Rapid bonding equipment and method for gasket of flexible printed circuit of inductor

A bonding equipment and sensor technology, applied in chemical instruments and methods, metal processing equipment, lamination devices, etc., can solve the problems of slow bonding speed, small size of sponge gasket, and inability to guarantee the bonding quality, etc., to achieve Enhance the lamination effect, save lamination time, and accelerate the effect of drying and curing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

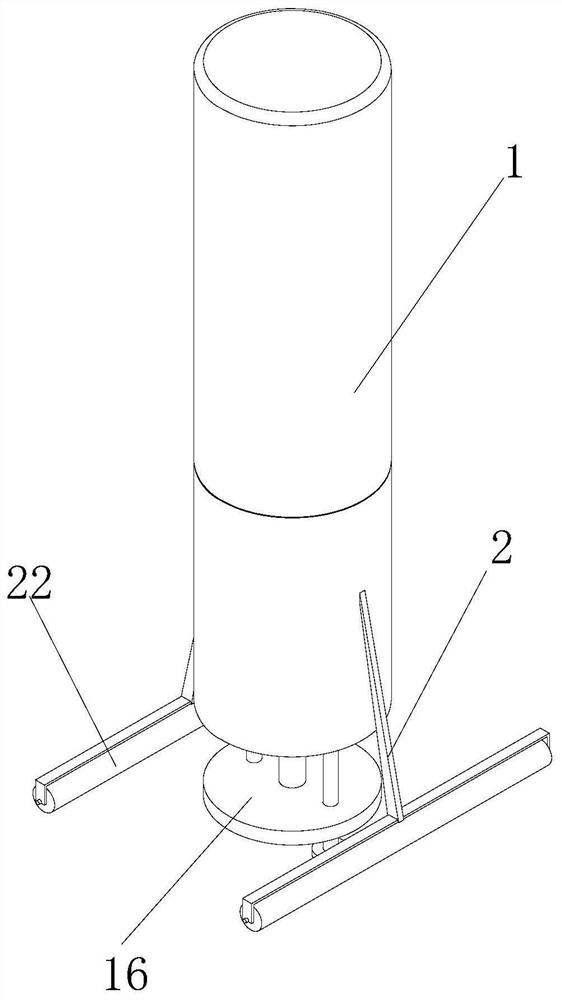

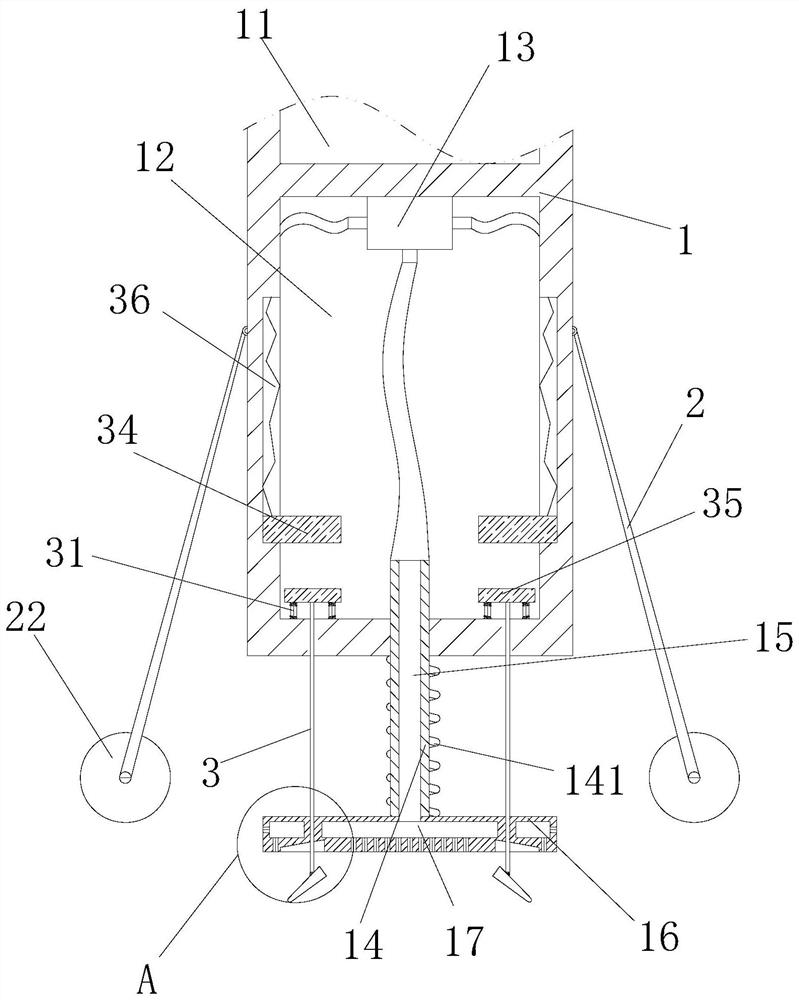

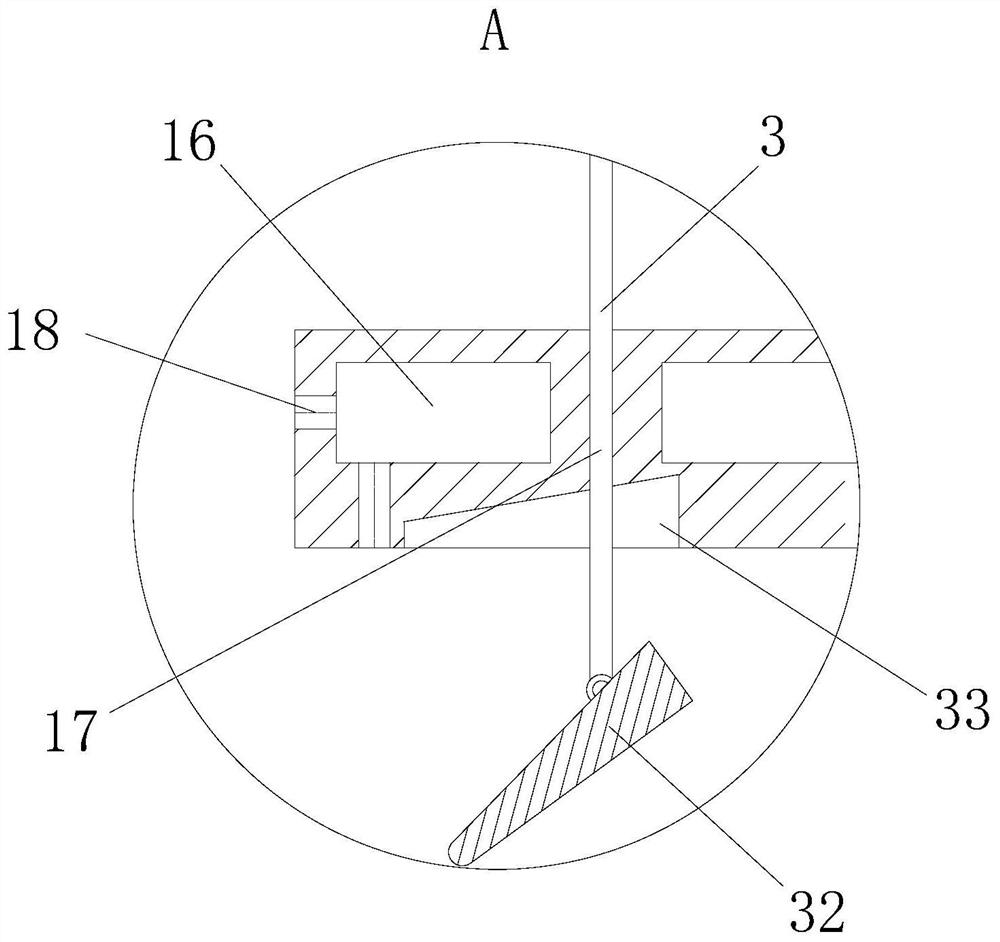

[0034] As an embodiment of the present invention, the first connecting post 14 is covered with a first spring 141, and the top end of the first connecting post 14 extends through the housing 1 into the first cavity 12; the first spring One end of 141 is affixed to the bottom of the housing 1, and the other end is affixed to the top of the suction cup 16; the side wall of the housing 1 is hinged with a bracket 2, and the hinge point is provided with a torsion spring; the bottom of the bracket 2 Both side walls are rotatably connected with a first rotating shaft 21; a pair of first rotating shafts 21 are fixedly connected with a pressure wheel 22; during work, after the sucker 16 absorbs the sponge gasket and fits it, press down Housing 1, at this time the first connecting column 14 shrinks under the action of the first spring 141, at this time the pressure wheel 22 is in contact with the sponge gasket, and the housing 1 continues to be pressed down, at this time the pressure whe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com