Patents

Literature

178results about How to "Easy to reciprocate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

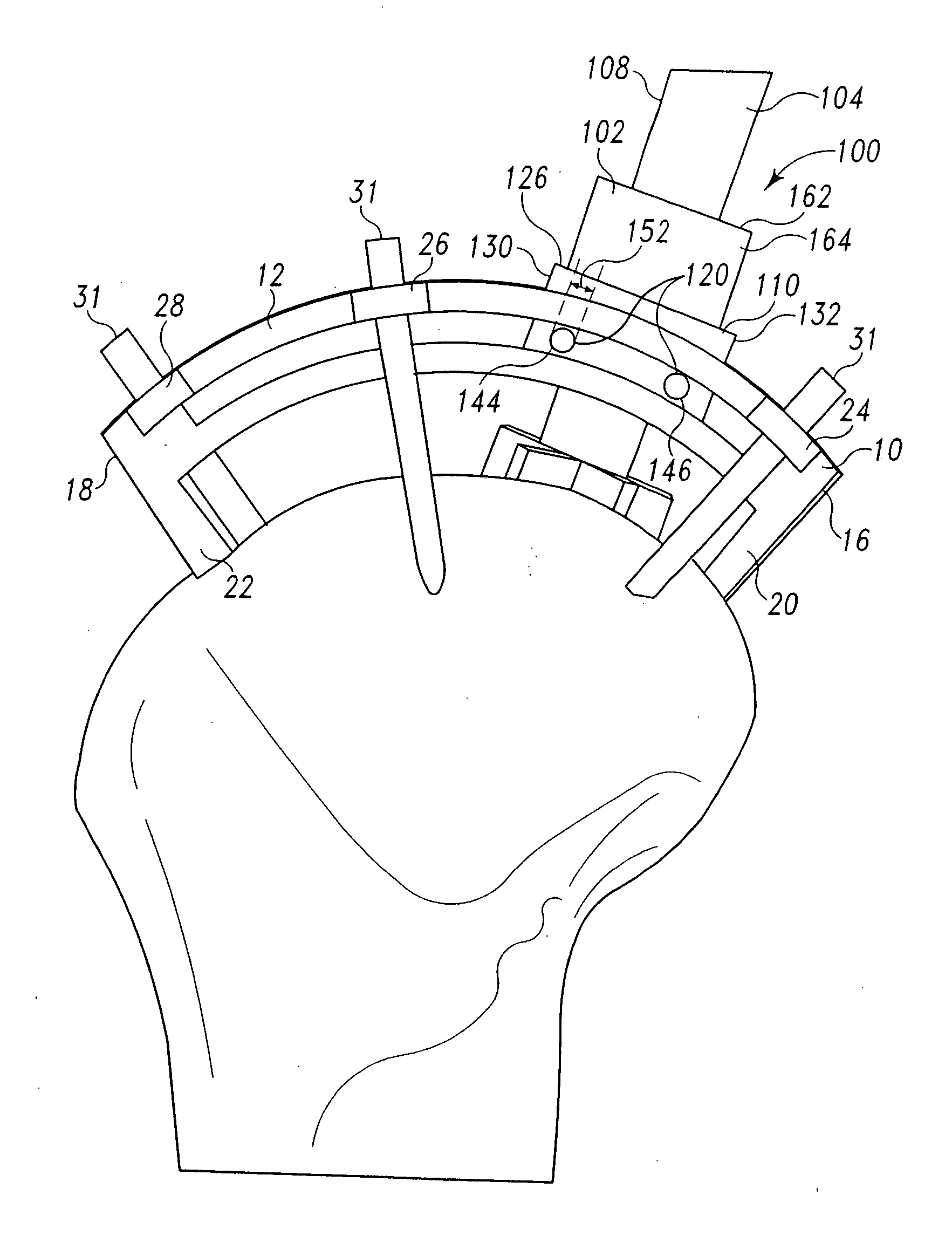

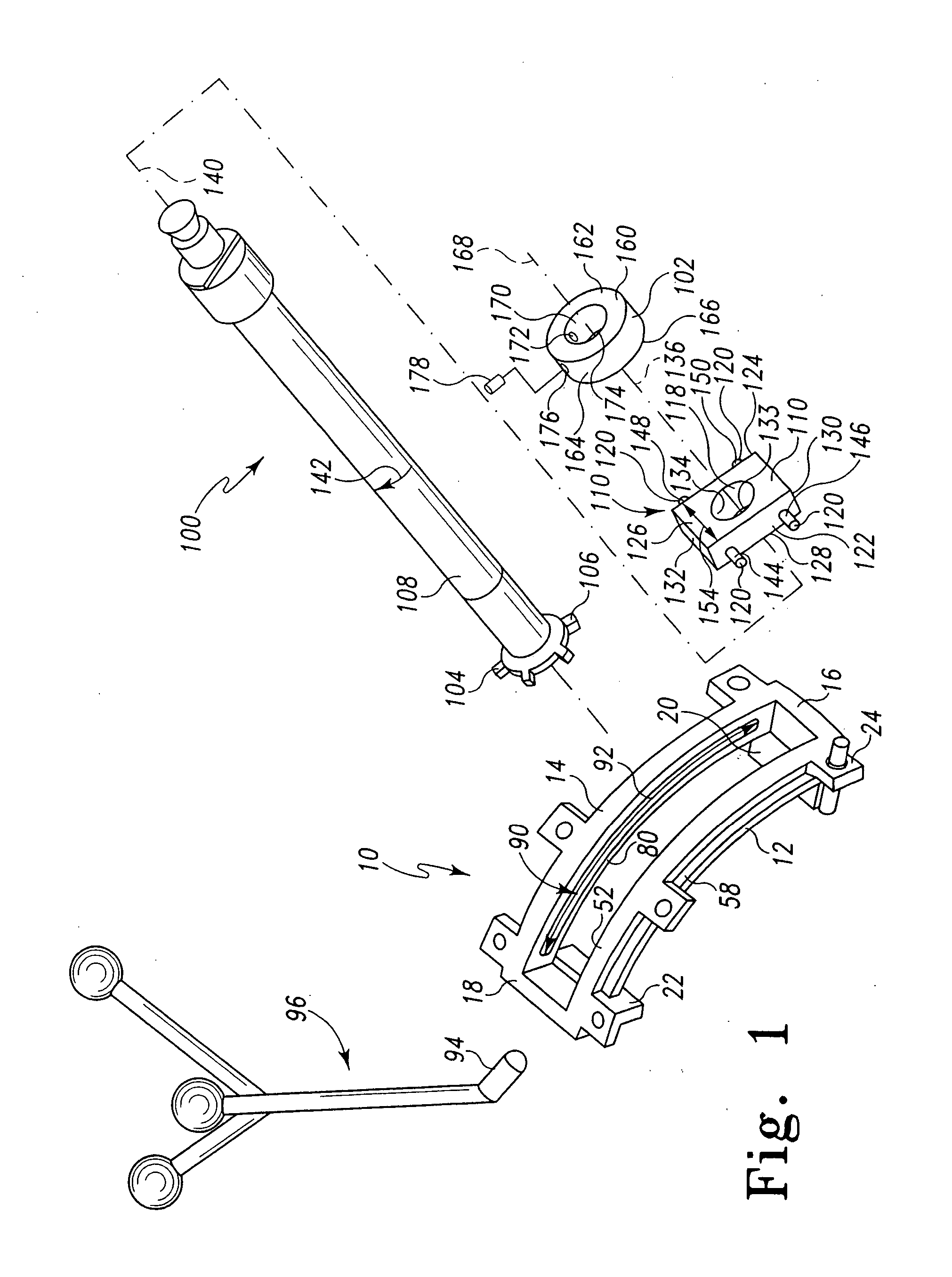

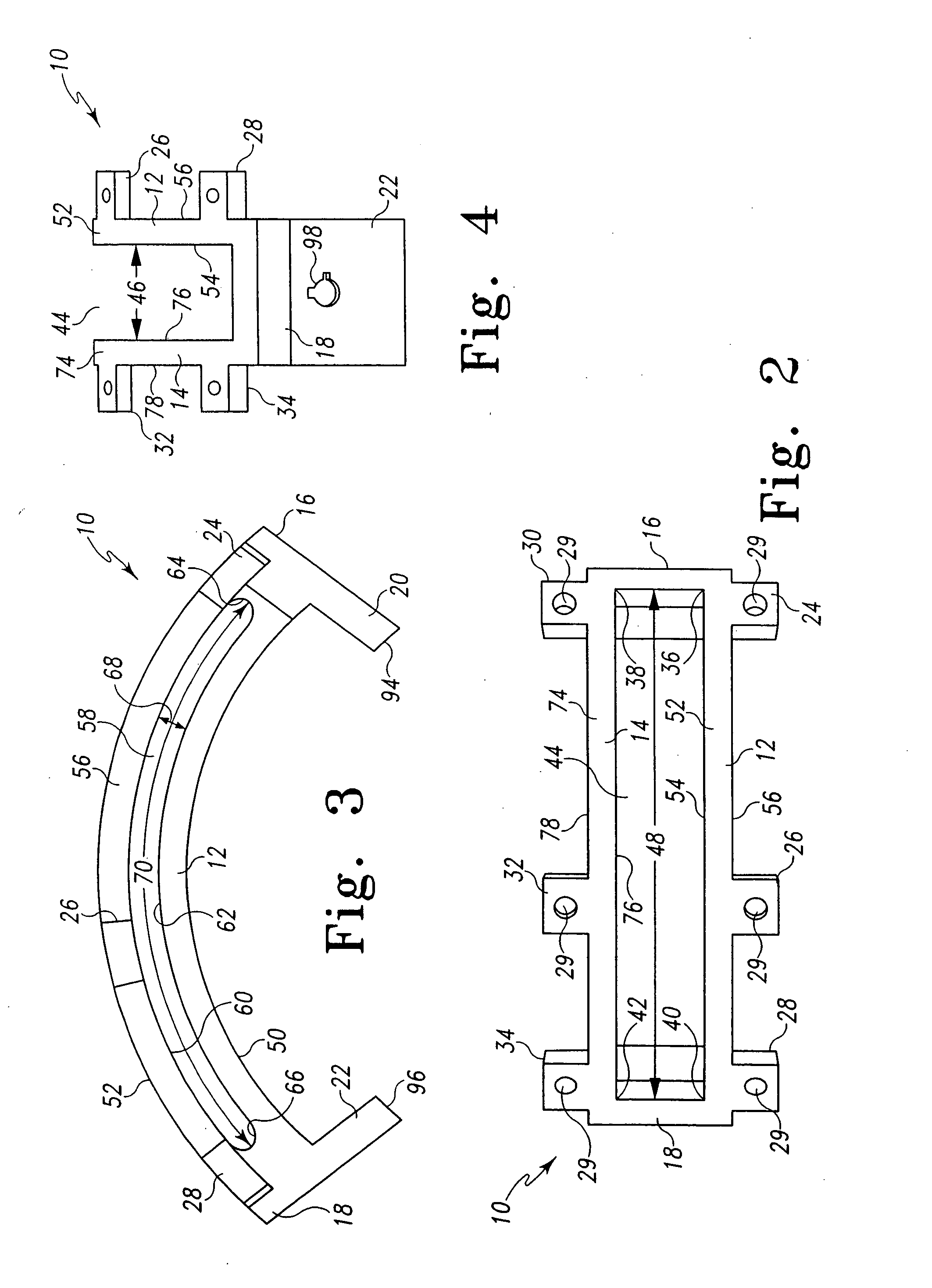

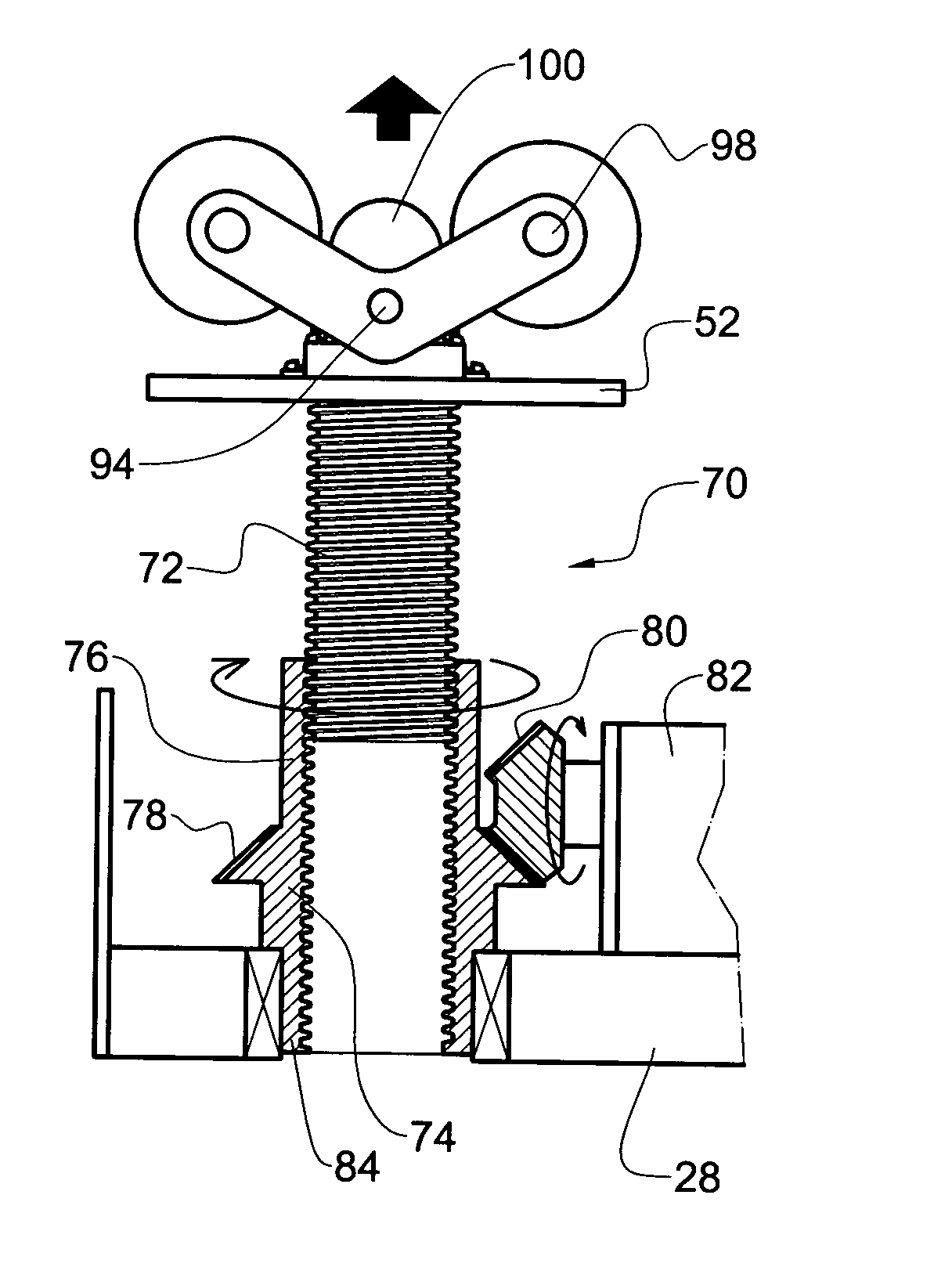

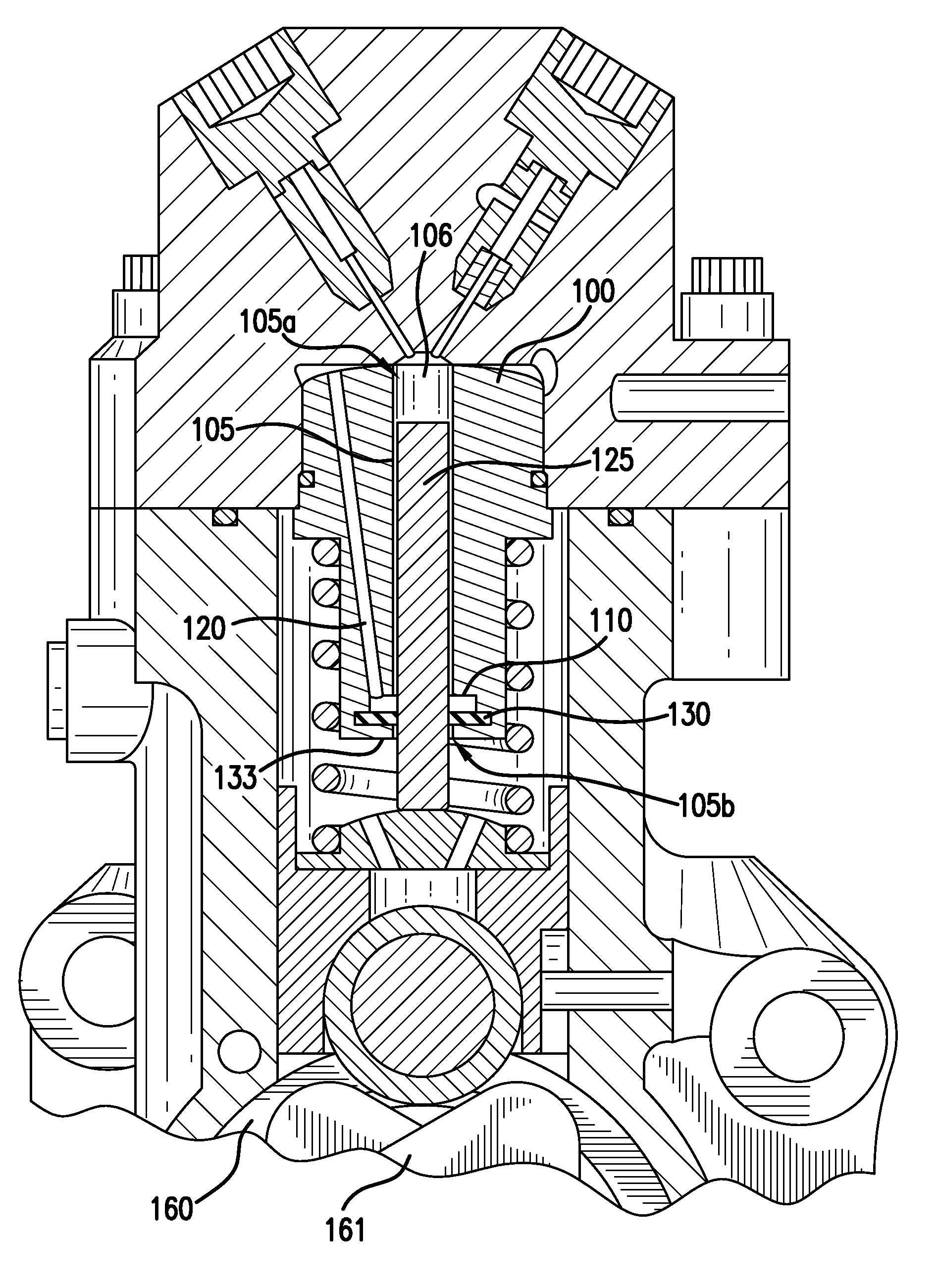

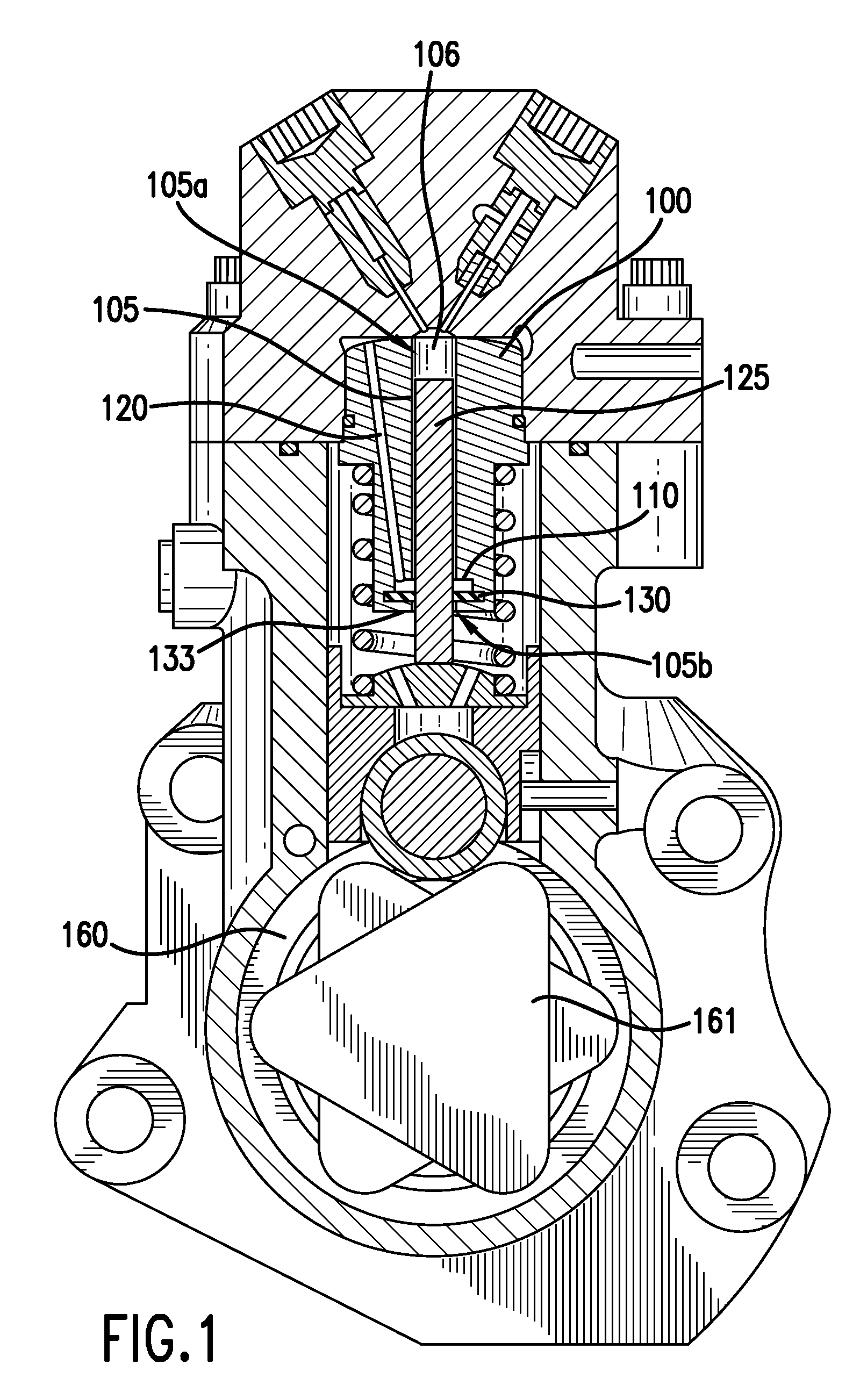

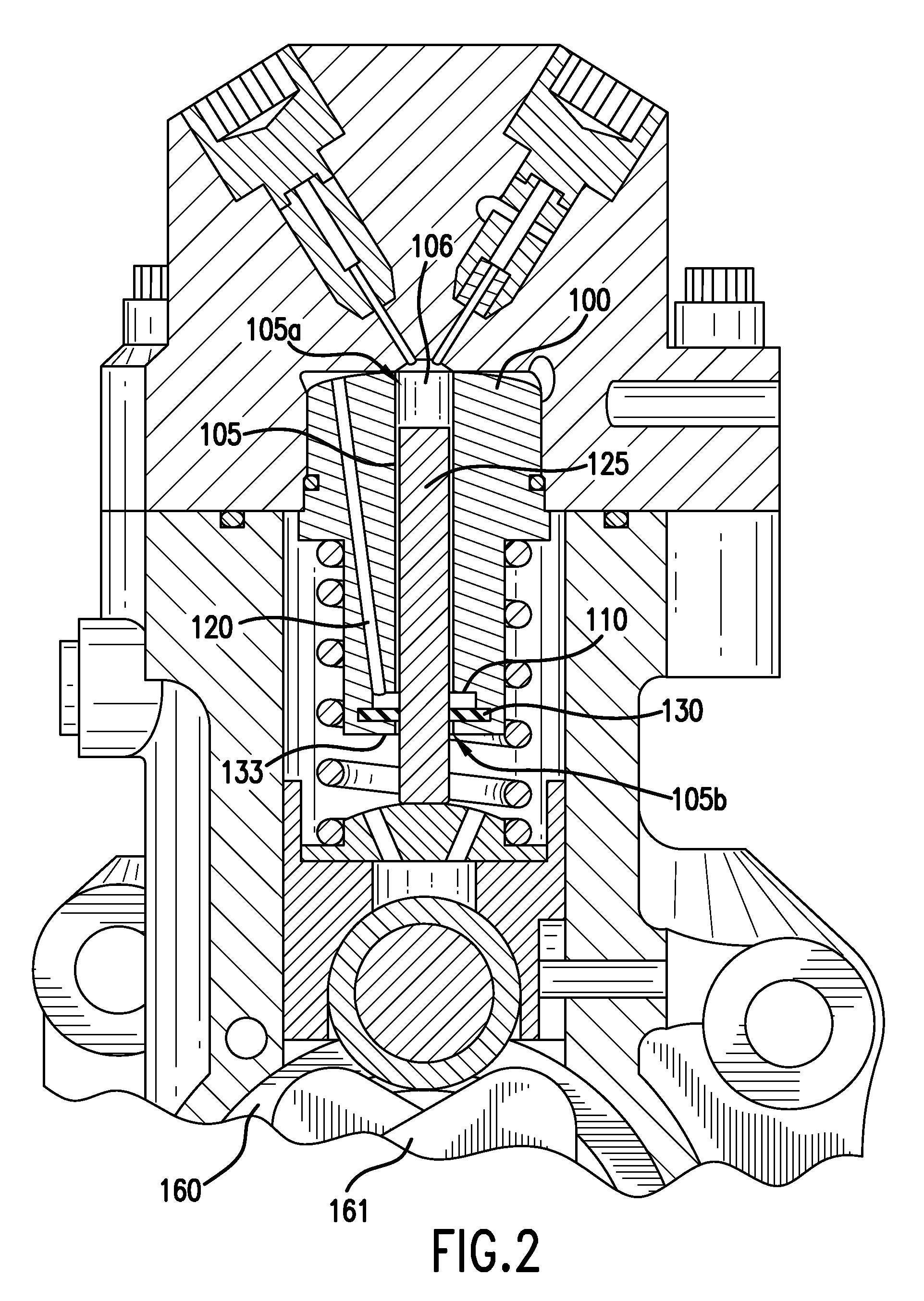

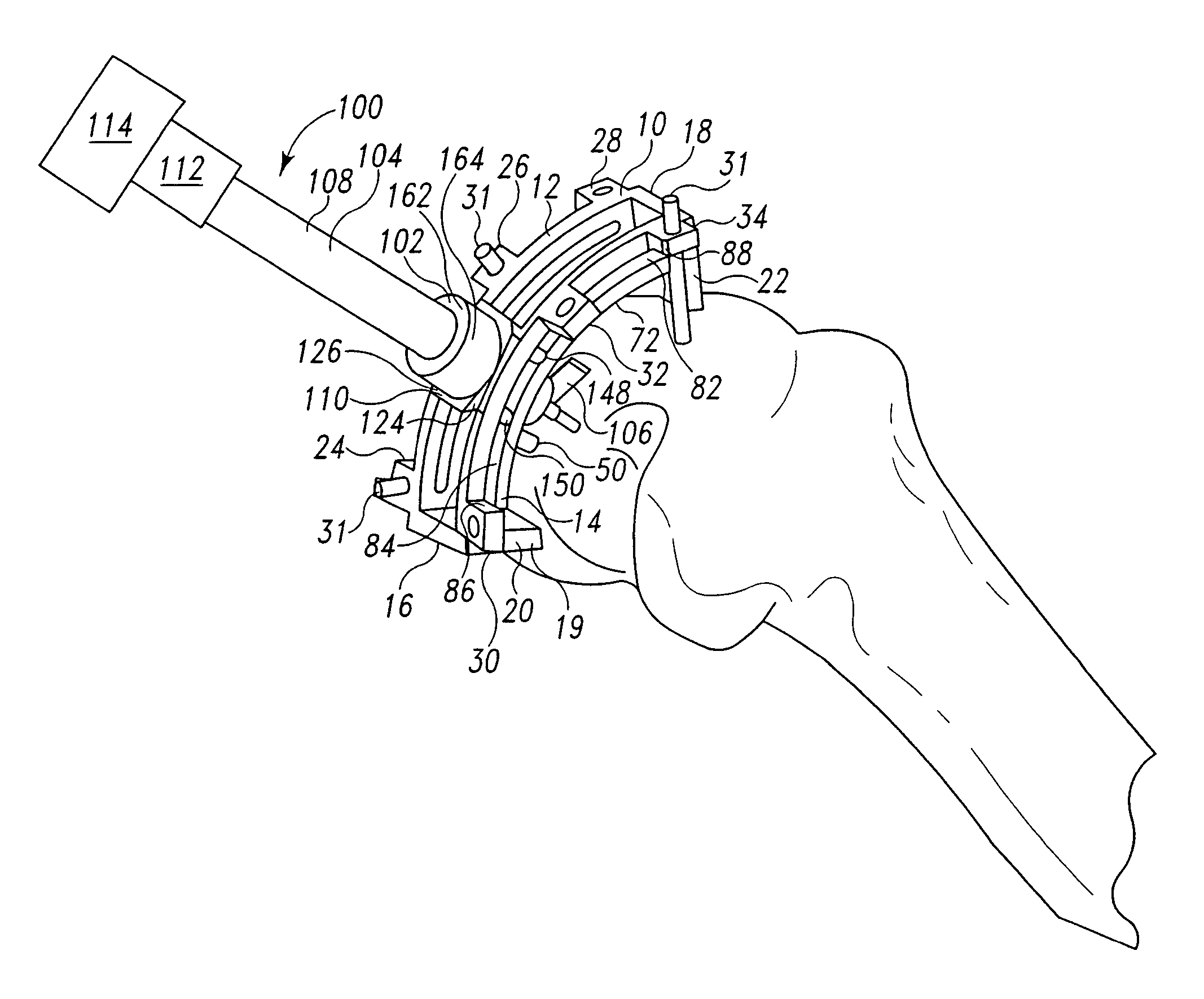

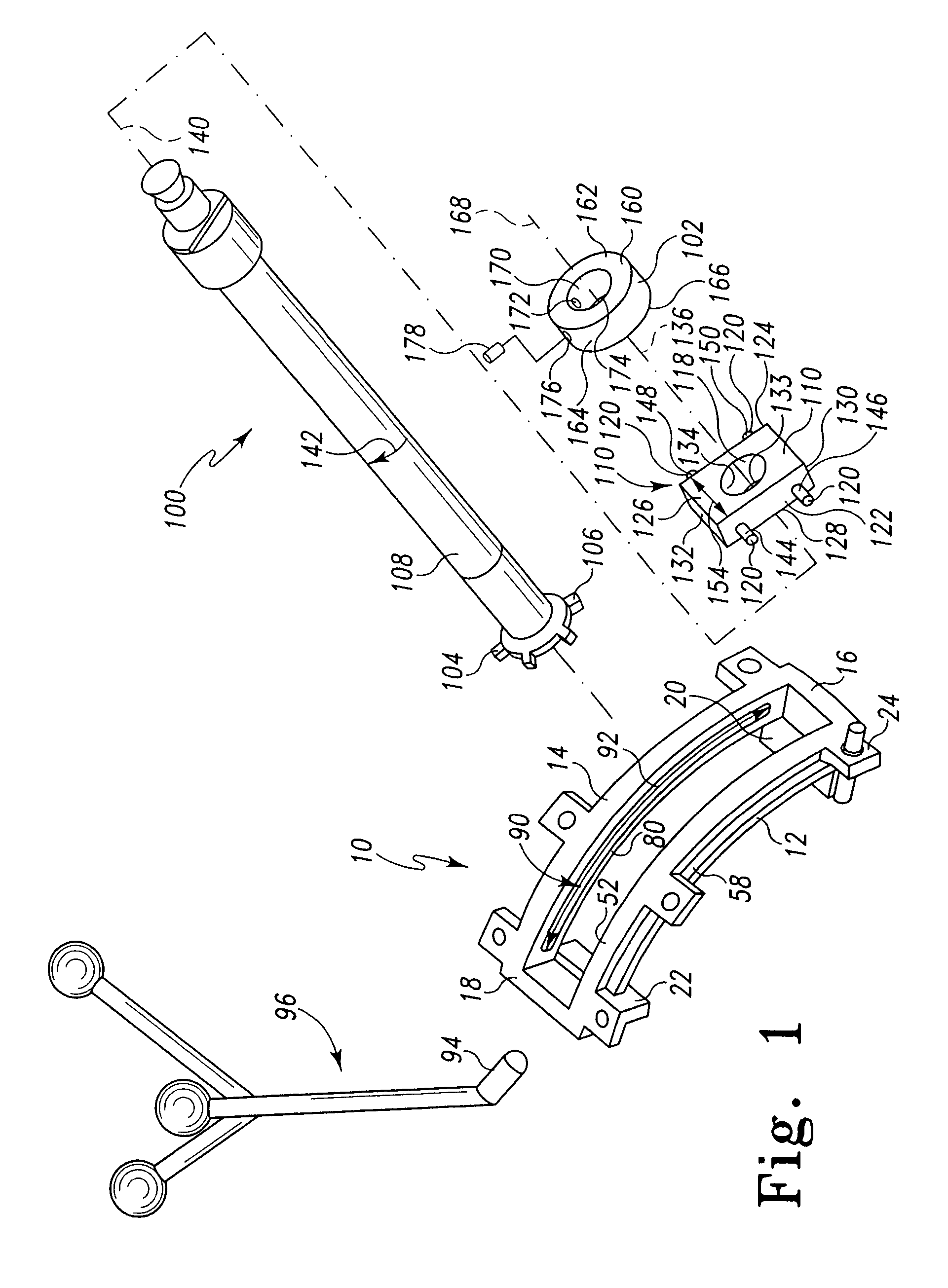

Bone shaping instrument and method for using the same

ActiveUS20060122616A1Small incisionGood functionNon-surgical orthopedic devicesSurgical sawsBone shapeProsthesis

