High-flux tissue grinder

A grinding machine and high-throughput technology, applied in the field of grinding machines, can solve the problems of inability to achieve dynamic mass balance, poor machine force balance, and low work efficiency, so as to overcome the poor force balance of the whole machine, improve machine life and work efficiency Efficiency and the effect of prolonging the service life of the instrument

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

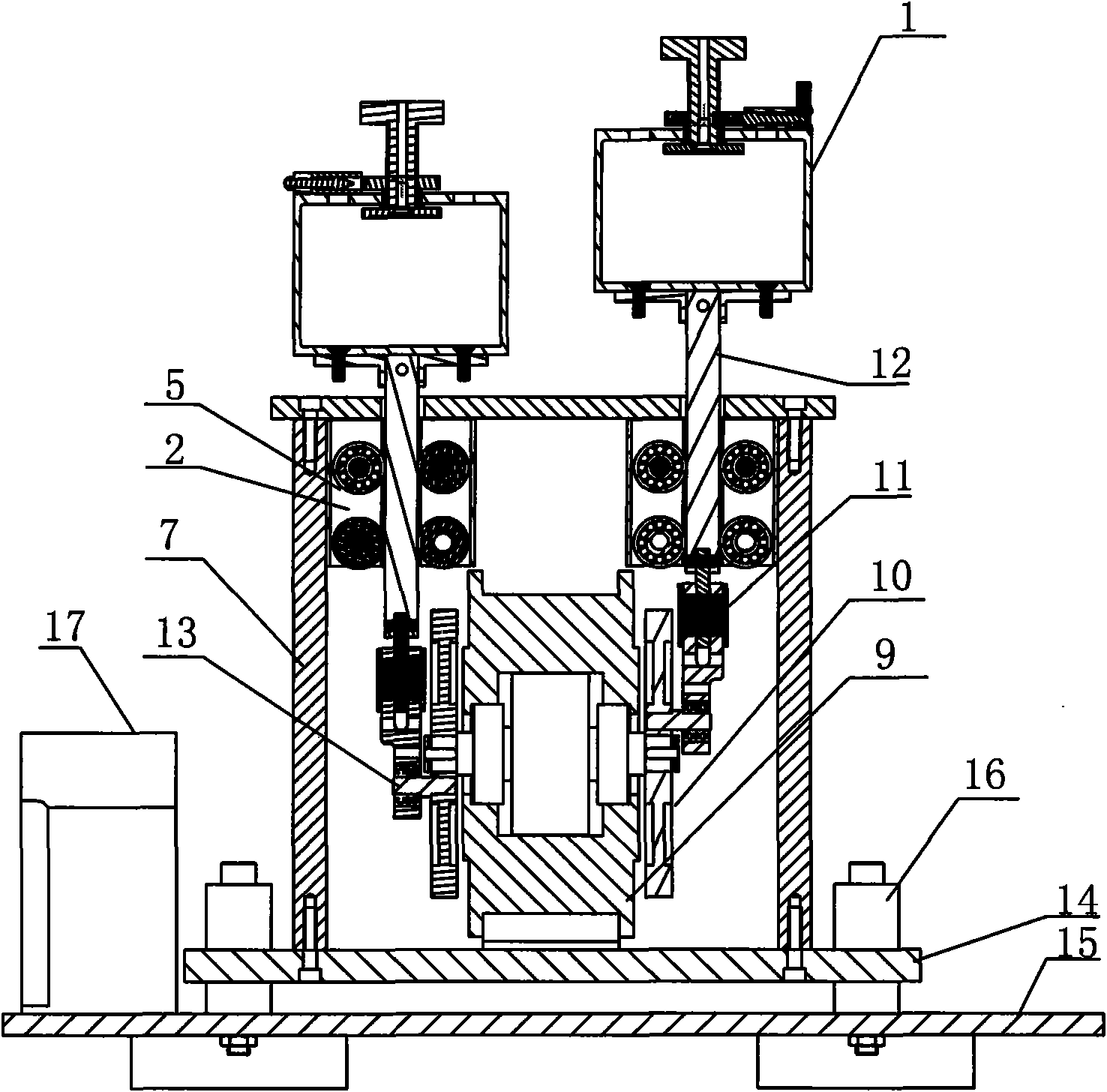

[0023] A high-throughput tissue grinding machine, which includes a base, two working frames 1 and a driving mechanism for driving the working frames 1, the working frame 1 and the driving mechanism are connected through a crank mechanism, and a sliding guide mechanism 2 is arranged on the crank mechanism .

