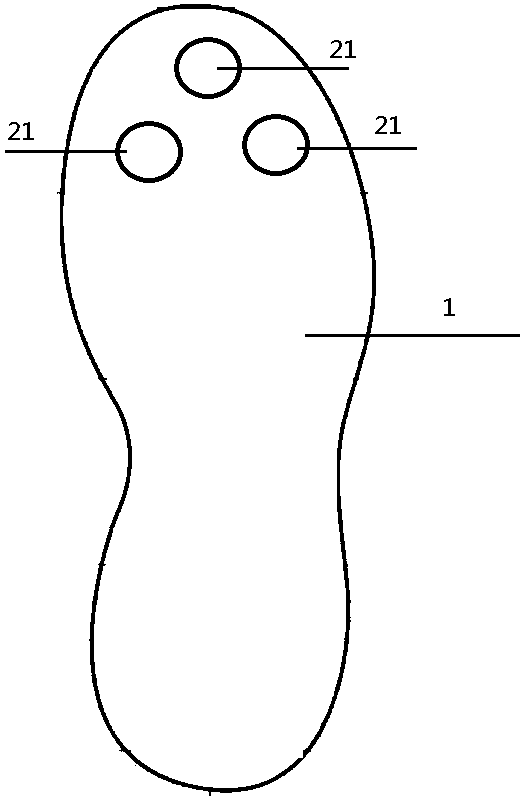

a sneaker

ActiveCN108552668BIncrease frictionEasy to walk in shoesSolesInsolesClassical mechanicsStructural engineering

Owner:东营红星劳保用品有限责任公司

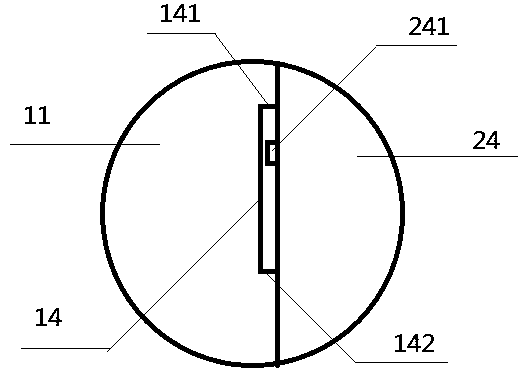

A friction disk locking mechanism for anti-skid shoes

ActiveCN108209032BIncrease frictionEasy to walk in shoesSolesInsolesEngineeringMechanical engineering

The invention relates to a friction disc locking mechanism for anti-sliding shoes. The friction disc locking mechanism (4) is used for preventing a friction disc (21) from retracting back into a mounting hole (13) after stretching out of the mounting hole (13) and comprises a driving block and a water-swelling water-sealing strip ring (42), wherein an annular cavity (15) is formed in an opening ofthe mounting hole (13), the water-swelling water-sealing strip ring (42) is arranged in the annular cavity (15) and is used for extruding the driving block along the horizontal direction, and an upper stressing oblique plane (41) is arranged at the upper part of the driving block; and a lower stressing oblique plane (211) is correspondingly arranged at the lower part of the friction disc (21), and the upper part of the friction disc (21) and the water-swelling water-sealing strip ring (42) form a limiting boss (212). The friction disc stretching out of the mounting hole is limited outside a sole by virtue of the friction disc locking mechanism, so that the friction disc is always outside the mounting hole during raining, and an increased friction force state of the sole is guaranteed.