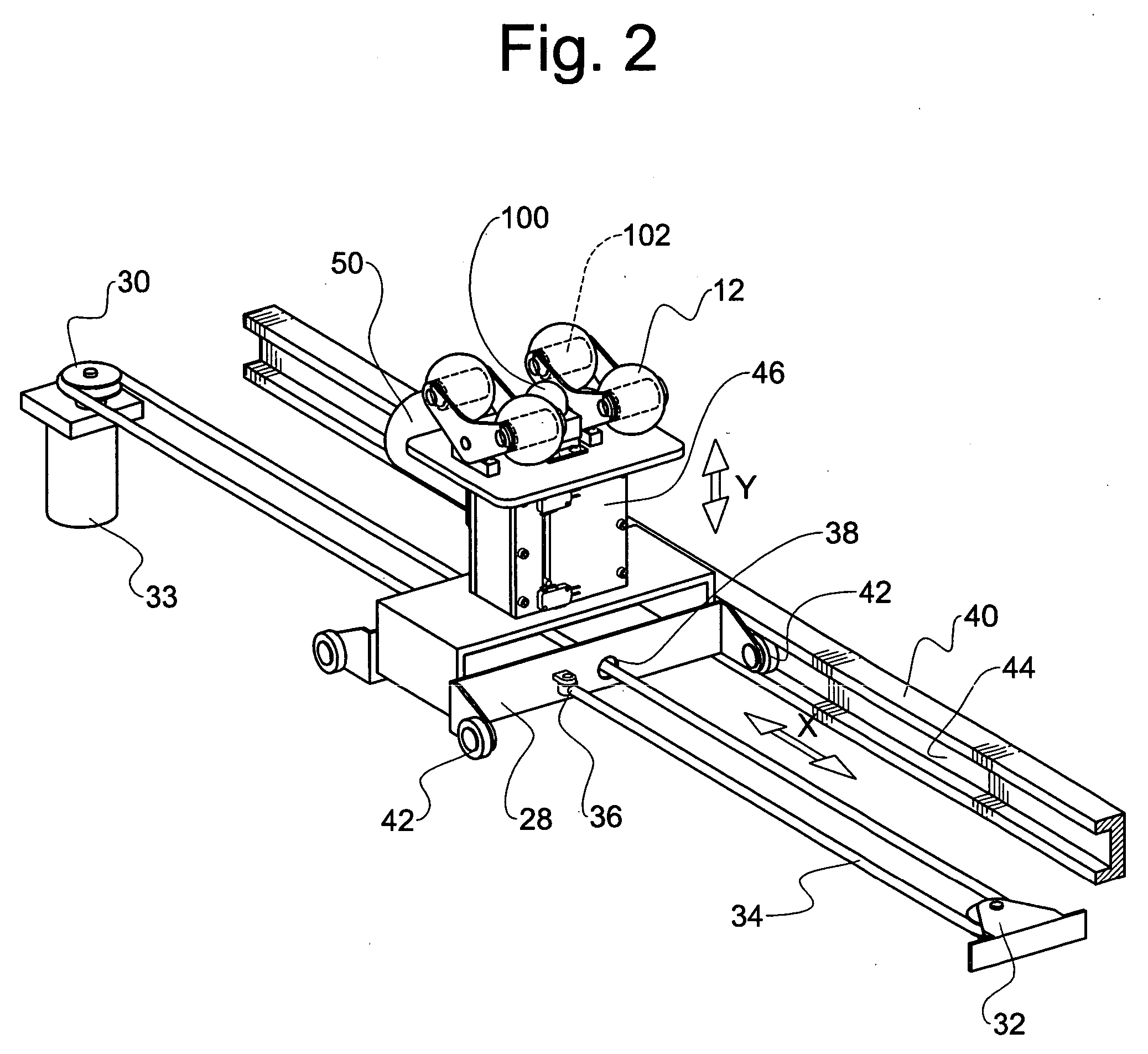

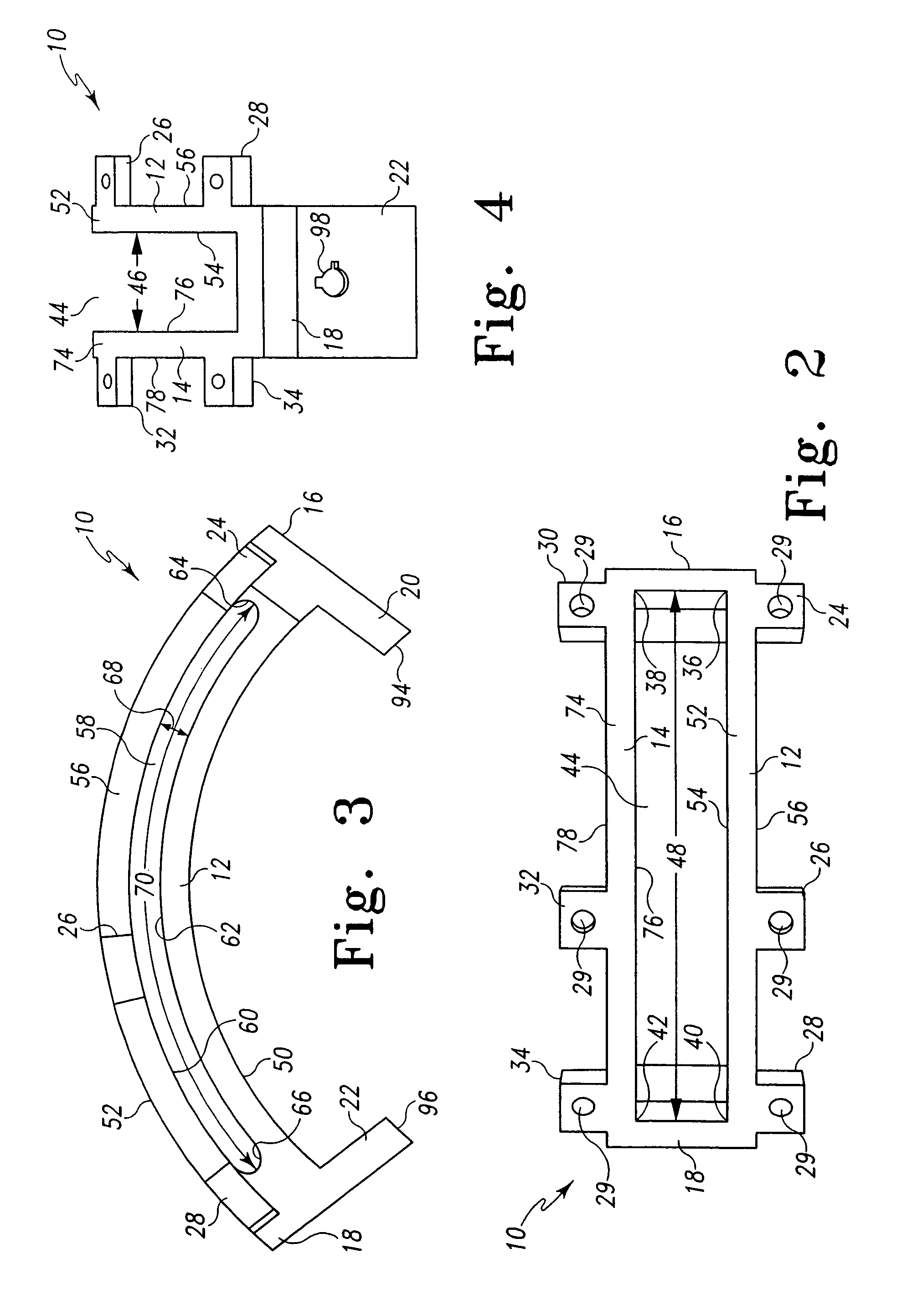

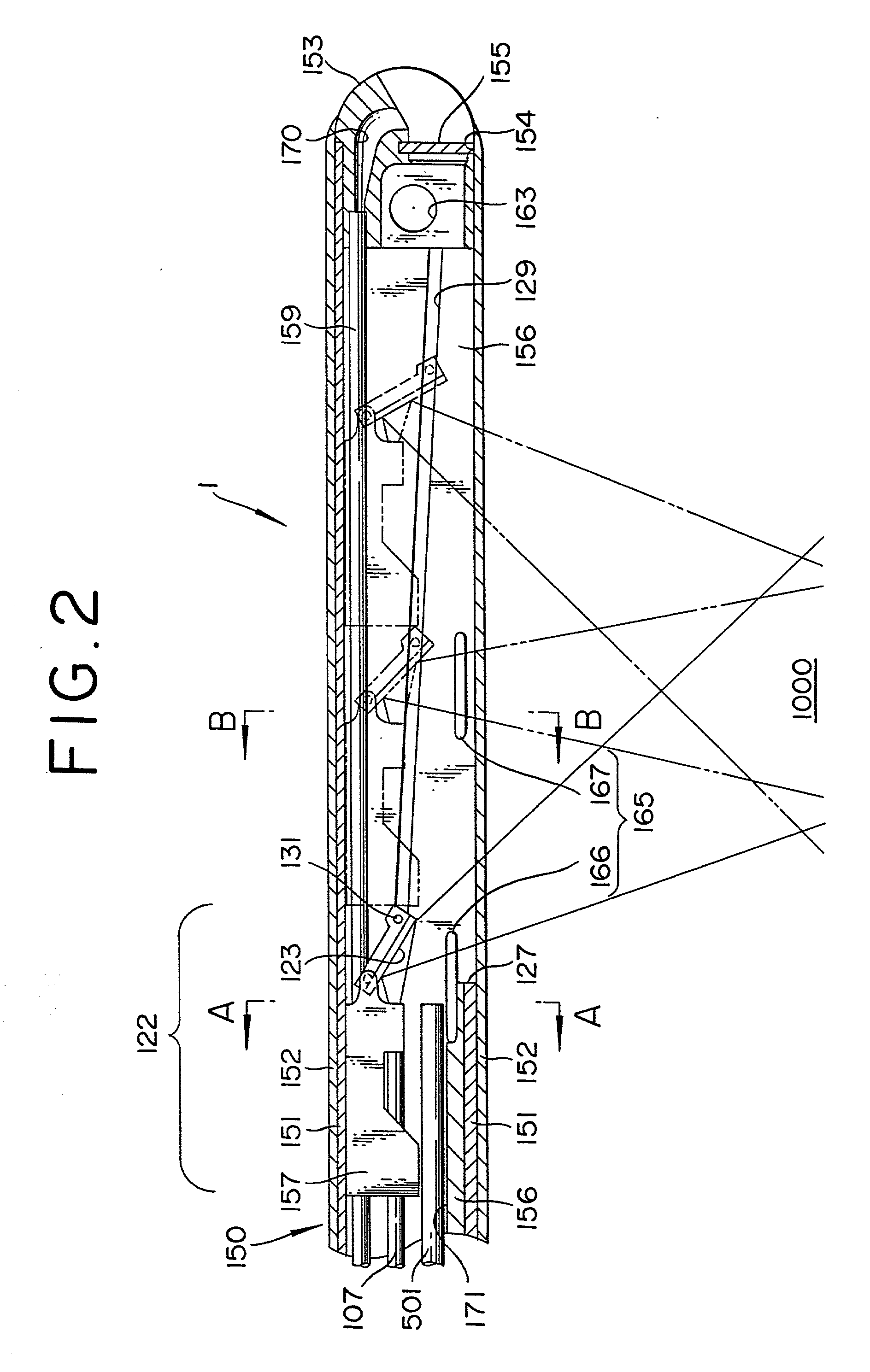

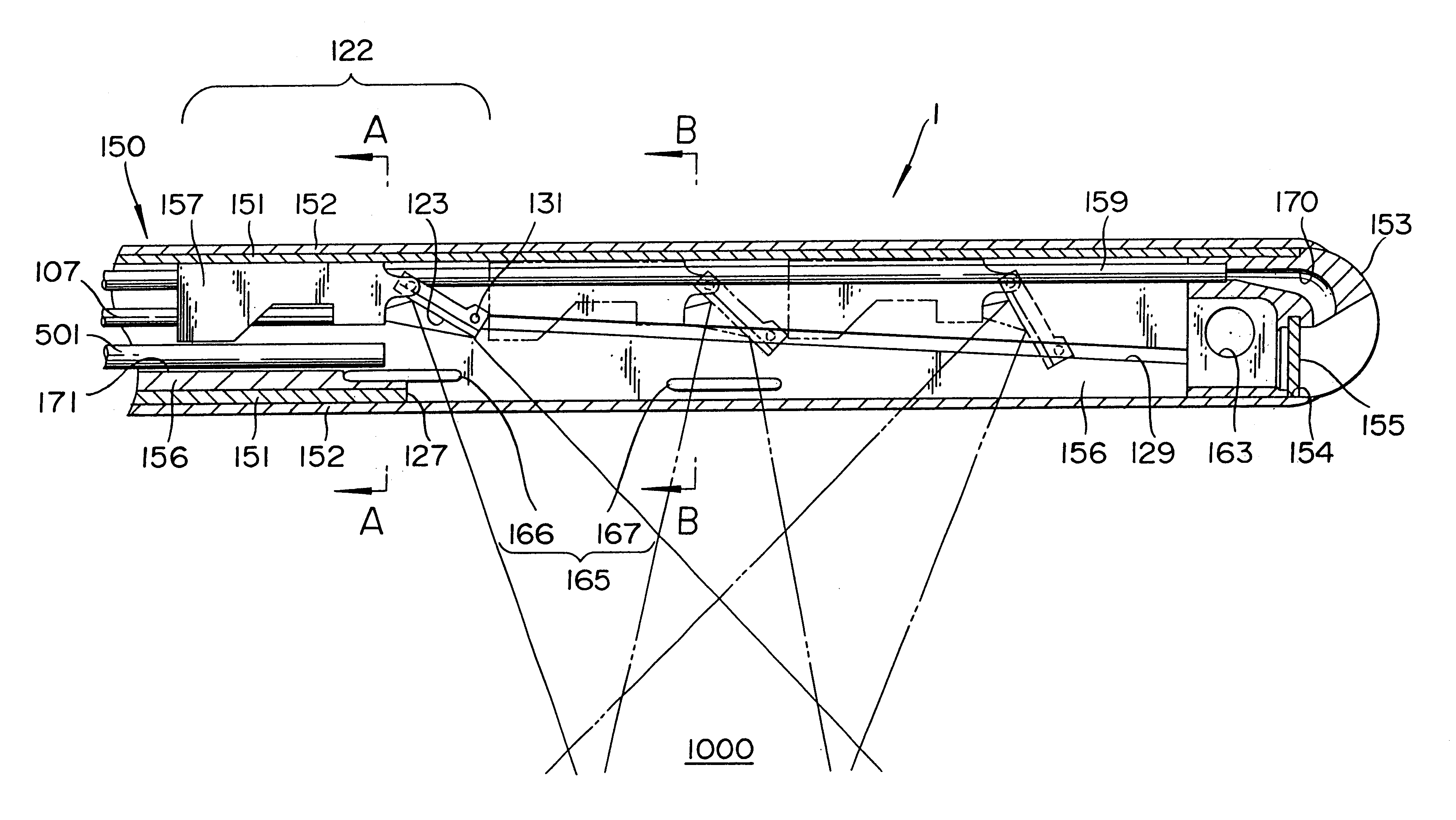

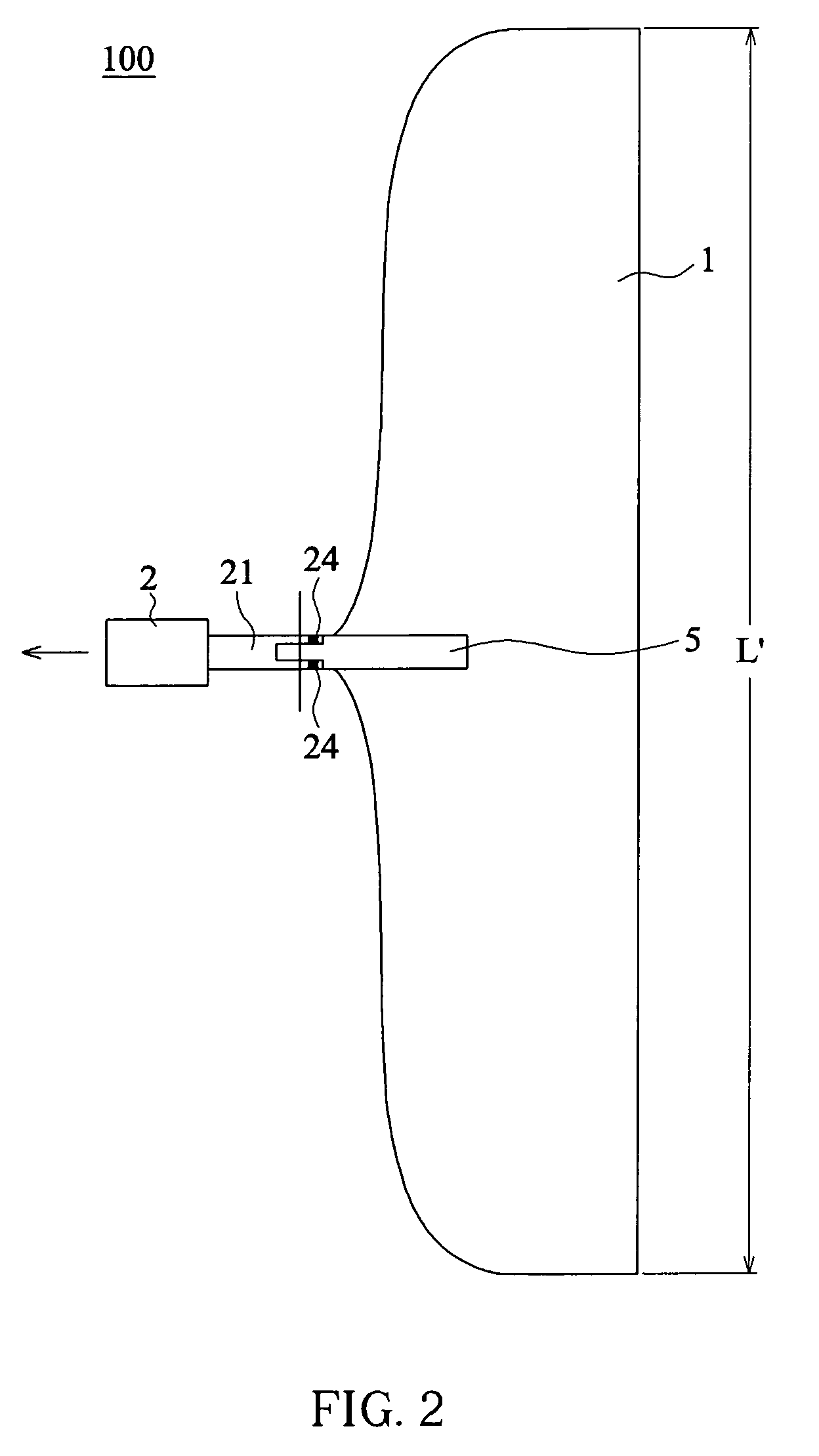

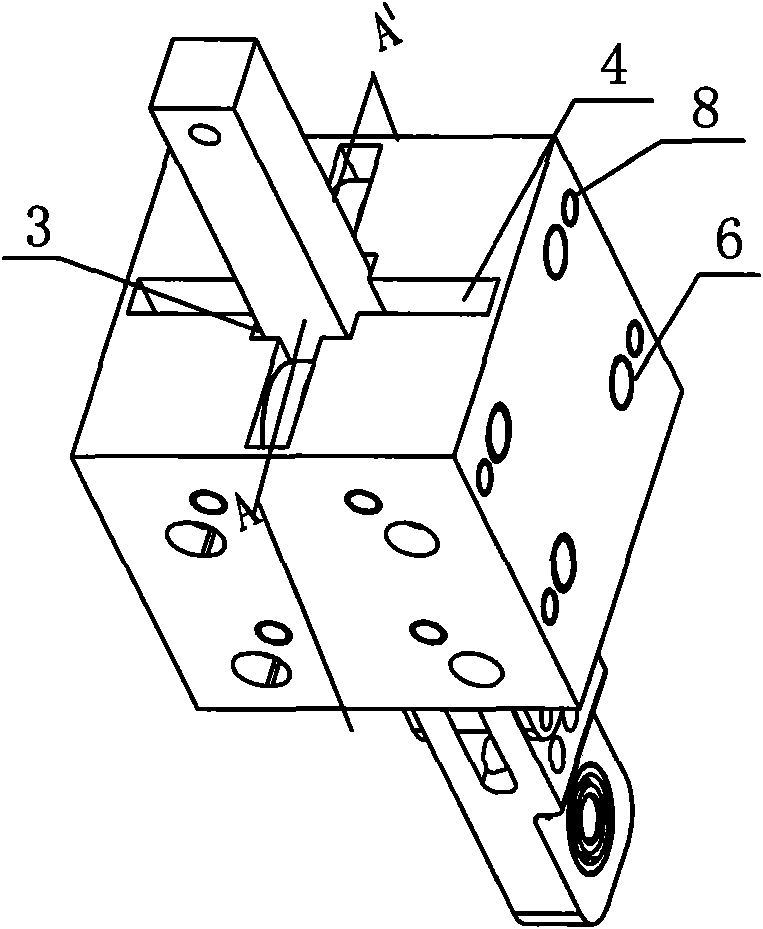

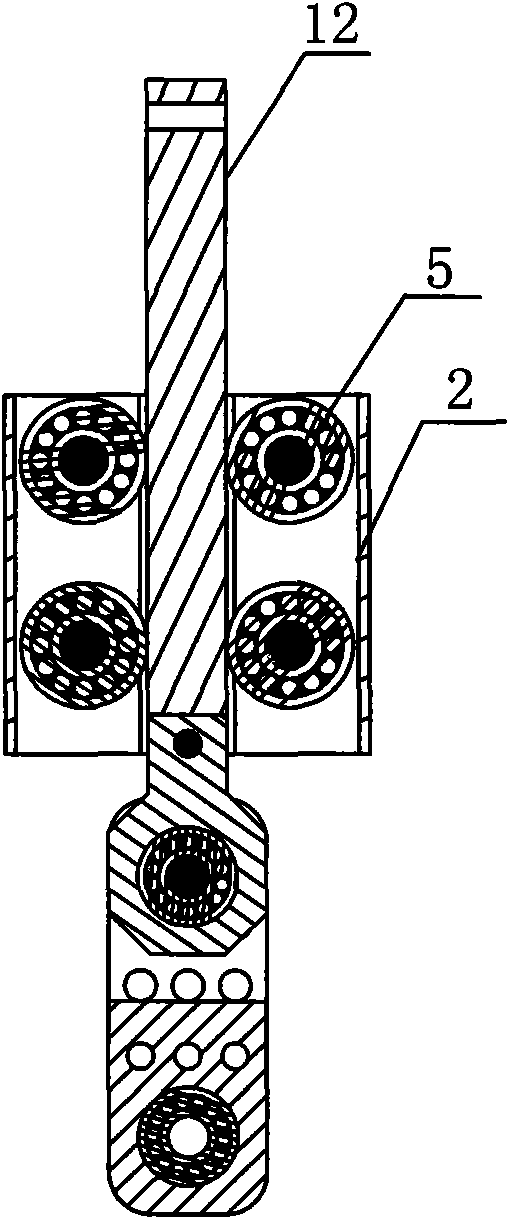

A bone resection tool for resecting an end of a bone along a surface having a curvature comprises a guide, a cutting tool and a track follower. The guide is configured to be removably attached in a fixed position to the end of the bone. The guide is configured to include a track exhibiting a curvature generally corresponding to the curvature of the surface to be resected in the bone. The cutting tool includes a cutting face. The track follower is configured to couple to the cutting tool and cooperate with the track to facilitate reciprocation of the cutting tool relative to the guide to induce the cutting face to resect the bone along the surface having the curvature. A method for cutting a bone along a curved surface conforming to the curvature of a curved surface of the underside of a prosthetic component comprises the steps of incising the tissue surrounding the surface of the bone, positioning a guide alongside the surface of a bone to be cut, affixing the guide to the bone, interconnecting a cutter having a cutting face with the guide, maintaining the cutting face generally parallel to the tangent of the curved surface and traversing the cutting face along the bone while guiding the cutter along the track. The tissue incision incises the tissue surrounding the surface of the bone to be cut in a minimally invasive fashion. The positioned guide includes a track configured to assimilate the curvature of the curved surface of the underside of the prosthetic component.

Owner:DEPUY PROD INC

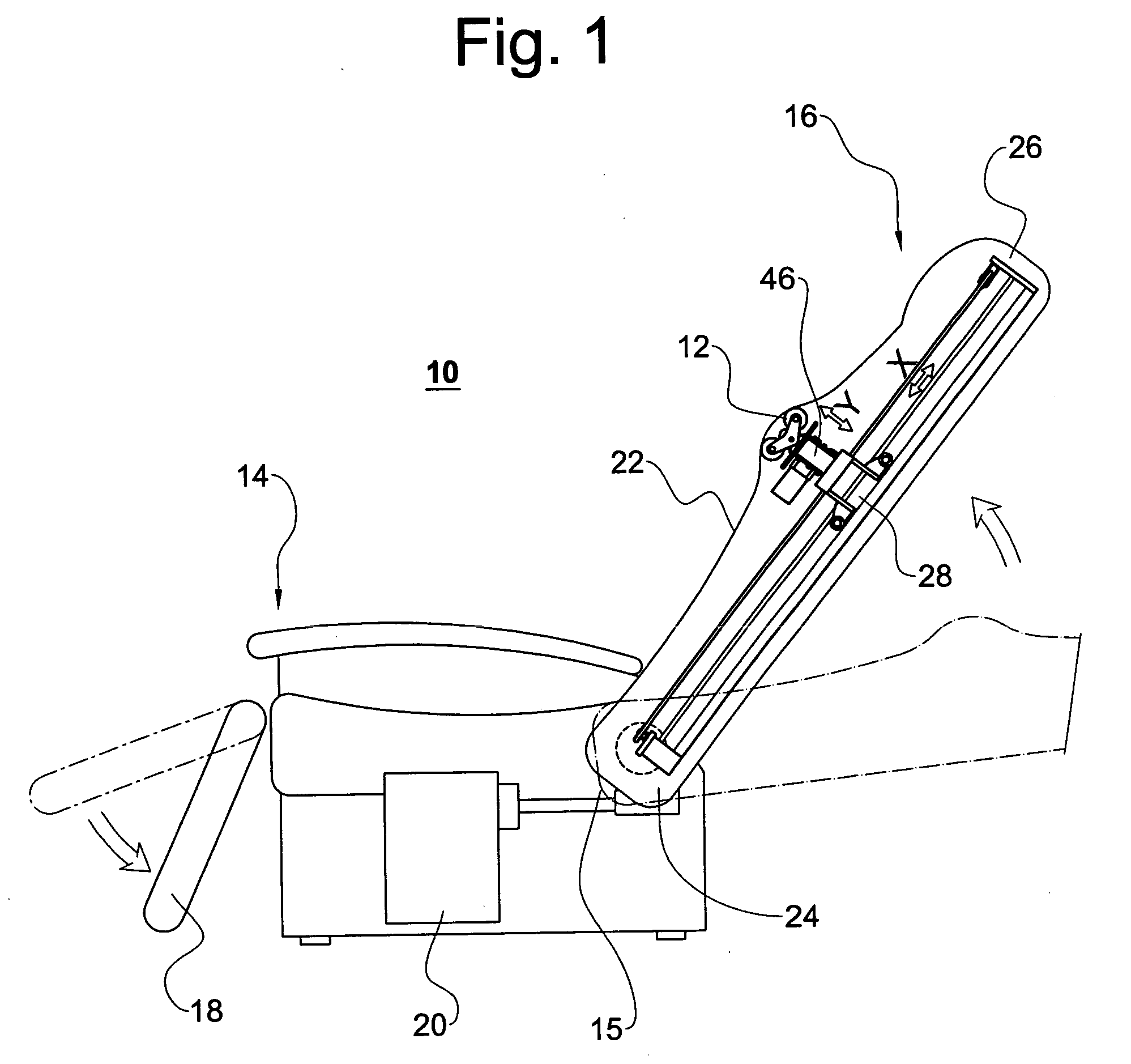

Chair massager

InactiveUS20050049531A1Maximize combinational effectOvercome disadvantagesChiropractic devicesEye exercisersReciprocating motionMassage

A chair massager comprises a base, a back support to place a user's back and neck thereon when the user is seated in the base. The back support has a cover, first and second ends with the first end fixed to the base. A rider makes a lengthwise reciprocal movement between the first and second ends of the back support, and a lifter liftedly engaged to the rider makes a forward reciprocal movement perpendicular to the lengthwise reciprocal movement. Massage bumps veiled by the cover and attached atop the lifter massage along the user's back and neck by the relative movements of the rider and lifter.

