Faceplate assembly line

An assembly line and panel technology, applied in the field of automated assembly, can solve the problems of defective products, low efficiency, and misalignment, and achieve the effect of ensuring effective separation, improving production efficiency, and ensuring product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0038] In order to facilitate the understanding of those skilled in the art, the present invention will be further described with reference to the accompanying drawings.

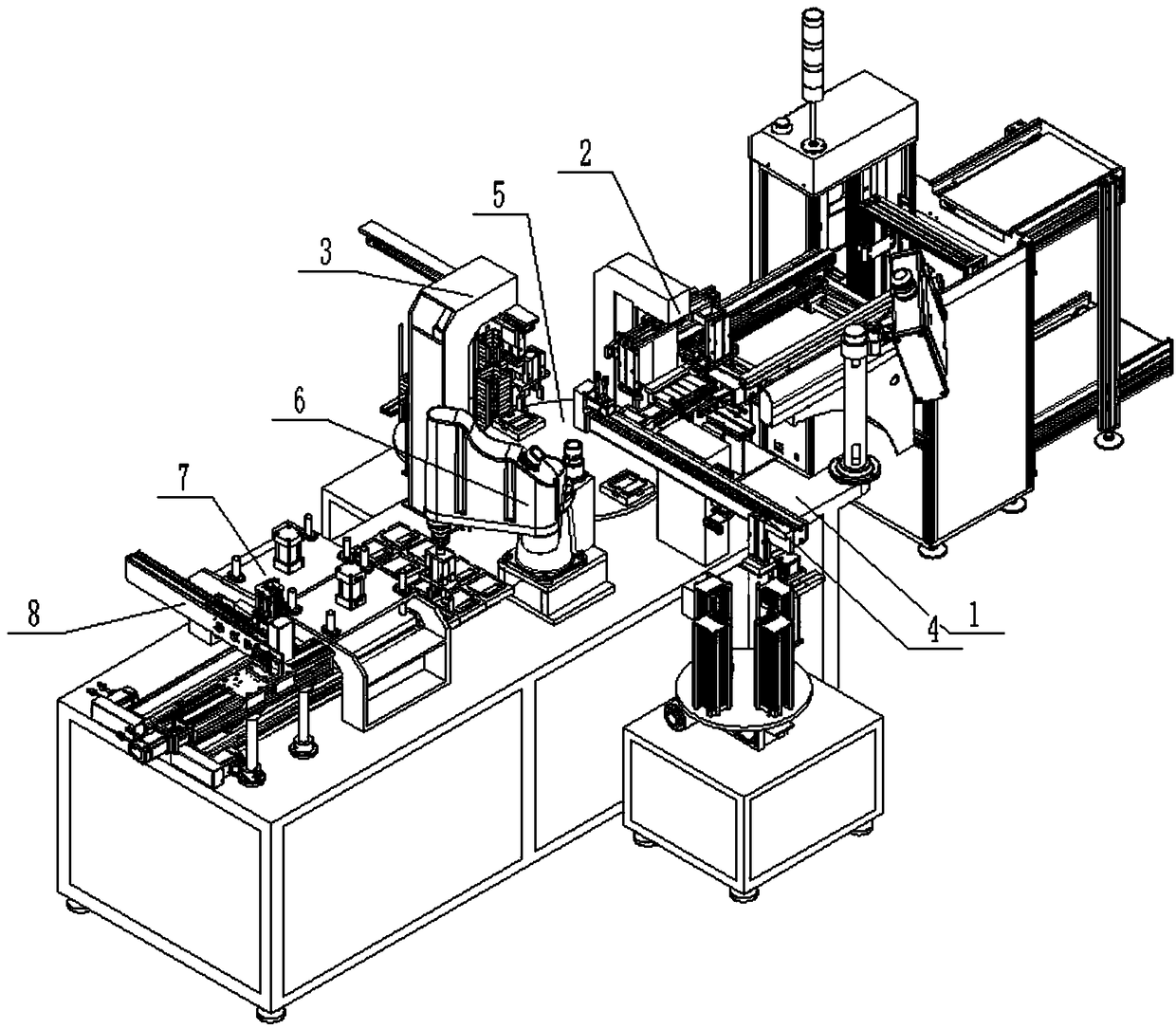

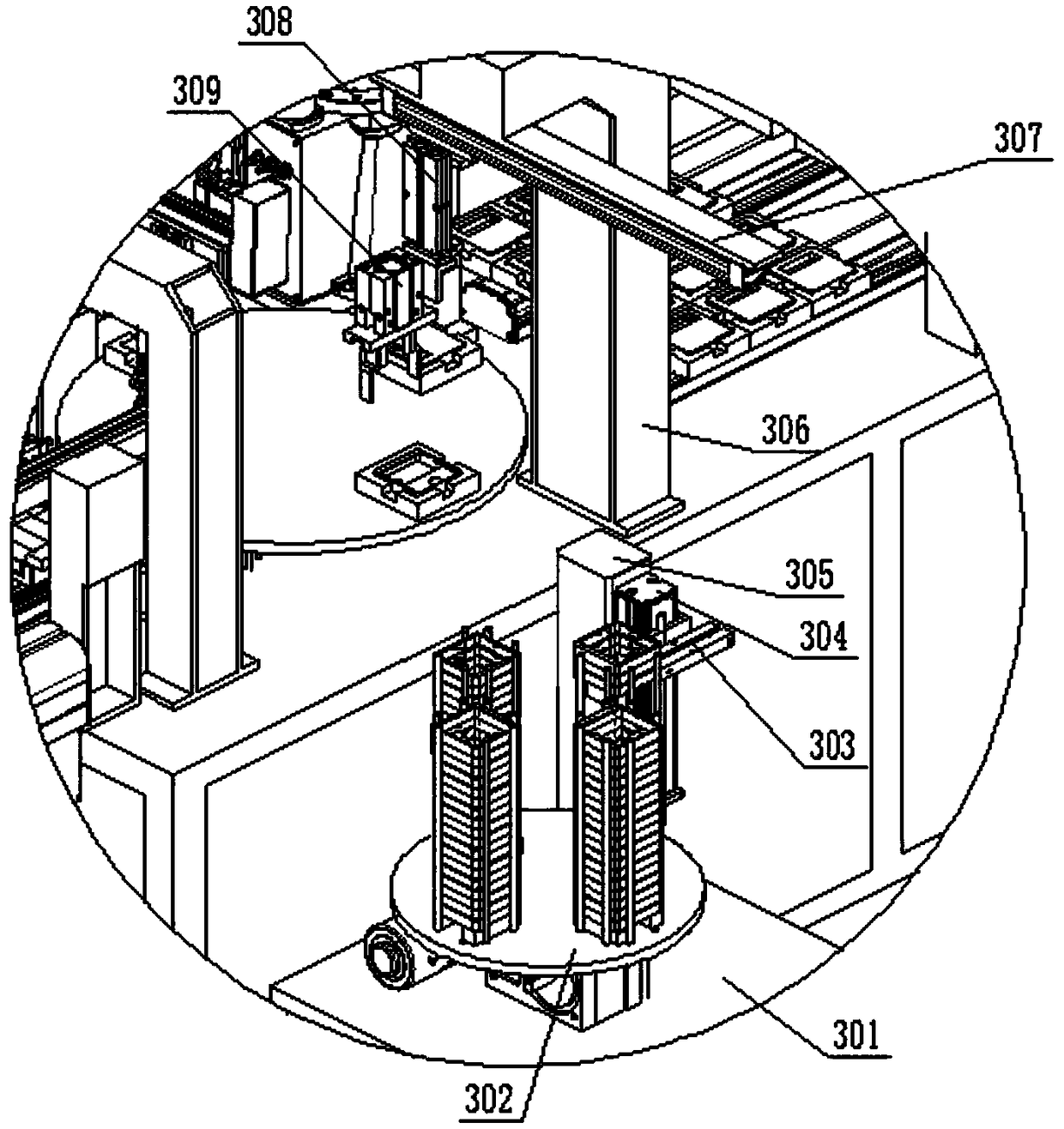

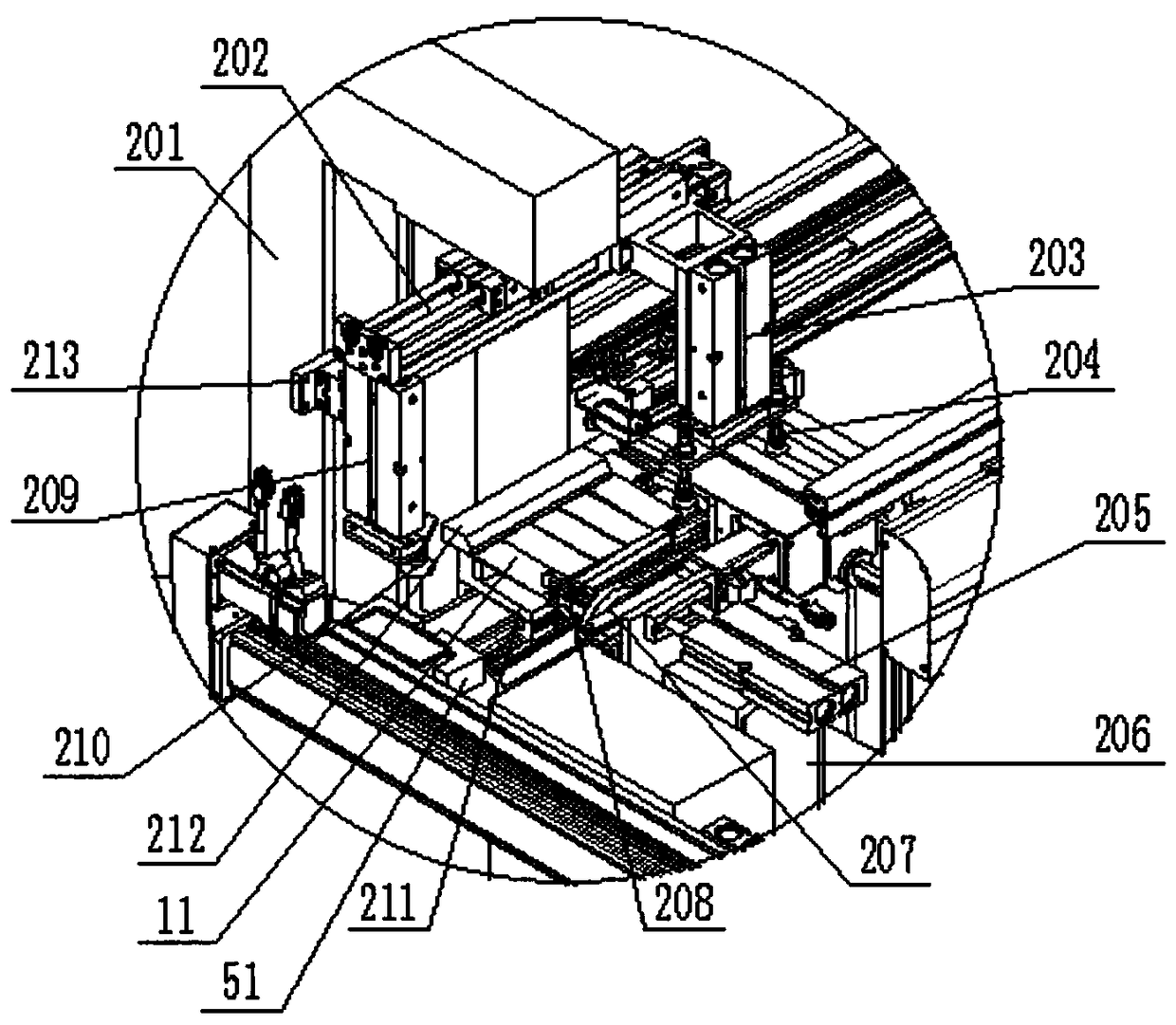

[0039] Such as Figure 1 to Figure 6 As shown, a panel assembly line includes a workbench 1, a multi-station turntable 5 is provided on the workbench 1, four assembly tooling tables 51 are provided on the multi-station turntable 5, and the assembly tooling table 51 is convenient for manipulator claw placement. A symmetrical concave platform 52 is provided for the material. The multi-station turntable 5 of the present invention is provided with a shell feeding device 3, a PCB board feeding device 2, a film feeding device 4, and a feeding device in sequence, through the shell feeding device 3 Realize the transfer of the shell to the assembly tooling table 51, the multi-station turntable 5 rotates to the PCB board feeding device 2, the PCB board 11 is installed on the shell 10, the multi-station turntable 5 rotate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com