Apparatus for processing body of internally-thickened alumium alloy drill pipe

A drill pipe and aluminum alloy technology is applied in the field of equipment for processing the inner thickening of the aluminum alloy drill pipe body, and can solve the problems that the deformation quality is difficult to control, the forming quality of the aluminum alloy drill pipe body is affected, and the deformation amount is large. To achieve the effect of simple structure, improve the quality of rolling forming, and ensure the effect of rolling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

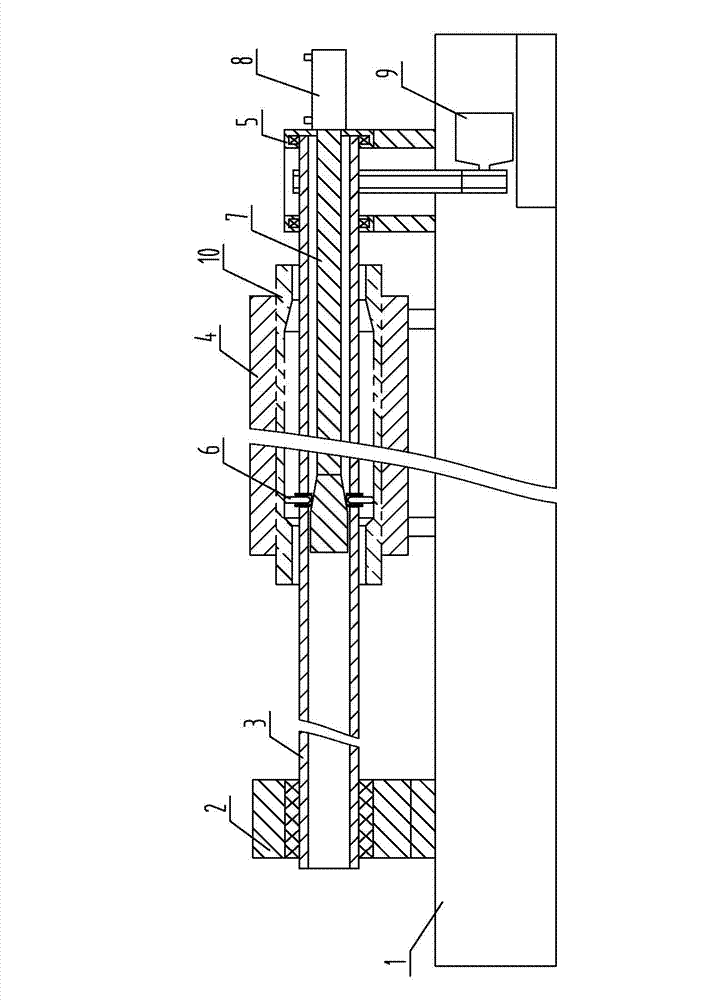

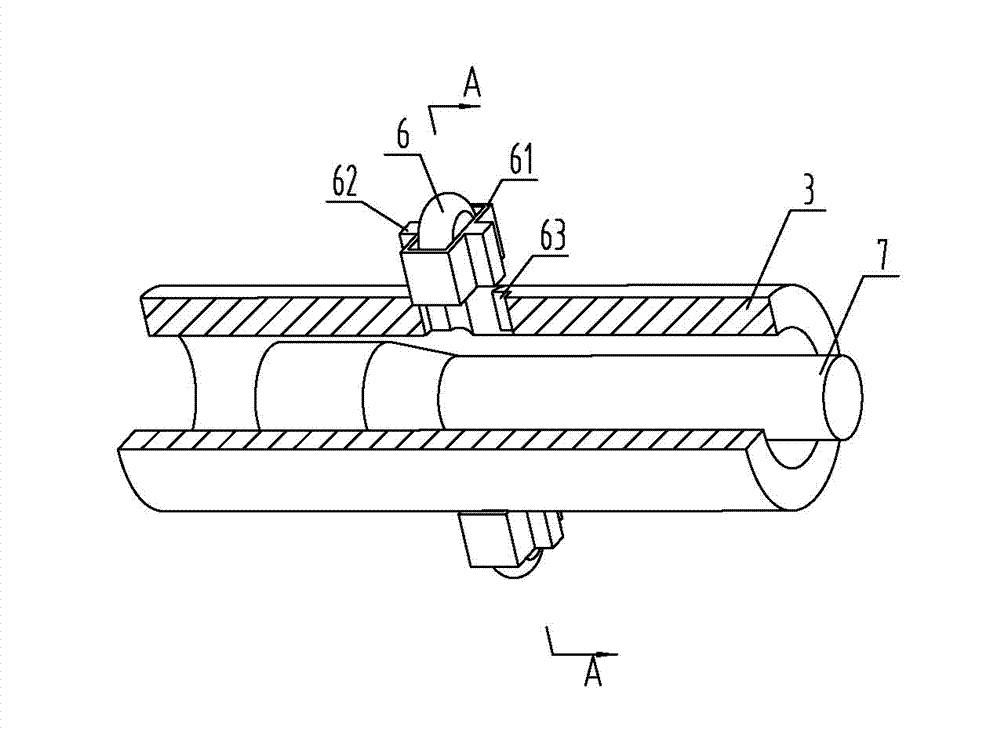

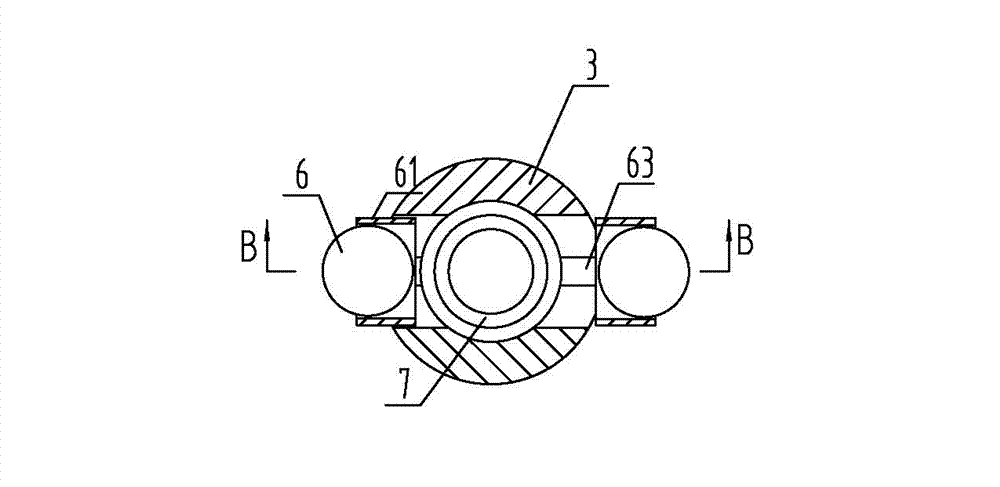

[0036] like figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 As shown, the front support seat 2, the outer support pipe 4 and the rear support seat 5 are successively arranged on the console 1 in the present invention; The support tube 4 is arranged coaxially with the outer support tube 4, the rolling head 6 is installed on the pipe wall of the pipe fitting 3, and the rolling head 6 is connected with the control mechanism, and the control mechanism makes the rolling head 6 move radially along the pipe fitting 3; the pipe fitting 3 is connected The motor 9, the motor 9 drives the pipe fitting 3 to rotate in the front support base 2 and the rear support base 5; the outer support tube 4 is connected to the first servo power device 46, and the first servo power device 46 drives the outer support tube 4 to move back and forth along the console 1 , the aluminum alloy pipe body 10 of equal inner diameter to be processed can be clamped and fixed in the outer support pipe ...

Embodiment 2

[0042] The control mechanism for controlling the opening of the rolling head 6 is the second servo power device, which is located in the inner cavity of the pipe 3 and connected to the inner end of the sliding bracket 61 . Wherein, the second servo power device can be the same as the first servo power device 46, and the servo oil cylinder, servo cylinder or servo motor in the prior art can be selected, and the rest are the same as the first embodiment.

[0043] The control mechanism can be installed in the inner cavity of the pipe fitting 3, or in the pipe wall of the pipe fitting 3 or in the cavity surrounded by the outer wall of the pipe fitting 3 and the inner wall of the aluminum alloy pipe body 10, as long as the rolling head 6 and the inner wall of the aluminum alloy pipe body 10 can be adjusted. The distance from the center of the pipe fitting 3 is sufficient.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com