Self-tightening half grouting sleeve connecting piece

A semi-grouting sleeve, self-tightening technology, applied in building components, building reinforcements, structural elements, etc., can solve the problems of low production efficiency of housing construction technology, inability to meet the rigid requirements of housing, and high labor intensity of workers. The effect of reducing the amount of grouting, increasing the fault tolerance and increasing the strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention is described in detail below in conjunction with accompanying drawing and embodiment:

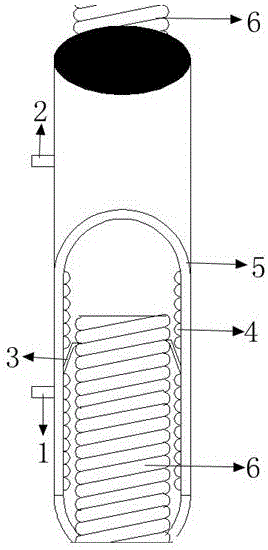

[0022] Self-tightening semi-grouting sleeve connectors, such as figure 1 As shown, its composition includes a grouting port 1, a grouting port 2, a paddle 3, a thread 4, a sleeve 5 and a steel bar 6, the diameter of the sleeve 5 is greater than the diameter of 6 steel bars, and the inner wall of the sleeve 5 is provided with a thread 4, The lower part of the sleeve 5 is provided with a grouting port 1 , the upper part of the sleeve 5 is provided with a grouting port 2 , and a paddle 3 is provided between the grouting port 1 and the grouting port 2 on the inner wall of the sleeve 5 .

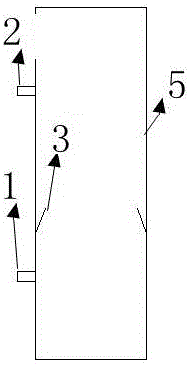

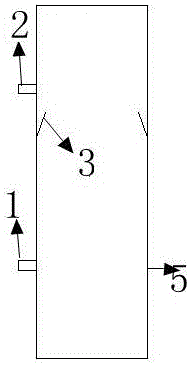

[0023] Such as figure 2 and image 3 As shown, the plectrum 3 is divided into upper and lower layers, the upper layer includes two plectrums 3 and is located on the left and right sides of the inner wall of the sleeve 5 respectively, and the lower layer includes two plectrums 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com