Prefabricated thin plate laminated type floor connector and manufacturing method and construction method thereof

A technology of connectors and thin plates, which is applied in the field of prefabricated thin-slab laminated floor connectors, can solve problems such as insufficient bonding force of the laminated surface, and achieve the effects of light weight, good adhesion, and convenient engineering application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to further illustrate the present invention, the present invention will be described in detail below in conjunction with the accompanying drawings and embodiments, but they should not be construed as limiting the protection scope of the present invention.

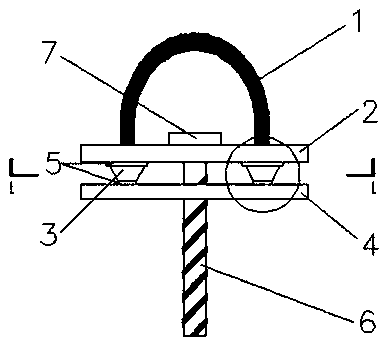

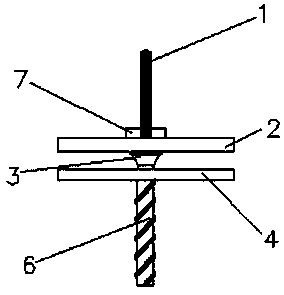

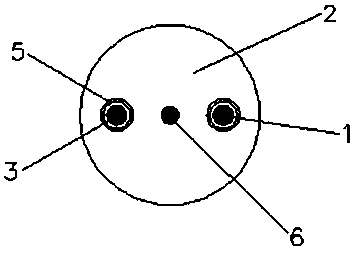

[0033] Such as figure 1 , 2 As shown, the prefabricated thin plate superimposed floor connector of the present invention includes a U-shaped light round steel bar 1, a baffle plate 2, a base 4 and a screw rod 6, the baffle plate and the base are arranged up and down in sequence, and a round table nut is arranged between the baffle plate and the base 3. Such as Figure 4 As shown, the outer surfaces of the two ends of the U-shaped light round steel bar 1 are provided with threads, and the two ends pass through the holes on the baffle and are threadedly connected with the round truncated nuts. The truncated cone nut 3 is a truncated cone with a wide top and a narrow bottom, and the nut is fastened with a th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com