Owner:KIM HAKJIN

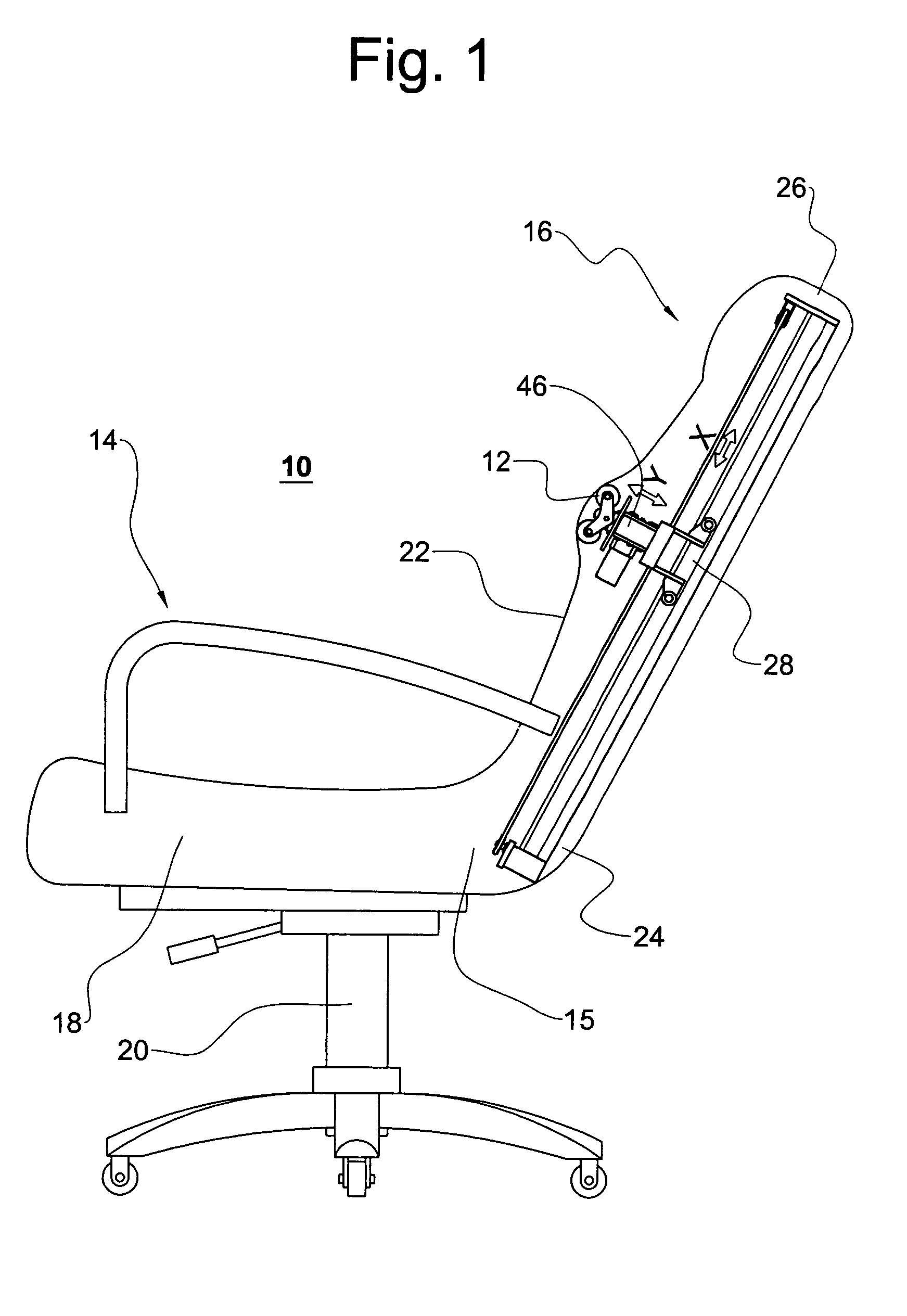

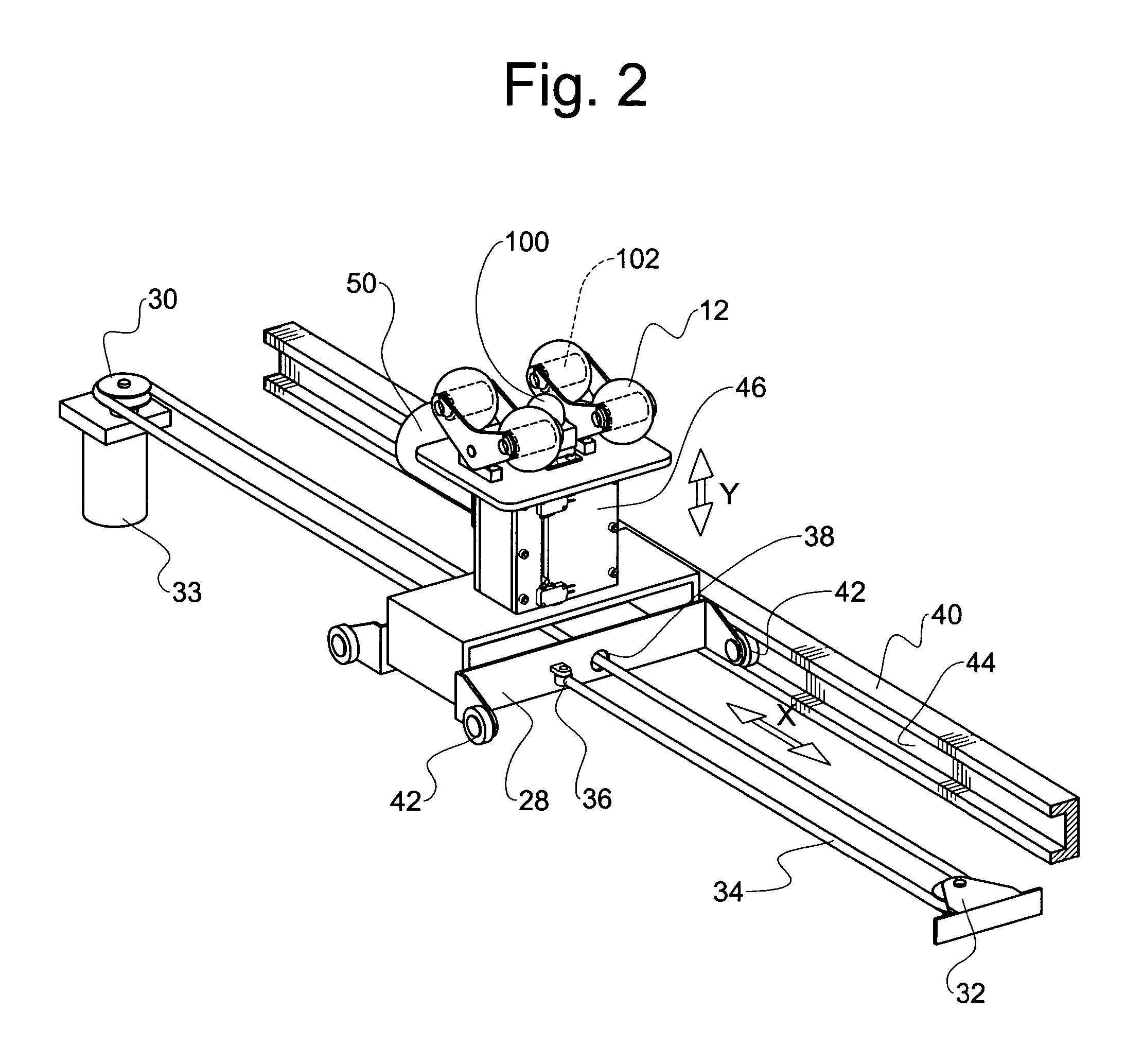

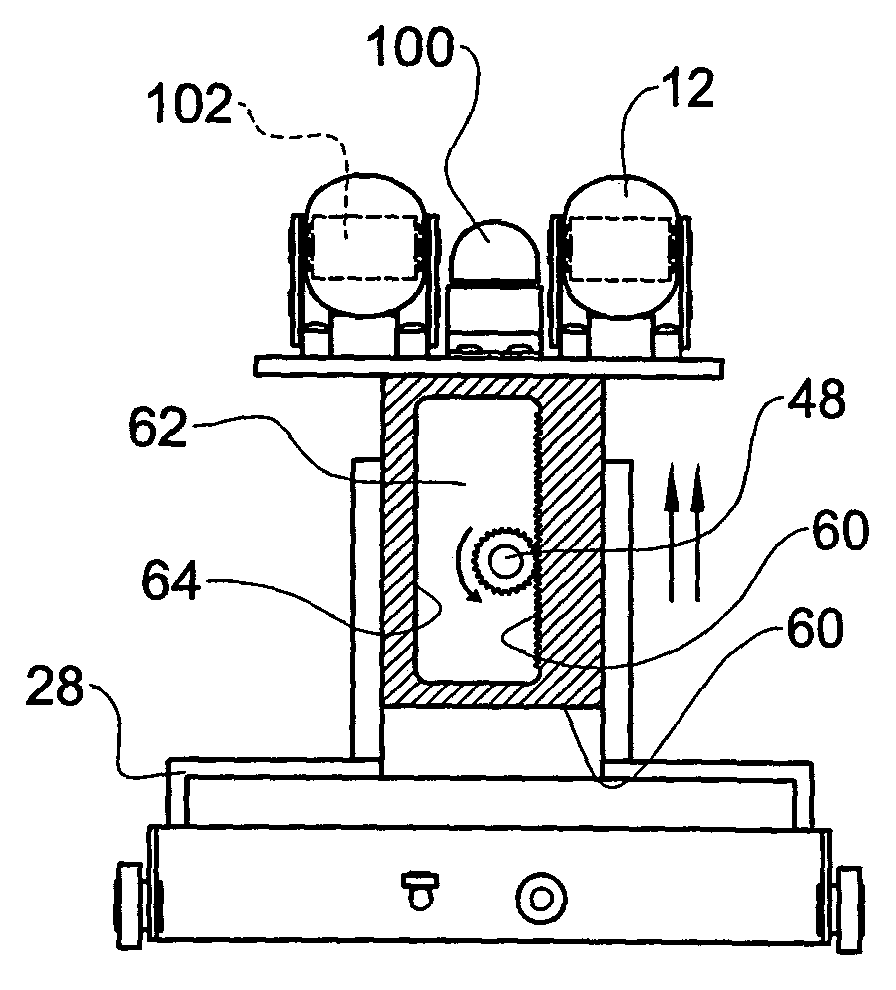

Reclining massager system

InactiveUS20050049530A1Maximize the effectImprove reliabilityChiropractic devicesEye exercisersReciprocating motionMassage

A reclining massager system comprises a base, a back support to place a user's back and neck thereon when the user is seated in the base. The back support has a cover, first and second ends with the first end rotatably connected to the base in a controllably reclining format. A rider makes a lengthwise reciprocal movement between the first and second ends of the back support, and a lifter liftedly engaged to the rider makes a forward reciprocal movement perpendicular to the lengthwise reciprocal movement. Massage bumps veiled by the cover and attached atop the lifter massage along the user's back and neck by the relative movements of the rider and lifter.

Owner:KIM HAKJIN

Telephone vibrator

A vibrator for cellular telephones and the like uses components of a camera. Thus, the need for a dedicated vibrator, and the cost associated therewith, are mitigated. A component of the camera can be moved so as to provide vibration. For example, a lens of the camera can be move back and forth rapidly by an actuator. The vibration can be used to indicate that the phone is ringing, for example.

Owner:DIGITALPTICS MEMS

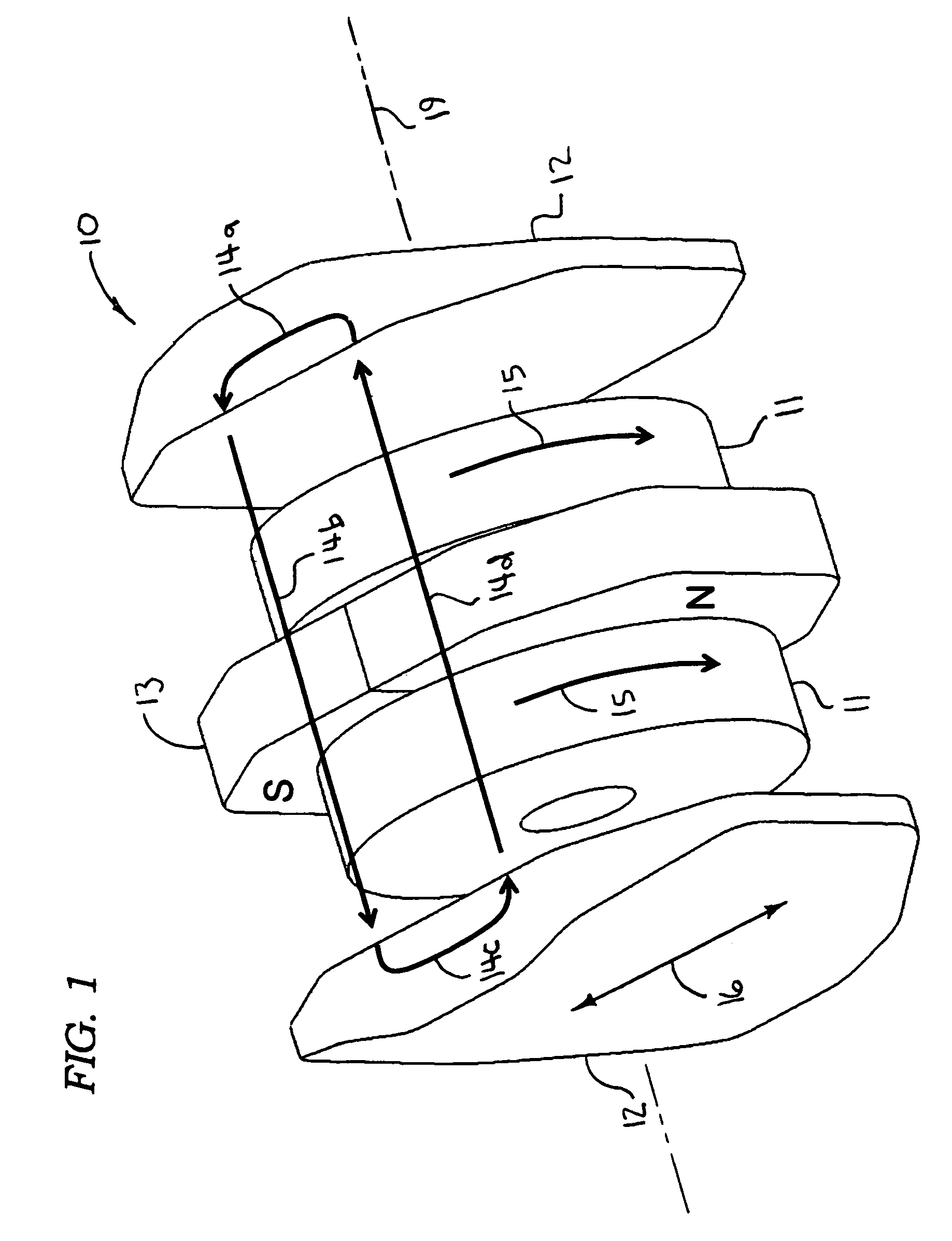

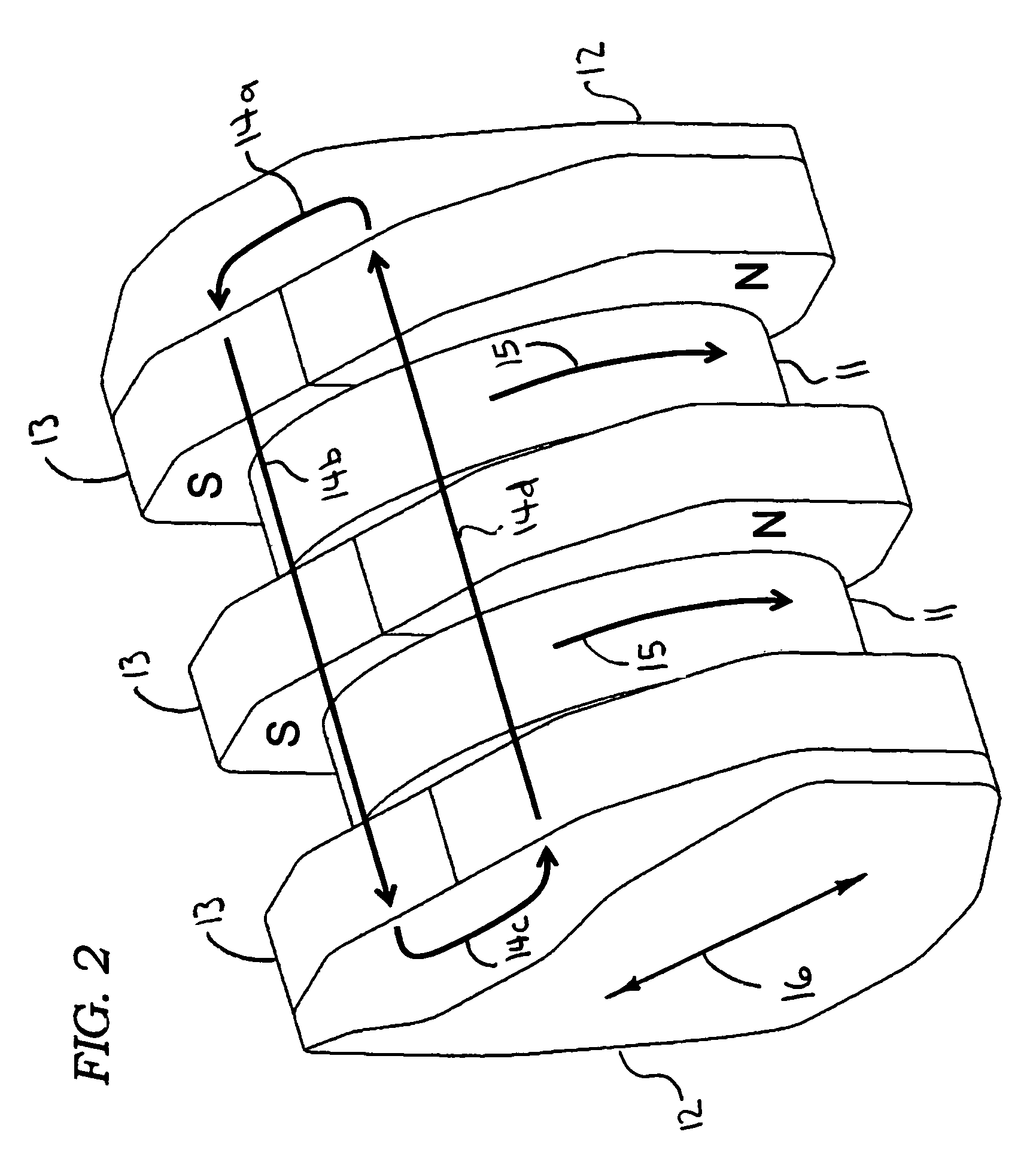

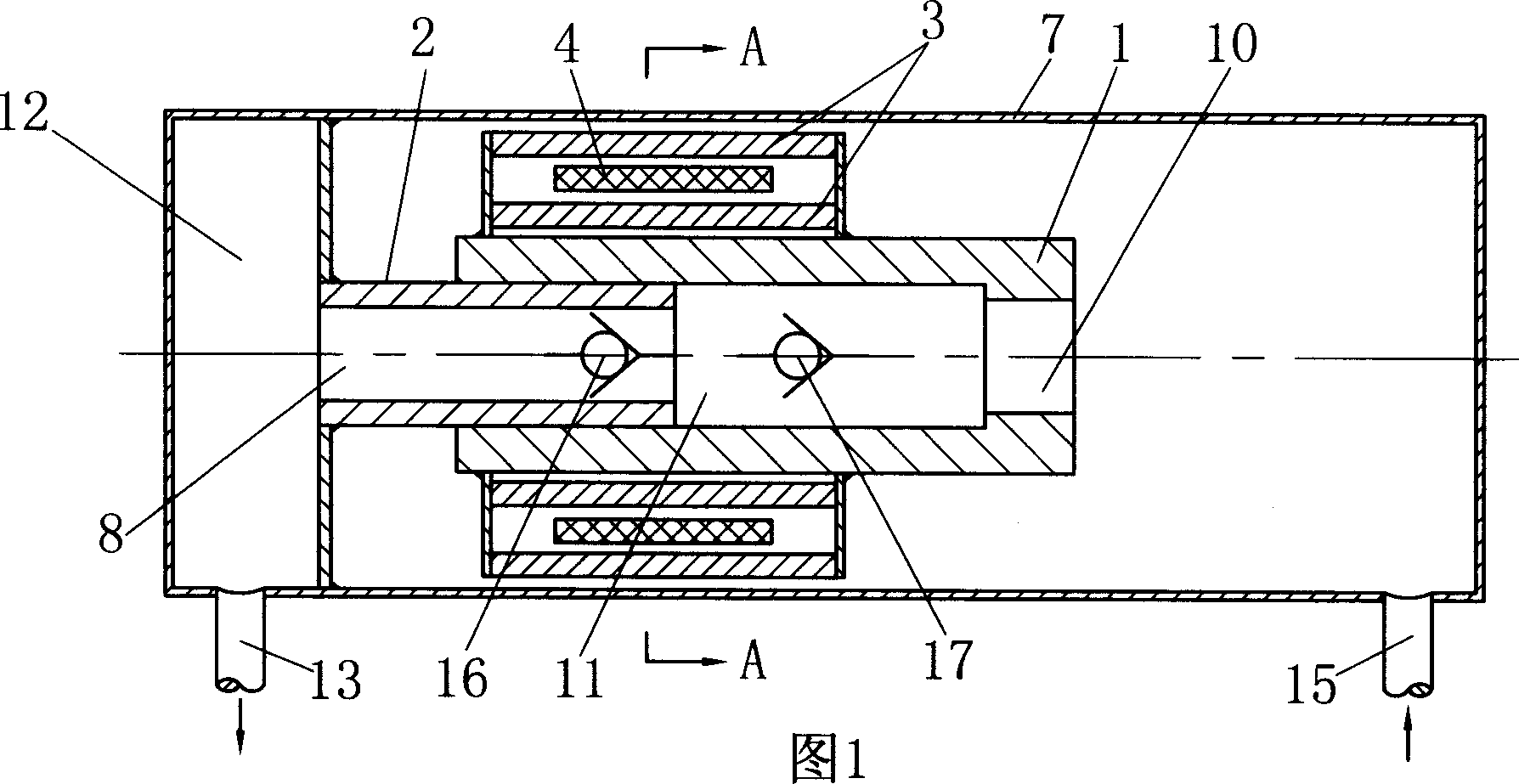

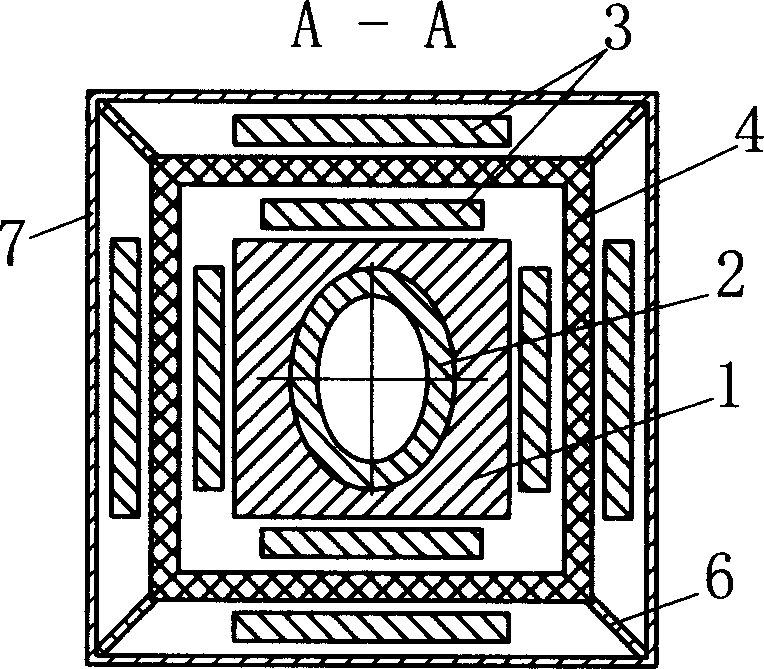

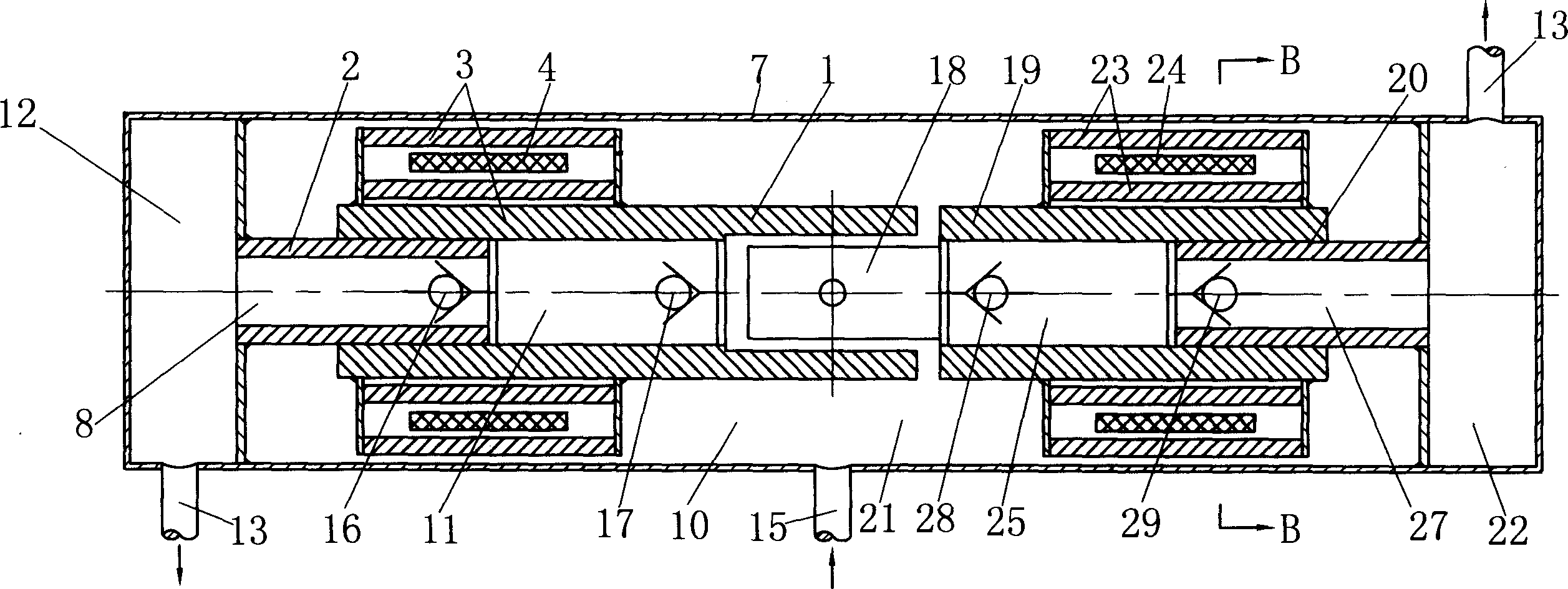

Magnetic linear piston pump

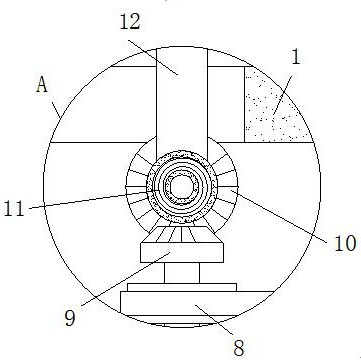

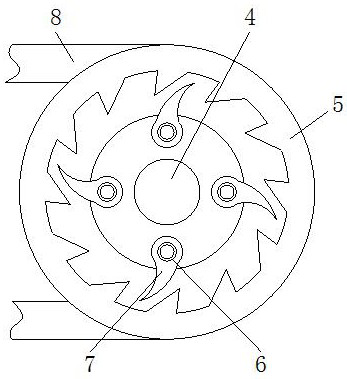

InactiveCN1554868AEasy to reciprocateReliable reciprocating motionPositive displacement pump componentsPumpsLow noiseLinear motion

The piston pump to utilize alternate magnetic field to produce linear motion includes casing, cylinder inside the casing, piston inside the cylinder to fit the cylinder axially and airtightly, electromagnetic coil around the cylinder and connected to vibrating power source, and permanent magnet connected to the outside of the cylinder. The piston has one end connected to the casing and the other end inside the inner hole of the cylinder and is provided with fluid hole. There are the first non-return valve and the second non-return valve set in the fluid hole or inner cylinder cavity to constitute three independent cavities, including low pressure cavity communicated with the inflow pipe, variable volume work cavity and high pressure cavity communicated with the outflow pipe. The present invention has the advantages of simple structure, low power consumption, low noise, etc. and may be used in pumping oil, water and other medium and in compressor.

Owner:俞国淼

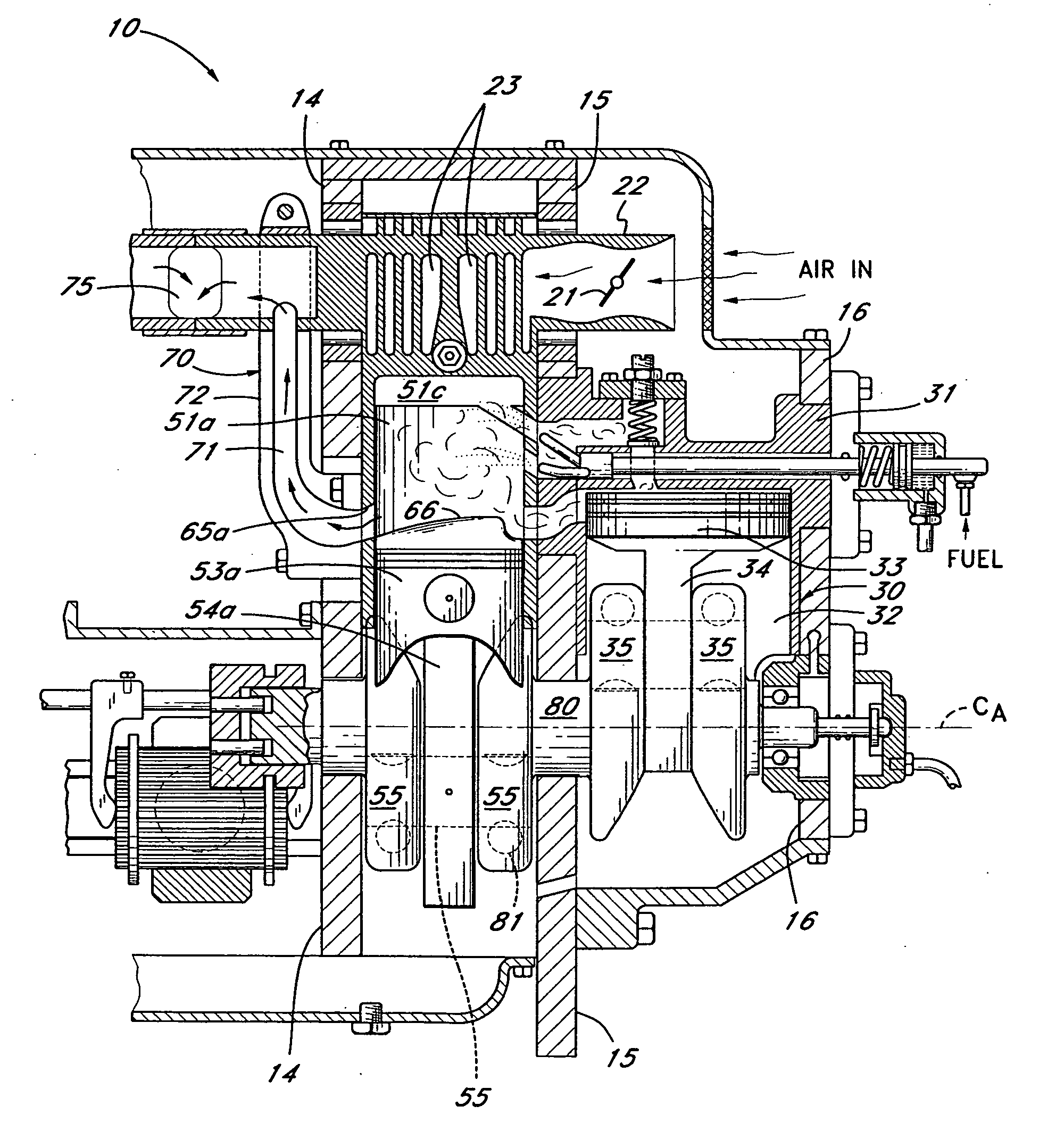

Fuel pump

ActiveUS20100043760A1Easy to reciprocateEngine sealsPositive displacement pump componentsEngineeringPlunger

A fuel pump is disclosed wherein a substantially cylindrical plunger bore is provided with an annular drain groove fluidically coupled to a drain duct. A pump plunger is driven by a drive system located in a separate mechanical compartment that holds a reservoir of lubricating oil. An annular seal is provided adjacent the drain groove substantially at the end of the bore and retained in position by a seal support. Exemplary embodiments provide the drain groove and seal as being positioned immediately adjacent one another so that the seal forms a lower wall of the drain groove.

Owner:CUMMINS INC

Bone shaping instrument and method for using the same

ActiveUS7766913B2More kinematically correctLess invasive surgeriesJoint implantsNon-surgical orthopedic devicesReciprocating motionProsthesis

A bone resection tool for resecting an end of a bone along a surface having a curvature comprises a guide, a cutting tool and a track follower. The guide is configured to be removably attached in a fixed position to the end of the bone. The guide is configured to include a track exhibiting a curvature generally corresponding to the curvature of the surface to be resected in the bone. The cutting tool includes a cutting face. The track follower is configured to couple to the cutting tool and cooperate with the track to facilitate reciprocation of the cutting tool relative to the guide to induce the cutting face to resect the bone along the surface having the curvature. A method for cutting a bone along a curved surface conforming to the curvature of a curved surface of the underside of a prosthetic component comprises the steps of incising the tissue surrounding the surface of the bone, positioning a guide alongside the surface of a bone to be cut, affixing the guide to the bone, interconnecting a cutter having a cutting face with the guide, maintaining the cutting face generally parallel to the tangent of the curved surface and traversing the cutting face along the bone while guiding the cutter along the track. The tissue incision incises the tissue surrounding the surface of the bone to be cut in a minimally invasive fashion. The positioned guide includes a track configured to assimilate the curvature of the curved surface of the underside of the prosthetic component.

