Rotary feeding device

A technology of rotary feeding and rotary table, which is applied in the field of machinery, can solve the problems of large overall occupied space, poor feeding stability, long conveying stroke, etc., and achieve the effects of convenient operation, improved work efficiency, and reduced occupation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

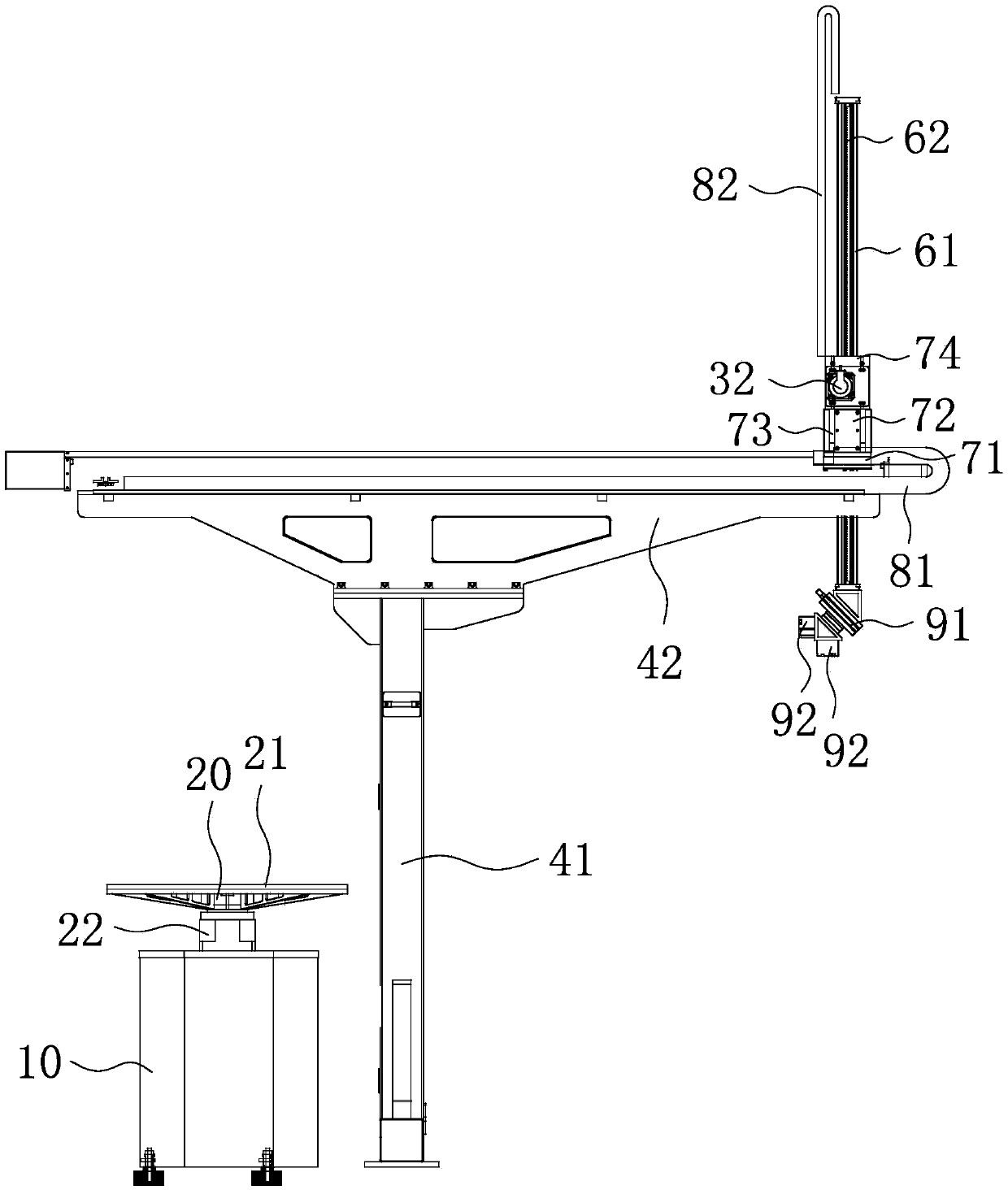

