Double-row filling machine

A packing machine and barrel technology, applied in the field of packing devices, can solve problems such as low efficiency and high labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

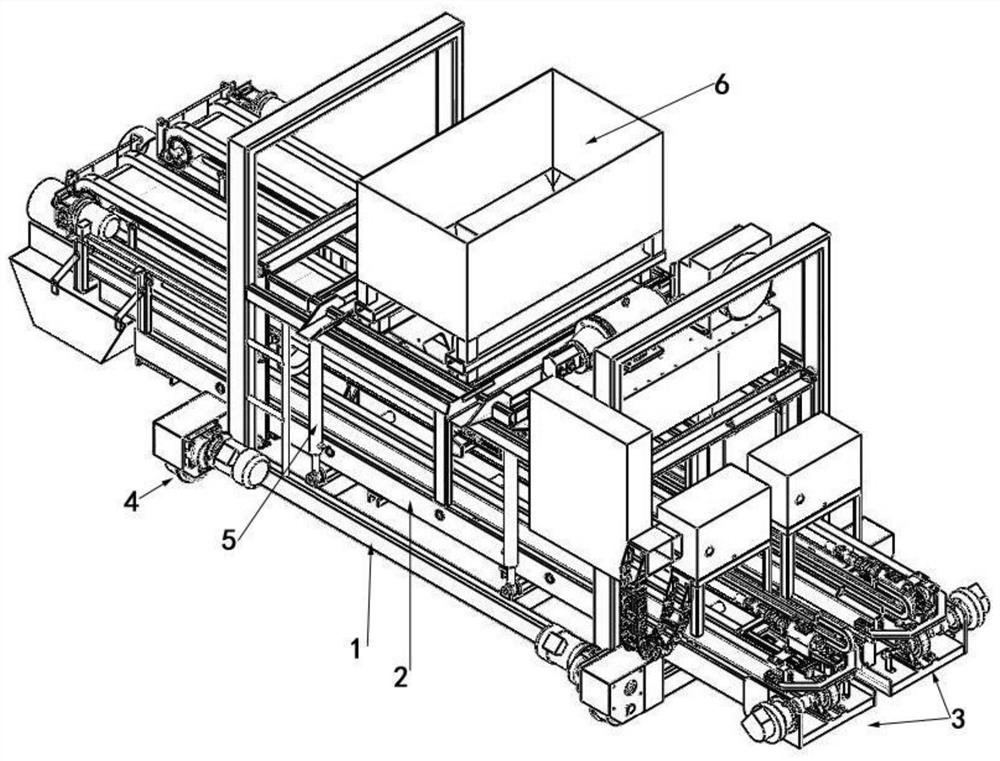

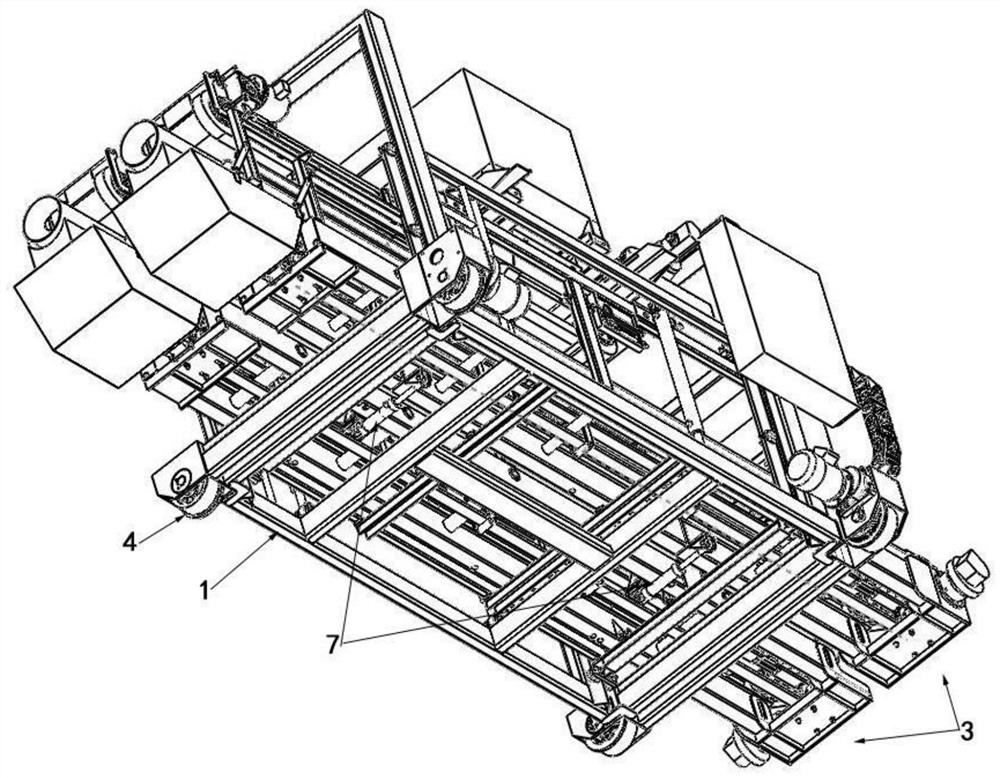

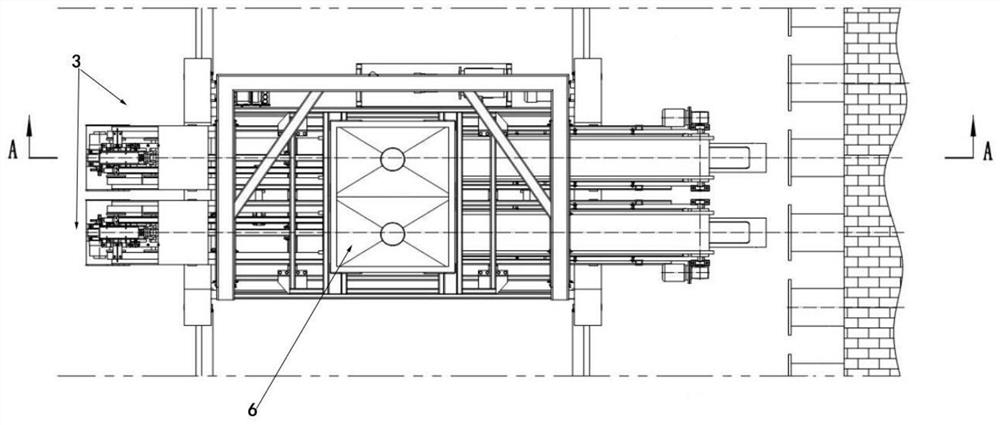

[0050] Such as Figure 1-Figure 15 As shown, the present embodiment provides a double-row filler, including: a chassis frame 1, a lifting frame 2, a hopper 6 and a plurality of filler devices 3 arranged side by side.

[0051] Lifting frame 2 is slidably connected on chassis frame 1. The hopper 6 is fixedly connected to the top of the lifting frame 2 . A plurality of filling devices 3 are connected to the elevating frame 2 , and the input ends of the plurality of filling devices 3 are located vertically below the discharge end of the hopper 6 .

[0052] Among them, the chassis frame 1 is used to support the whole device, and the lifting frame 2 is used to drive the height of the filling device 3 to be adapted to the feeding port of the smelting vessel, so that the filling device 3 can add materials into the smelting vessel.

[0053] Wherein, there are two filling devices 3, and the two filling devices 3 can simultaneously add materials into the smelting vessel, thereby improv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com