Slurry mixture material distributing device and method

A cloth device and slurry technology, which is applied to supply devices, manufacturing tools, etc., can solve the problems of easy deformation, inability to achieve, complex decorative effects, etc., and achieve the effect of ensuring strength, coordination of decorative effects, and rich decorative effects.

Inactive Publication Date: 2010-12-01

KEDA INDUSTRIAL GROUP CO LTD

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The purpose of the present invention is to provide a slurry mixing distributing device and a distributing method, which can effectively solve the existing technical defects in the existing slurry distributing method that complex decorative effects cannot be achieved, and deformation, cracks, and air bubbles are prone to occur during production.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

no. 1 example

no. 2 example

no. 3 example

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

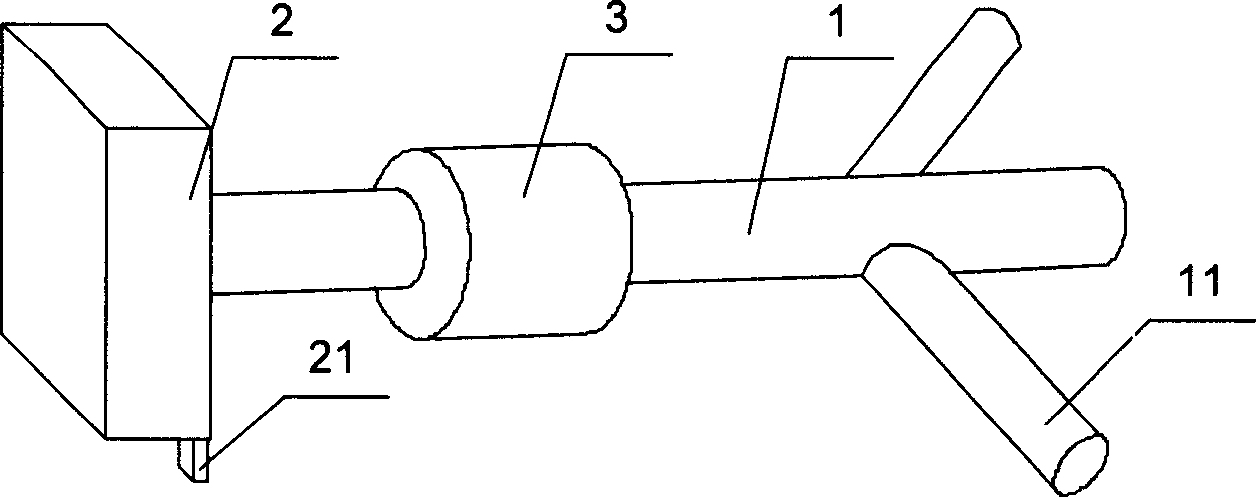

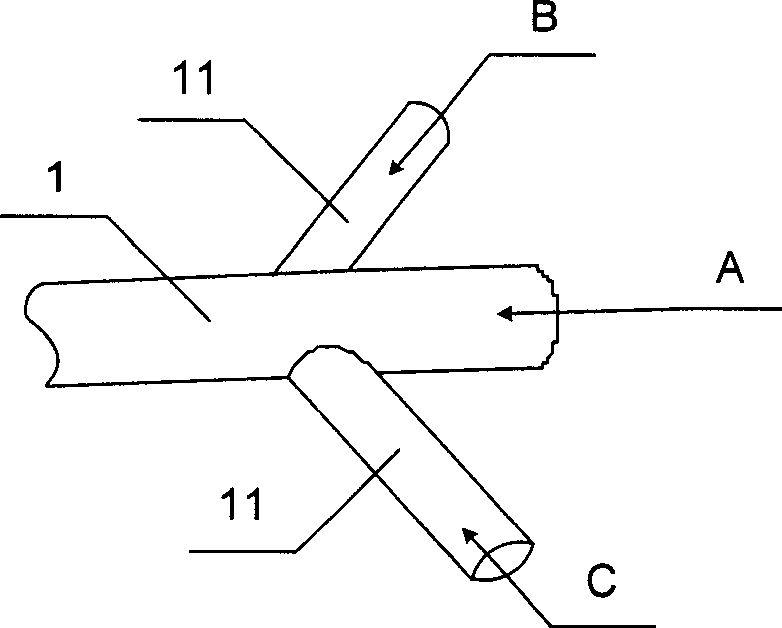

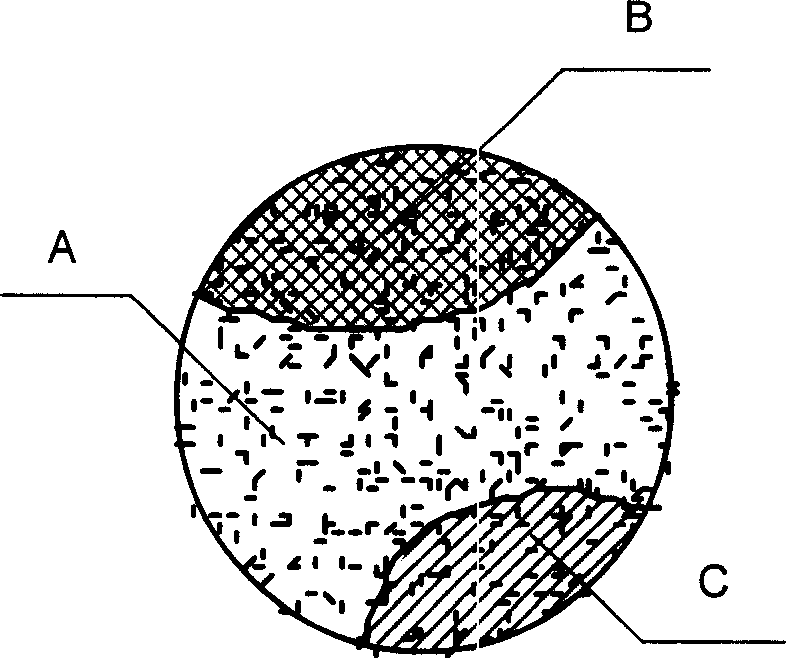

The present invention relates to slurry mixture material distributing device and method. The material distributing device includes one pipe for conveying slurry mixture material, one material storing box connected to the pipe, and one stirrer set on the pipe to regulate the single color slurry position. The material distributing method includes mixing the single color slurries in the pipe to formslurry mixture, regulating the single color slurry position with the stirring blades in the slurry mixing passage, storing the slurry mixture in the material storing box and flowing out the mixture slurry continuously or intermittently. The present invention can ensure the continuity of the integral pattern in the glazed tiles, and alter the decorating line pattern in the glazed tiles to richen the decoration effect.

Description

Slurry mixing and distributing device and distributing method technical field The invention relates to a material distribution device and a material distribution method for producing ceramic tiles, in particular to a slurry mixing material distribution device and a material distribution method. Background technique In the layout decoration of ceramic tiles, the ceramic industry usually adopts the method of dry pink material cloth and liquid pigment printing. Among them, the dry pink material cloth method has been developed so far that it is very mature, and it is difficult to have a major breakthrough; and the liquid pigment printing method is due to the limitation of the printing method itself, and the texture pattern is relatively fixed, and it is difficult to meet people's increasing aesthetic requirements. In order to improve the decorative effect of ceramic tiles, a slurry distributing method has appeared in recent years. This distributing method is to increase the h...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): B28B13/02

Inventor 武桢

Owner KEDA INDUSTRIAL GROUP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com