Wave detector embedding machine

A technology of a geophone and a vibration excitation mechanism, which is applied to rotary drilling rigs, seismic signal receivers, drilling equipment and methods, etc. To achieve integrated operation and other issues, to achieve the effect of easy and reliable guarantee of verticality, light weight and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

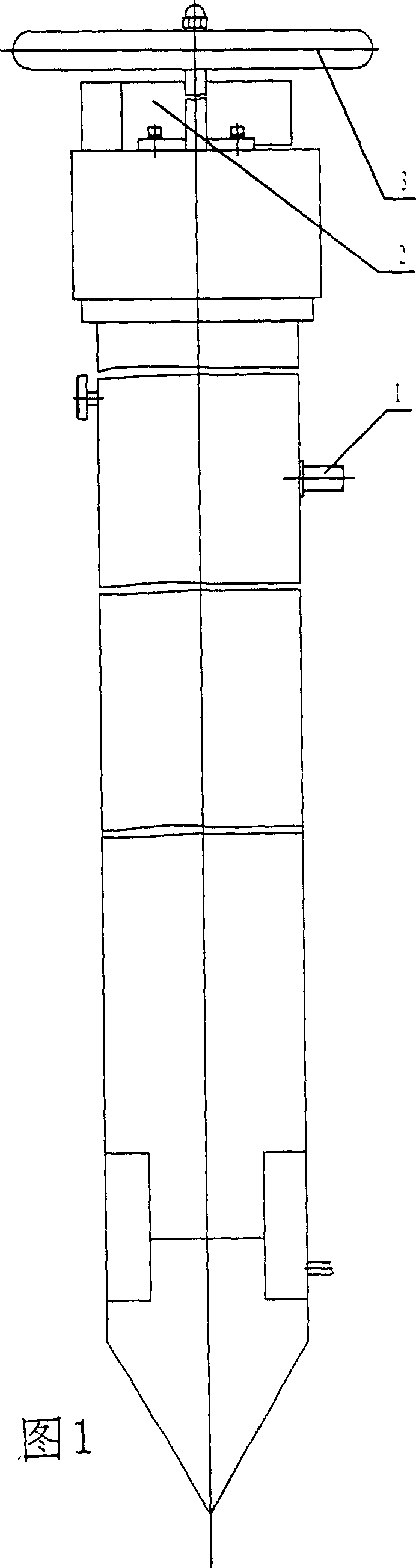

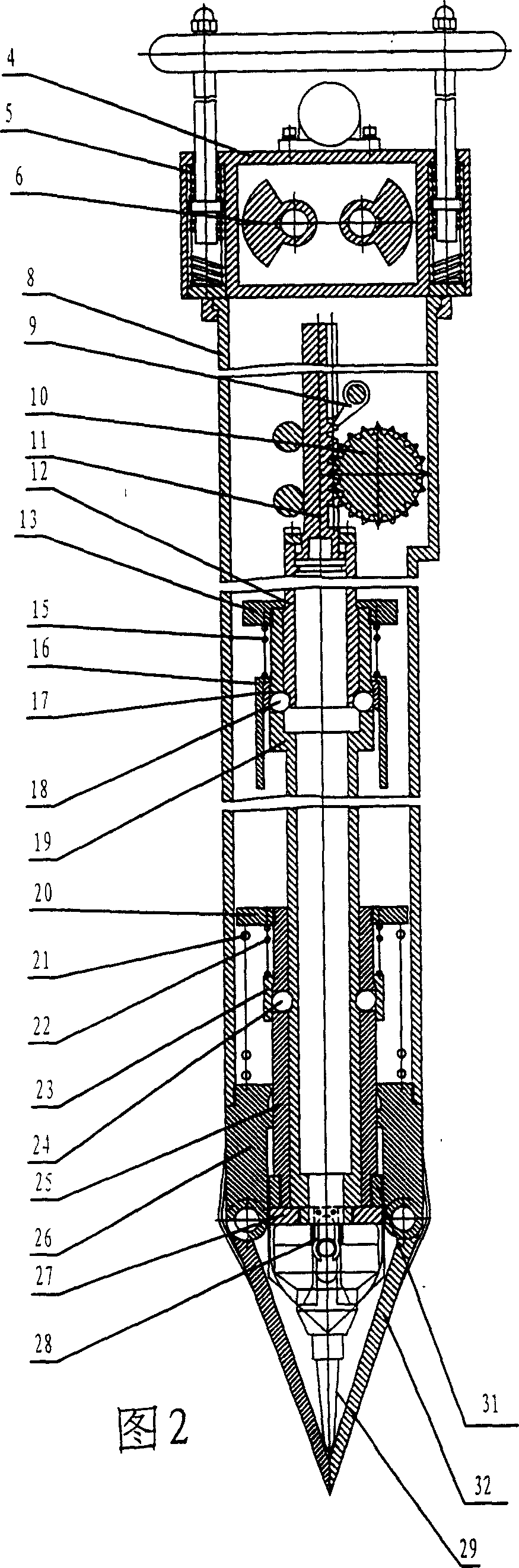

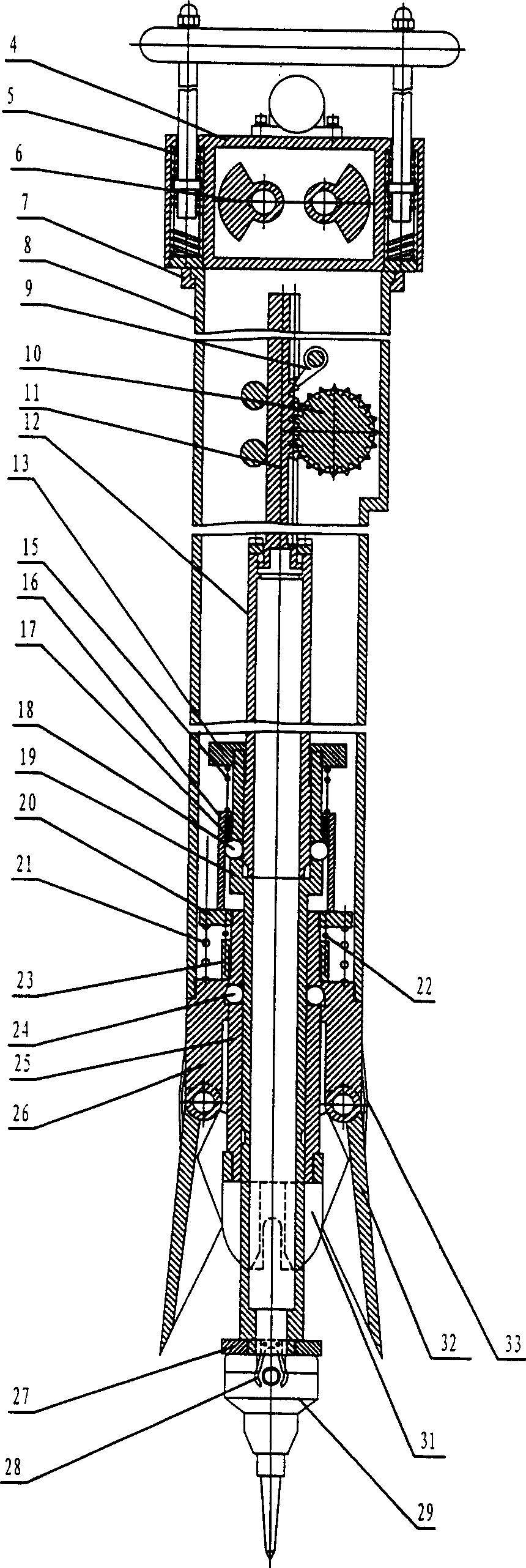

[0022] Referring to Fig. 1, the geophone embedding machine of the present invention includes a housing 8, a hand-held frame 3 is installed at the upper end of the housing 8, and an impact cone is arranged at the lower end, and the cone head opening and closing export mechanism located in the housing, the drive opening Close the driving mechanism of the export mechanism and the rebound control mechanism of the export mechanism.

[0023] When the geophone is embedded deeply, a suspended vibration excitation mechanism that can generate vertical vibration is installed on the upper end of the housing 8, and the hand-held frame is installed on the vibration excitation mechanism through a spring, which can reduce the impact of vibration on the human body.

[0024] The function of the suspended vibration excitation mechanism is to generate vibration, including an excitation body 4, a power machine 2 installed on the vibration body 4, two symmetrically placed eccentric bodies 6 and The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com