Owner:DEPUY PROD INC

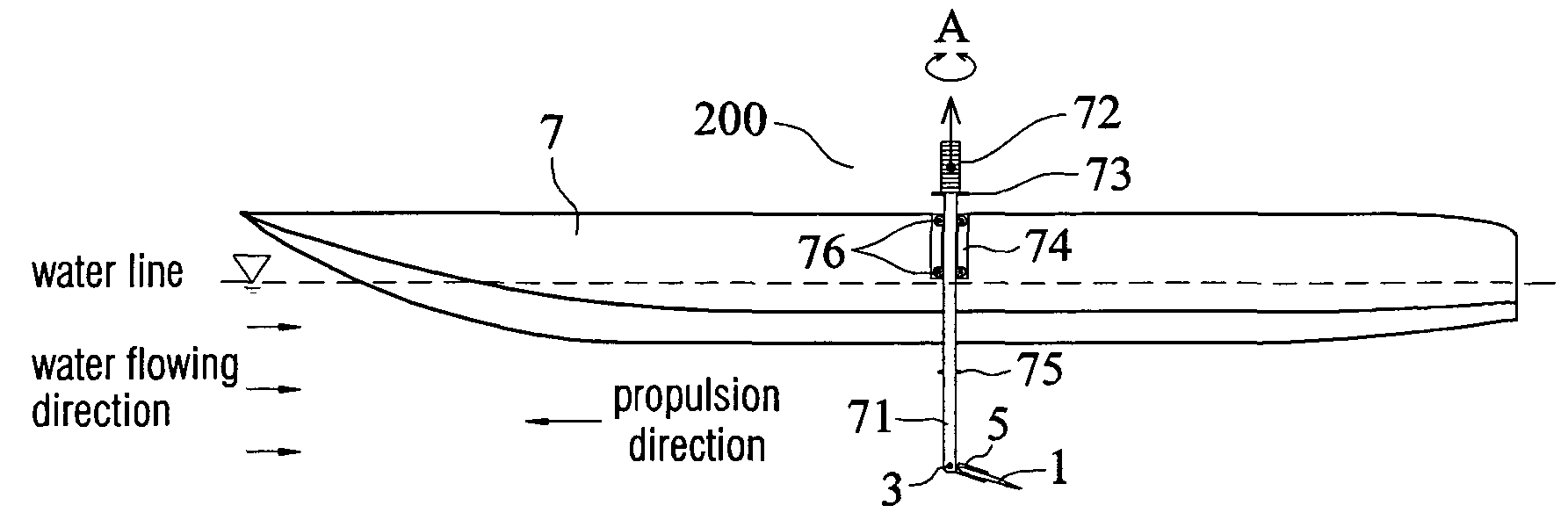

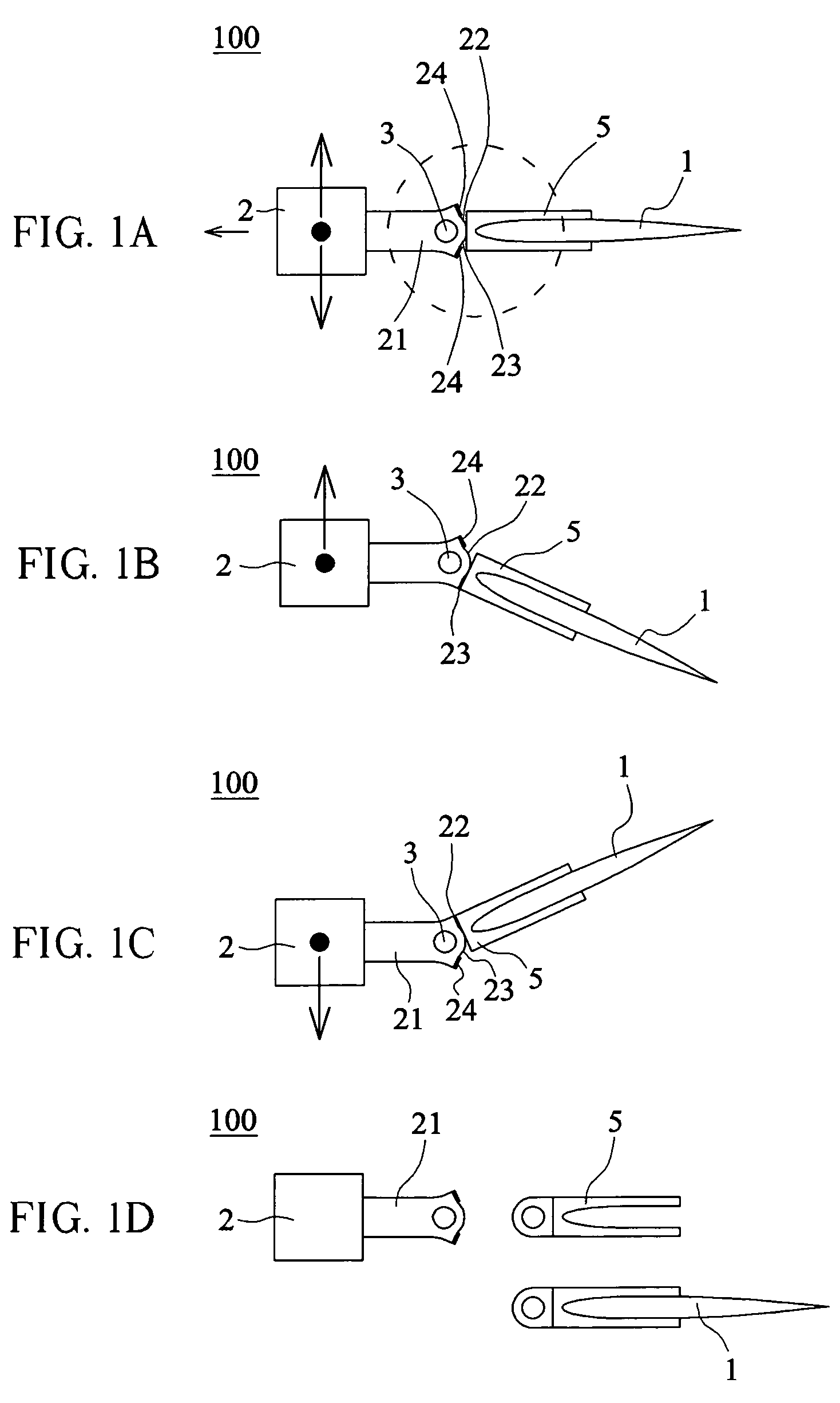

Oscillating-foil type underwater propulsor with a joint

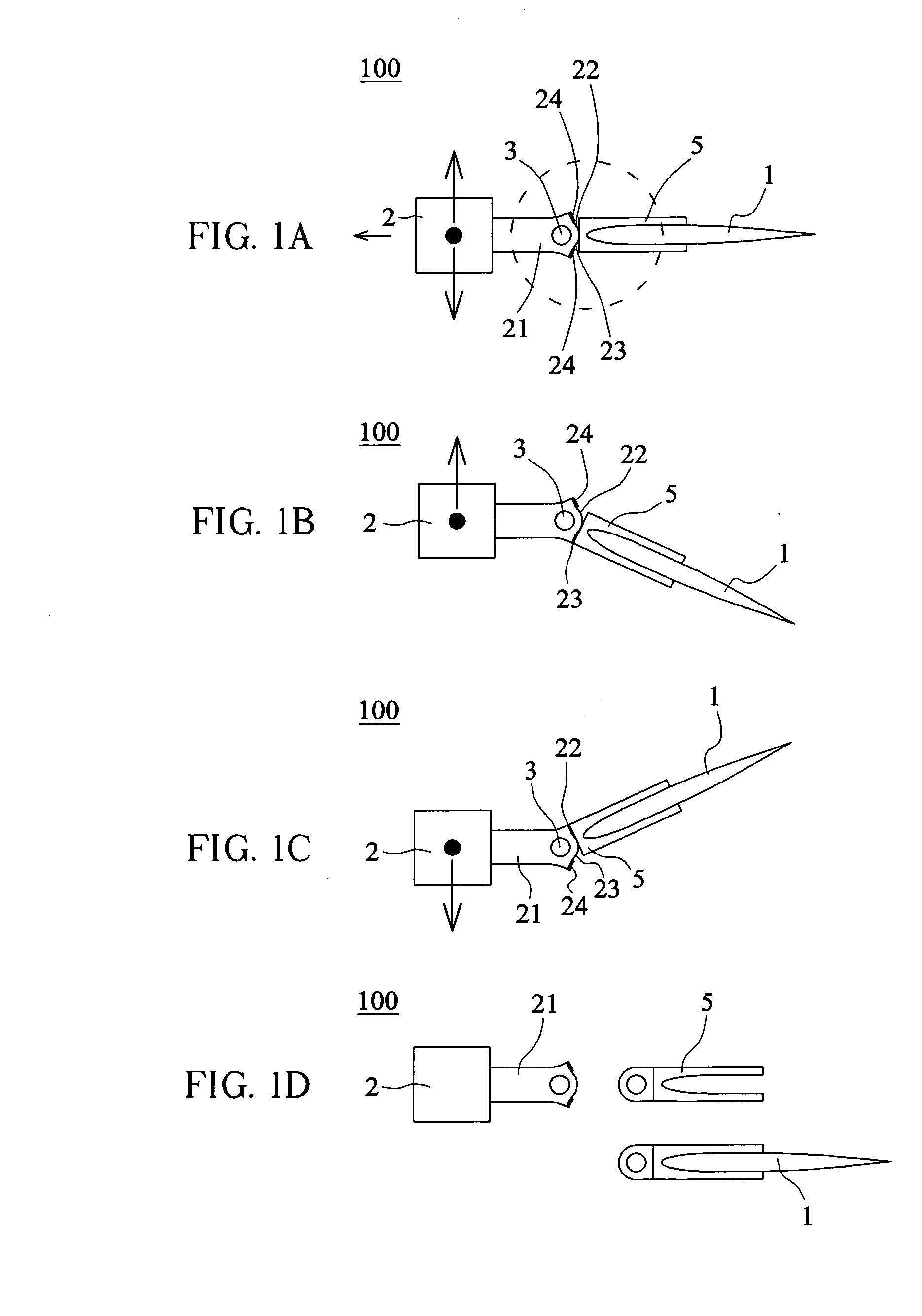

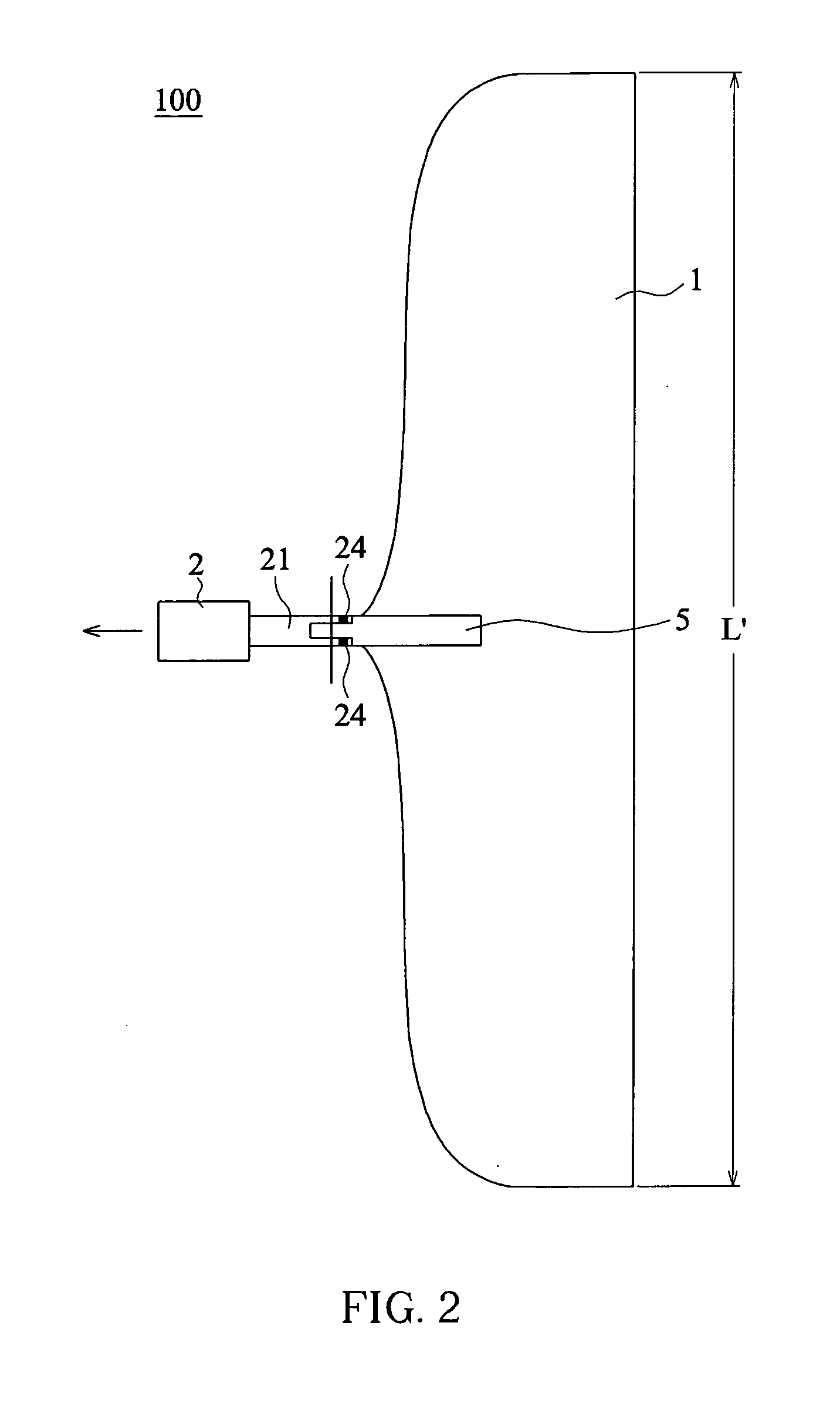

InactiveUS20090191772A1Easy to operateImprove propulsion efficiencyPropulsive elements of non-rotary typeMuscle power acting propulsive elementsMarine engineeringUnderwater

An oscillating-foil type underwater propulsor with a joint provided in the invention, the propulsor including a streamline foil having a foil surface being parallel to a water surface and a span length of at least twice as long as an average chord length of the streamline foil, and a heaving mechanism undergoing heaving motion perpendicular to a propulsion direction of the propulsor and having a transmission section, wherein the transmission section is pivotally connected to the streamline foil to form a joint, the joint being provided at the middle of the span length and having a rotation center located within a circular area, which has a radius of one third of the average chord length and is centered at the point one third of the average chord length ahead of the lifting center of the streamline foil.

Owner:CHANG JUNG CHRISTIAN UNIV

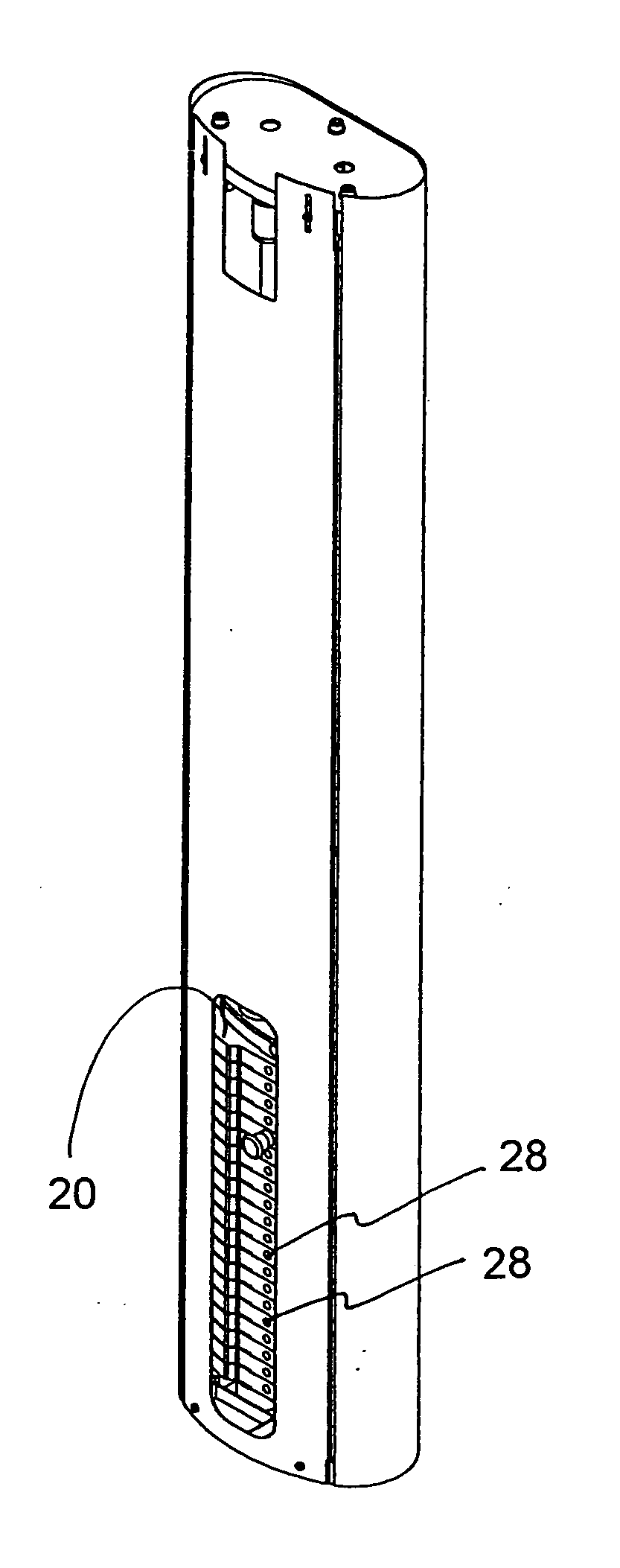

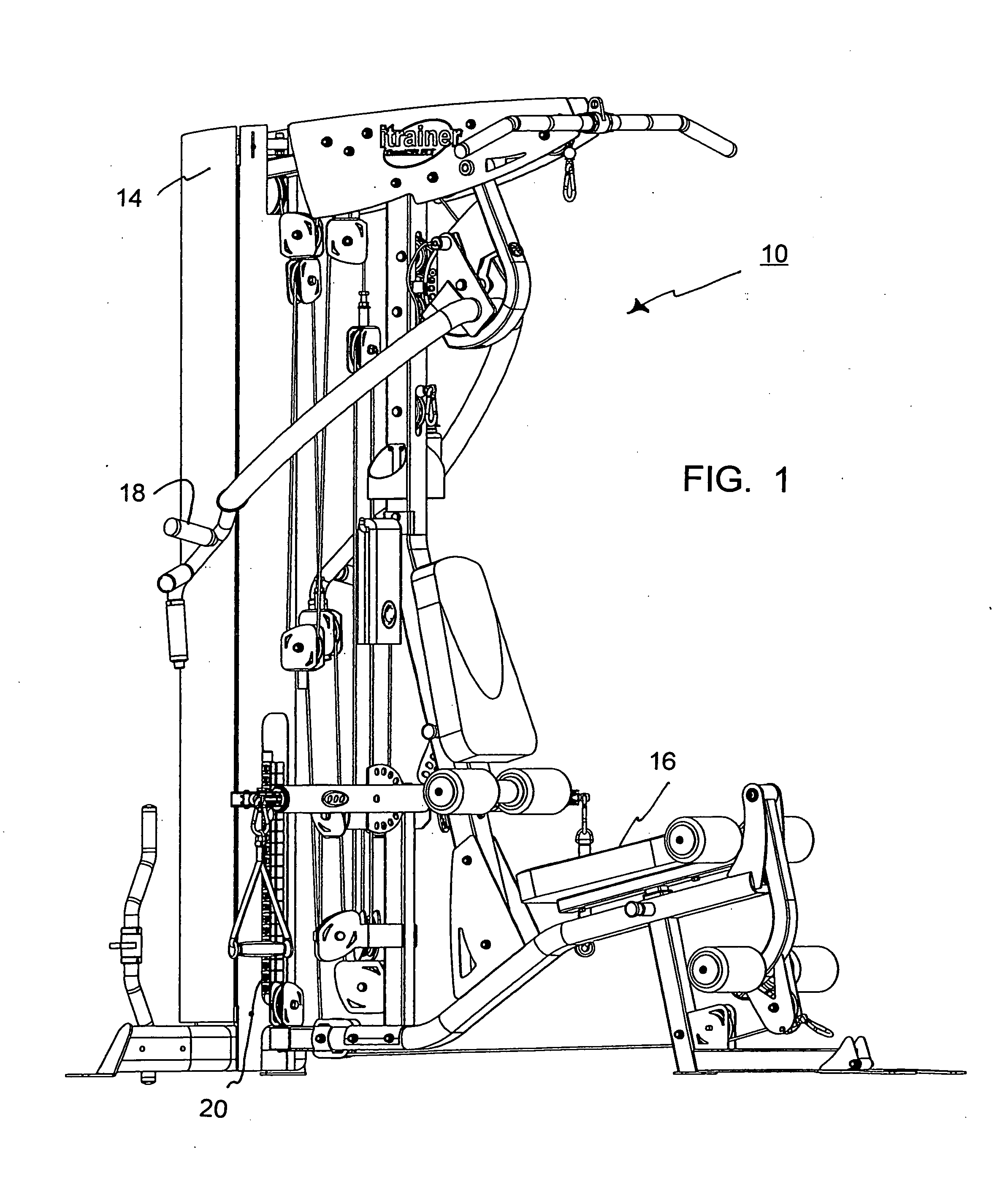

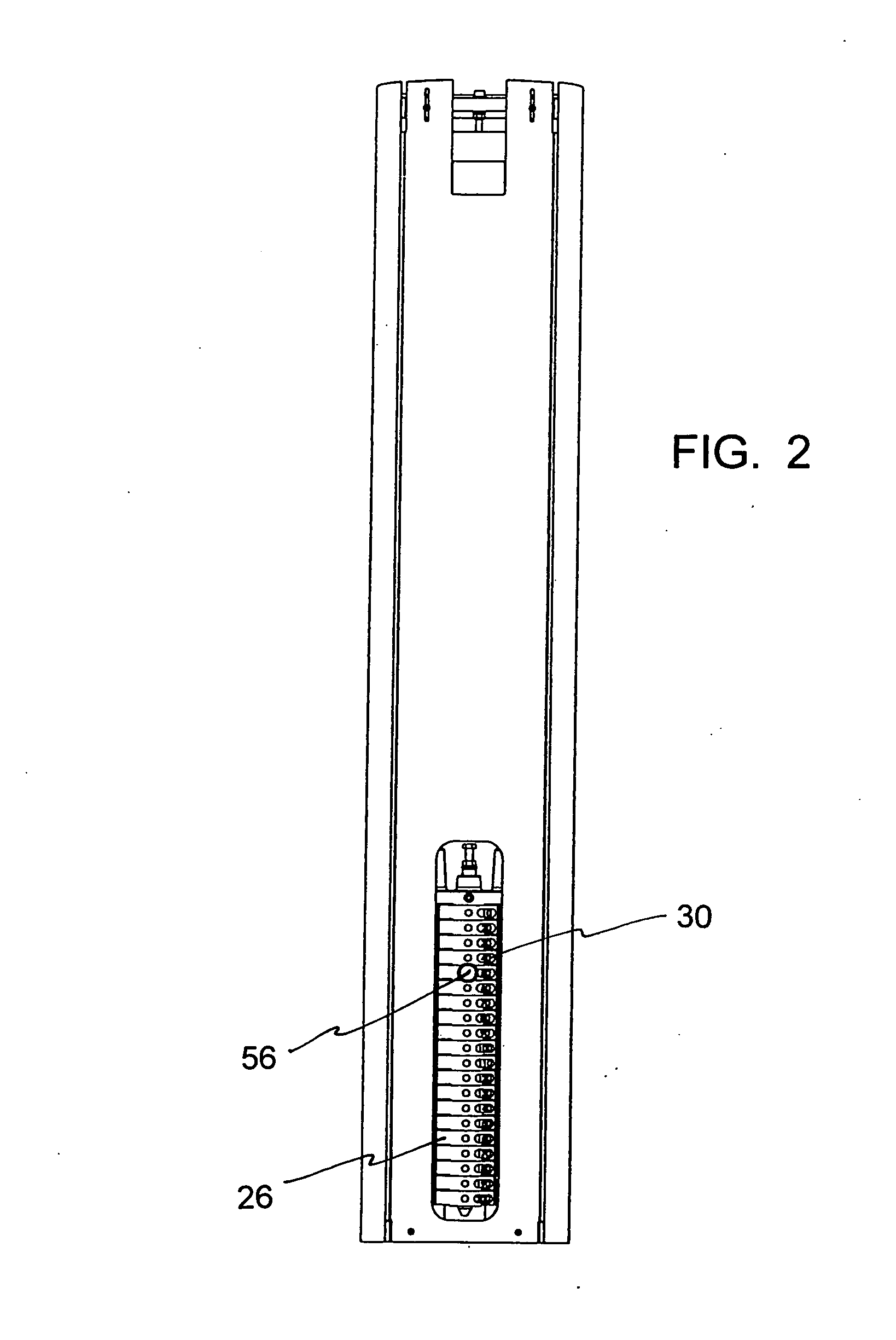

Body building system with shrouded weight stack

InactiveUS20100056345A1Easy and efficient to manufactureDurable and reliable constructionSpace saving gamesMuscle exercising devicesCouplingEngineering

A plurality of similarly configured weight plates each with a planar face having a horizontal coupling aperture and a numerical value form a weight stack. A front cover, with a generally rectangular cutout in a central section exposing all of the numerical values and coupling apertures, and a rear cover form a cover assembly.

Owner:LIU PING

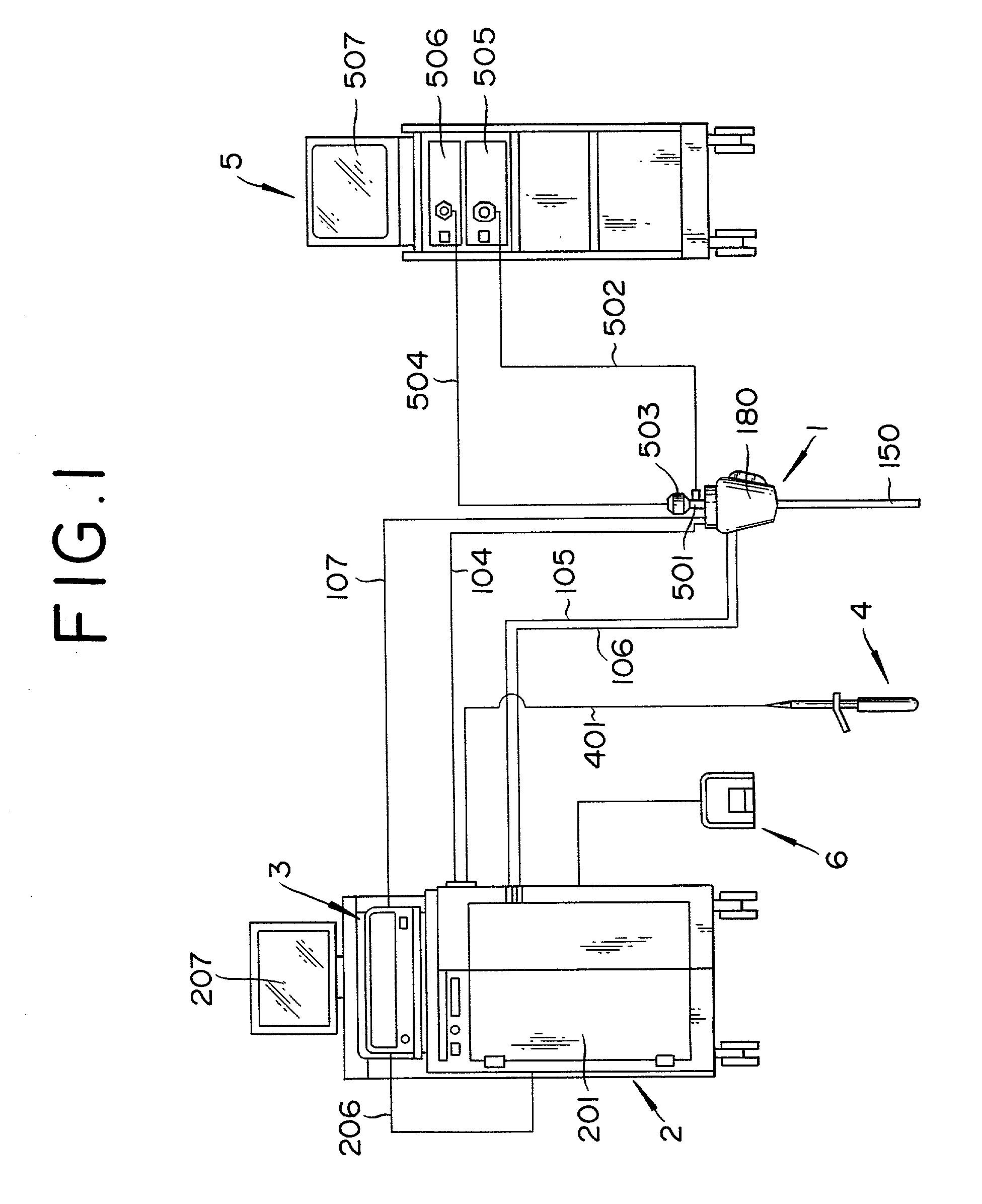

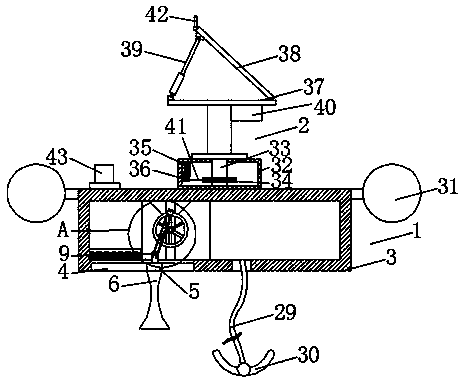

Photovoltaic power generation device

PendingCN107483006AEasy to reciprocateReduce power generation efficiencyPhotovoltaic supportsSolar heating energyWater storage tankWater resources

The invention discloses a photovoltaic power generation device, which includes a bottom base, a support base and a mounting plate. The support base is fixedly arranged on the top of the bottom base. A rotary base is installed at the center of the top of the support base. A driving motor is mounted on the top of the rotary base. A support rod is fixedly arranged on a rotary base at one side of the driving motor, and an electric lifting support rod is fixedly arranged on the rotary base at the other side of the driving motor, and the support rod and one end of the electric lifting support rod far away from the rotary base are fixedly connected with the bottom of the mounting plate arranged above the rotary base. One end of the mounting plate is fixedly provided with a rainwater collecting tank, and the other end of the mounting plate is equipped with a recovery funnel. In the invention, rain water is collected by the rainwater collecting groove arranged on one side of the mounting plate and is transported to a water storage tank through a delivery pipe where the rain water is stored to provide cooling water resources for a cooling mechanism. The device of the invention is convenient to use, environment-friendly and pollution-free.

