Method for tunnel smooth blasting drill construction

A construction method and smooth blasting technology, which is applied to drilling equipment and methods, blasting, tunnels, etc., can solve problems such as increased project cost, increased slag output and lining amount, unfavorable downstream processes, etc., and avoid stress concentration , reduce the secondary disturbance, and ensure the effect of construction safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to make the object, technical solution and advantages of the present invention more clear, the present invention will be further described in detail below in conjunction with the examples. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

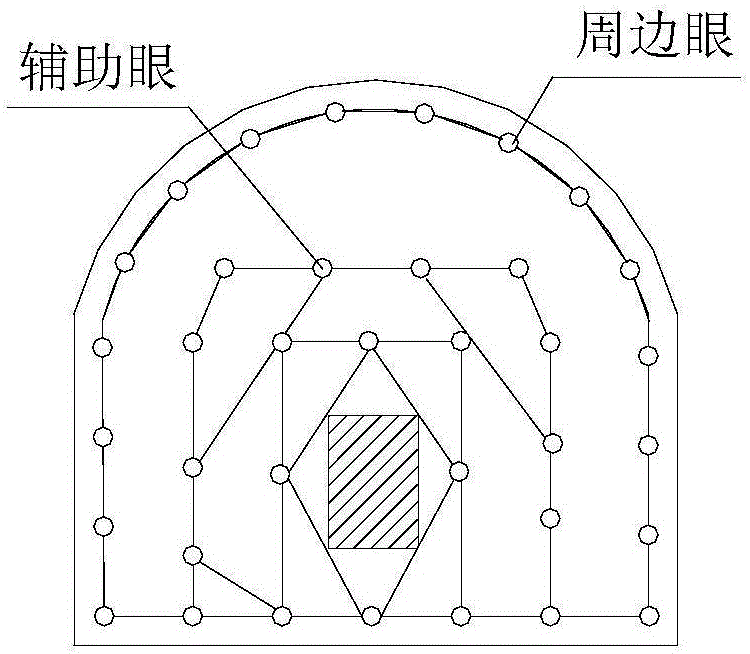

[0017] Such as figure 2 As shown in the figure, construction preparations are carried out for smooth blasting blasthole layout: along the contour line of the tunnel arch, the blastholes are arranged circle by circle. Mark the positions of the cut holes and peripheral holes, and drill holes in strict accordance with the design position, depth, angle and diameter of the blast hole. Among them, the angle of the blast hole is particularly important, which directly affects the effect of smooth blasting. The control of the blast hole angle is controlled by the "drilling rig direction controller".

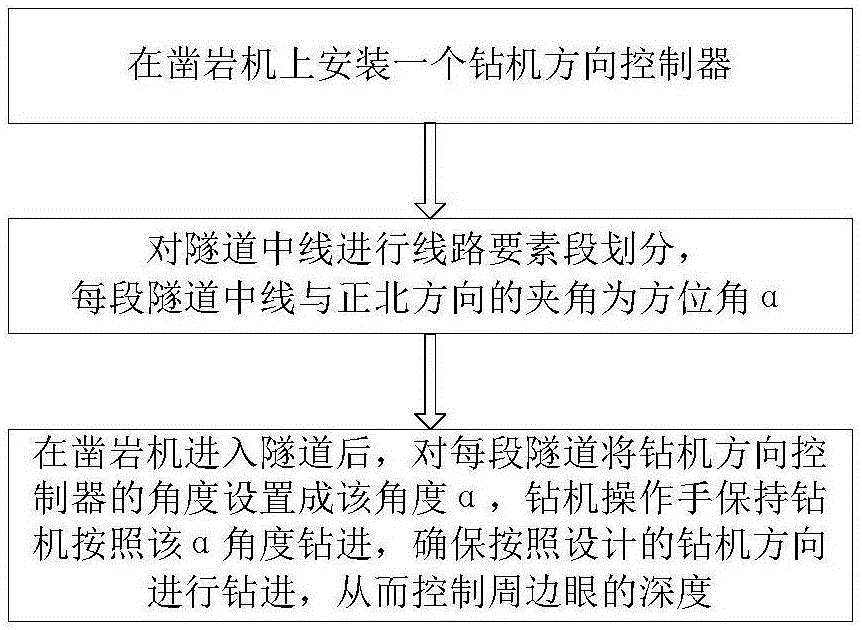

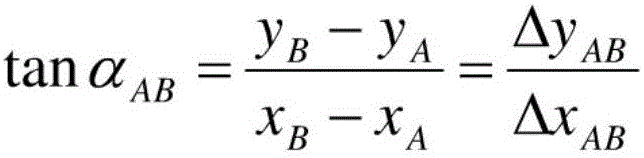

[0018] Such as figure 1 Sho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com