Device for controlling multi-hole type punching and bolt implanting accuracy of tunnel

A precision control, multi-hole technology, applied in the direction of drilling/drilling equipment, manufacturing tools, striking tools, etc., can solve the problems of low drilling and bolting precision, achieve simple structure, significant effect, and prevent offset Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described through specific embodiments below in conjunction with the accompanying drawings.

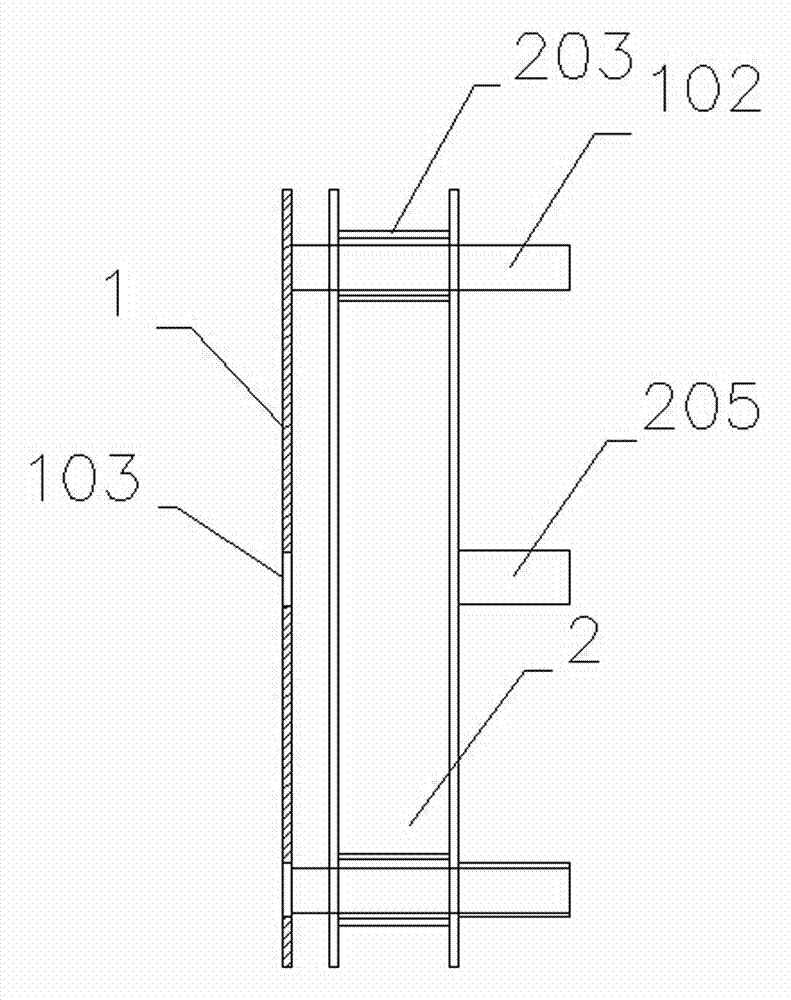

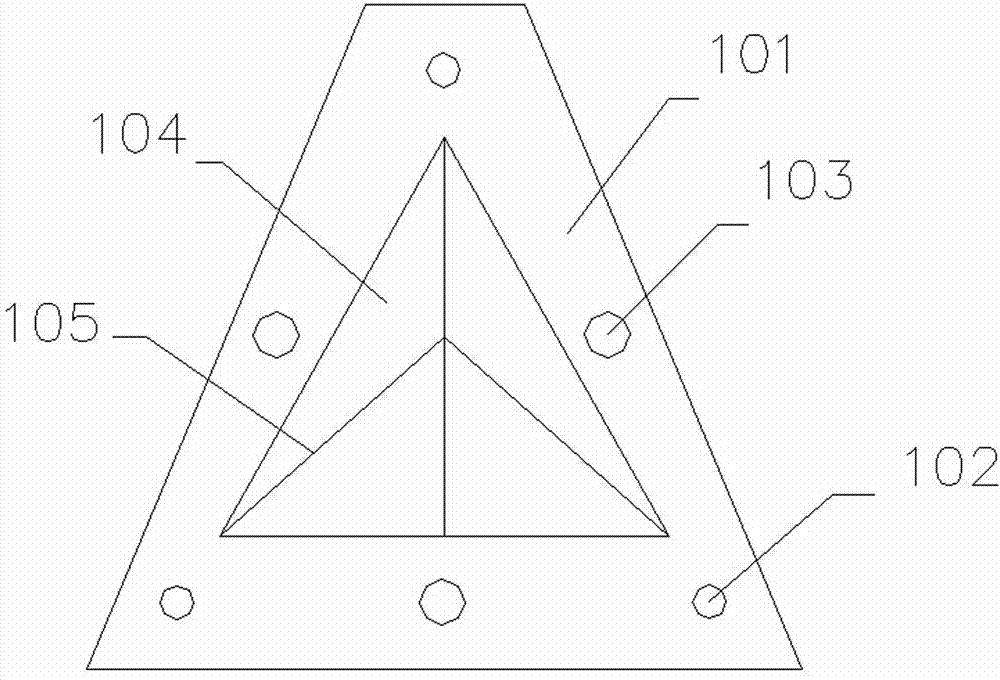

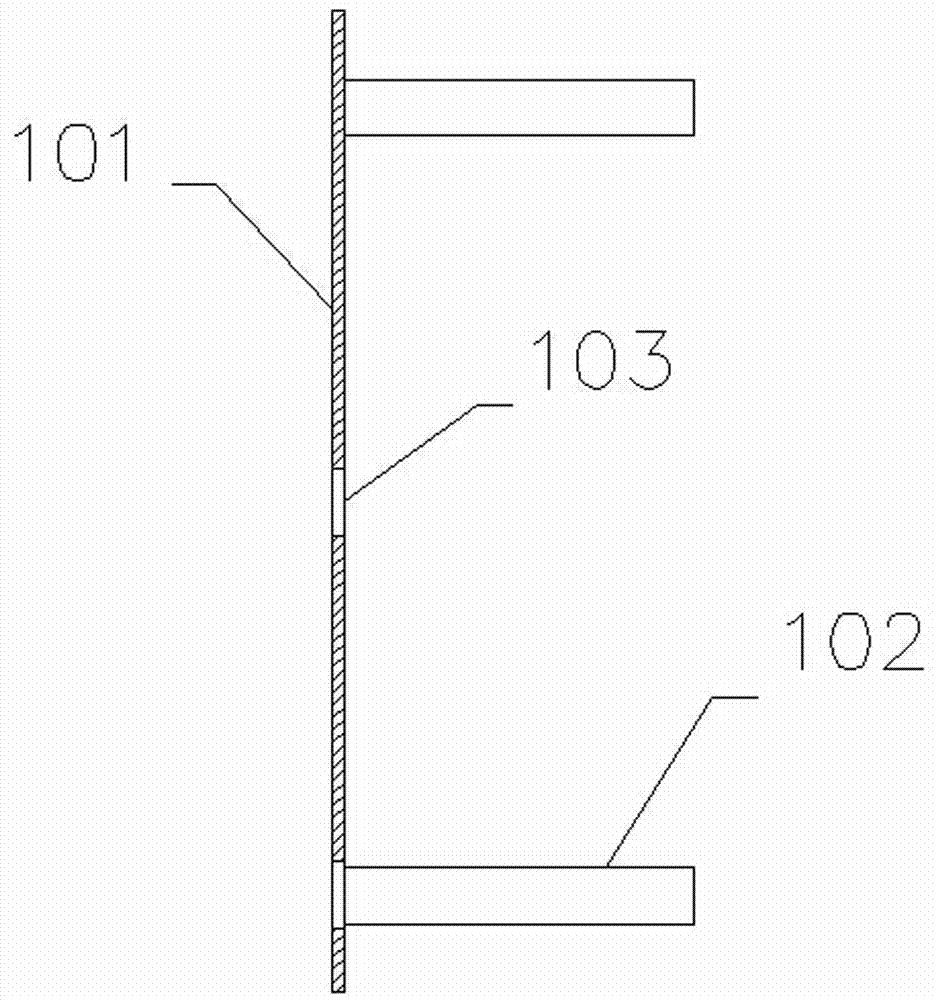

[0023] A multi-hole punching and bolting precision control device for tunnels, which is used for the precision control of the drilling and bolting process before installing the porous flange base. The bottom of the porous flange to be installed is an isosceles trapezoid with three holes , the precision control device is composed of device I1 and device II2, and the shape and size of the orthographic projection of device I1 and device II2 are the same as the shape and size of the porous flange base to be installed, and they are all equal-sized isosceles trapezoids, Wherein, the device I1 is a flat plate 101 made of a steel plate. A triangular opening I104 is opened in the center of the flat plate 101. In the opening I104, a plurality of auxiliary rods I105 intersecting at the same point are welded. The point is the auxiliary center, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com