Owner:CHAOHU UNIV

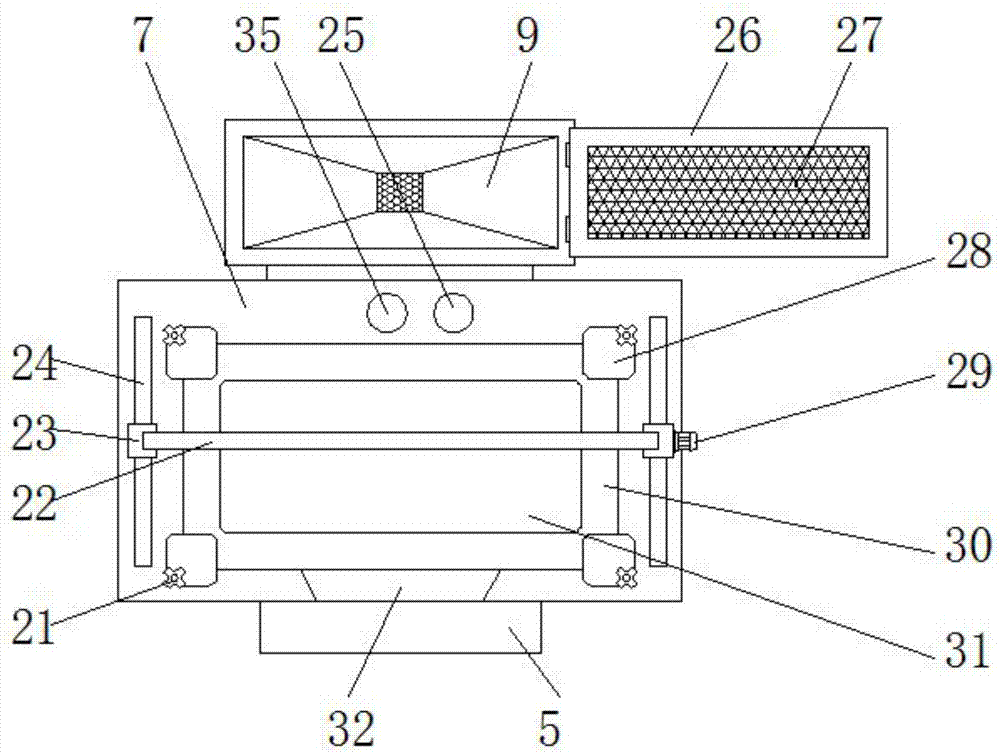

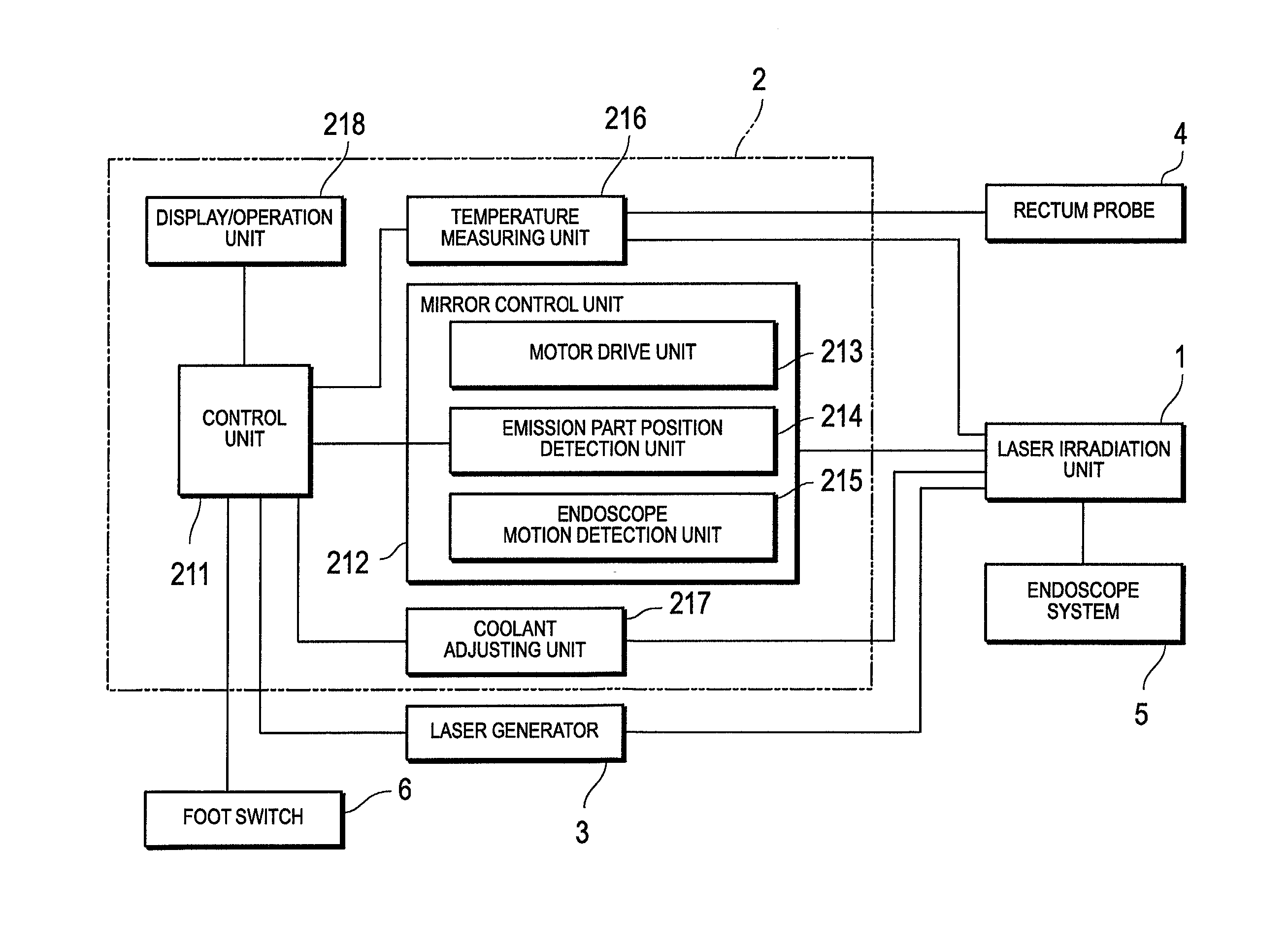

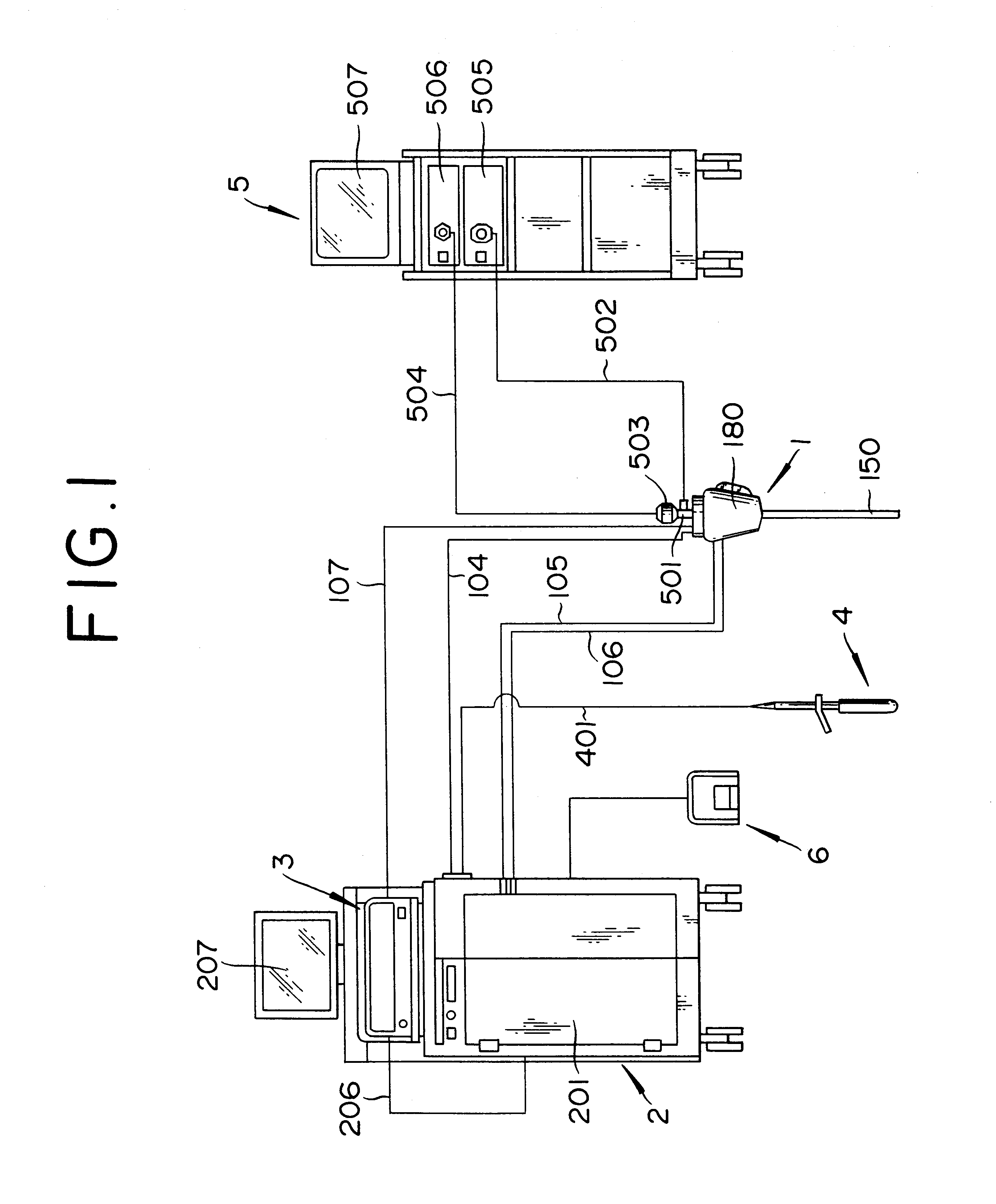

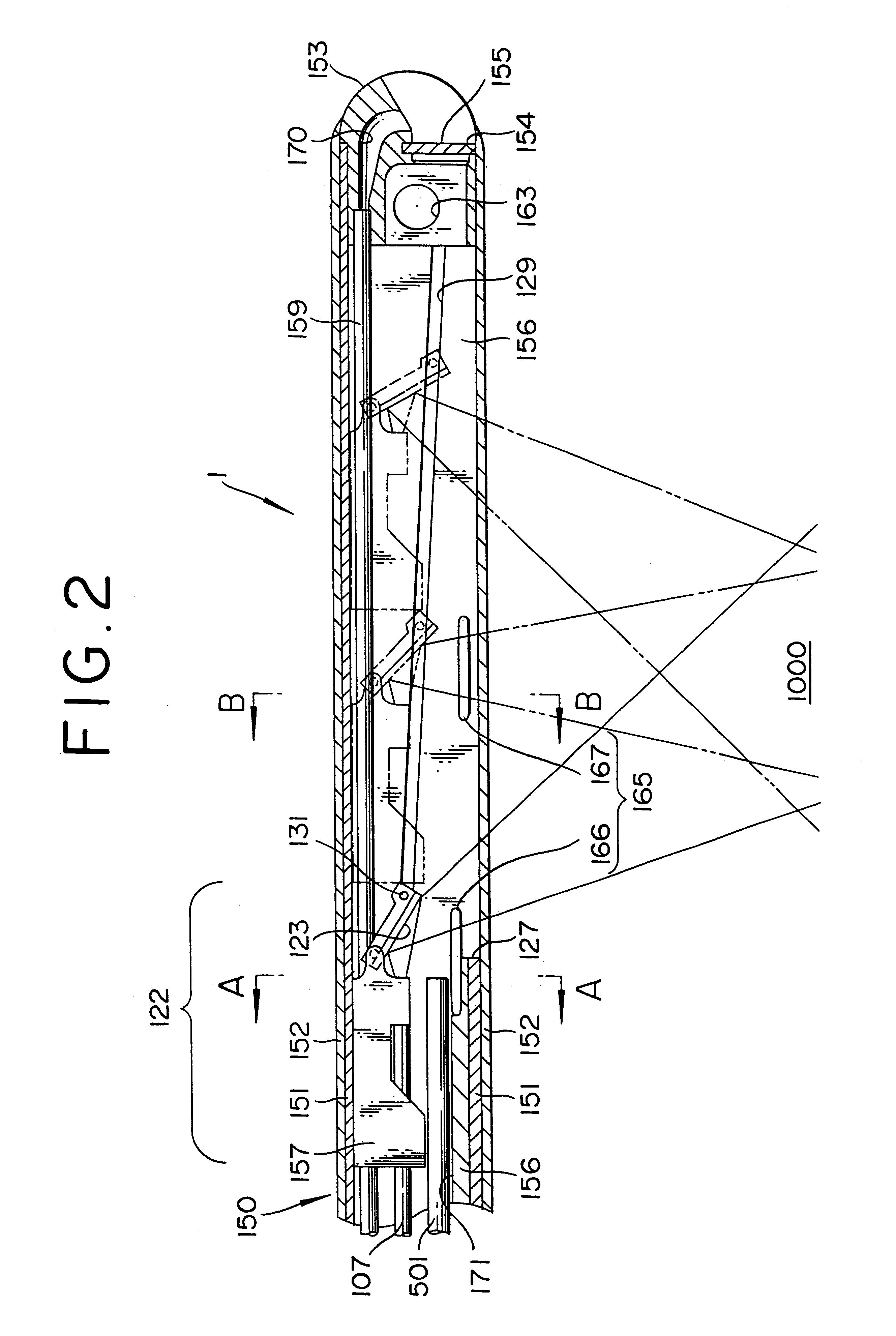

Thermal treatment apparatus

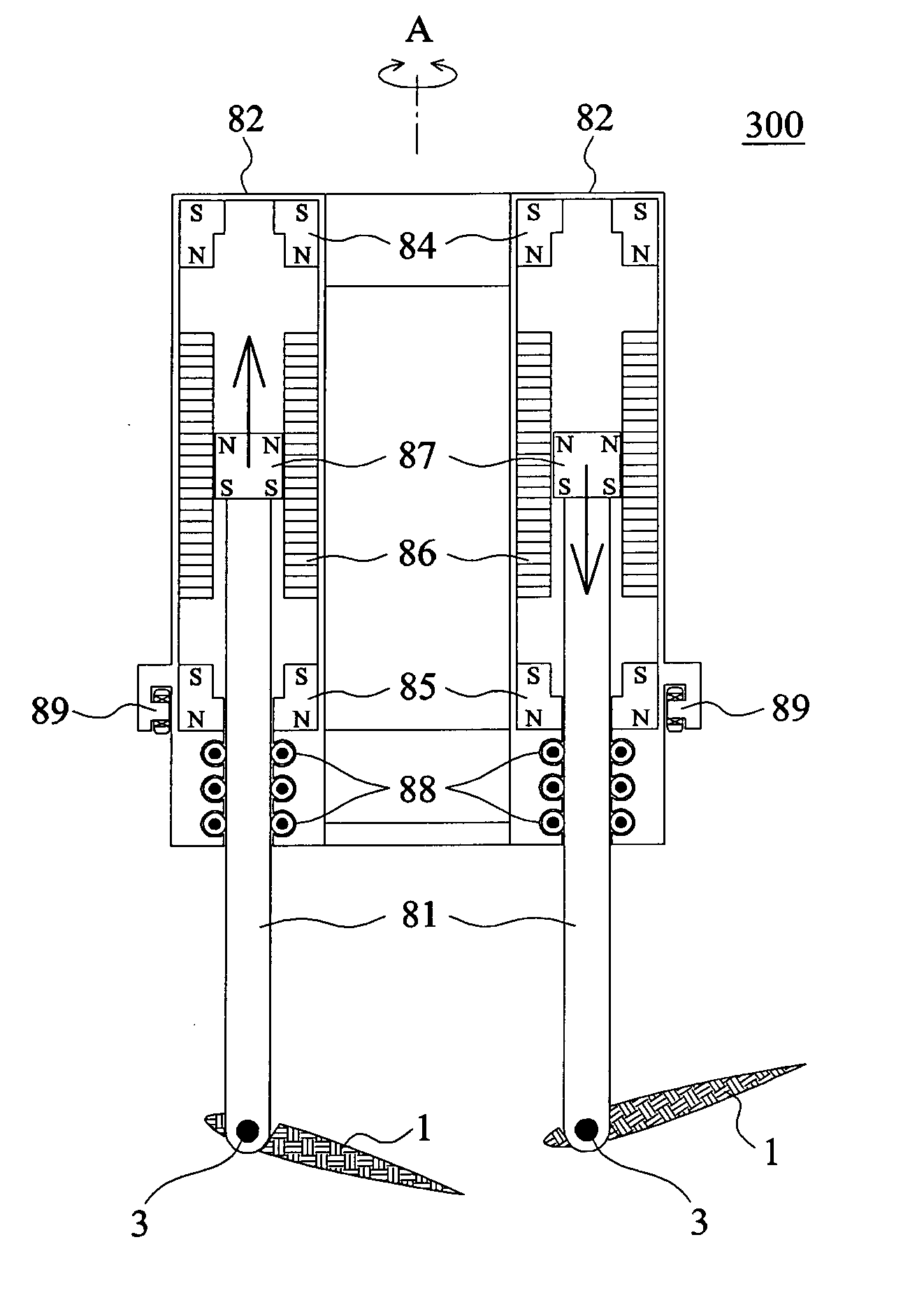

InactiveUS20030065315A1Easy to reciprocateGood treatment effectEndoscopesSurgical instrument detailsReciprocating motionControl system

The thermal treatment apparatus is equipped with a laser generator for supplying laser beams, a laser irradiation unit for applying the supplied laser beams to tissues, and a control unit for totally controlling various parts of the system. The laser irradiation unit is equipped with a movable laser emission part for emitting laser beams to tissues, a motor for reciprocating a laser emission part, and a guide lumen for supporting an endoscope in such a way as to enable it to move in the direction of the laser emission part. The control unit controls the motor that drives the laser emission part to make reciprocation motion in such a way that the laser emission part stops at a position where it does not interfere with the moving passage of the endoscope.

Owner:TERUMO KK +1

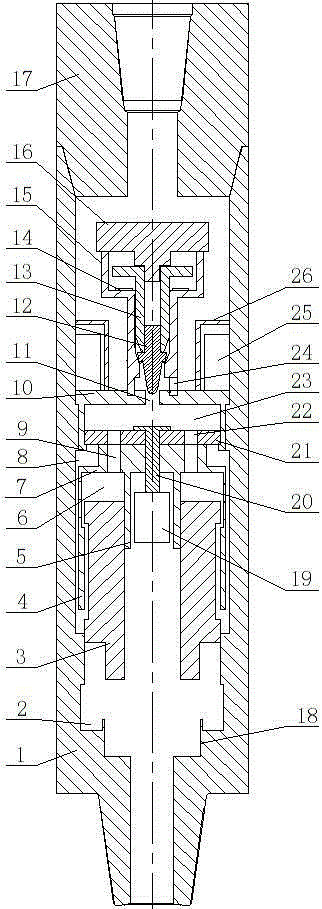

Connection device

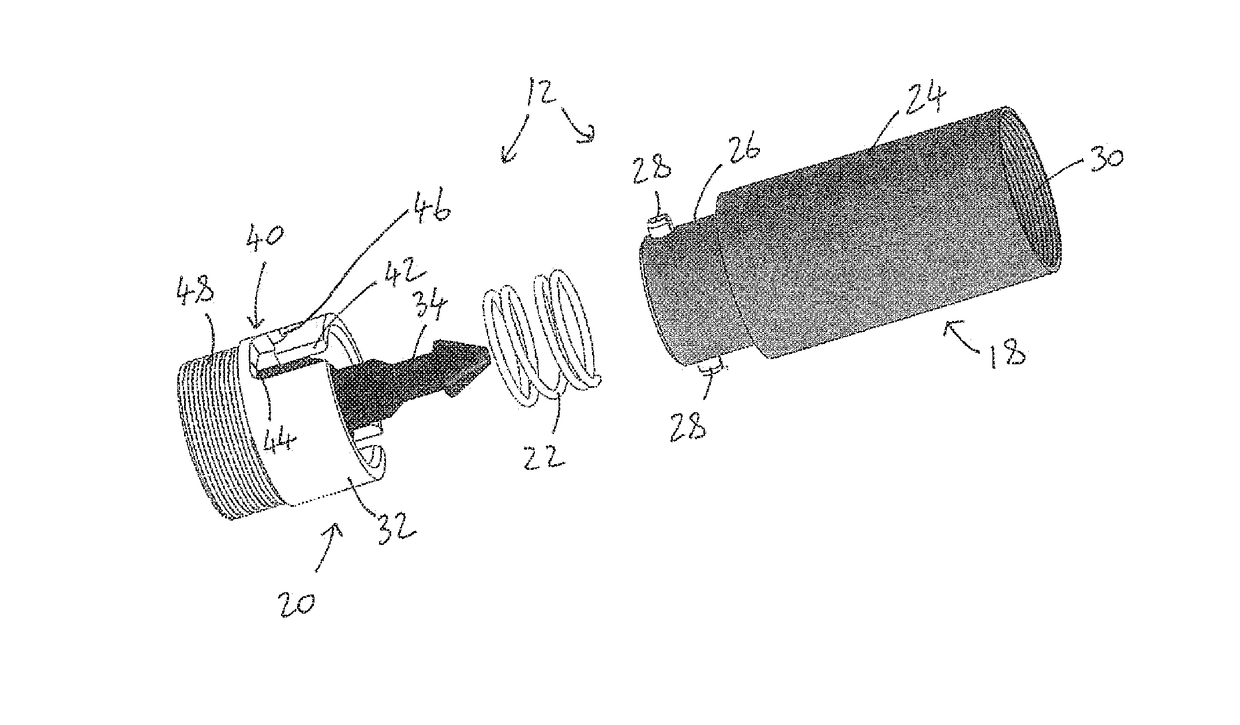

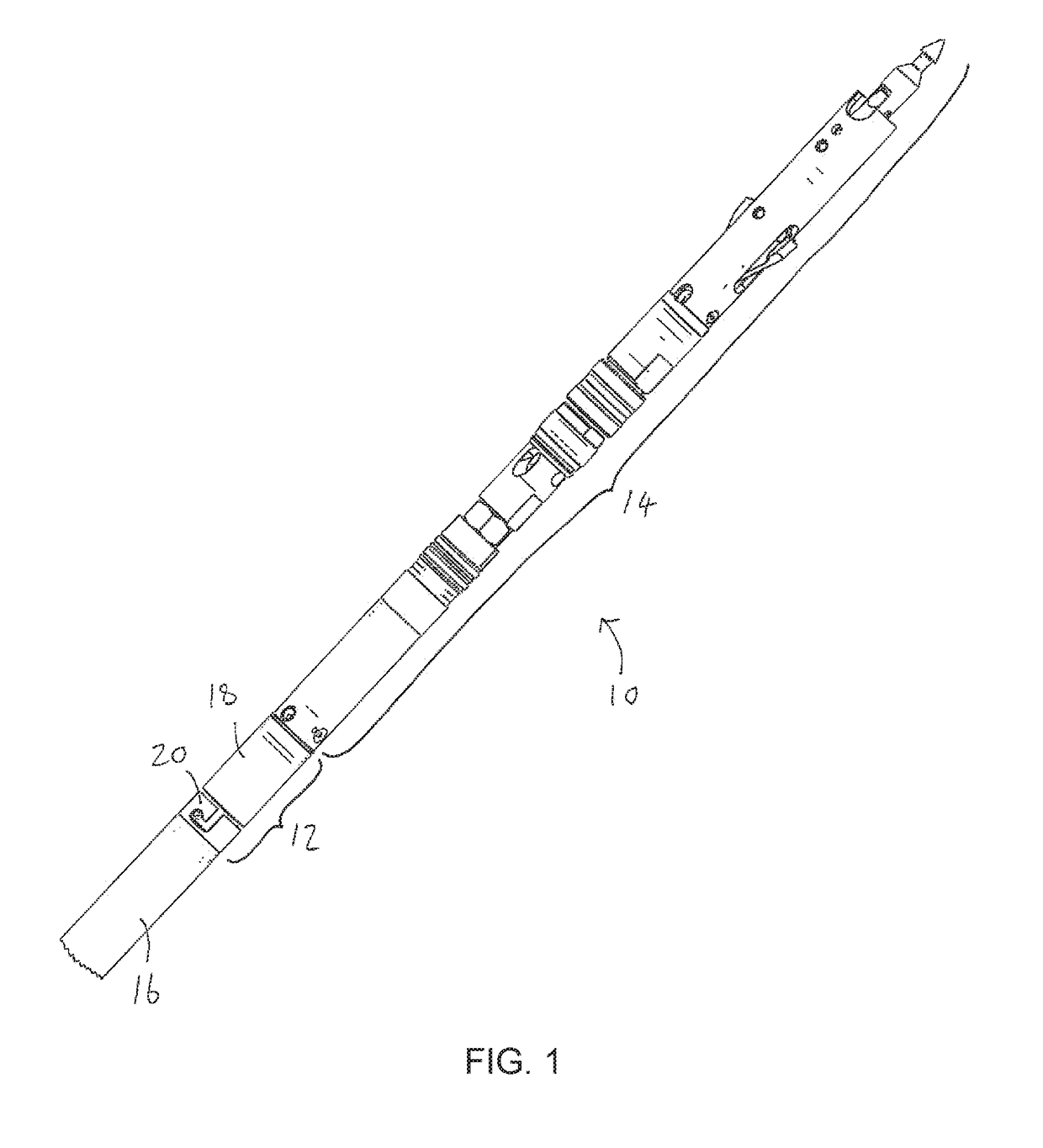

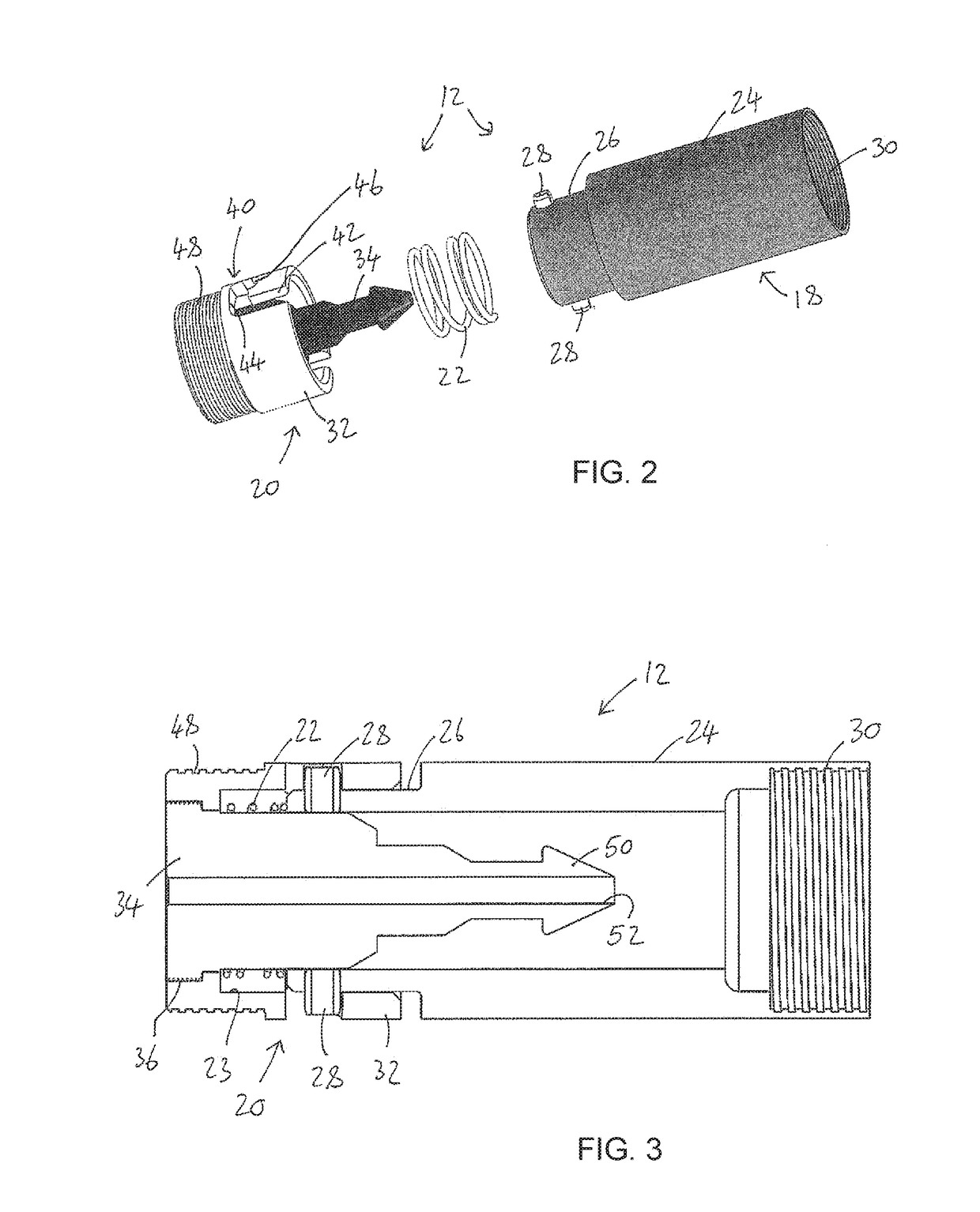

ActiveUS20180252052A1Prevent movementEasy to reciprocateSleeve/socket jointsDrilling rodsEngineeringElectrical and Electronics engineering

A connection device for a core drilling assembly is disclosed, the connection device connectible between a head assembly of a core drilling assembly and an inner tube of the core drilling assembly. The connection device comprises a first connection portion and a second connection portion, and includes a connection mechanism arranged to facilitate engagement of the first and second connection portions with each other and disengagement of the first and second connection portions from each other.

Owner:SWICK MINING SERVICES

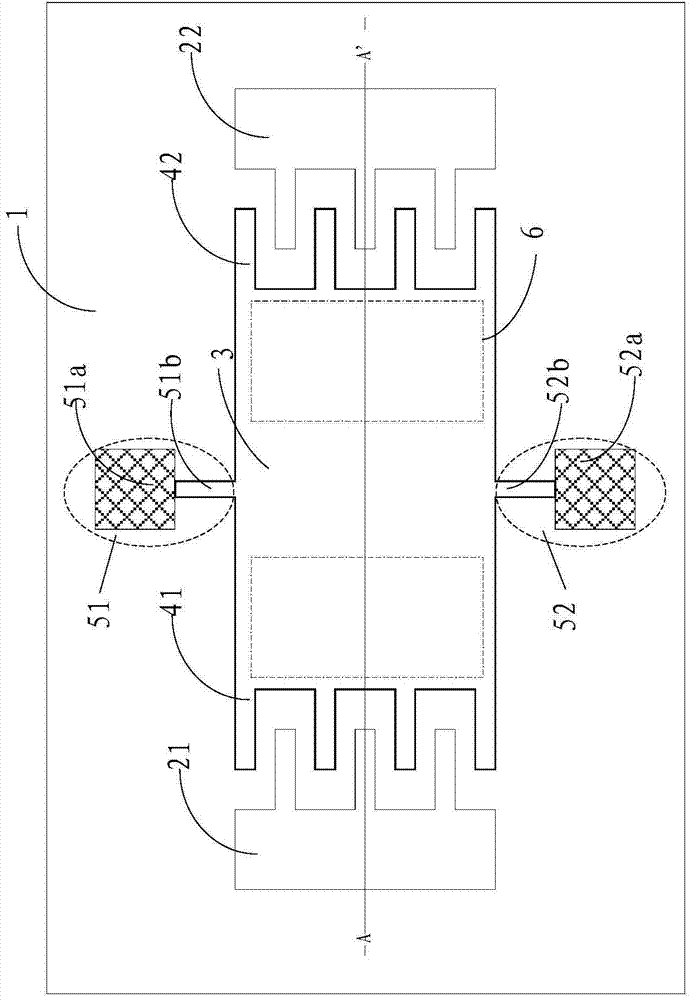

Oscillation control method for micromechanical resonator and micromechanical resonator

ActiveCN104333344AImprove stabilityControl natural frequencyImpedence networksVibration controlReciprocating motion

The invention discloses an oscillation control method for a micromechanical resonator and the micromechanical resonator. The micromechanical resonator comprises a substrate, and an oscillation structure and a driving structure which are arranged on the substrate. The driving structure is used for driving the oscillation structure of the micromechanical resonator to move in a reciprocating way, generating facilitating electrostatic force which is applied to the oscillation structure and facilitates reciprocating movement of the oscillation structure when the oscillation structure moves in the reciprocating way, and generating restricting electrostatic force which is applied to the oscillation structure and restricts reciprocating movement of the oscillation structure so that frequency deviation generated by the softening effect of an electrostatic spring and frequency deviation generated by the hardening effect of the electrostatic spring in reciprocating movement of the oscillation structure can be mutually cancelled, and thus the micromechanical resonator is controlled to work at the inherent frequency and work stability of the micromechanical resonator is enhanced.