Owner:阜阳和益鞋业有限公司

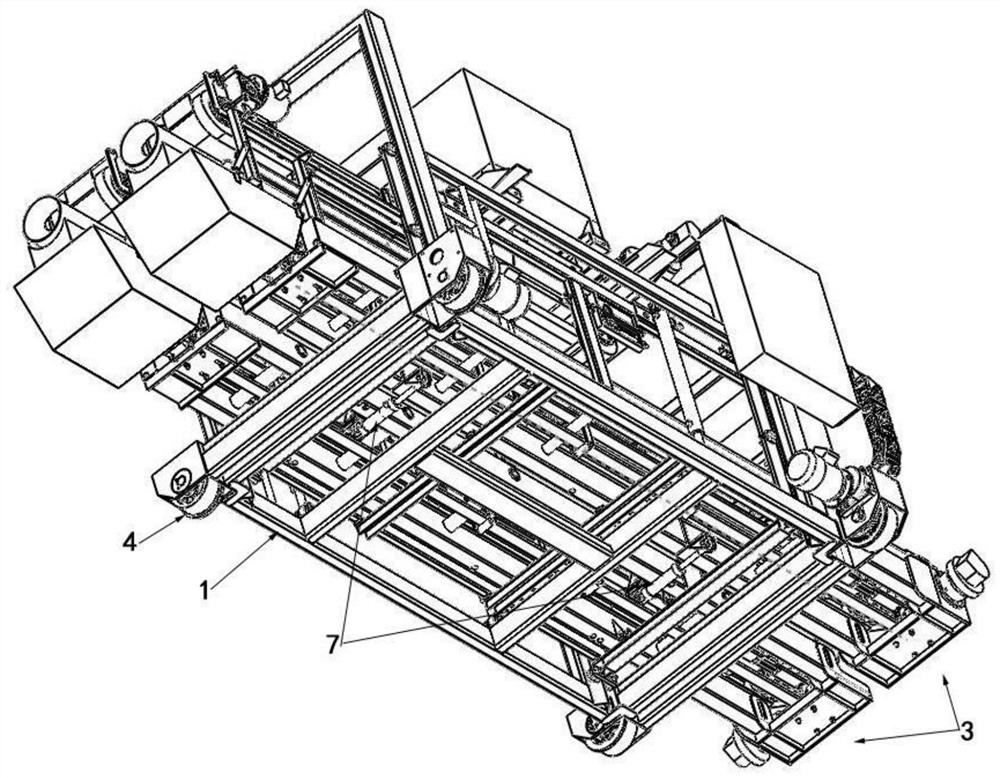

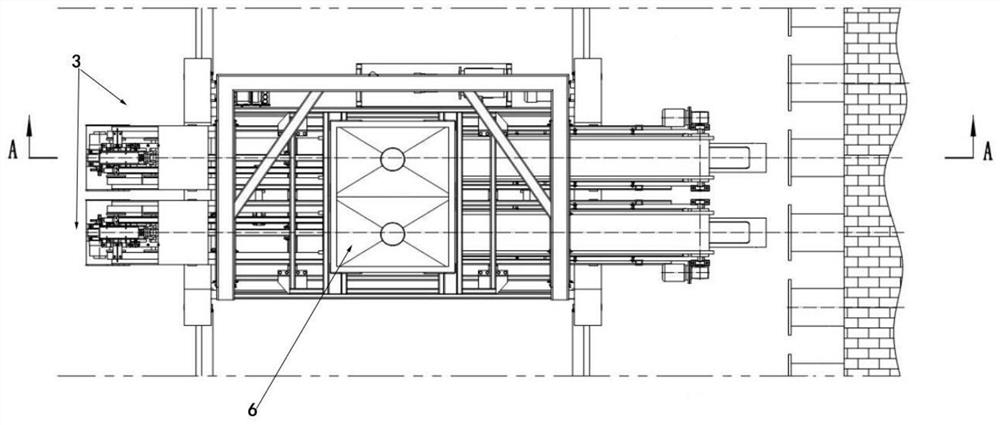

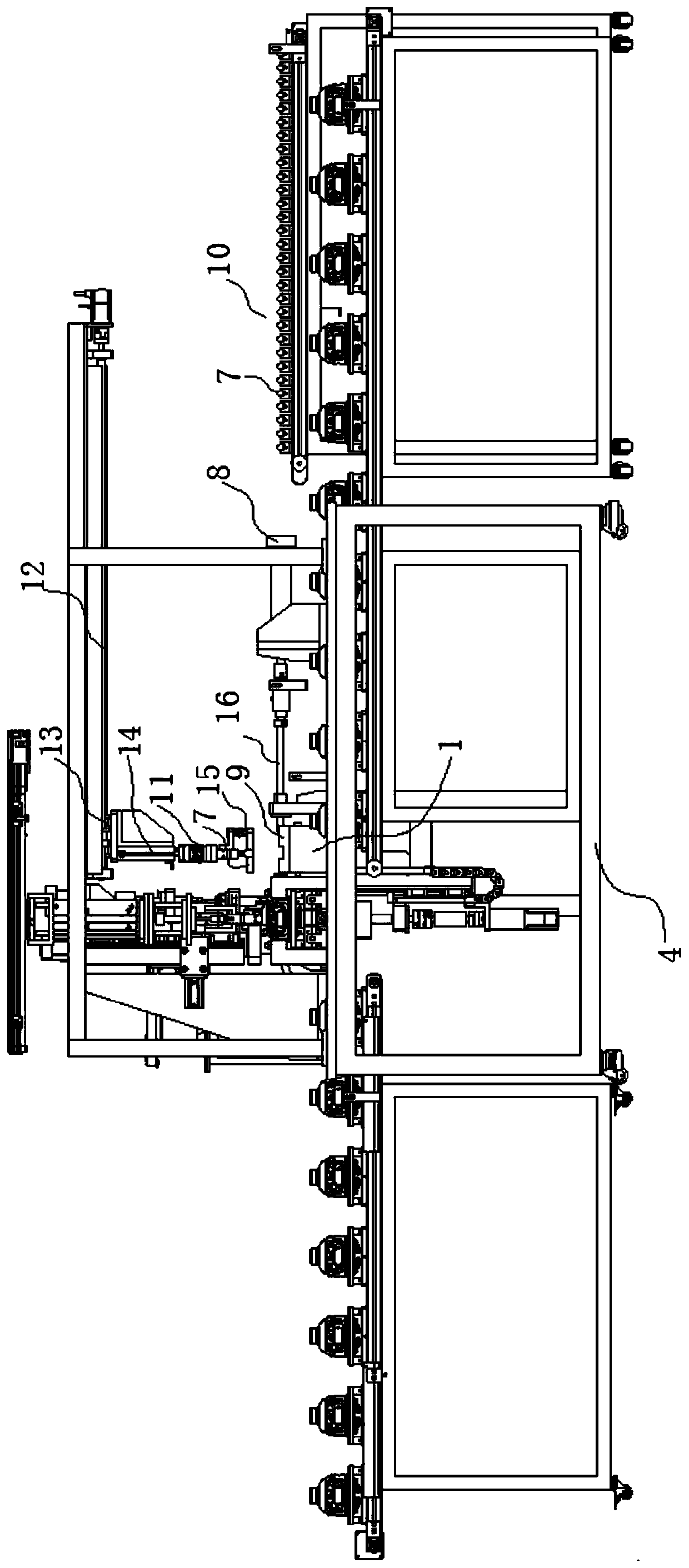

A processing system and processing technology for drill pipe production

ActiveCN113231832BGuaranteed tensionPrevent tooth skipping phenomenonOther manufacturing equipments/toolsBraced frameEngineering

The invention discloses a drill pipe processing technology, and in particular relates to a processing system for producing a drill pipe and a processing technology thereof, including a feeding device, a rough processing device, a welding device and a heat treatment device, the feeding device includes a machine body, and the The machine body is provided with a bottom plate and side plates oppositely arranged at both ends of the bottom plate. The bottom plate is provided with a drill rod box, and the side plate is provided with a stepped feeding mechanism. The stepped feeding mechanism includes several upper A material loading unit, the loading unit includes a material loading support frame and a driving device for driving the material loading support frame to move along the vertical direction of the side plate. The structure of the drive support plate on the two frames is the same, both including two oppositely arranged support frames and a guide frame in the middle, a sprocket and a chain are arranged on the support frame, the chain connects the support plate, and the sprocket drives the chain so that the support plate Moving up and down, the raw steel pipes in the drill box are lifted up step by step, thus completing the entire feeding process.

Owner:衢州市衢江区新恒兴机械厂

Rapid bonding equipment and method for gasket of flexible printed circuit of inductor

ActiveCN112917114AShorten lamination timeGuaranteed bonding efficiencyLaminationLamination apparatusEngineeringInductor

The invention belongs to the technical field of gasket bonding, and particularly relates to rapid rapid bonding equipment and method for a gasket of a flexible printed circuit of an inductor. The equipment comprises a shell, wherein a battery cavity and a first cavity are arranged in the shell; the battery cavity is arranged right above the first cavity; a switch piece is arranged at the top end of the shell; a first connecting column is arranged at the bottom end of the shell; a first through hole is arranged in the first connecting column; the bottom end of the first connecting column is fixedly connected to a suction cup; a second cavity is arranged in the suction cup; air suction holes are arranged in the bottom end and the side wall of the suction cup; and the first through hole, the first cavity and the air suction holes are in a communicated state. The rapid bonding equipment and method for the gasket of the flexible printed circuit of the inductor solve the problems that when a sponge gasket is bonded on the flexible printed circuit of the inductor, manual bonding is generally adopted, but the bonding speed is slow and the bonding quality cannot be ensured due to the fact that the sponge gasket is small in size and generally operated by tweezers and a pressing sheet.