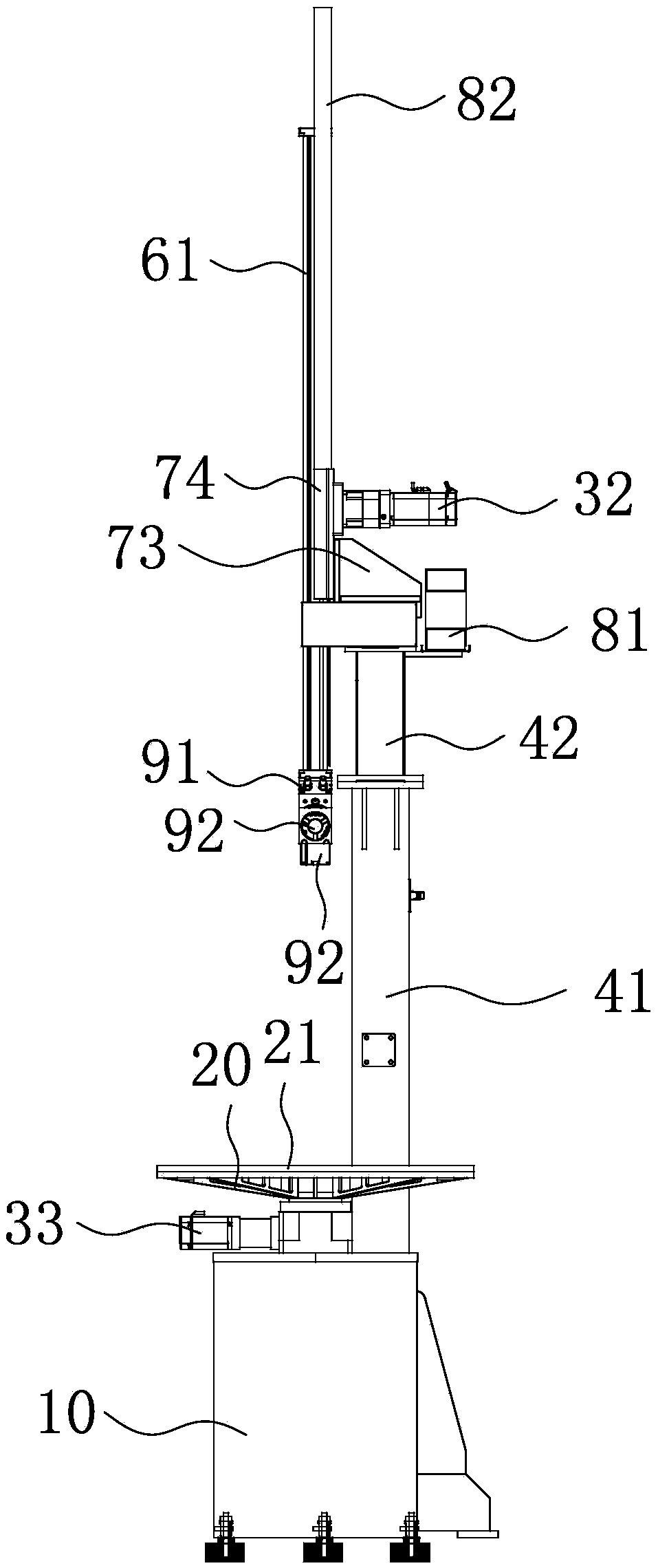

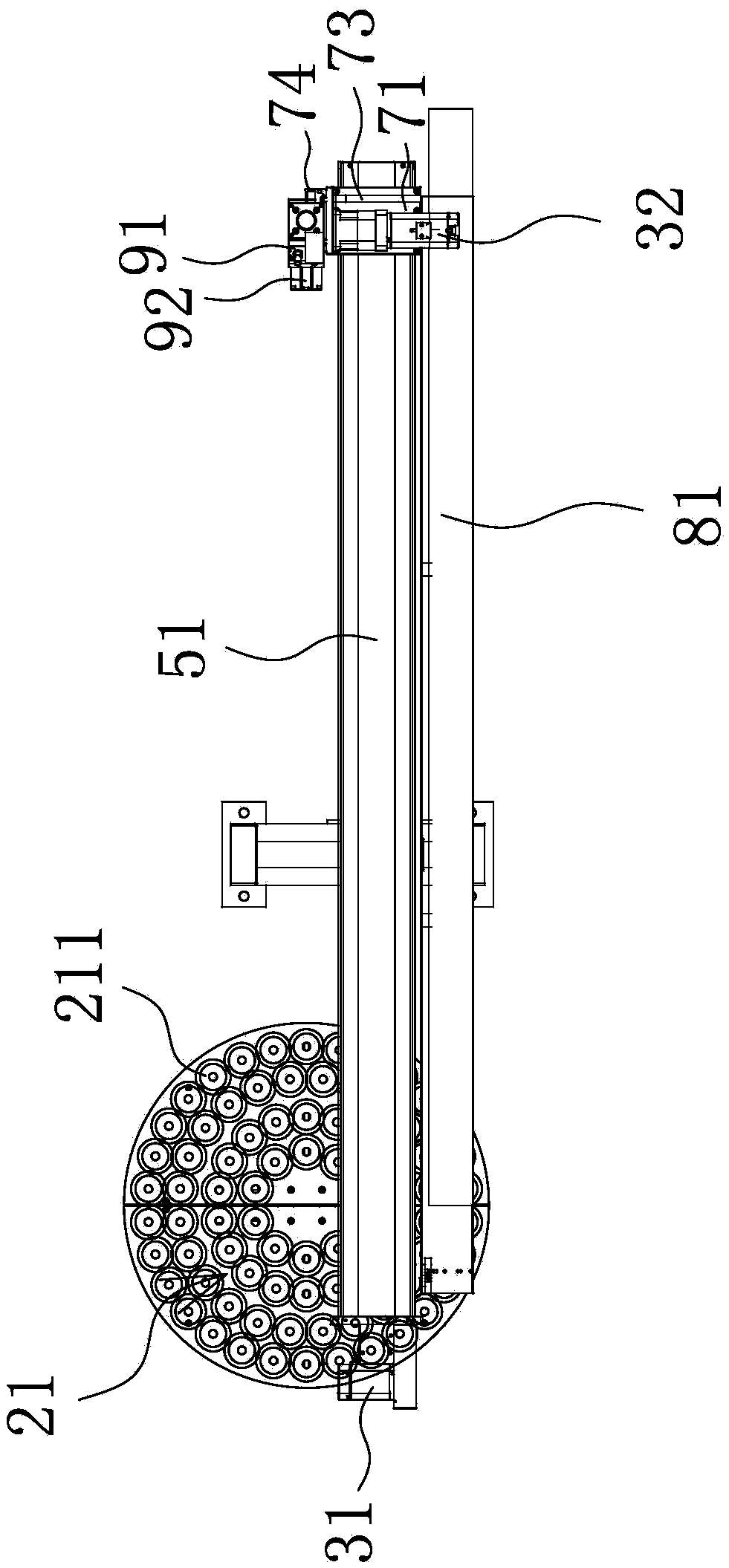

[0027] Such as Figure 1 to Figure 3 As shown, the rotary feeding device includes:

[0028] Rack 10;

[0029] The rotary table 20 is horizontally arranged on the frame 10 and is movably connected with the frame 10 through the rotary shaft 22, and the rotary table 20 is detachably mounted with a tray 21 for placing workpieces;

[0030] The servo motor 33 is connected to the rotating shaft 22 and can drive the rotating shaft 22 to rotate together with the rotary table 20 and the material tray 21;

[0031] The support 41 is arranged on one side of the turntable 20 , and a manipulator capable of picking up the workpiece and taking it away from the turntable 20 is arranged on the support 41 .

[0032] The existing feeding de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com