Cold extrusion combination type reducing reinforcing steel bar connection device and method

A connection equipment and composite technology, which is applied in the field of steel bar connection, can solve the problems of manpower occupation and low efficiency of connecting steel cages, and achieve the effects of improving efficiency, saving manpower, and ensuring connection strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

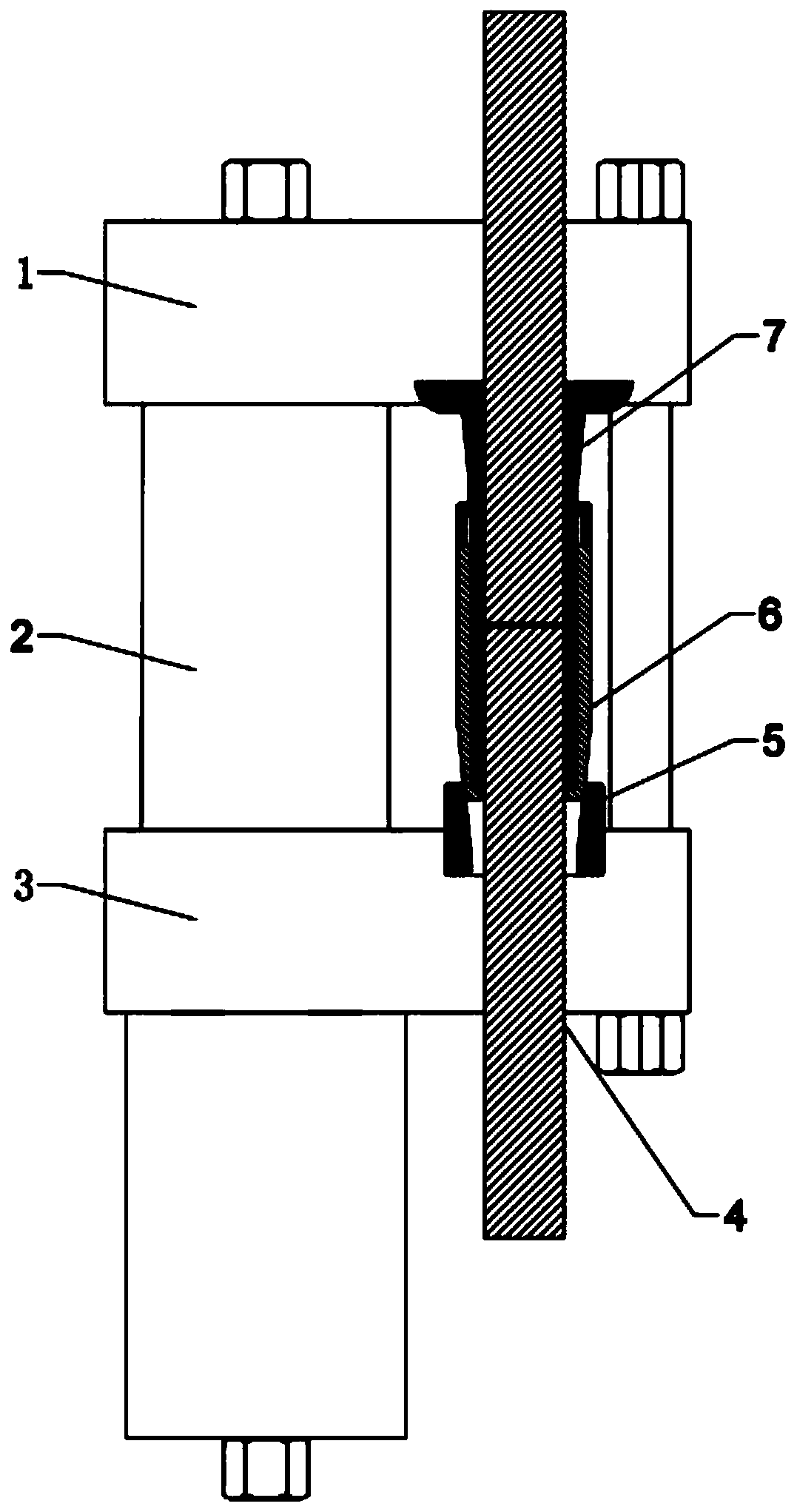

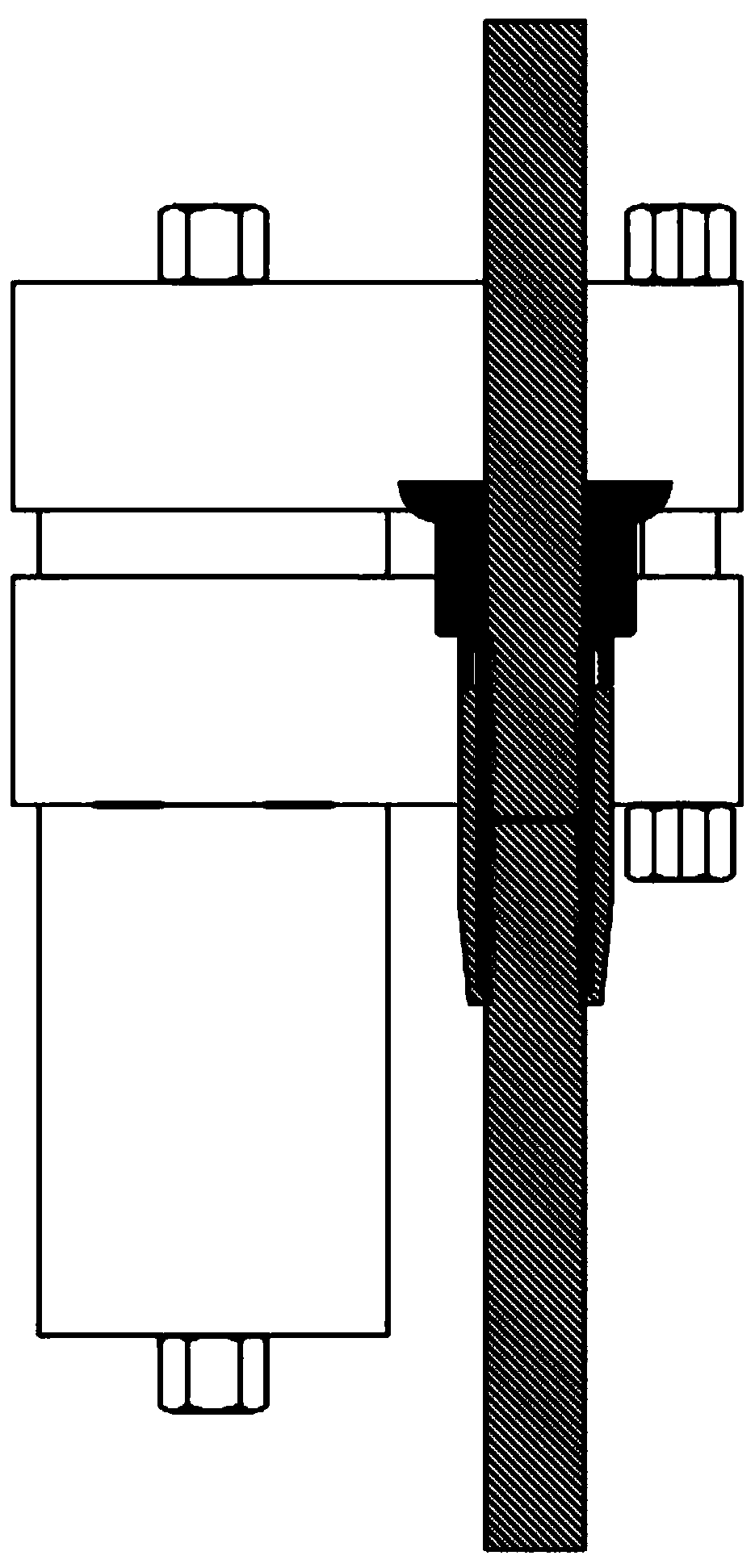

[0029] A rebar 4 connection device such as figure 1 As shown, it includes a bracket, an extrusion assembly and a connecting workpiece 6; the support is provided with a steel bar fixing structure, the extrusion assembly is installed on the bracket, and the extrusion assembly includes a first extrusion tooling 7, a second extrusion Press tooling 5 and extruding device; The connecting workpiece 6 is placed on the second extrusion tooling 5, and the first extrusion tooling 7 and the second extrusion tooling 5 are all provided with through holes for the steel bar 4 to pass through. The connection workpiece 6 is a hollow structure with openings at both ends, and the inner wall of the connection workpiece 6 is provided with an internal thread: the first extrusion tool 7 and the second extrusion tool 5 cooperate to extrude the connection workpiece 6 through an extrusion device, A balance structure is provided in the middle of the connecting workpiece 6 .

[0030] In order to prevent ...