Owner:深圳市磐锋精密技术有限公司

An intelligent tool management device for a machining workshop

ActiveCN109160162BEasy to take outSave the hassle of finding knivesStorage devicesElectromagnetTool management

The invention discloses an intelligent tool management device for a machining workshop. The intelligent tool management device comprises a device body, first rotation shafts and first electromagnets.Openings are formed in one side of the device body and internally provided with handles. The handles are connected with connecting plates. The first rotation shafts are arranged on the two sides of the connecting plates. The first rotation shafts are connected with second rotation shafts through connecting rods, and the second rotation shafts are fixed to the two sides of conveying platforms. Thelower sides of the conveying platforms are connected with bottom plates through supporting rods. The first electromagnets are arranged between the conveying platforms and the connecting plates. Grooves are reserved in the middles of the supporting rods. Rotation wheels are arranged in the middles of the grooves. Containing boxes are arranged at the edge positions of the upper end faces of the conveying platforms. Second electromagnets are arranged on one sides of the containing boxes. According to the intelligent tool management device for the machining workshop, tools are classified so that the proper tools can be conveniently found to be used, meanwhile, the tools can be conveniently taken out, and the trouble of tool searching is saved.

Owner:ANHUI HUITENG INTELLIGENT TRANSPORTATION TECH CO LTD

a non-slip shoe

Owner:HAIYU SHOES

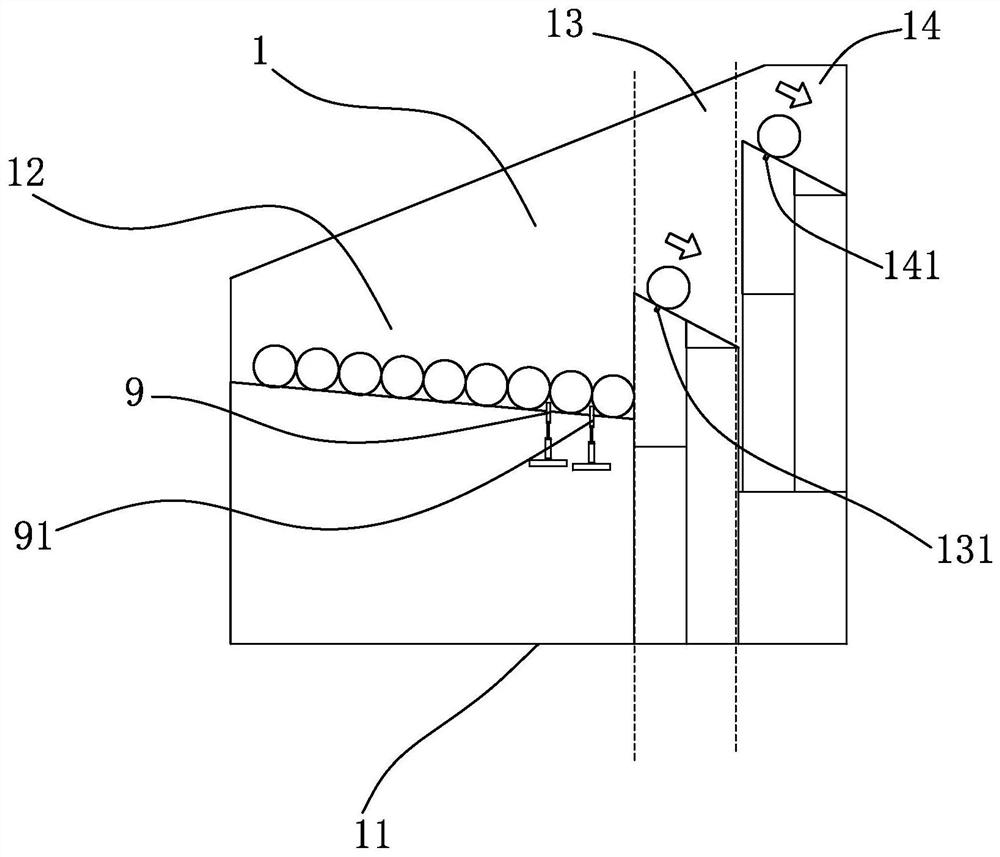

Machining system for drill rod production and machining process of machining system

