Production method of flexible circuit board

A flexible circuit board and manufacturing method technology, applied in the directions of printed circuit manufacturing, printed circuits, electrical components, etc., can solve problems such as tearing flexible circuit boards, and achieve the effect of convenient maintenance of molds

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Flexible circuit boards are generally formed by bonding and fixing a layer of copper foil on one side of the base film, and then bonding and fixing a layer of cover film on the top of the copper foil. This technology is an existing technology. Therefore, it will not be described in detail here.

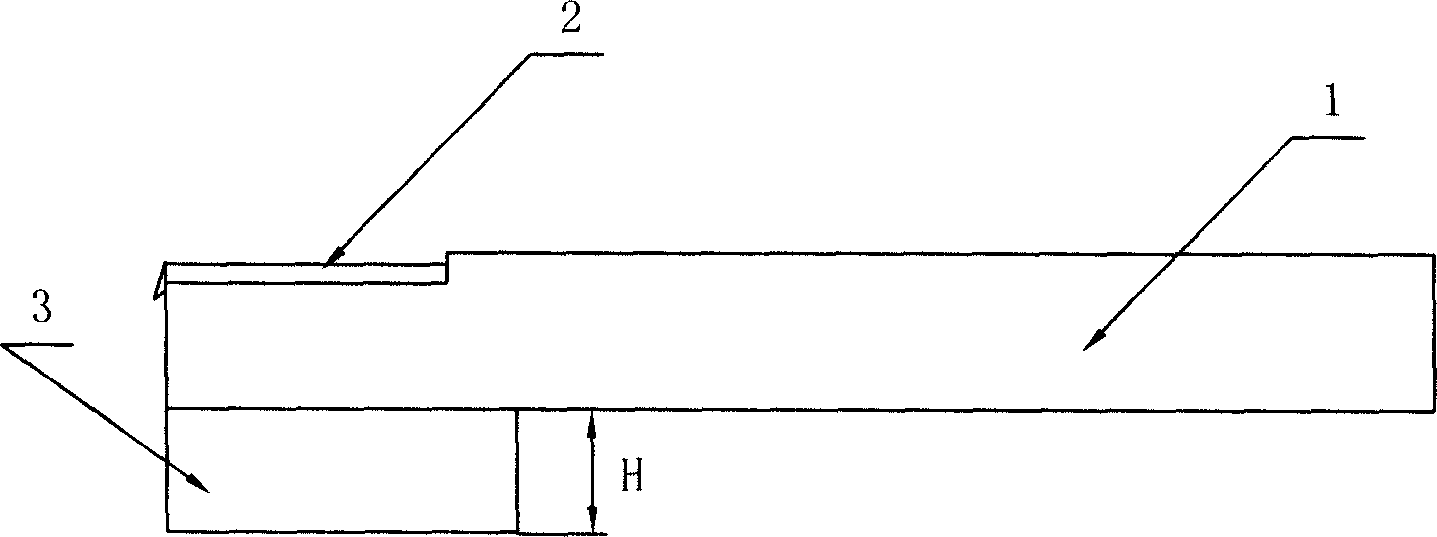

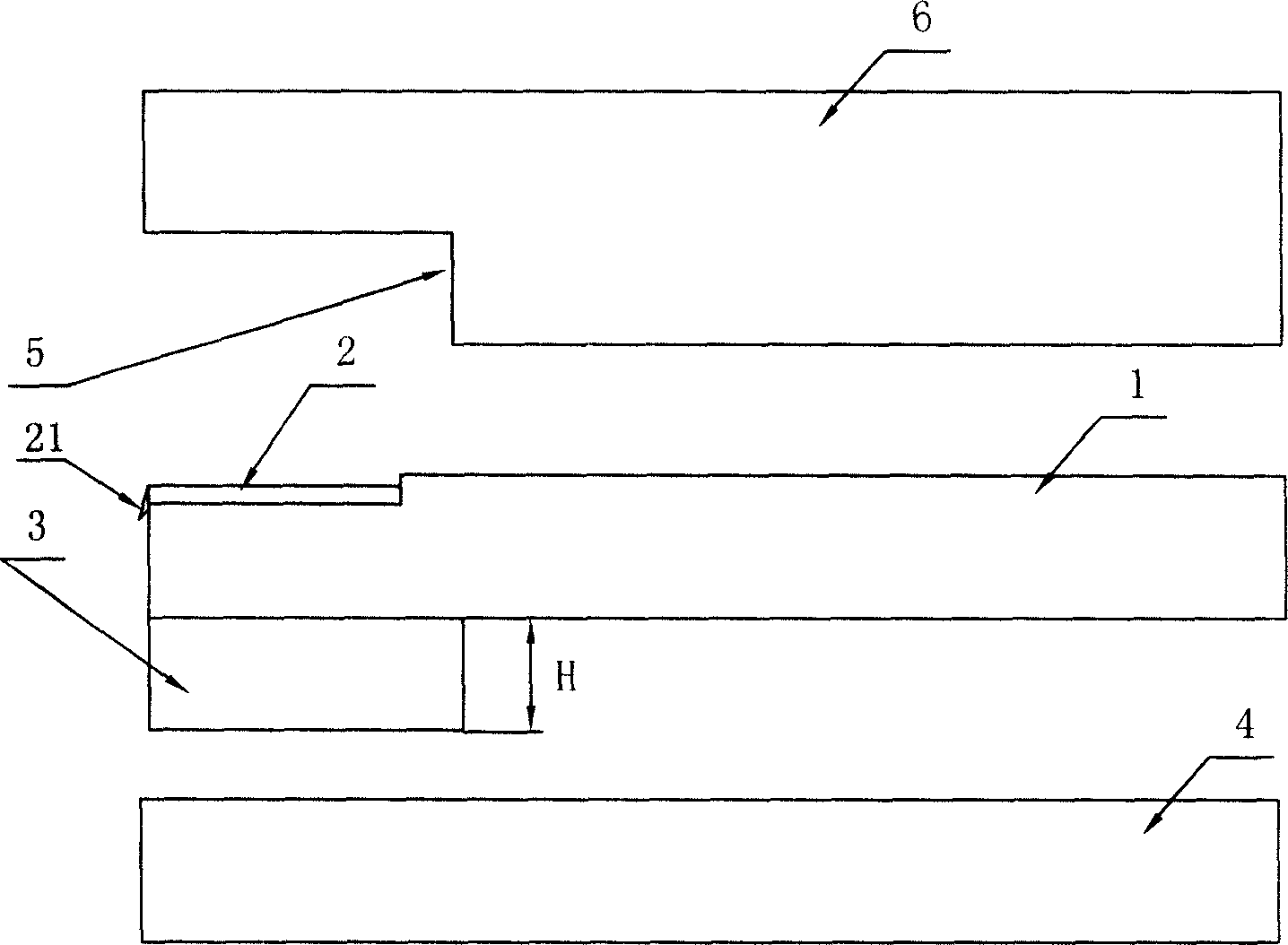