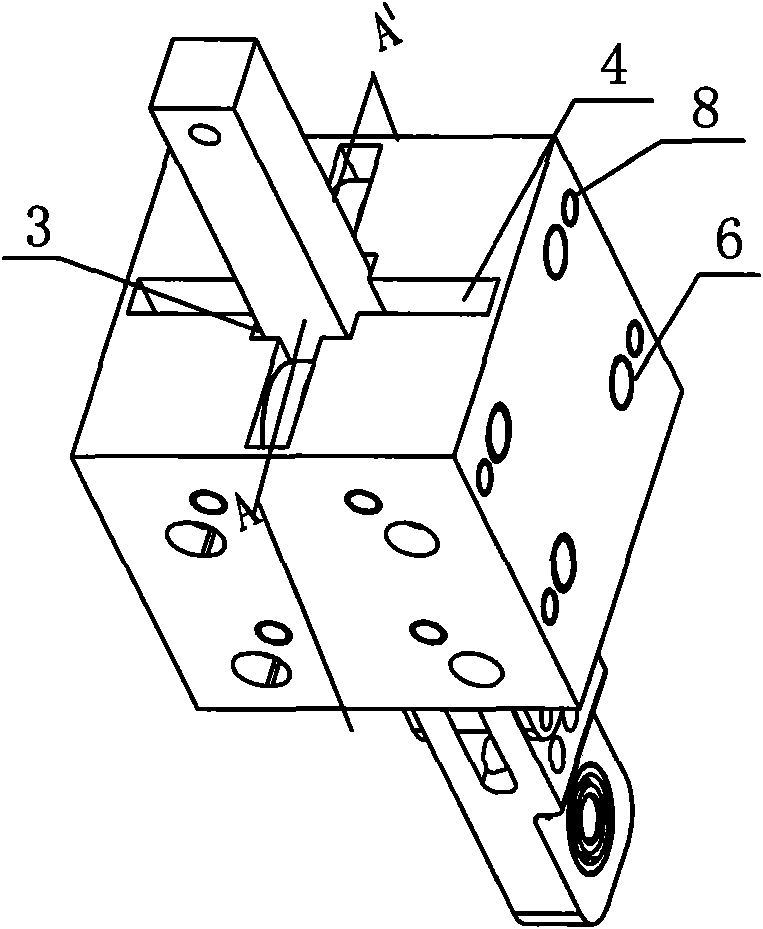

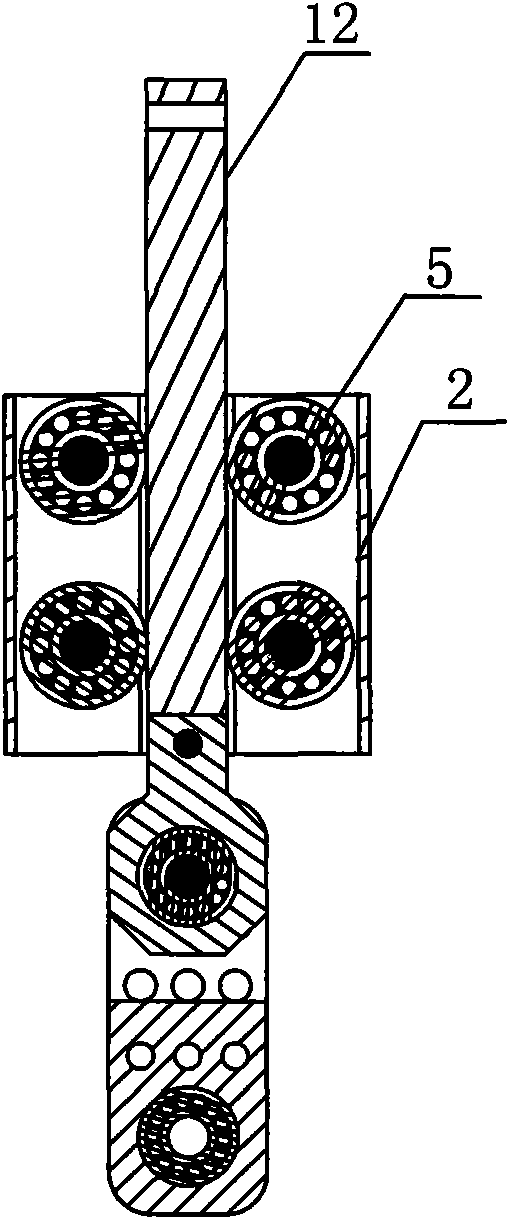

[0024] The sliding guide mechanism 2 comprises a sliding guide block, the sliding guide block is provided with a central through hole 3, and the outer periphery of the central through hole 3 is provided with four rolling grooves 4, and at least one rolling bearing 5 is arranged in the rolling groove 4, and the radial direction of the rolling bearing 5 and The direction of the central through hole 3 is parallel, and the sliding guide block is provided with a pin hole 6, and the direction of the pin hole 6 is perpendicular to the direction of the central through hole 3, and the sliding guide block is also provided with a bracket 7 connected and fixed on the base. Connection ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com