ActiveCN113231832AGuaranteed tensionPrevent tooth skipping phenomenonOther manufacturing equipments/toolsBraced frameSprocket

The invention discloses a drill rod machining technology, and particularly relates to a machining system for drill rod production and a machining process of the machining system. The machining system comprises a feeding device, a rough machining device, a welding device and a heat treatment device. The feeding device comprises a machine body, and the machine body is provided with a bottom plate and side plates oppositely arranged at the two ends of the bottom plate. A drill rod box is arranged on the bottom plate, stepped feeding mechanisms are arranged on the side plates, each stepped feeding mechanism comprises a plurality of feeding units, and each feeding unit comprises a feeding supporting frame and a driving device for driving the corresponding feeding supporting frame to move in the vertical direction of the side plates. Structures for driving supporting plates on two machine frames are the same, and each structure comprises two oppositely-arranged supporting frames and a guiding frame in the middle, chain wheels and chains are arranged on the supporting frames, the chains are connected with the supporting plates, the chain wheels drive the chains to enable the supporting plates to move up and down, raw material steel pipes in the drill pipe box are lifted upwards step by step, and therefore the whole feeding process is completed.

Owner:衢州市衢江区新恒兴机械厂

Double-row filling machine

PendingCN113390260AEasy to joinThe distance is easy to adjustCharge manipulationCrucible furnacesElectrical and Electronics engineeringRolling chassis

The invention relates to a double-row filling machine, and belongs to the technical field of filling devices. The double-row filling machine comprises a chassis frame, a lifting frame, a hopper and multiple filling devices, wherein the lifting frame is connected onto the chassis frame in a sliding manner; the hopper is fixedly connected to the top end of the lifting frame; the multiple filling devices are arranged in parallel and connected onto the lifting frame; and the input ends of the multiple filling devices are located vertically below the discharging end of the hopper. The double-row filling machine can replace manual filling, so that the labor intensity of workers is reduced, and the filling efficiency is improved.