Owner:SENODIA TECH (SHANGHAI) CO LTD

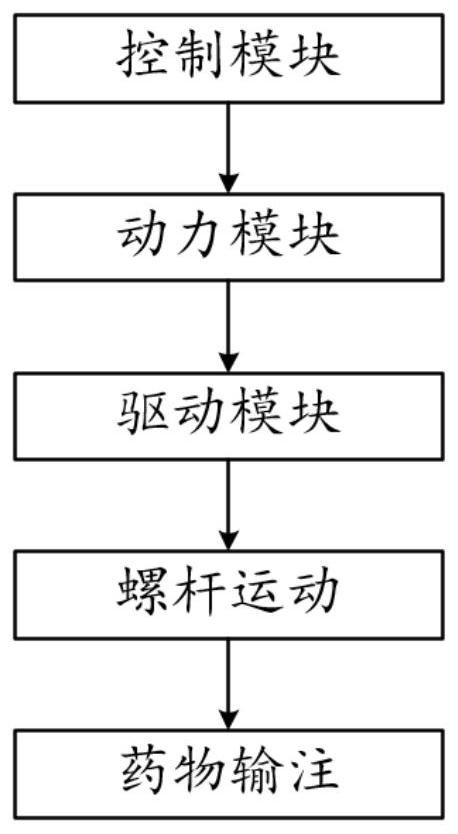

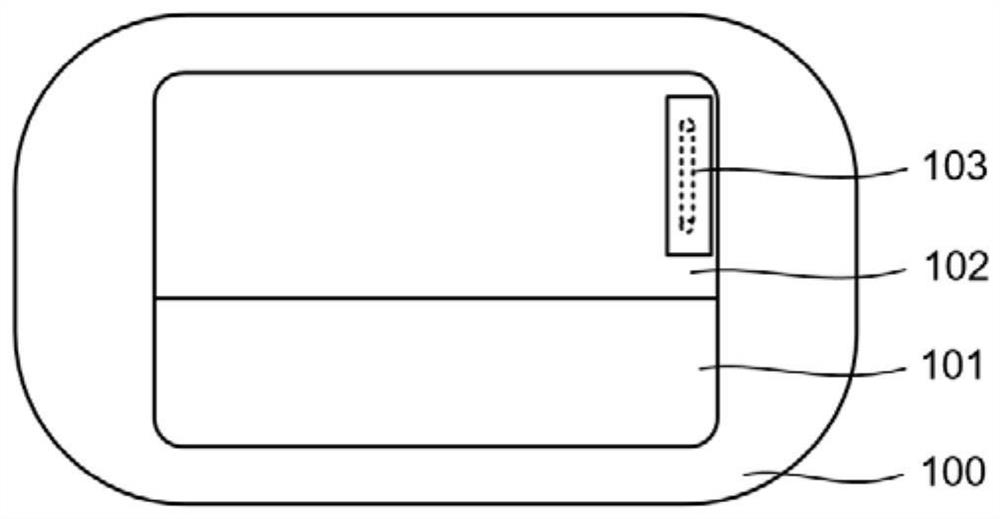

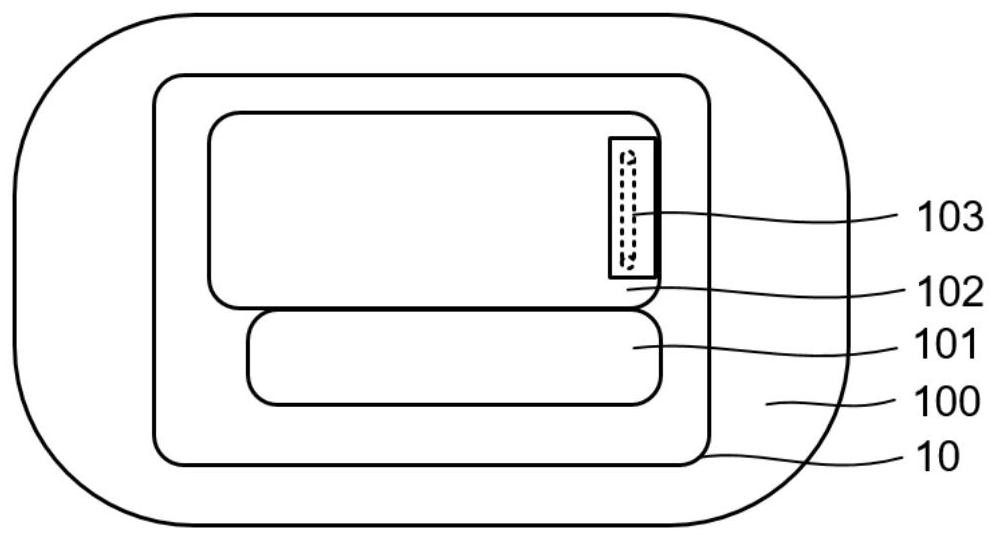

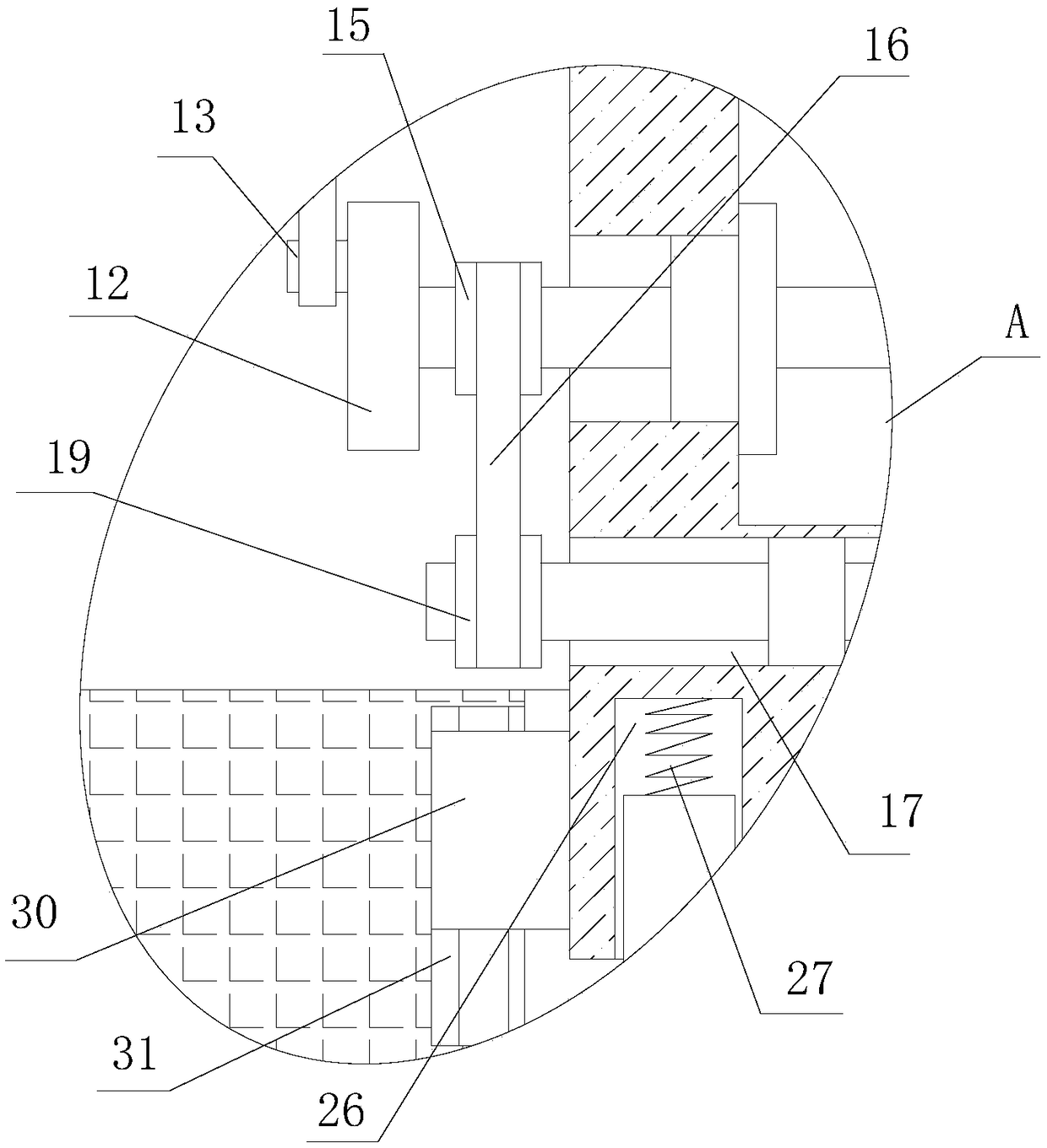

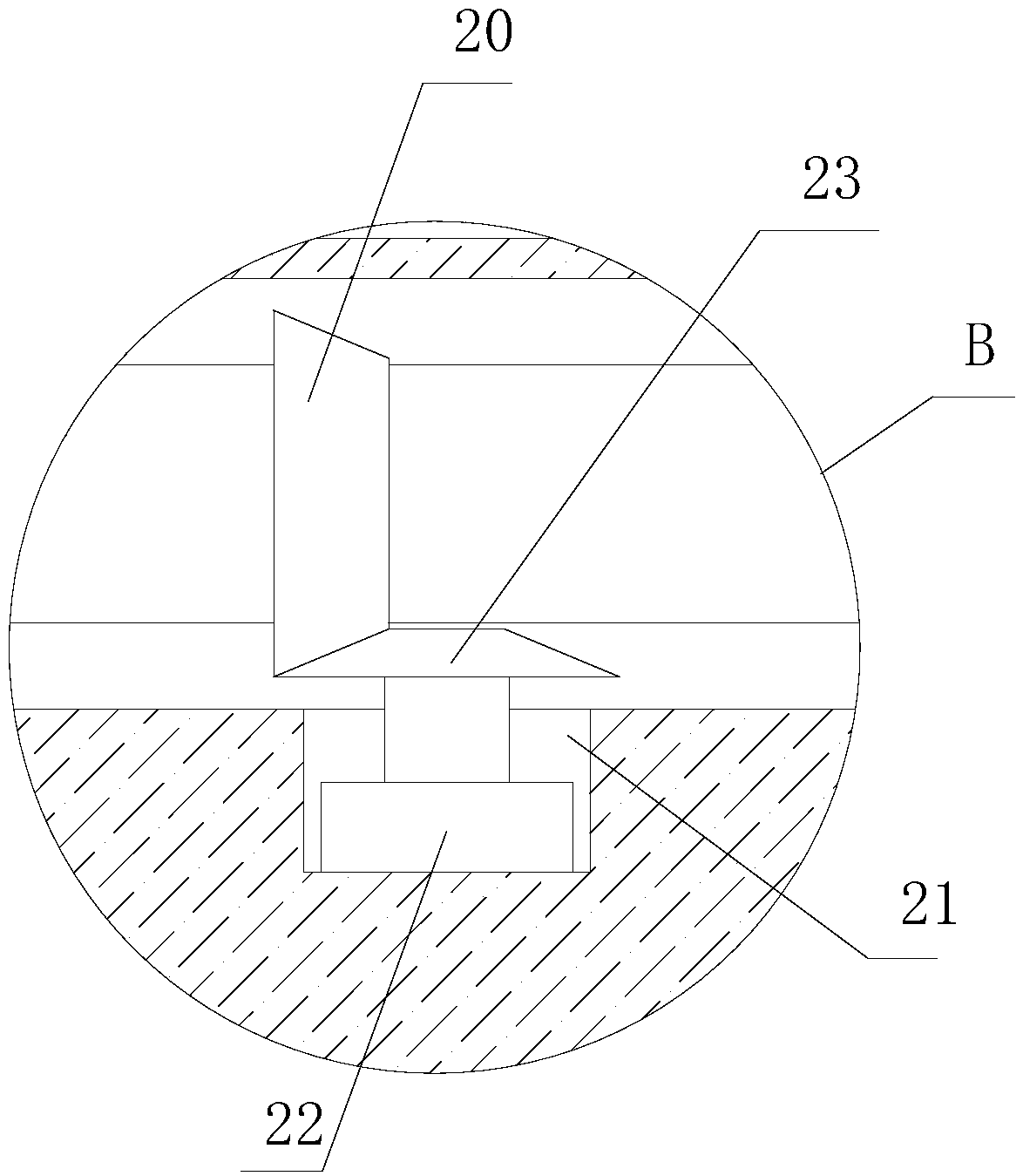

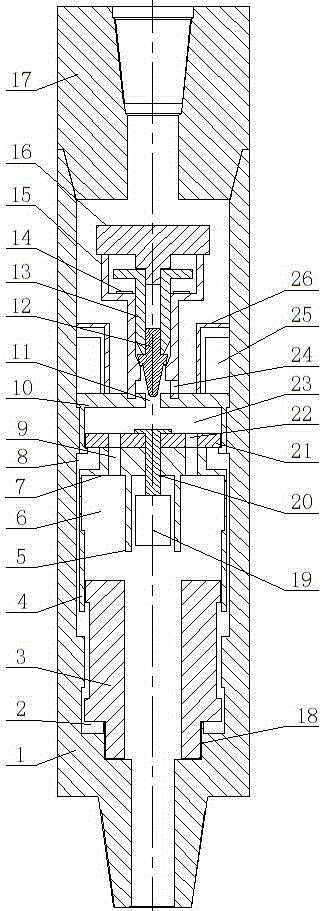

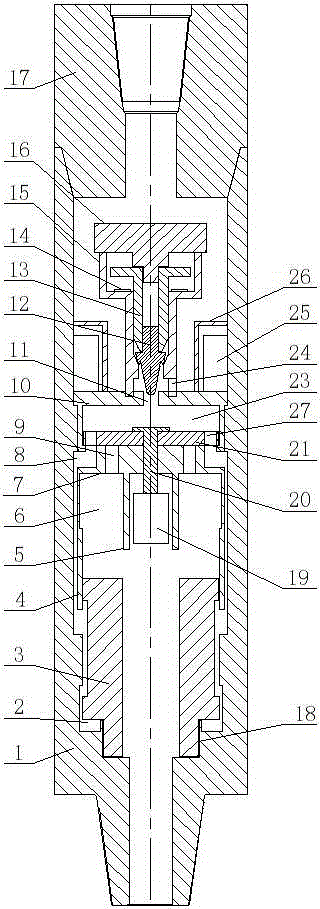

Medicine infusion device having multiple infusion modes

ActiveCN111939387AImprove experiencePrecise control levelAutomatic syringesMedical devicesMedication infusionPharmacy medicine

The invention discloses a medicine infusion device having multiple infusion modes. The medicine infusion device comprises a medicine storage unit, a piston, a screw rod, a driving module, a power module and a control module; the piston is arranged in the medicine storage unit; the piston is connected with the screw rod; the driving module at least comprises a first driving unit and a second driving unit, which are matched with each other to operate; the second driving unit drives the screw rod to advance; the power module is connected with the first driving unit; the control module is connected with the power module; and the control module controls the power module to apply different acting forces to the first driving unit, so that the first driving unit has multiple different operation modes, and the infusion device has multiple different unit infusion amounts or infusion rates. A user can select different infusion modes to infuse medicines, so that the user experience is enhanced.

Owner:MEDTRUM TECH

Swing type wave energy power generation buoy

PendingCN109412503ACompact structureIncrease input speedPhotovoltaic supportsWaterborne vesselsSolar trackerSeawater

Owner:LUDONG UNIVERSITY

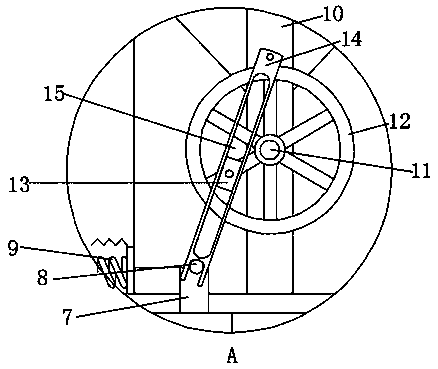

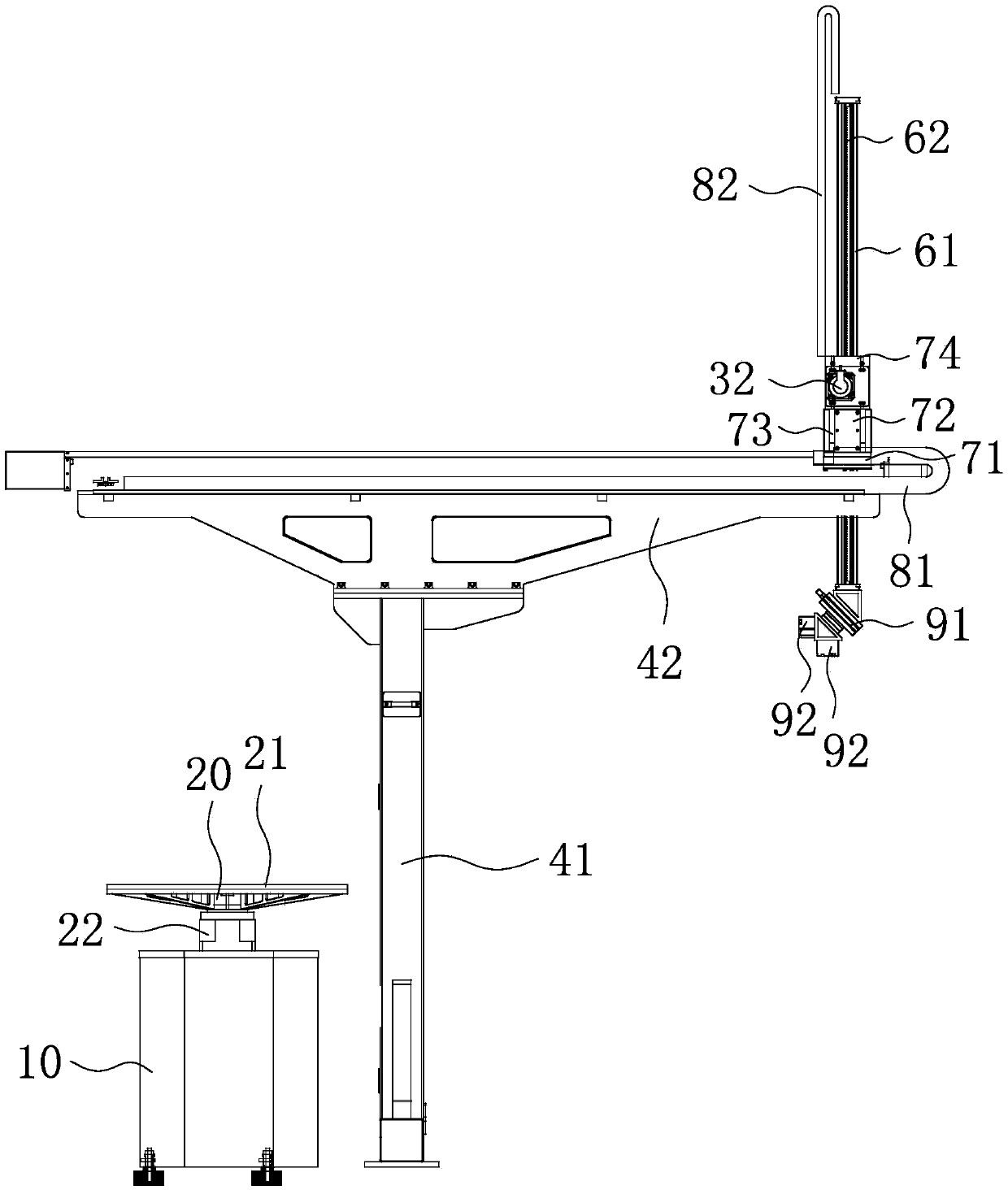

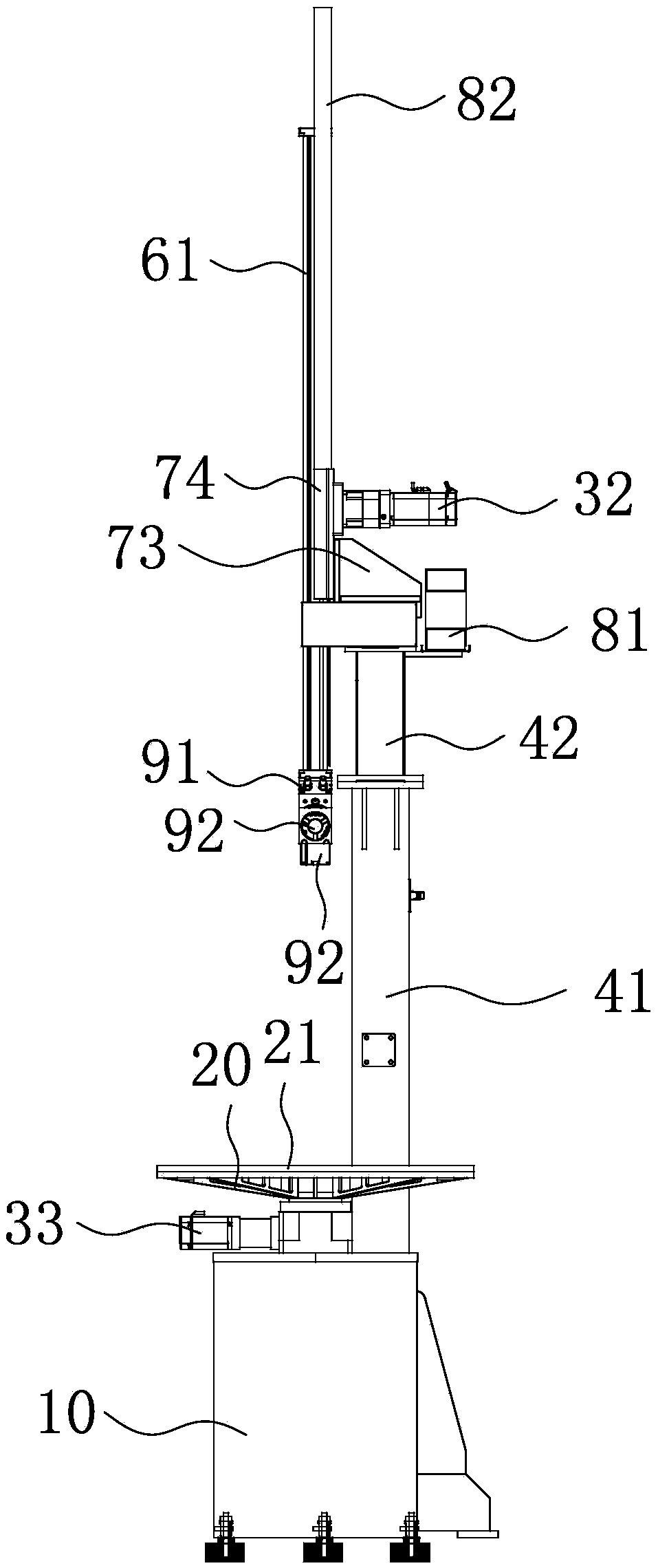

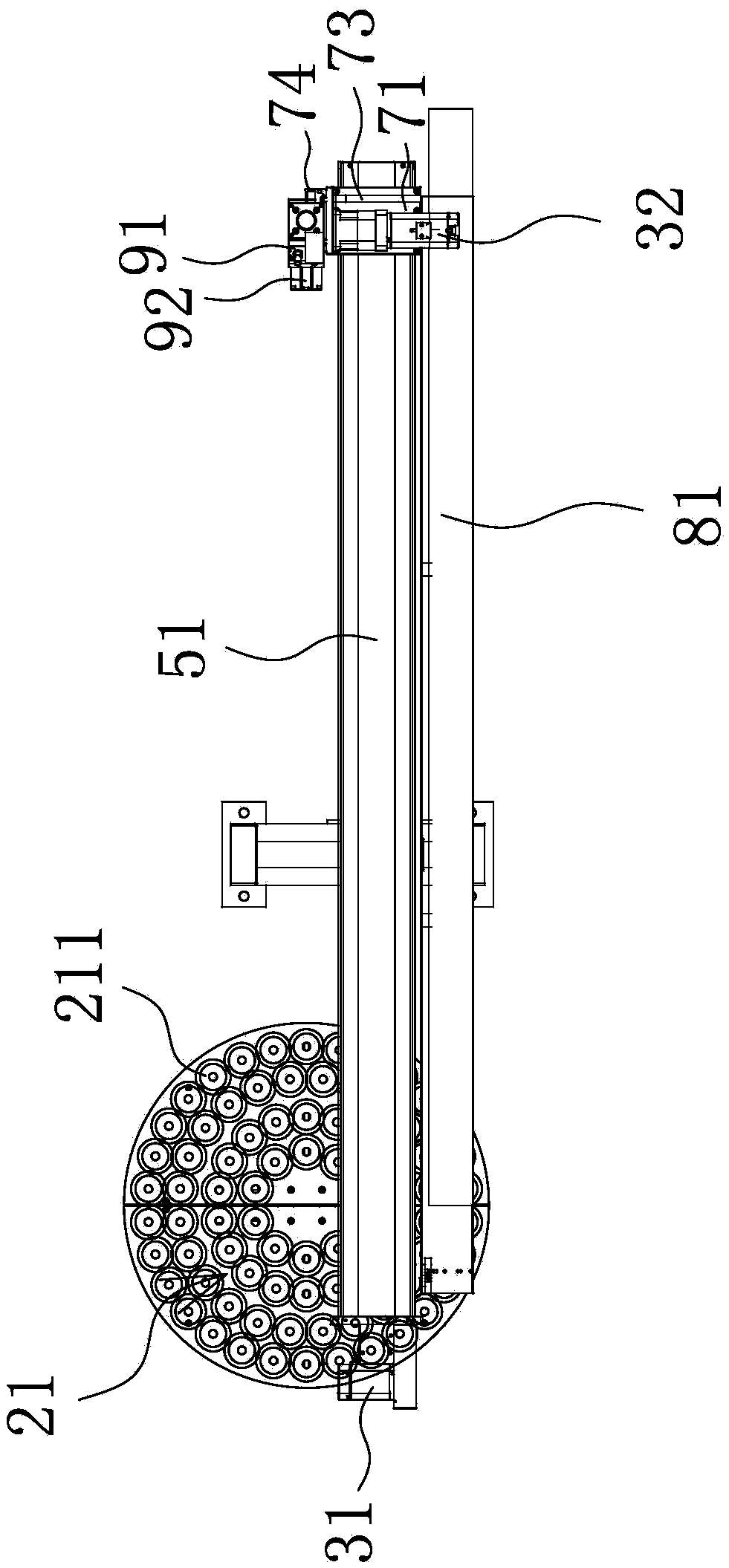

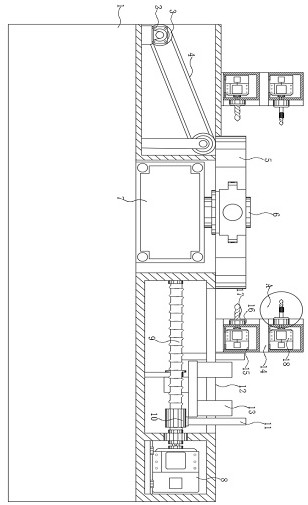

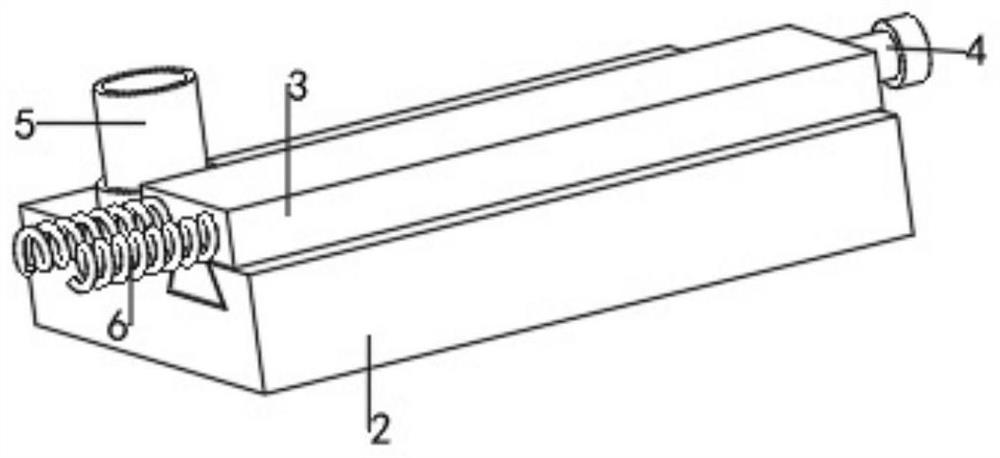

Rotary feeding device

The invention provides a rotary feeding device and belongs to the technical field of machines. The problem that an existing feeding device is large in occupied space is solved. The rotary feeding device comprises a rack, a rotary table, a servo motor and a support, wherein the rotary table is horizontally arranged on the rack and movably connected with the rack through a rotating shaft, and a tray for holding a workpiece is detachably mounted on the rotary table. The servo motor is connected with the rotating shaft and can drive the rotating shaft to rotate together with the rotary table and the tray. The support is arranged on one side of the rotary table, and the support is provided with a manipulator capable of grabbing the workpiece and taking the workpiece away from the rotary table. The rotary feeding device has the advantages of being small in occupied space and stable in work.

Owner:NINGBO LONG WALL FLUID KINETIC SCI TECH

Thermal treatment apparatus

InactiveUS6764485B2Easy to reciprocateGood treatment effectEndoscopesSurgical instrument detailsReciprocating motionControl system

The thermal treatment apparatus is equipped with a laser generator for supplying laser beams, a laser irradiation unit for applying the supplied laser beams to tissues, and a control unit for totally controlling various parts of the system. The laser irradiation unit is equipped with a movable laser emission part for emitting laser beams to tissues, a motor for reciprocating a laser emission part, and a guide lumen for supporting an endoscope in such a way as to enable it to move in the direction of the laser emission part. The control unit controls the motor that drives the laser emission part to make reciprocation motion in such a way that the laser emission part stops at a position where it does not interfere with the moving passage of the endoscope.

Owner:TERUMO KK +1

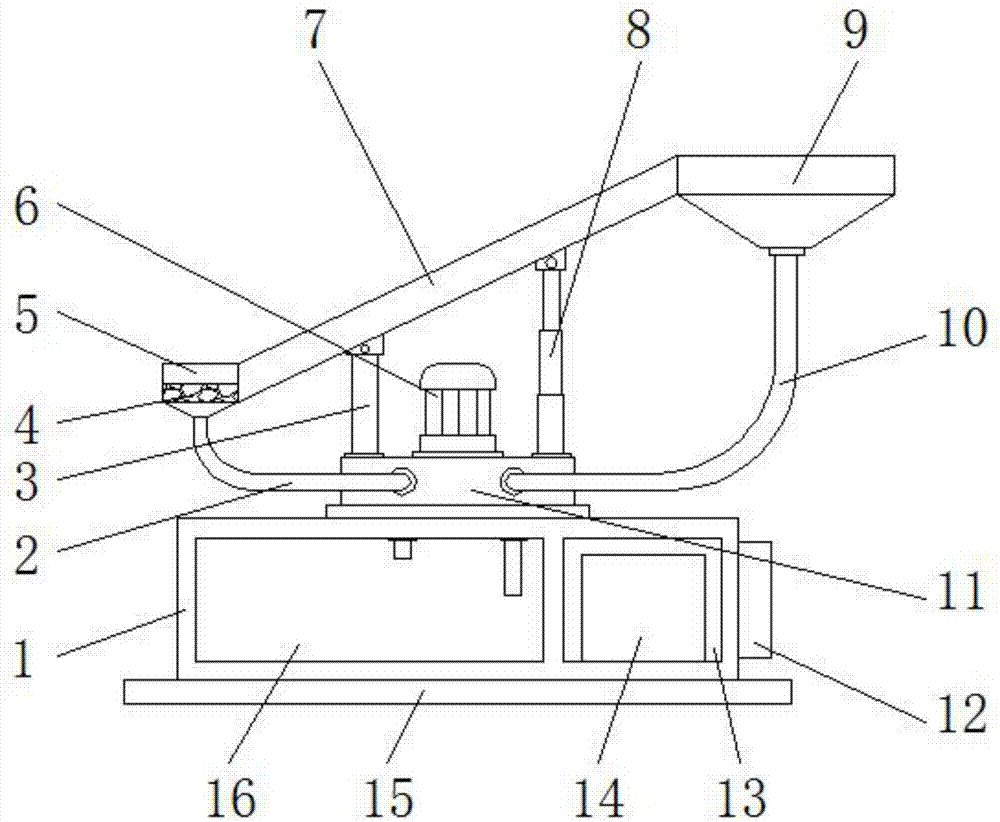

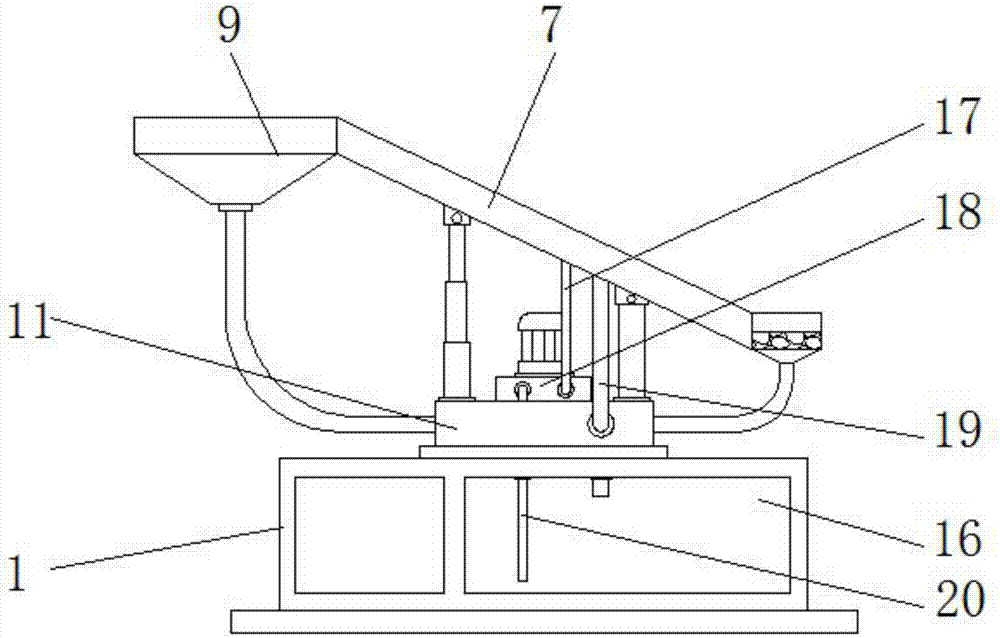

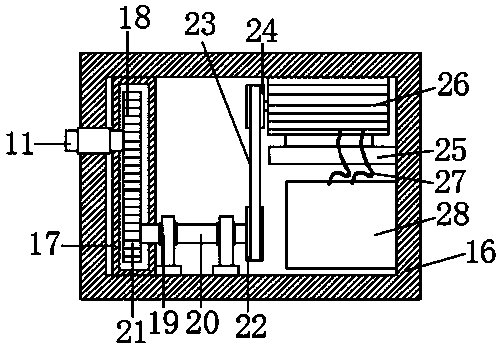

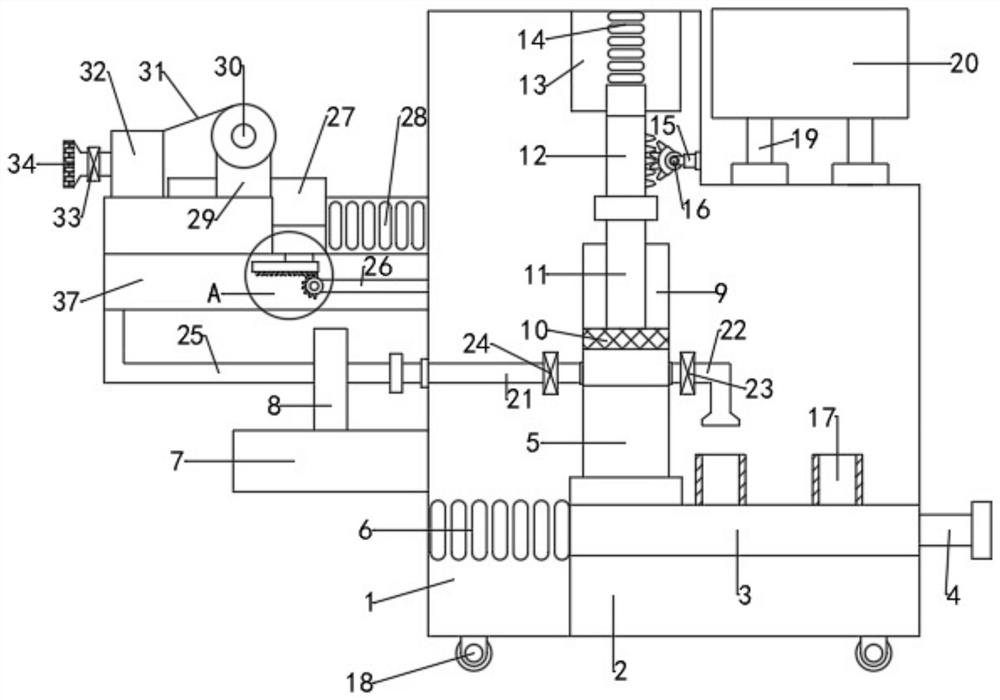

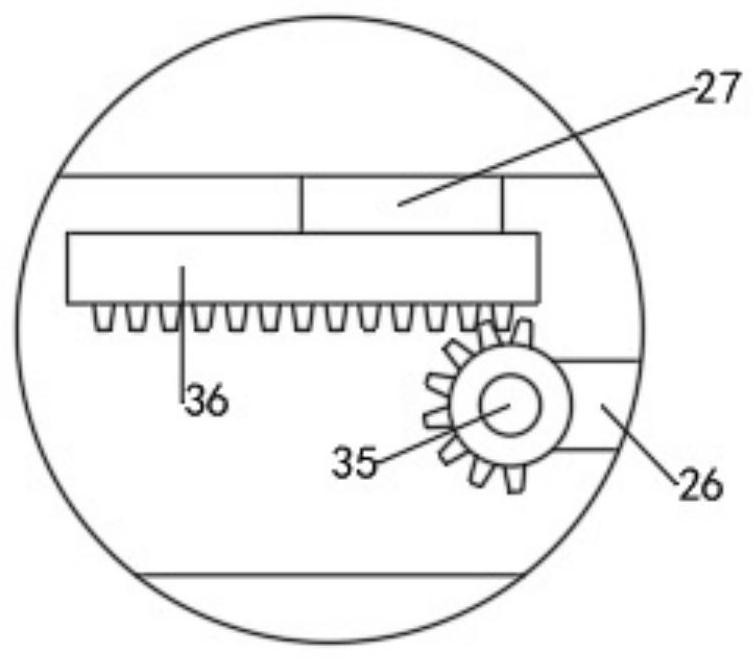

Powdery pharmaceutical mechanical equipment

ActiveCN109127395AEasy to sieveEasy to reciprocateSievingTransportation and packagingReciprocating motionPulp and paper industry

The invention discloses powdery pharmaceutical mechanical equipment. The equipment comprises a base, a buffer groove is formed in the top of the base, a stirring box is arranged in the buffer groove in a sliding mode, sliding holes are formed in the two sides of the stirring box respectively, the two sliding holes are internally provided with the same sliding plate in a sliding mode, and the two sides of the sliding plate extend to the outer side of the stirring box; and a mounting hole located in the stirring box is fixedly arranged on the sliding plate, a screening box with an opening at thetop and an opening at the bottom is fixedly arranged in the mounting hole, a screening plate is fixedly arranged in the screening box, rotating holes are formed in the two sides of the stirring box respectively, the two rotating holes are located below the two sliding holes, the same stirring rod is rotationally arranged in the two rotating holes, and the two ends of the stirring rod extend to the outer side of the stirring box. According to the equipment, powder materials can be screened conveniently, thus the powder materials can be more uniform; and meanwhile, continuous reciprocating motion up and down of the screen plate can be facilitated, thus the material screening speed is increased, damping to the stirring box can also be facilitated; and the equipment is simple in structure, and convenient to use.

Owner:FUJIAN GUTIAN PHARMA

Gas drilling shaft bottom near-bit continuous impact focus nipple

The invention relates to a gas drilling shaft bottom near-bit continuous impact focus nipple, comprising a nipple body, a cylinder body, a piston (3) and a gas distribution device, wherein the cylinder body is arranged in a shell (1), the piston (3) is arranged in the cylinder body, a lower gas inlet passage (8) is formed between the cylinder body and the shell (1), a lower gas chamber (2) is formed between the lower end of the piston (3) and the inner wall of the shell (1), the lower gas inlet passage (8) is communicated with the lower gas chamber (2), an upper gas inlet passage (9) is formed at the bottom (7) of the cylinder body, an upper gas chamber (6) is formed between the upper end of the piston (3) and the cylinder body, the upper gas inlet passage (9) is communicated with the upper gas chamber (6), and the gas distribution device is arranged at the upper part of the cylinder body. According to the focus nipple, a focus in seismic exploration is applied to a shaft bottom near a bit, a focus linear (Chirp) scanning technology can be combined with a Mini-SOSIE technology, and the focus excites the ground to generate linear scanning pulse signals through a pulse coding technology, so that the excitation quality of seismic wave is improved.

Owner:SOUTHWEST PETROLEUM UNIV

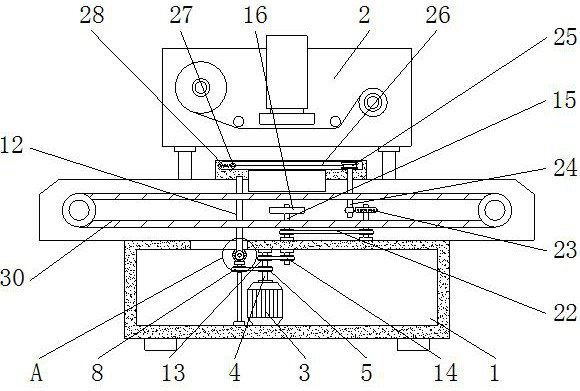

Hardware plate double-face grinding device based on clamping turnover mechanism

PendingCN112720115AImprove practicalityEffective sandingGrinding carriagesGrinding drivesElectric machineryScrew thread

The invention relates to the technical field of grinding equipment, in particular to a hardware plate double-face grinding device based on a clamping turnover mechanism. The device comprises a clamping turnover structure, wherein the clamping turnover structure comprises a working bin; a middle frame is hinged to the upper end of the working bin; a clamping turnover plate is installed in the working bin; clamping frames are installed at the side ends of clamping plates; clamping lead screws are arranged in clamping frames; the clamping lead screws are in threaded connection with the clamping frames; clamping motors are arranged at one side ends of the clamping lead screws correspondingly; the clamping motors are located on the outer side of the working bin; the bottoms of the side ends, opposite to the clamping plates, of the clamping motors are movably connected through connecting rods; and rotating rods are symmetrically arranged on the surfaces of the side ends of the clamping plates. By means of the clamping turnover structure, the clamping turnover structure can enable a hardware plate to be clamped in multiple sizes, overturning is conducted after one side of the hardware plate is ground, the other side of the hardware plate can be synchronously ground, and the grinding efficiency is improved.