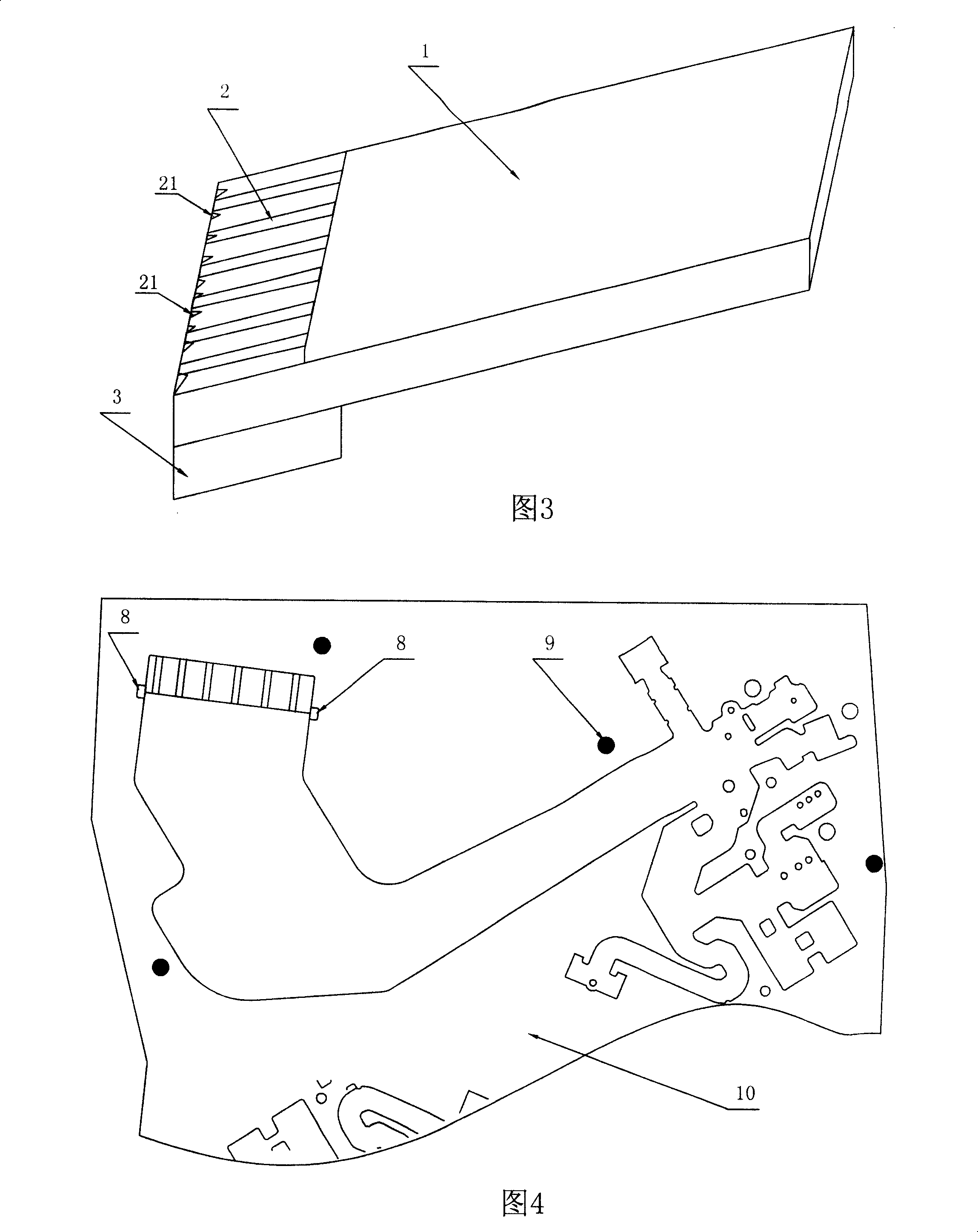

[0016] The invention relates to a method for manufacturing a flexible circuit board, which relates to a method for manufacturing a flexible circuit with a reinforcing plate 3 on the back of the golden finger 2 of the flexible circuit board 1. Board 10 (please refer to FIG. 4, generally a small connecting board with a plurality of flexible circuit board products arranged according to a certain rule) forms a gold finger part 2 on one side of each flexible circuit board 1 correspondingly; The second step is the process of pasting the reinforcing plate, that is, attaching the reinforcing plate 3 on the other side of each flexible circuit board 1 opposite to the gold finger 2; the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com