Owner:陕西矿智云智能自动化有限公司

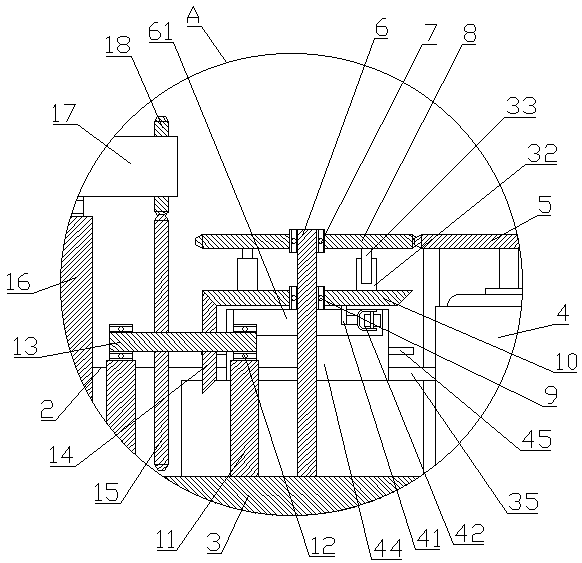

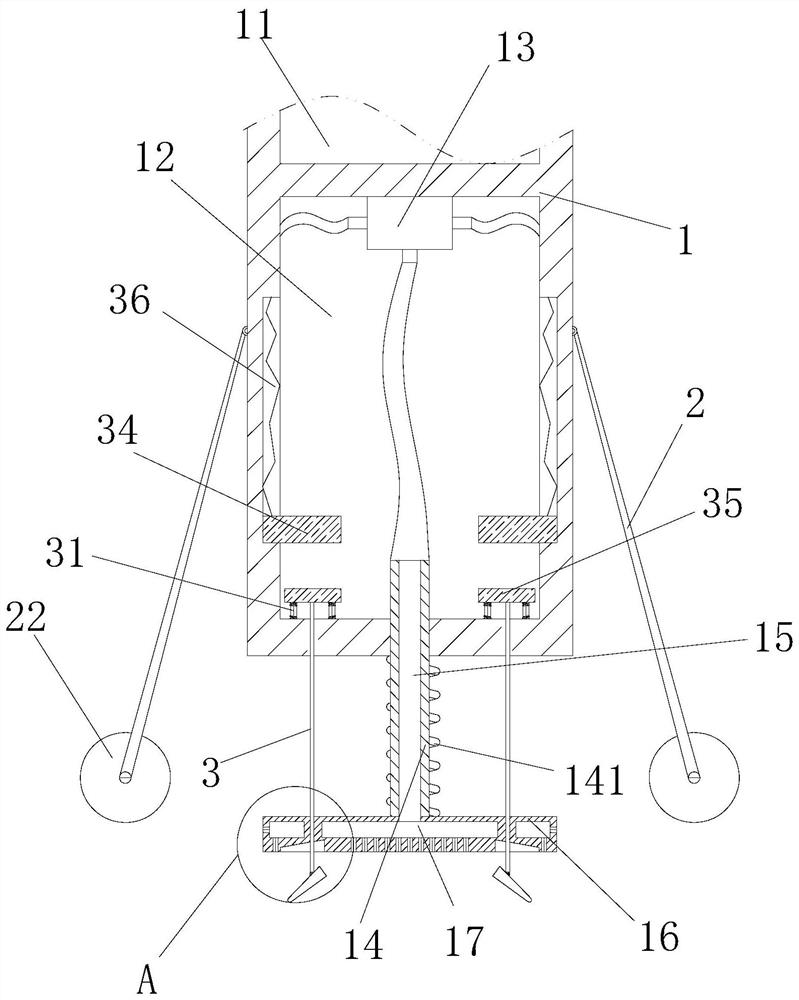

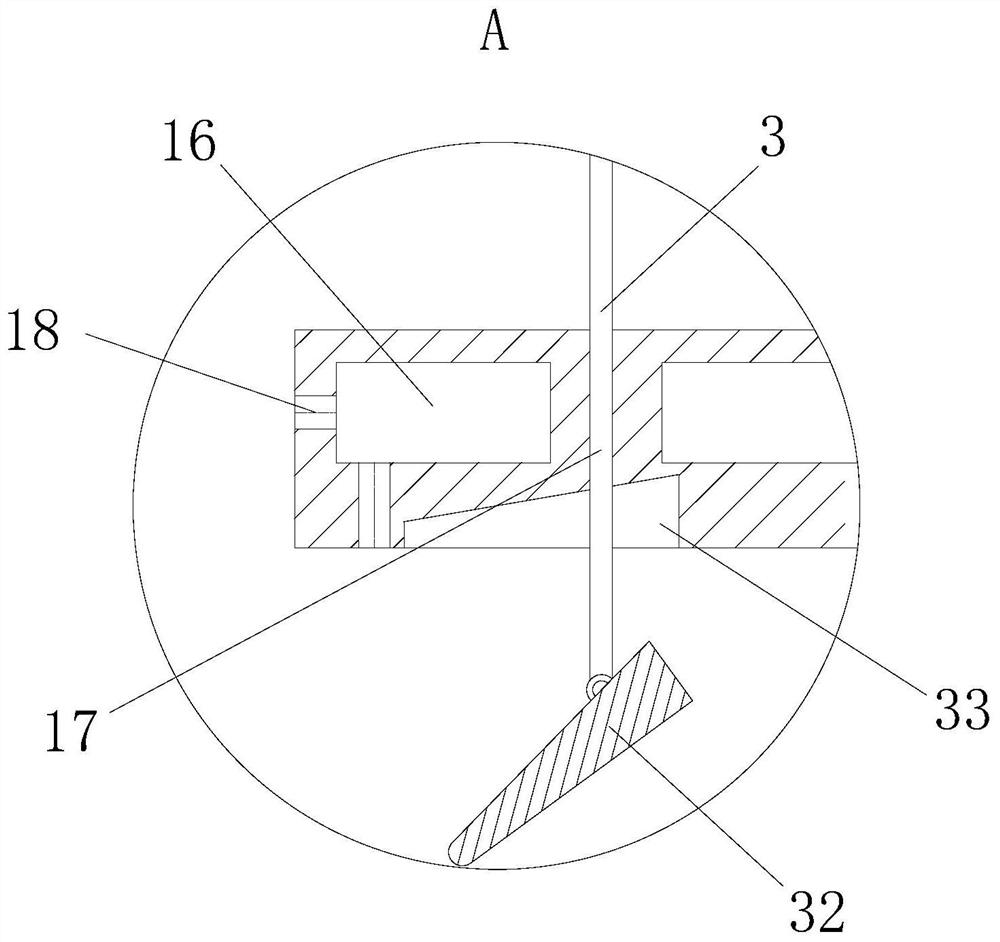

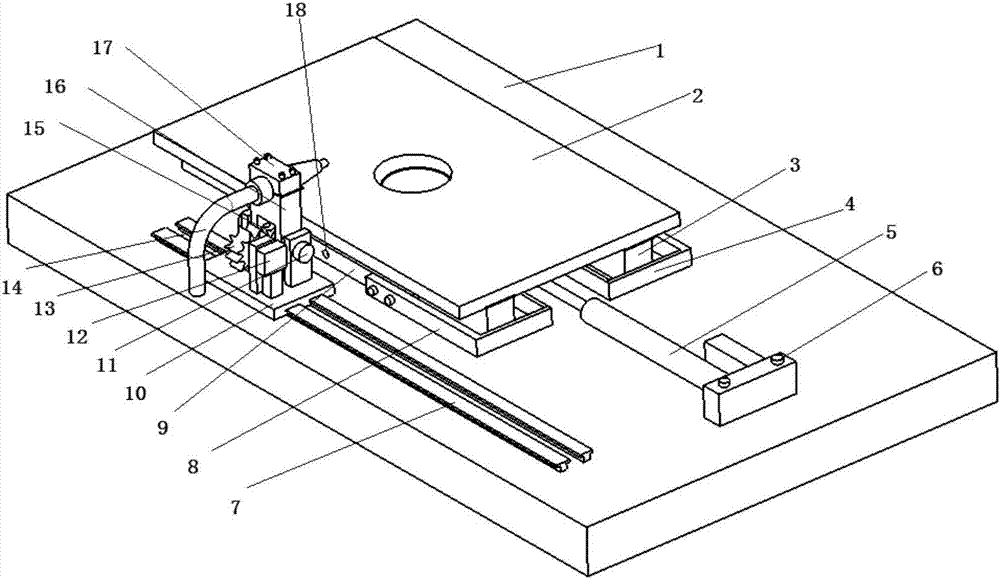

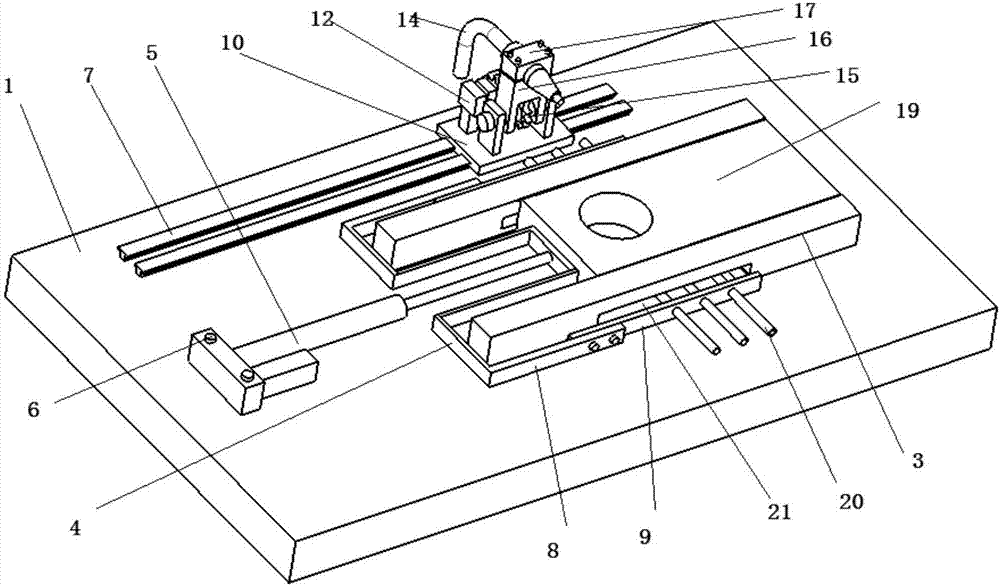

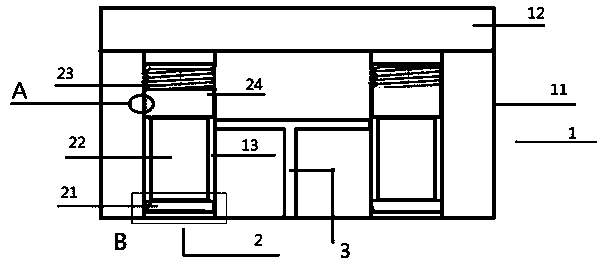

A differential gear shaft assembly equipment

ActiveCN108817901BGuaranteed direction of movementImprove insertion accuracyMetal working apparatusPilot holeStructural engineering

The invention relates to an assembly device for a rotating shaft of a differential, comprising an assembly seat and a movable seat, the assembly seat is provided with a guide hole, the guide hole is facing the installation hole of the rotating shaft on the differential, and the frame is provided with a guide rail of the movable seat , the movable seat is movably installed on the guide rail of the movable seat, a limit pin is provided on the movable seat, and a lifting drive device is arranged between the limit pin and the movable seat, the limit pin can be inserted into the pin hole on the rotating shaft, and the rotating shaft assembly equipment It also includes a rotating shaft pushing mechanism, the rotating shaft pushing mechanism includes a cylinder, the piston rod of the cylinder is aligned with the rear end face of the rotating shaft, and a limit pin lifting control device is also included, and the limit pin lifting control device controls the lifting of the limit pin; When the depth of the rotating shaft inserted into the mounting hole of the rotating shaft reaches the set value, the limit pin is