Owner:魏琦

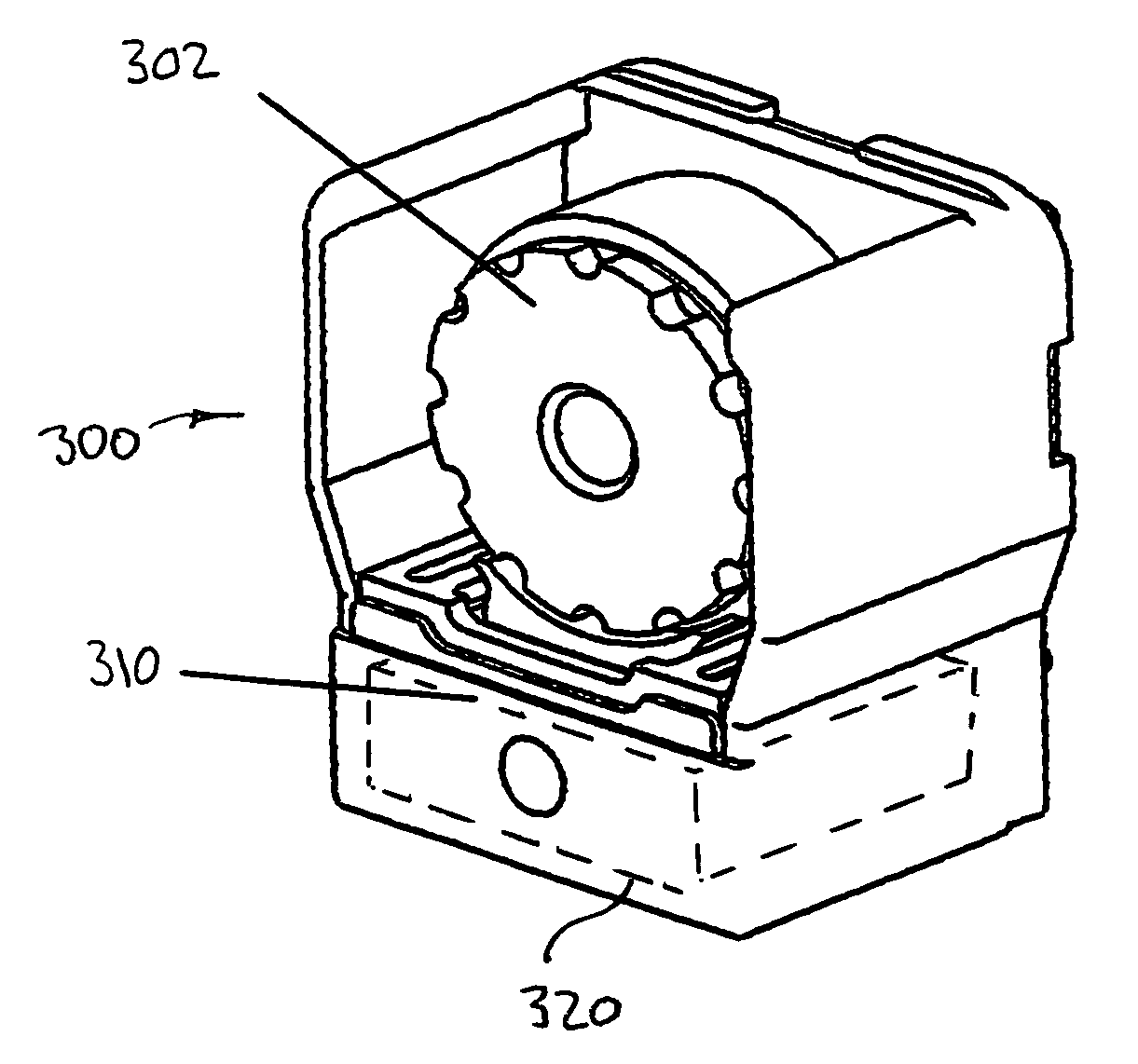

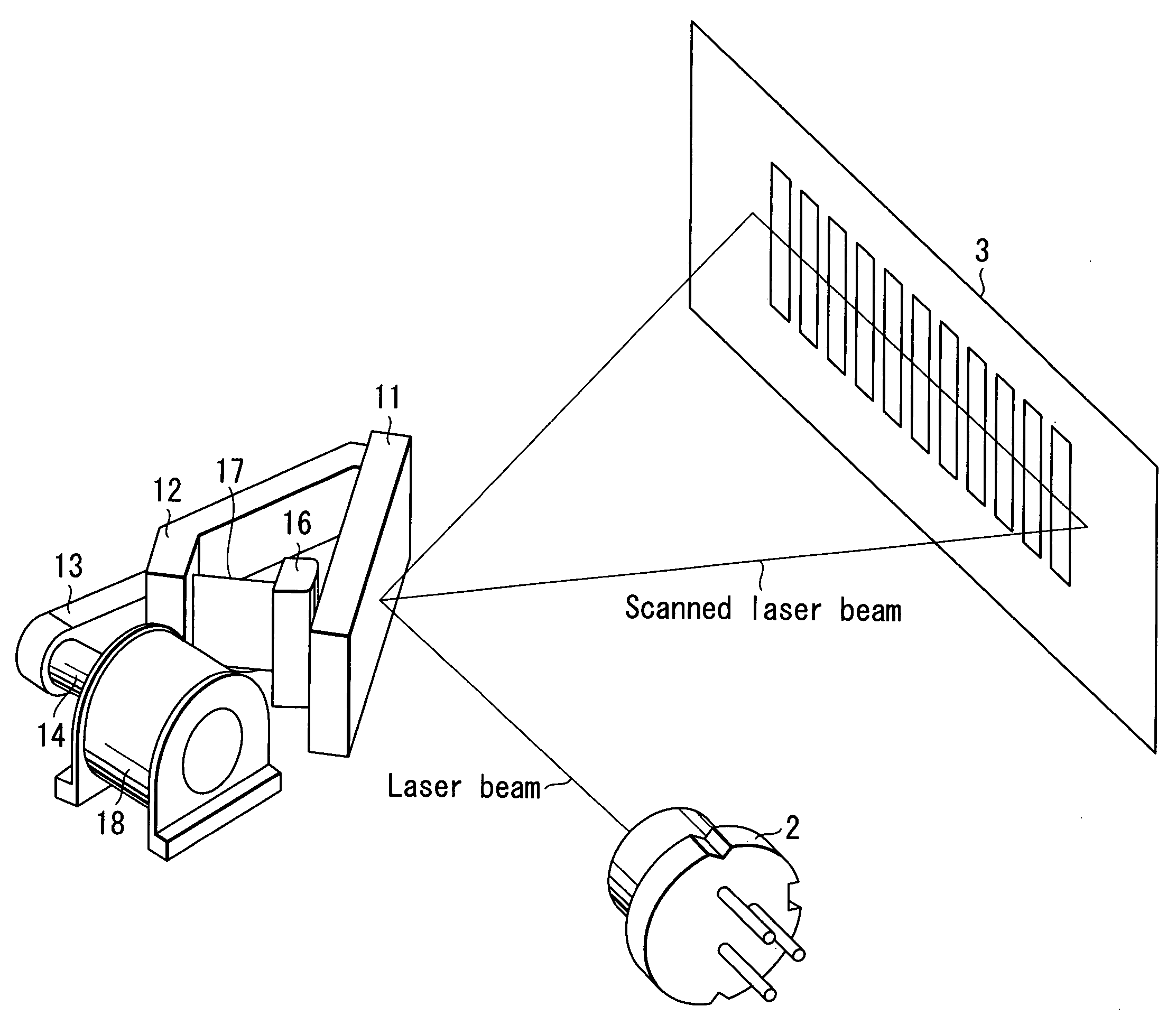

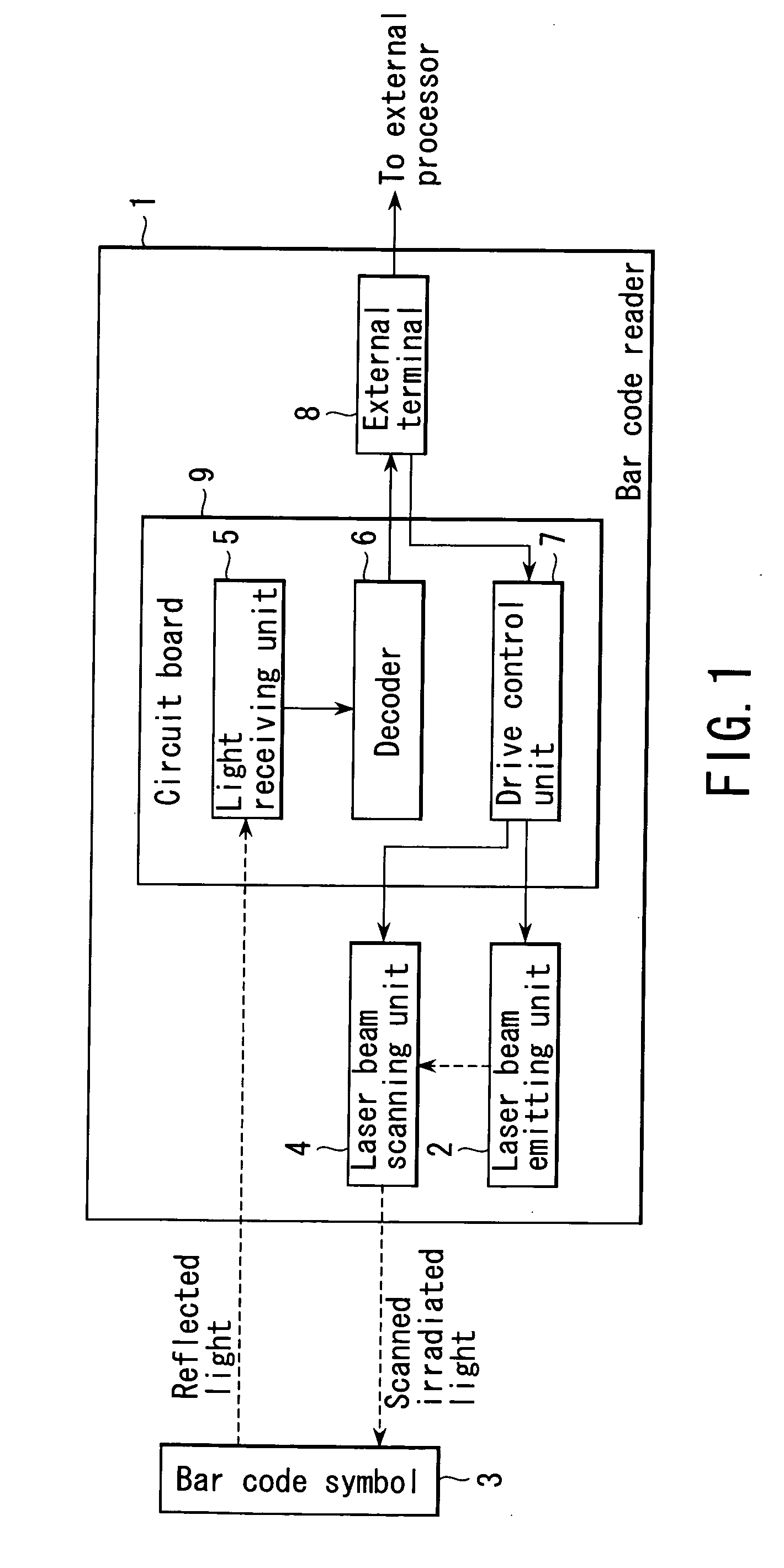

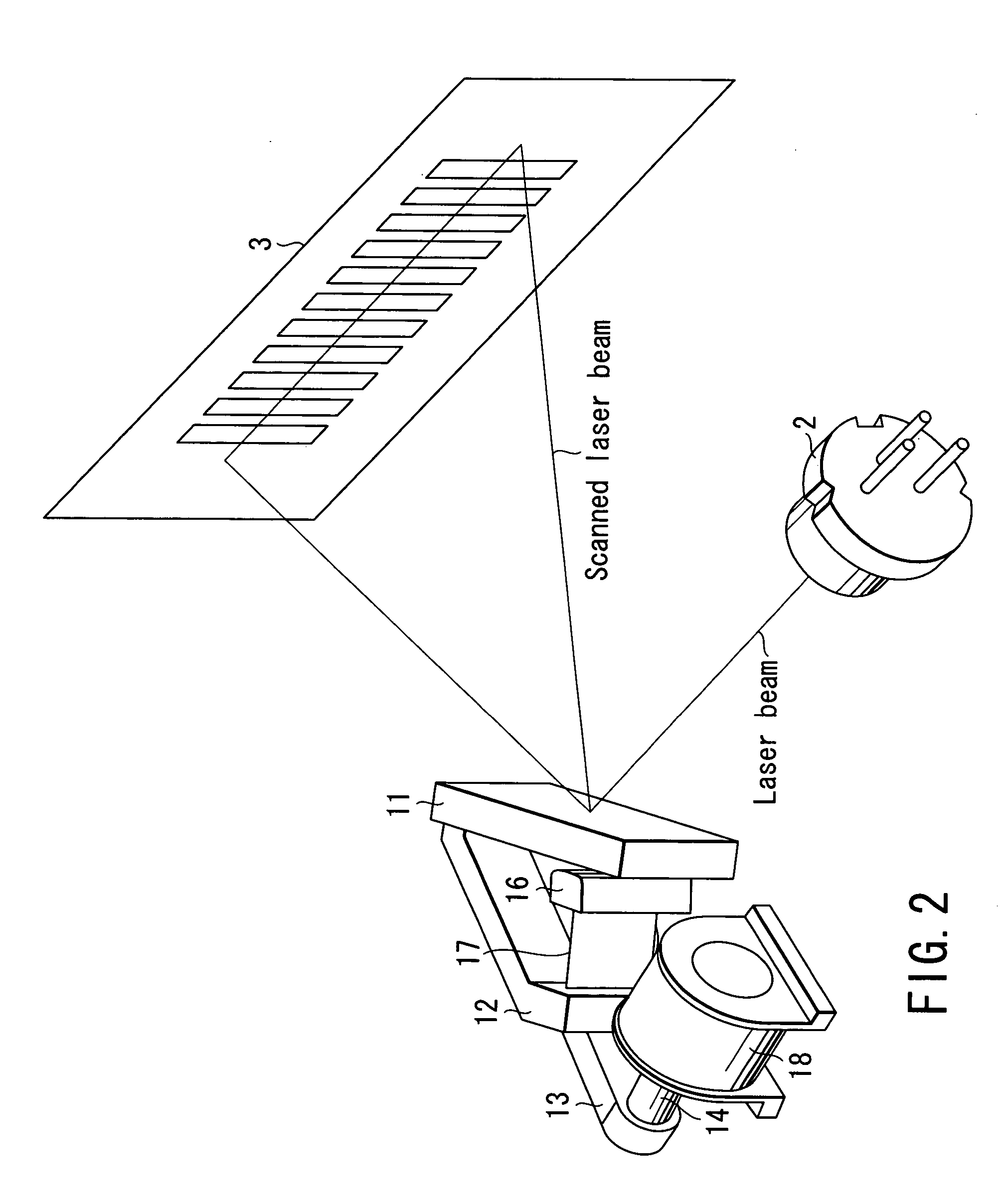

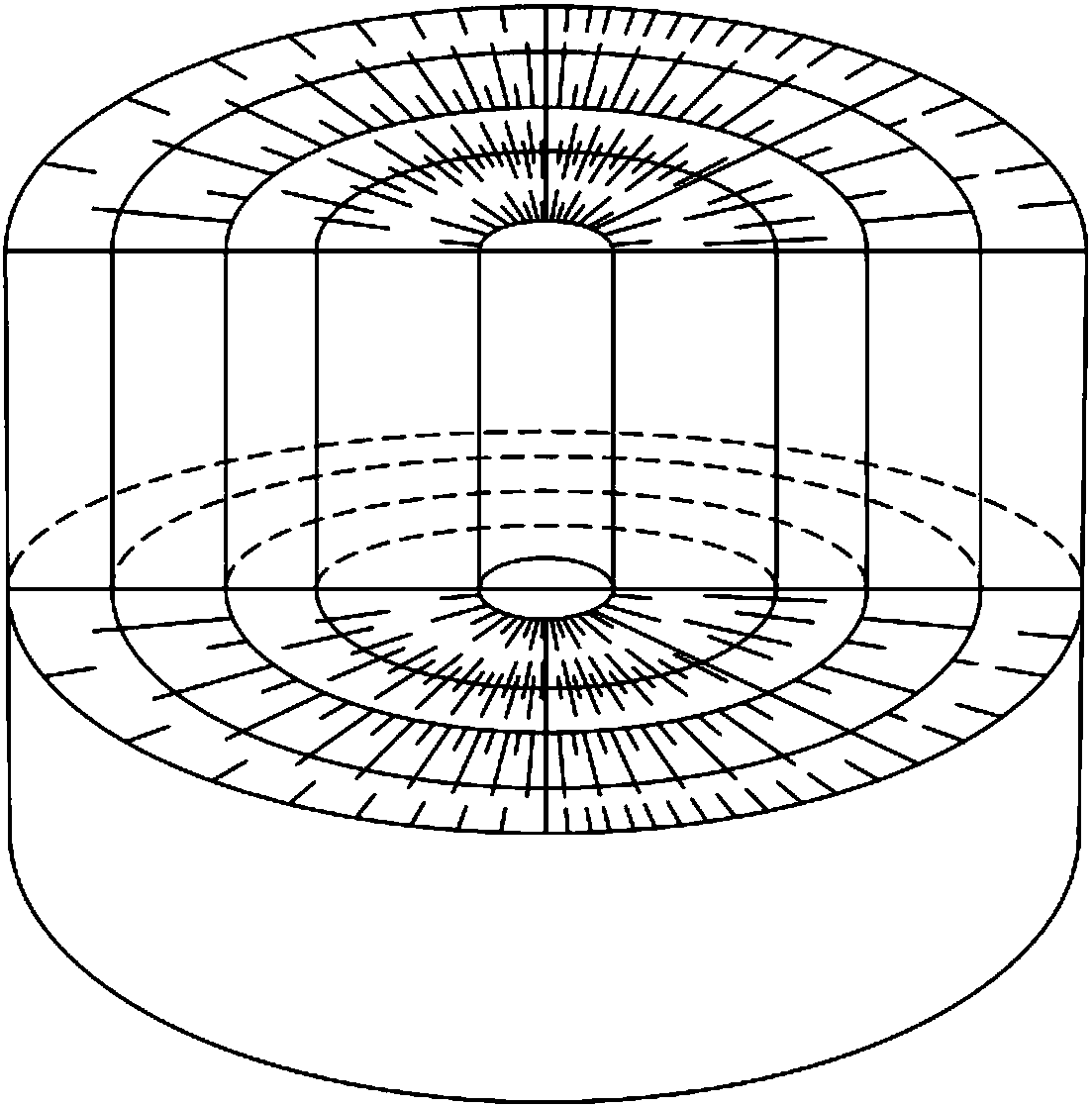

Barcode reader

InactiveUS20050092842A1Easy to reciprocateLow temperature dependence of eigen frequency fTelevision system scanning detailsCharacter and pattern recognitionBeam scanningEngineering

The present invention provides a barcode reader, which irradiates a scanned laser beam onto a barcode symbol and reads the information written in the symbol, wherein a laser beam scanning unit is made by insertion molding as one body with a movable support member, a support member fixed to the main body, and a metallic elastic member connecting these support members, the support members are molded as one body with a scanning mirror, and a permanent magnet is fixed to the support members. A driving coil is provided in proximity to the permanent magnet, and generates an attractive force or a repulsive force to rotate the magnet at a periodic laser beam scanning angle. Further, a stopper mechanism is provided to soften an external impact to the rotation of the scanning mirror.

Owner:OLYMPUS CORP

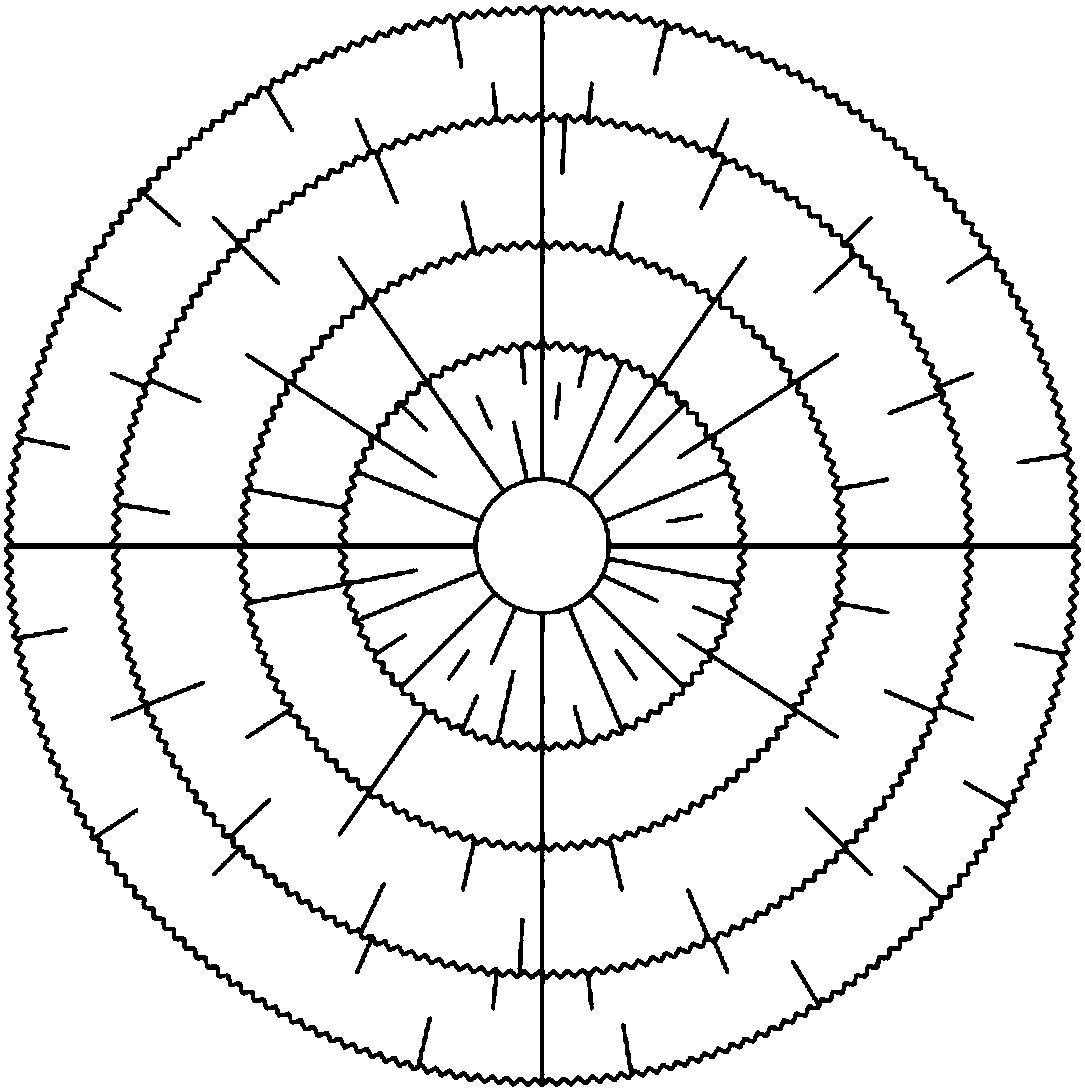

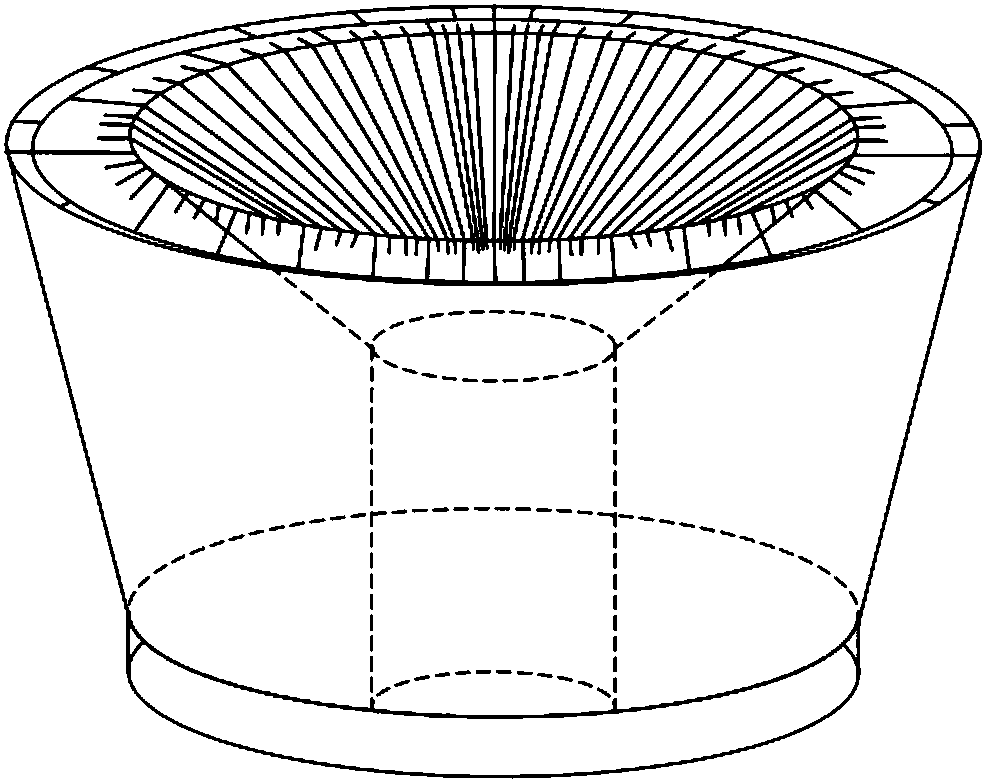

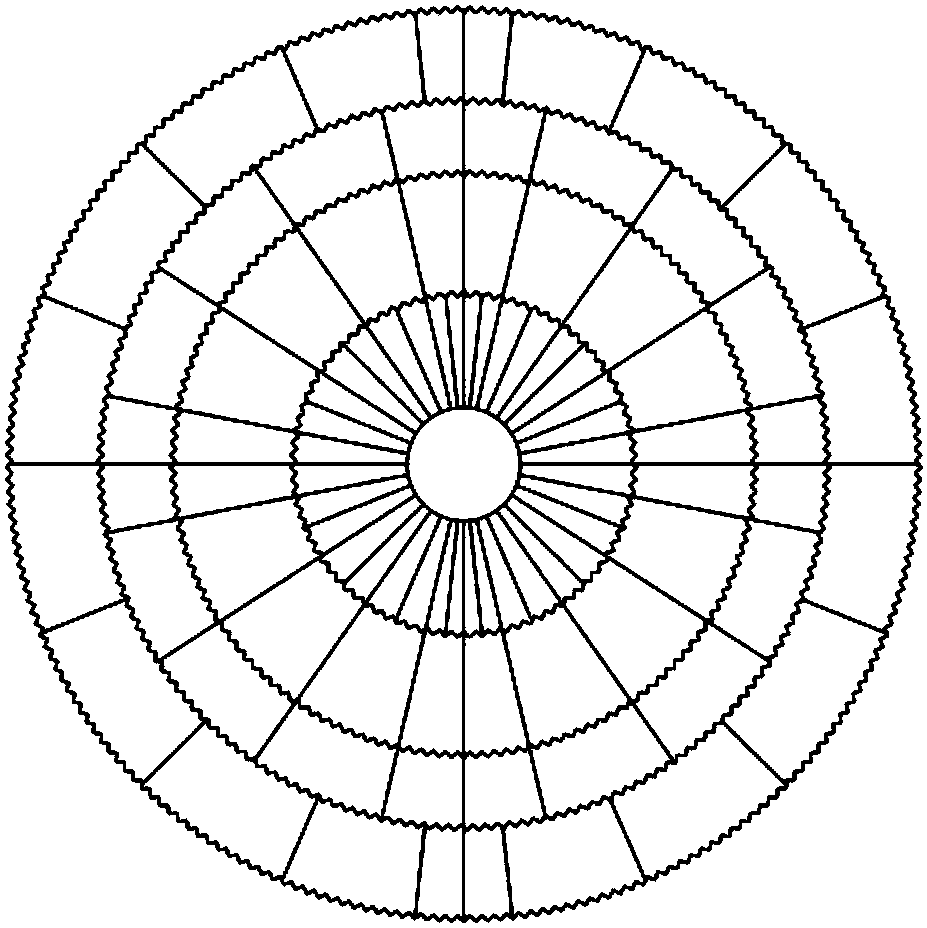

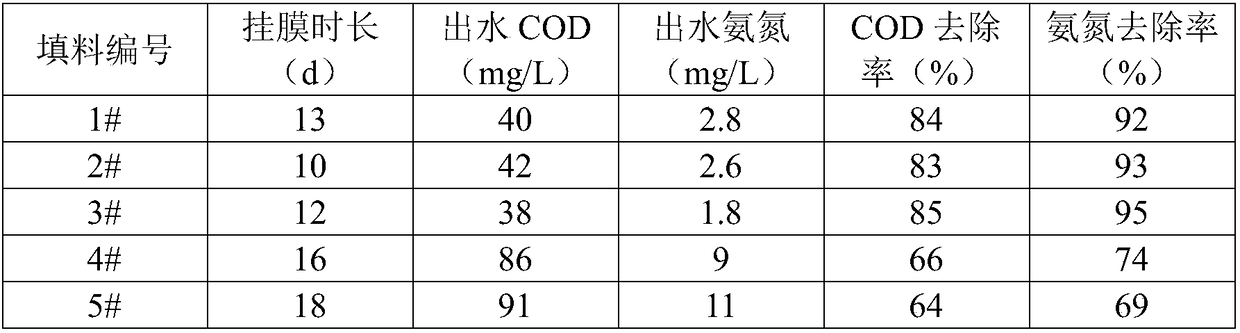

MBBR slow release carbon filler and preparation method thereof

InactiveCN108529758AImprove hydrophilic abilityBiological affinityWater contaminantsBiological water/sewage treatmentSewageAmmonia nitrogen

The invention discloses an MBBR slow release carbon filler and a preparation method thereof. The product provided by the invention has the advantages of fast biofilm formation speed, strong biologicaladhesion, difficult falling and high treatment efficiency, and is especially used for treatment of domestic sewage and industrial wastewater with high BOD5 content. The biological filler provided bythe invention has strong hydrophilicity and biological affinity, and the filler itself contains a slow-release carbon source, can provide the carbon source needed for biological metabolism, and the porous walnut sand material is beneficial to microbial growth, shortening of the biofilm formation time and improvement of the microbial treatment efficiency. With an ammonia nitrogen removal rate of greater than 92% and COD removal efficiency all exceeding 83%, compared with the existing filler, the MBBR slow release carbon filler provided by the invention can better treat biodegradable sewage.

Owner:GUIZHOU MATERIAL IND TECH INSTITUE

Oscillating-foil type underwater propulsor with a joint

InactiveUS7744434B2Improve efficiencyEasy to operatePropulsive elements of non-rotary typeMuscle power acting propulsive elementsMarine engineeringUnderwater

An oscillating-foil type underwater propulsor with a joint provided in the invention, the propulsor including a streamline foil having a foil surface being parallel to a water surface and a span length of at least twice as long as an average chord length of the streamline foil, and a heaving mechanism undergoing heaving motion perpendicular to a propulsion direction of the propulsor and having a transmission section, wherein the transmission section is pivotally connected to the streamline foil to form a joint, the joint being provided at the middle of the span length and having a rotation center located within a circular area, which has a radius of one third of the average chord length and is centered at the point one third of the average chord length ahead of the lifting center of the streamline foil.