Embodiment 2

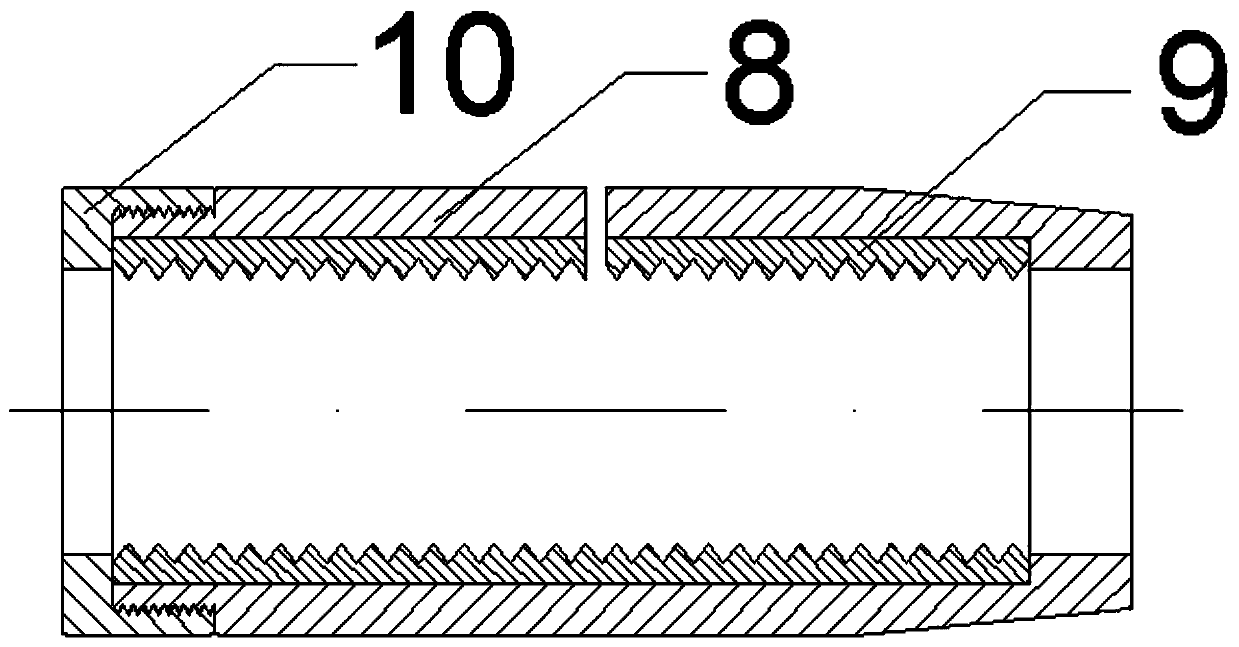

[0035] Improvements are made on the basis of Example 1. In order to avoid excessive deformation of the connecting workpiece 6 after extrusion and affect the connection effect of the steel bar 4, the connecting workpiece 6 includes an outer sleeve 8 and an inner sleeve 9, and the outer sleeve 8 and the inner sleeve 9 Both are hollow structures, the outer sleeve 8 is set on the outside of the inner sleeve 9, the inner wall of the inner sleeve 9 is provided with internal threads, and the deformation direction of the inner sleeve 9 is restricted by setting the outer sleeve 8, so that the connecting workpiece 6 is subjected to After being squeezed, the inner sleeve 9 is mainly deformed inward, so that the inner thread engages with the steel bars 4 so as to connect and fix the two steel bars 4 .

[0036]Specifically, the balance structure includes a screw, and the middle part of the outer sleeve 8 and the inner sleeve 9 is provided with a matching opening, and the opening communicate...

Embodiment 3

[0038] Improvements are made on the basis of Example 2. Further, in order to facilitate the extrusion of the connecting workpiece 6, the connecting workpiece 6 includes a positioning sleeve 10, and the middle part of the positioning sleeve 10 is provided with a through hole for the steel bar 4 to pass through. The positioning sleeve 10 is threadedly matched with the outer sleeve 8, and the positioning sleeve 10 is installed on the end of the outer sleeve 8 away from the second extruding tool 5.

[0039] Further, in order to fix the position of the inner sleeve 9 and ensure that the inner thread extrudes the steel bar 4 when the inner sleeve 9 is deformed, a step is provided on the side of the outer sleeve 8 close to the second extrusion tooling 5, and one end of the inner sleeve 9 Against the step, the other end of the inner sleeve 9 abuts on the positioning sleeve 10 , and the outer wall of the inner sleeve 9 is attached to the inner wall of the outer sleeve 8 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com