lowered, and the limit pin is no longer inserted into the pin hole, and the rotating shaft pushing mechanism continues to push the rotating shaft until the rotating shaft is completely inserted into the mounting hole of the rotating shaft. Effectively guarantee the insertion accuracy of the rotating shaft and have high reliability.

Owner:SHENGRUI TRANSMISSION

Mobile integrated substation accident oil pool oily wastewater treatment device

ActiveCN110937704BExtended stayReduce dwell timeFatty/oily/floating substances removal devicesWater contaminantsDaily operationFiltration

The invention discloses a mobile integrated substation accident oil pool oily waste water treatment device, which is used for treating the oily waste water inside the accident oil pool. bin, the first filter bin and the second filter bin; the inclined plate packing, which is located on the upper part of the oil-water separation bin; the oil storage tank, which is arranged inside the oil-water separation bin and is located above the inclined plate packing. The present invention is an integrated design and can be transported by vehicle, does not involve on-site hoisting, is completed off-site, and can be directly debugged and run on site. The processing time is short and does not affect the daily operation of the substation, so as to adapt to the characteristics of compact substation layout and tight land use. Moreover, the invention has a simple structure, can automatically separate oil and water, has less manual care during operation, is convenient for maintenance, and only needs to regularly clean up waste oil, and has low operating costs.