Owner:CHANG JUNG CHRISTIAN UNIV

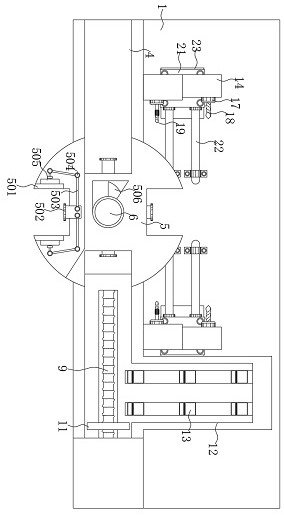

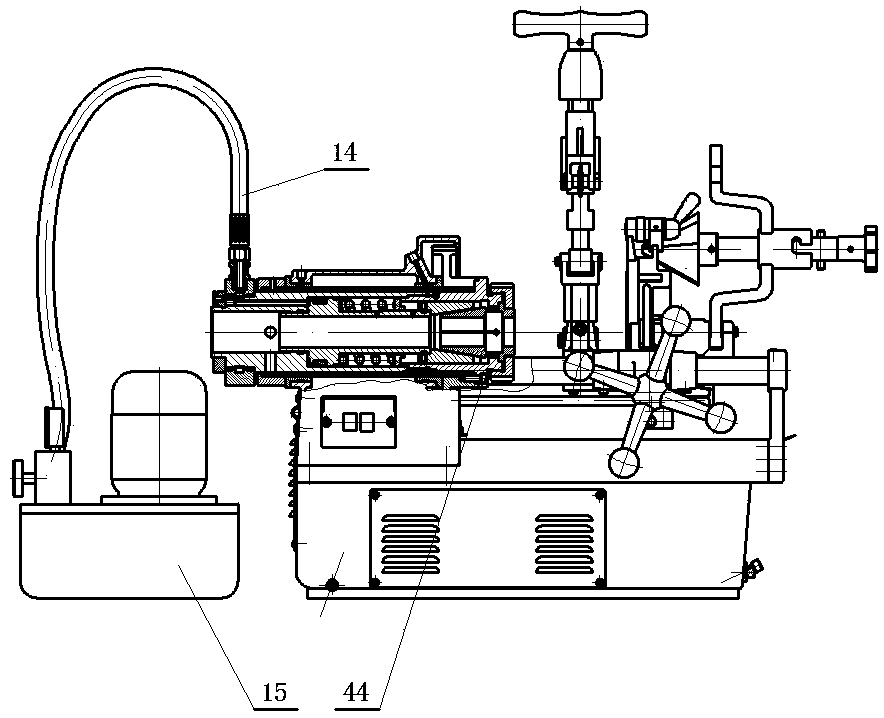

Machining equipment used for producing special-shaped ornaments and having automatic drilling and polishing functions

PendingCN112059627AAvoid errorsEasy to move horizontallyAutomatic control devicesFeeding apparatusDrill holeServo

The invention discloses machining equipment used for producing special-shaped ornaments and having automatic drilling and polishing functions. The equipment comprises a bottom case. A first servo motor is installed above the left of an inner cavity of the bottom case. A center shaft is arranged at the centering position of a center line of a rotary clamping base vertically in a transverse penetrating manner. Flow guide grooves are connected above plane overlooking pushing plates of the bottom case. Gap conveying mechanisms are arranged on the middle portions of the flow guide grooves. Slidingcases are symmetrically installed on the rotary clamping base. Controllers are arranged on the bottoms of the sliding cases. Sliding rods are symmetrically arranged on the two sides of the interiors of the controllers. According to the equipment, the gap conveying mechanisms are arranged in the flow guide grooves, the pushing plates on conveying plates of the gap conveying mechanisms are arrangedat equal distance, the ornaments can be moved horizontally and conveniently one by one, meanwhile, by arranging the pushing plates and the rotary clamping base, the ornaments can be conveniently pushed to the rotary clamping base to be rotated to the inner sides of the sliding cases, errors caused by manual feeding and discharging are avoided, and the ornaments are positioned beneficially.

Owner:东莞市优伟机电科技有限公司

Self-oxygenation microorganism degradation filler and preparation method thereof

ActiveCN108504058AImprove processing efficiencyReduce surface tensionSustainable biological treatmentBiological water/sewage treatmentBiocompatibility TestingBiofouling

The invention discloses self-oxygenation microorganism degradation filler and a preparation method thereof. A product disclosed by the invention has a rapid film formation speed, strong biological adhesiveness, uneasiness of falling off and high treatment efficiency and is especially used for treating domestic sewage and industrial wastewater with relatively high BOD5 (Biochemical Oxygen Demand 5)content; the product disclosed by the invention has extremely strong hydrophilicity and biocompatibility; the filler contains an oxygen-carrying material and surface tension between air bubbles and awater surface can be reduced; oxygen can be dissolved into sewage and the growth of microorganisms is facilitated; the film formation time is shortened and the microorganism treatment efficiency is improved. The ammonia nitrogen removal rate is higher than 90 percent and the removal efficiency of COD (Chemical Oxygen Demand) exceeds 80 percent; compared with existing filler, the sewage with relatively high BOD5 content can be treated better.

Owner:安徽绿源高分子材料科技有限公司

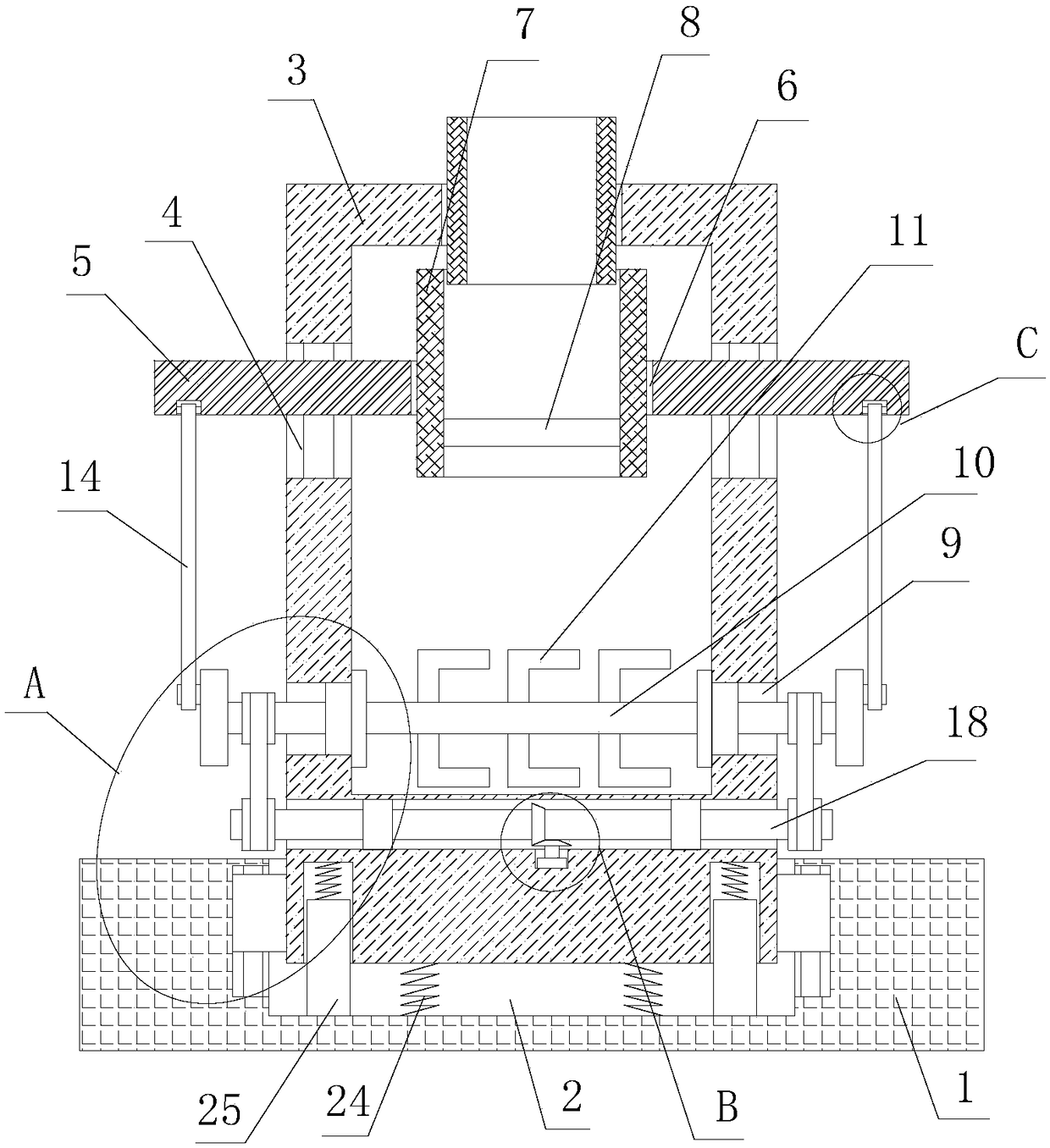

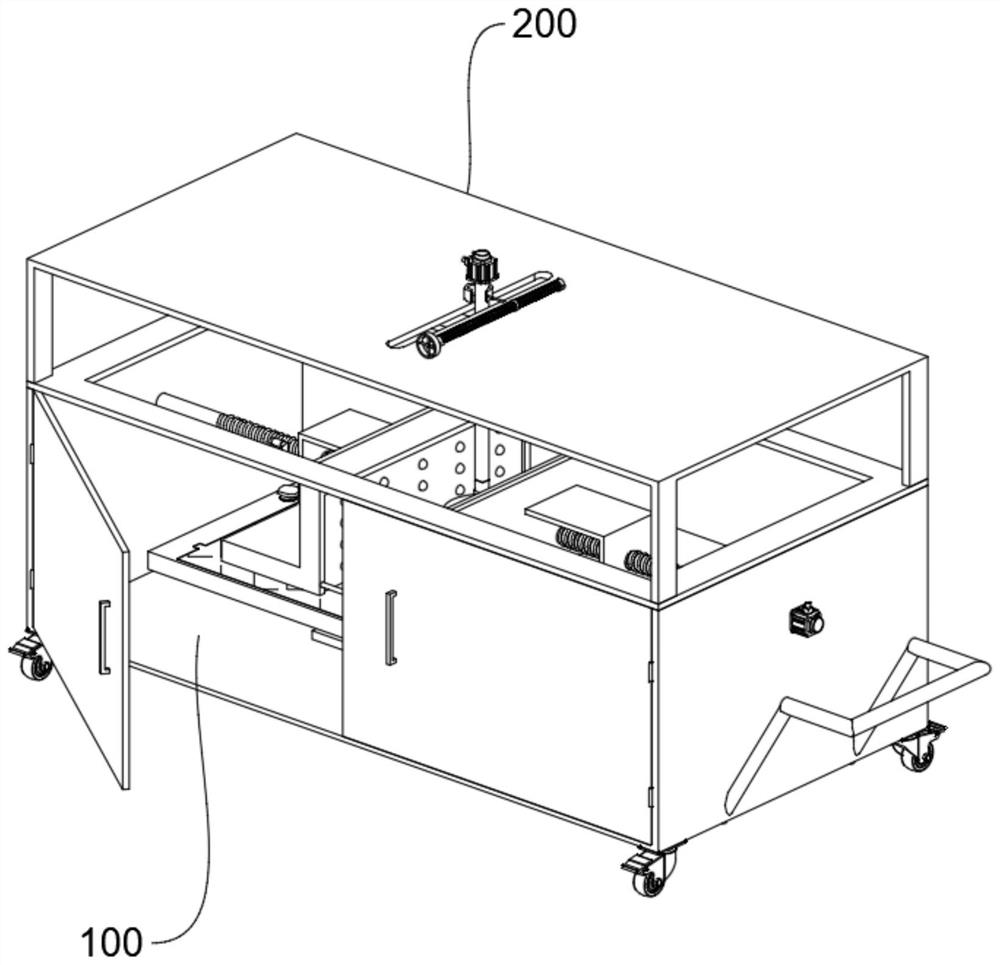

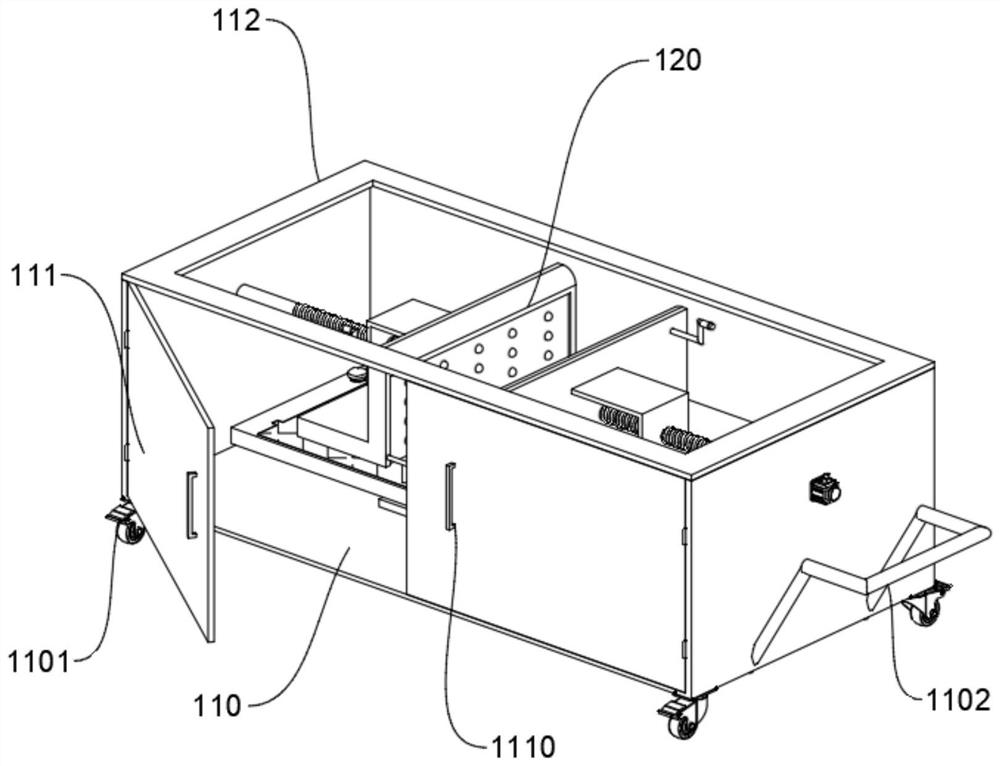

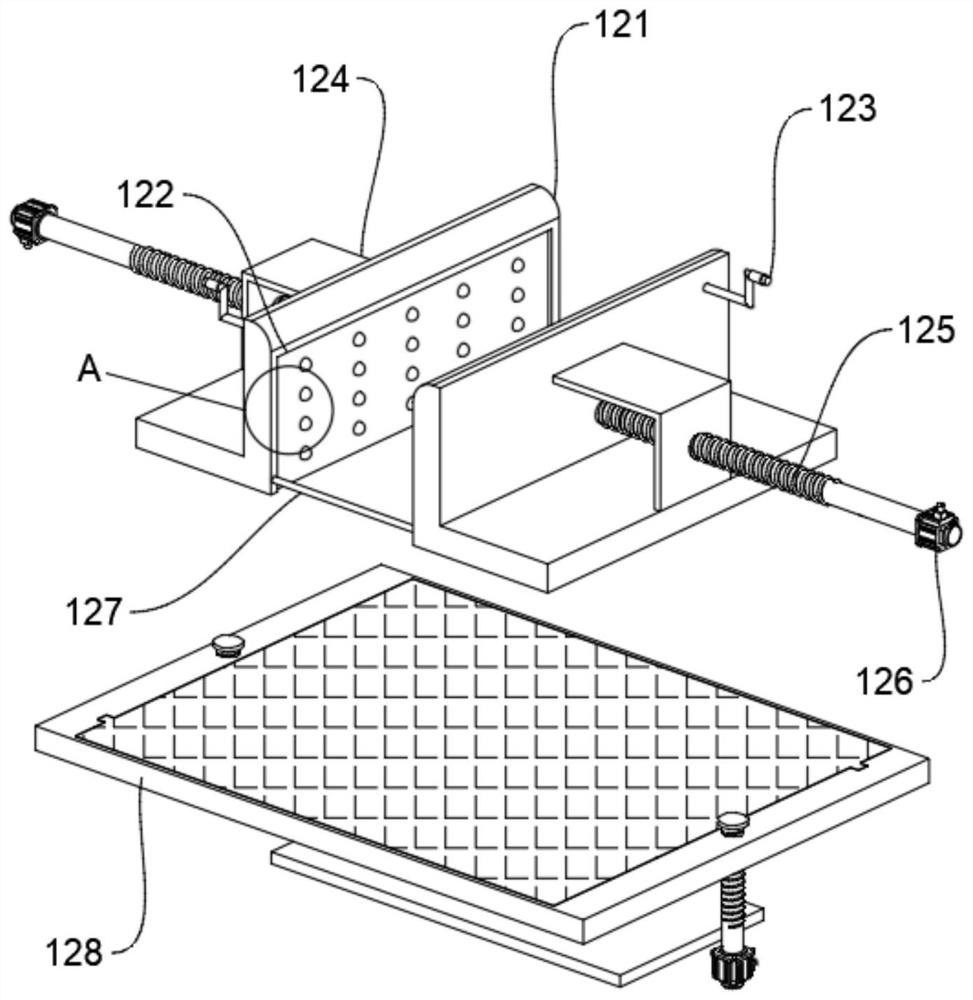

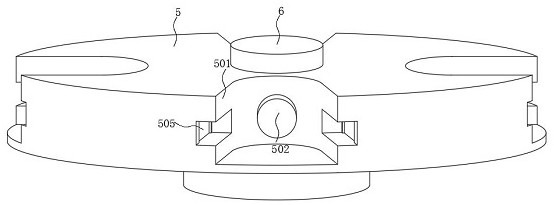

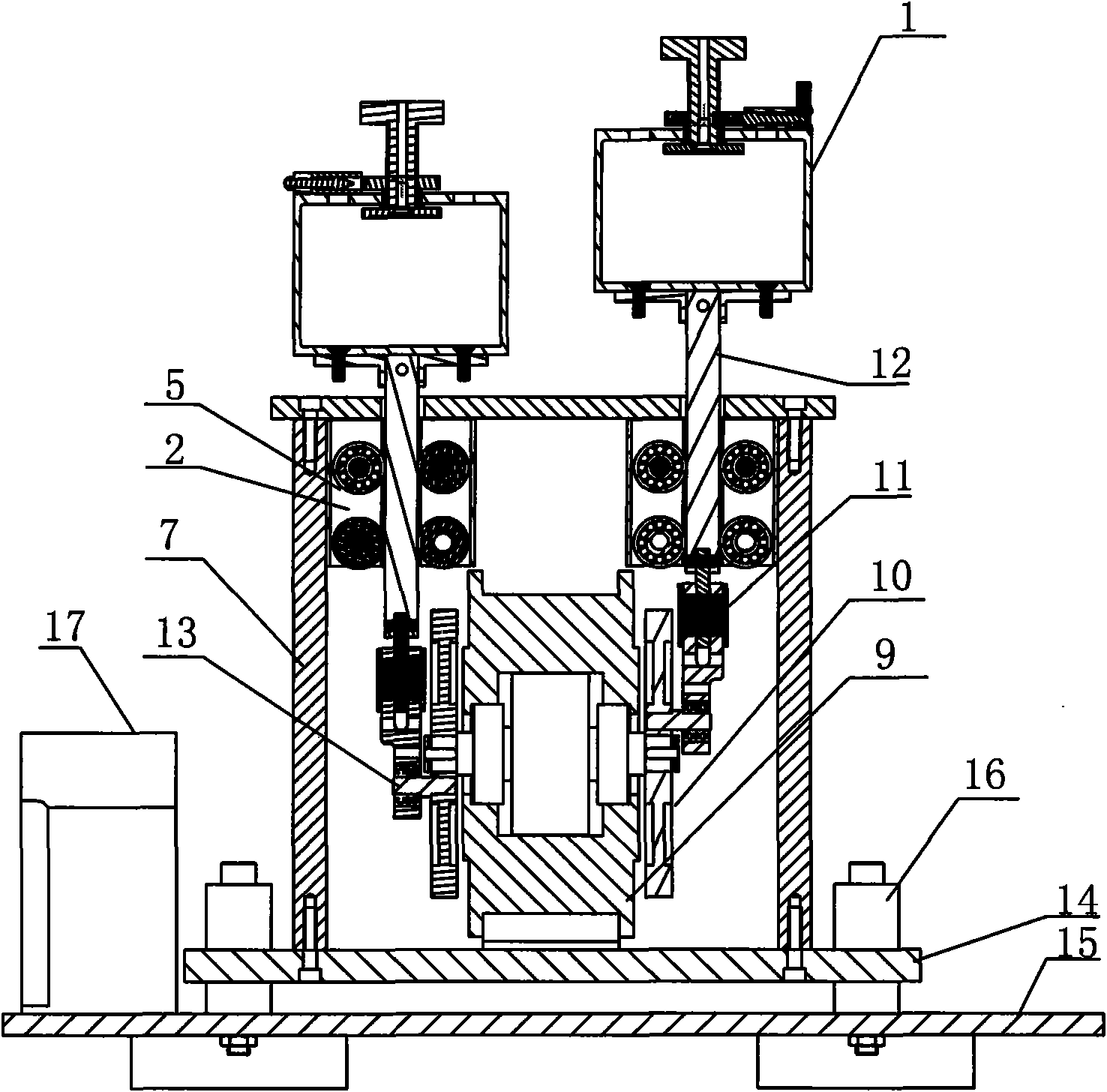

High-flux tissue grinder

ActiveCN101852695AAvoid damageExtend your lifePreparing sample for investigationGrain treatmentsSelf-oscillationHigh flux

The invention discloses a high-flux tissue grinder which comprises a pedestal, at least one working frame and a driving mechanism, wherein the driving mechanism is used for driving the working frame, and the working frame and the driving mechanism are connected through a crank mechanism. The invention is characterized in that a sliding guide mechanism is arranged on the crank mechanism and has the advantages that machine damage easily caused by poor overall force balance and overall self-oscillation can be overcome, so that the whole grinder is in dynamic balance, the machine life is prolonged, and the work efficiency is improved.

Owner:NINGBO SCIENTZ BIOTECH

Water quality sampling detection equipment

PendingCN111665095AFacilitated releaseEasy to reciprocateWithdrawing sample devicesWater qualityEngineering

The invention discloses water quality sampling detection equipment which comprises a machine body. A base is assembled in the machine body, a sliding seat is assembled on the base in a sliding mode, an assembling cavity is formed in one side of the sliding seat, a sampler is installed in the assembling cavity, a plurality of non-through assembling grooves are formed in the sliding seat at equal intervals, and sampling cups are arranged in the assembling grooves. According to the water quality sampling detection equipment, a rope and a sampling hose are unwound and matched at the same time, thesampling hose can be conveniently released to a proper depth for sampling, and the real-time sampling depth can be measured through cooperation of a pressure sensor and a display screen; moreover, adriving gear matches an assembling rack, so that the piston is conveniently driven to reciprocate, and a sample can be obtained without manual operation; besides, a plurality of sampling cups are arranged on the sliding seat, so that a plurality of groups of same samples can be obtained conveniently, and the accuracy of subsequent detection is improved.

Owner:ANALYSIS & TESTING CENT CHINESE ACADEMY OF TROPICAL AGRI SCI

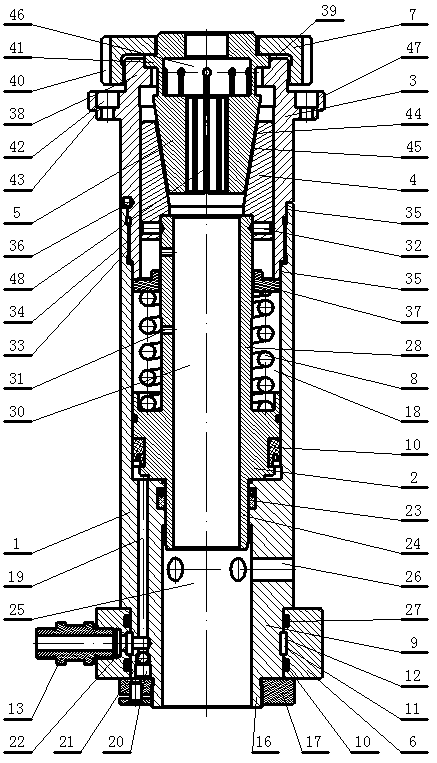

Hydraulic chuck for diehead threading machine

PendingCN108237418AGuaranteed not to deformGood effectPositioning apparatusMetal-working holdersEngineeringHigh pressure

The invention relates to a hydraulic chuck for a diehead threading machine. The hydraulic chuck for the diehead threading machine comprises an oil cylinder, a piston, a front sleeve, a taper sleeve, ajacket, a slide sleeve, a pressing ring and a spring; an oil cylinder cavity in the oil cylinder comprises a large cavity at the upper part and a small cavity at the lower part; the large cavity andthe small cavity communicate to form a step form; the piston is placed in the oil cylinder cavity; the front sleeve is arranged in a cavity mouth of the large cavity; the taper sleeve is mounted in the front sleeve; the lower end of the taper sleeve butts against the piston; a conical hole is formed in the taper sleeve; the jacket is mounted in the conical hole, and is locked on the front sleeve through the pressing ring; the spring sleeves the piston; the lower end of the spring butts against a projection at the middle lower part of the piston; the upper end of the spring butts against an annular baffle plate; the annular baffle plate butts against the end surface of the front sleeve; the slide sleeve is arranged on the outer surface of the oil cylinder in the small cavity; an oil nozzleis mounted on the slide sleeve; and the oil nozzle is connected with a pump station through a high-pressure oil pipe. The hydraulic chuck for the diehead threading machine has the beneficial effects of no deformation of steel pipes, high tightening strength and good tightening effect.

Owner:CEC JINJIANG INFO IND

Environment-friendly automatic labeling device for paper diaper production

ActiveCN113184320ALimit work fastQuick alignment workCleaning using toolsLabelling machinesRatchetEngineering

The invention discloses an environment-friendly automatic labeling device for paper diaper production. The environment-friendly automatic labeling device comprises a labeling device main body, a first half gear, a power rod and a cleaning rod, wherein the top of the labeling device main body is provided with a labeling mechanism, the labeling device main body is internally provided with a servo motor, the top of the servo motor is connected with a main shaft, and the surface of the main shaft is connected with a forward ratchet wheel through torsional springs and ratchets. According to the environment-friendly automatic labeling device for paper diaper production, a baffle is arranged in the labeling device main body, so that the baffle can limit a paper diaper main body; and a cam rotates to push push plates, the push plates drive clamping plates to correct and clamp the position of the paper diaper main body through connecting rods, so that the environment-friendly automatic labeling device can quickly align the paper diaper main body, the phenomenon of skewing during labeling is avoided, and the accuracy of the environment-friendly automatic labeling device is facilitated.

Owner:李月红

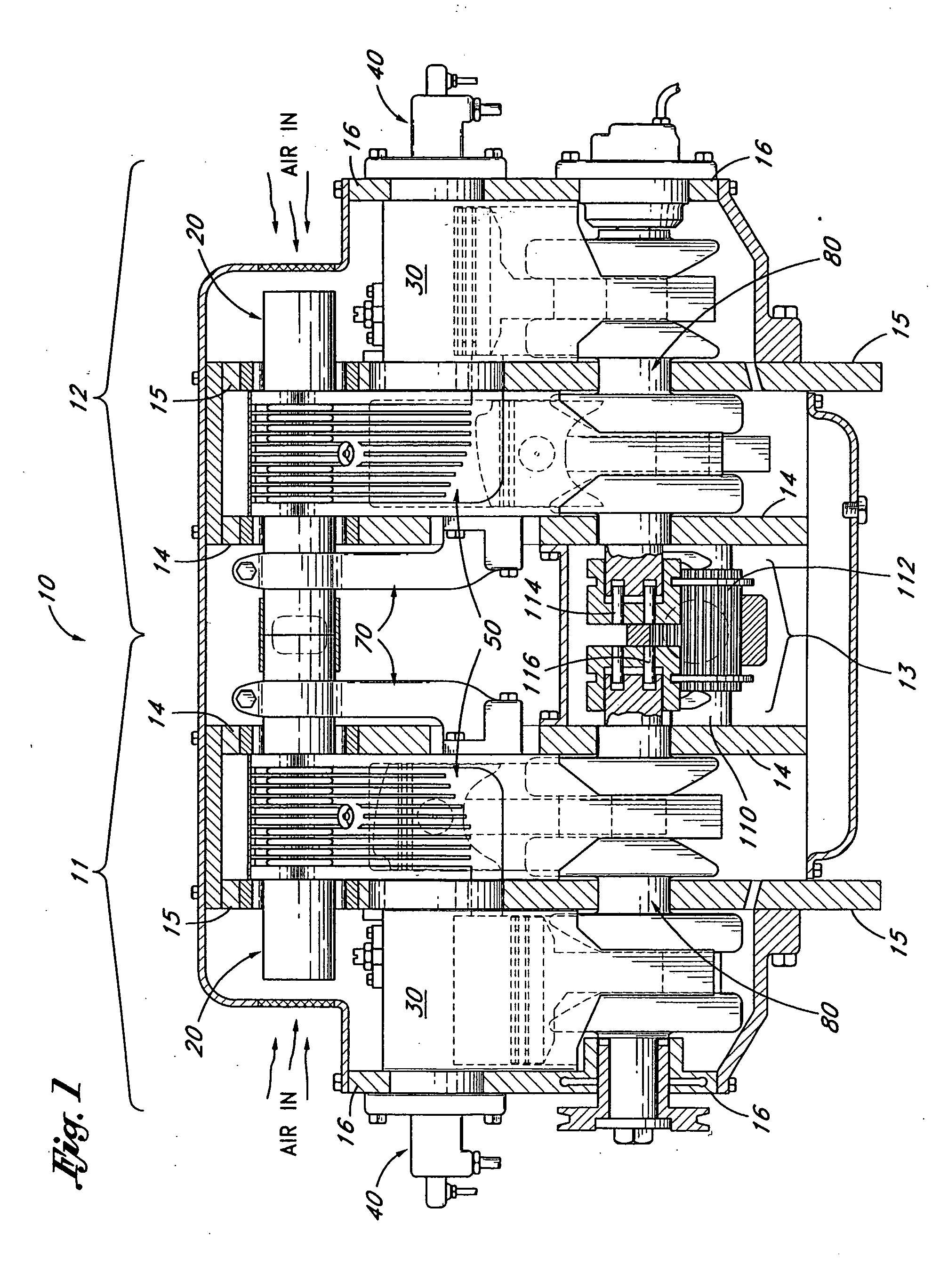

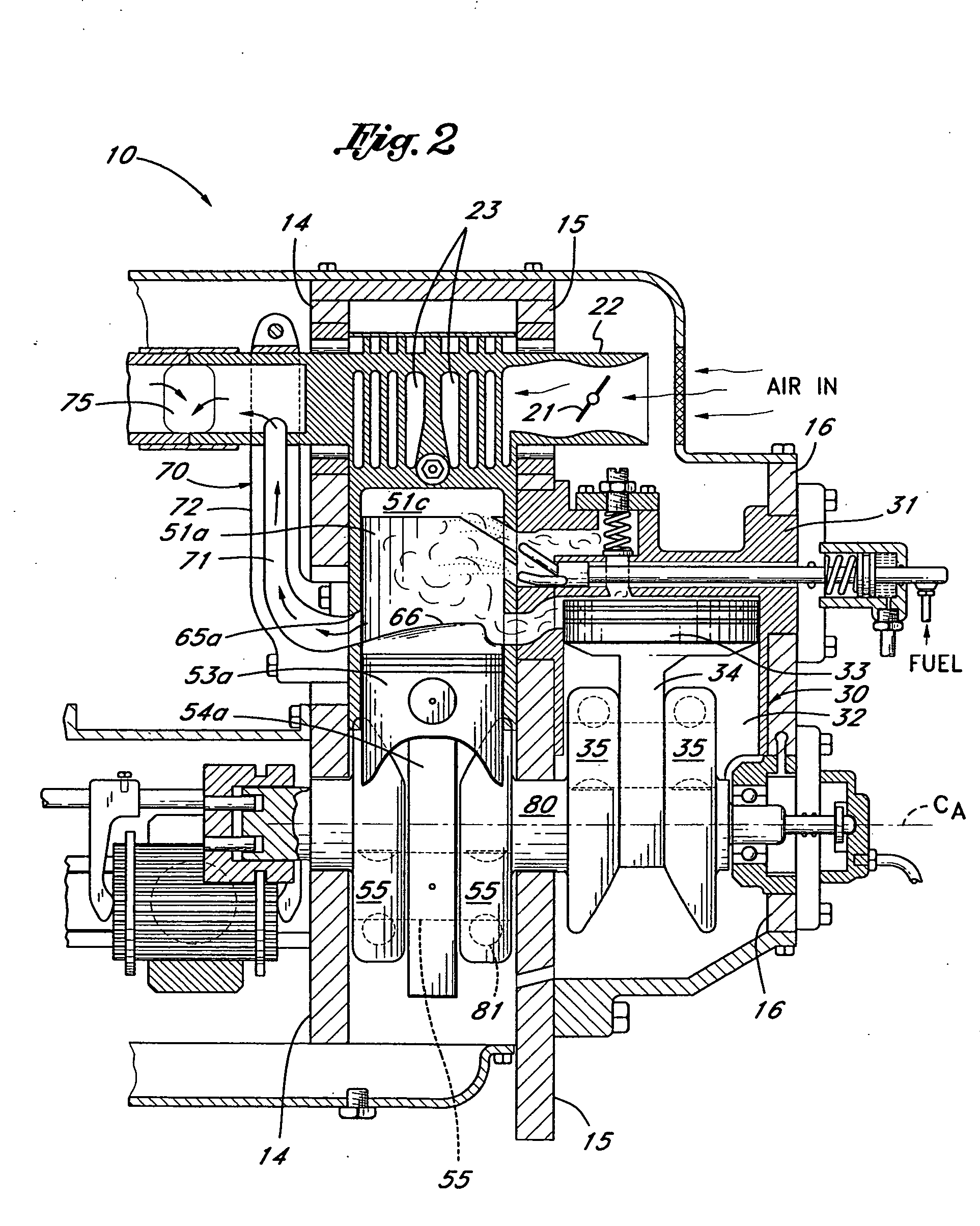

Internal combustion engine with actuating oscillating cylinders

InactiveUS20060180104A1Improved swirlPromotes even distributionInternal combustion piston enginesCombustion chamberVaporization

An internal combustion engine having one or more modules each employing fluidly-communicating, oscillating, power cylinder and air cylinder. The power and air cylinders oscillate about separate, individually supporting sets of trunnions positioned non-linearly with respect to each other and permitting the passage of air therethrough. The air cylinder includes a pre-combustion chamber for the purpose of withholding the delivery of a portion of compressed air to the power cylinder until all spent gases have been evacuated from the power cylinder. Means for enhancing fuel dispersion and / or vaporization is provided whereby cavities are provided in the cap of both the air cylinder and the power cylinder that are in selective synchronous fluid communication. A blower is provided to not only assist in the elimination of exhaust from the combustion chamber but also purge the combustion piston cap cavity of exhaust backflow prior to the delivery of fresh charge

Owner:SPRINGER

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com