Feeding device for drill rod production and feeding method thereof

A drill pipe and drill pipe box technology, used in conveyor control devices, loading/unloading, transportation and packaging, etc., can solve problems such as decreased feeding efficiency, chaotic transfer, and crowded joints to ensure stability and prevent tilting. , to ensure the effect of consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] In order to enable those skilled in the art to better understand the technical solutions in the present invention, the technical solutions in the embodiments of the present invention are clearly and completely described below in conjunction with the accompanying drawings:

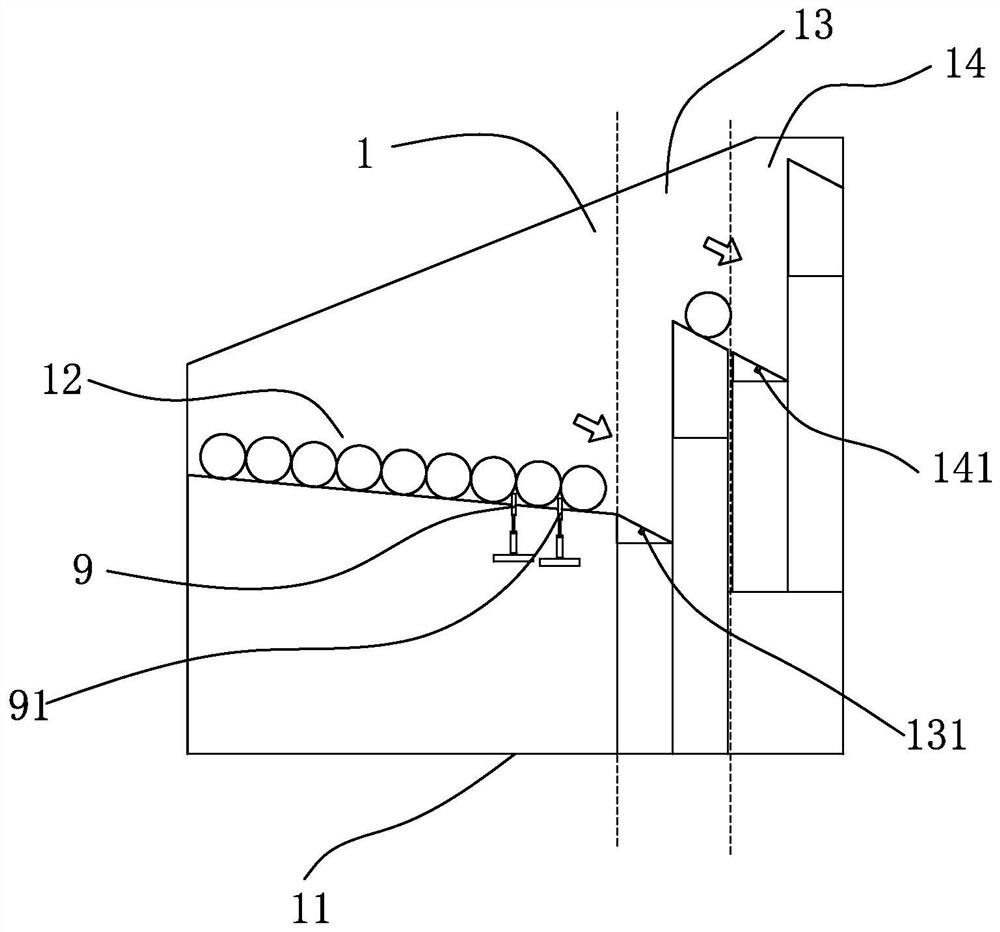

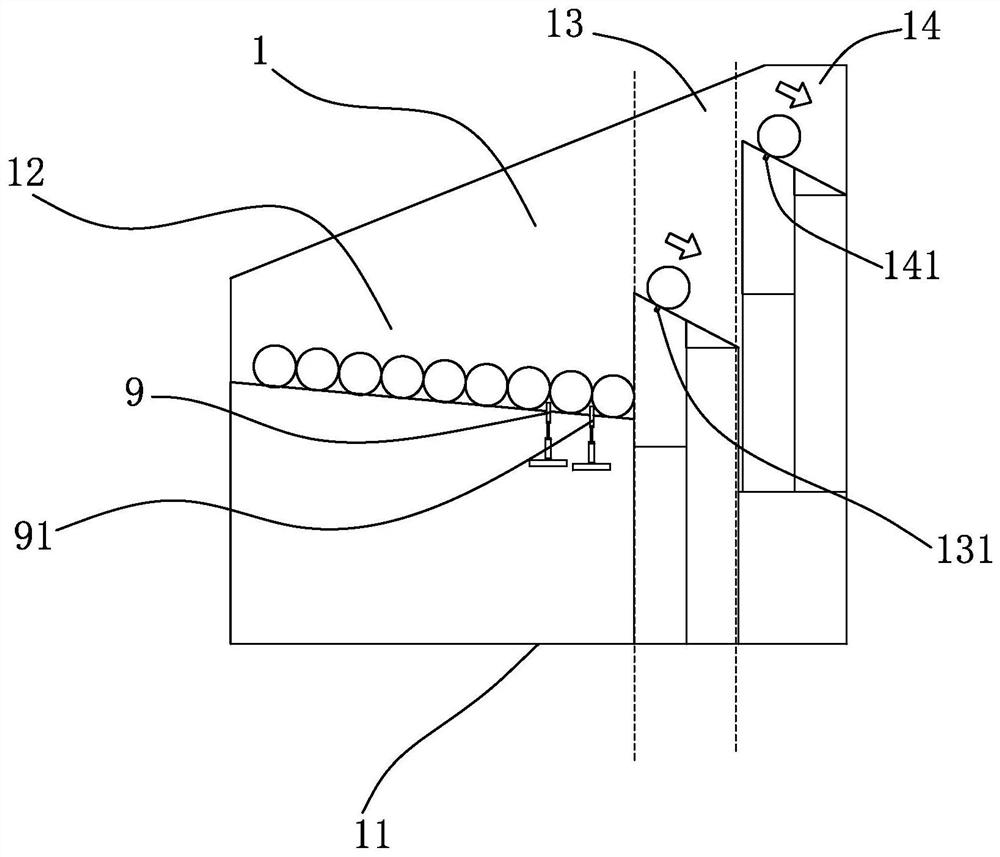

[0042] refer to figure 1 , figure 2 , a feeding system for drill pipe production, including a base plate 11 and side plates 1 oppositely arranged on both sides of the base plate 11, a drill rod box 12 is set on the base plate 11, and a stepped feeding mechanism is set on the side plate 1. The bottom of the drill rod box 12 is inclined towards the stepped feeding mechanism. The drilling rod box 12 is provided with limited drilling, including a first movable plate 9 and a second movable plate 91, the first movable plate 9 is located between the penultimate raw material and the penultimate raw material, and the second movable plate 91 is located Between the penultimate raw material and the last raw m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com