Owner:STATE GRID HUBEI ELECTRIC POWER CO LTD MAINTENANCE CO +1

Ultrasonic image recording diagnostic apparatus

InactiveCN114159095AEasy to liftImplement rollout usingUltrasonic/sonic/infrasonic diagnosticsInfrasonic diagnosticsImage recordingPulley

The invention discloses an ultrasonic image recording diagnostic apparatus which comprises a diagnostic apparatus main body, a base is arranged at the lower end of the diagnostic apparatus main body, a plurality of supporting seats are arranged at the lower end of the base, a display screen is arranged at the upper end of the diagnostic apparatus main body, and pulleys are arranged at the lower ends of the supporting seats; a groove is formed in the lower end of the supporting seat, and a pneumatic lifting mechanism used for lifting the pulley is arranged in the groove; the upper end of the base is fixedly connected with an inflator pump for driving the pneumatic lifting mechanism to operate; a fixing plate is fixedly connected to the side wall of the display screen, a storage groove is formed in the lower end of the fixing plate, and a U-shaped plate is arranged in the storage groove. Lifting of the pulleys is achieved in a pneumatic mode, movement and use of the device are facilitated, the stability of the device is guaranteed, cleaning of the display screen can be achieved through the cleaning roller, meanwhile, the cleaning roller can be stored, and the occupied space is reduced.

Owner:中牟县人民医院

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com