Synthesis reactor and device and method for synthesizing methylhydrazine by chloramine process

A technology for synthesizing reactors and methylhydrazine, which is applied in chemistry/physics/physicochemical fixed reactors, hydrazine preparation, organic chemistry, etc., can solve the problems of excessive three wastes, high energy consumption, and low yield, and achieve three wastes Low energy consumption, high yield and high selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

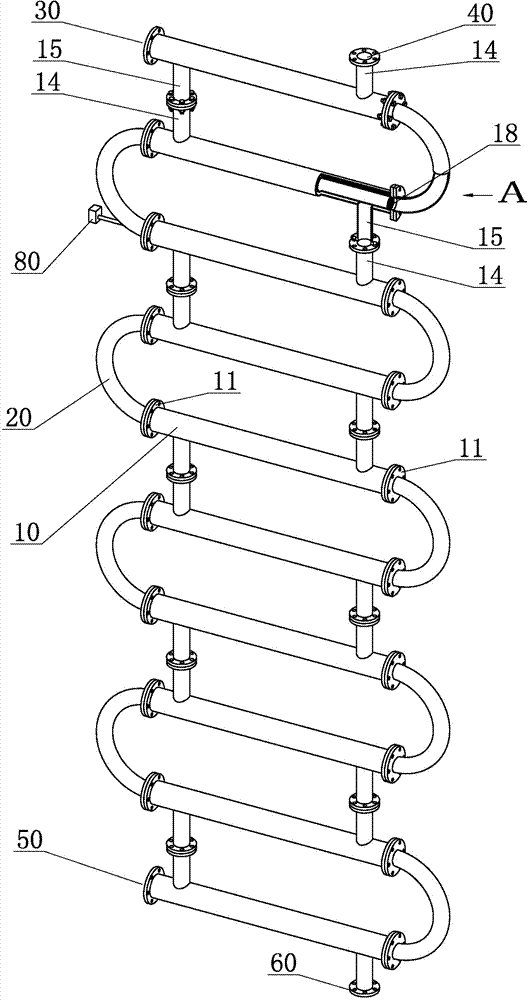

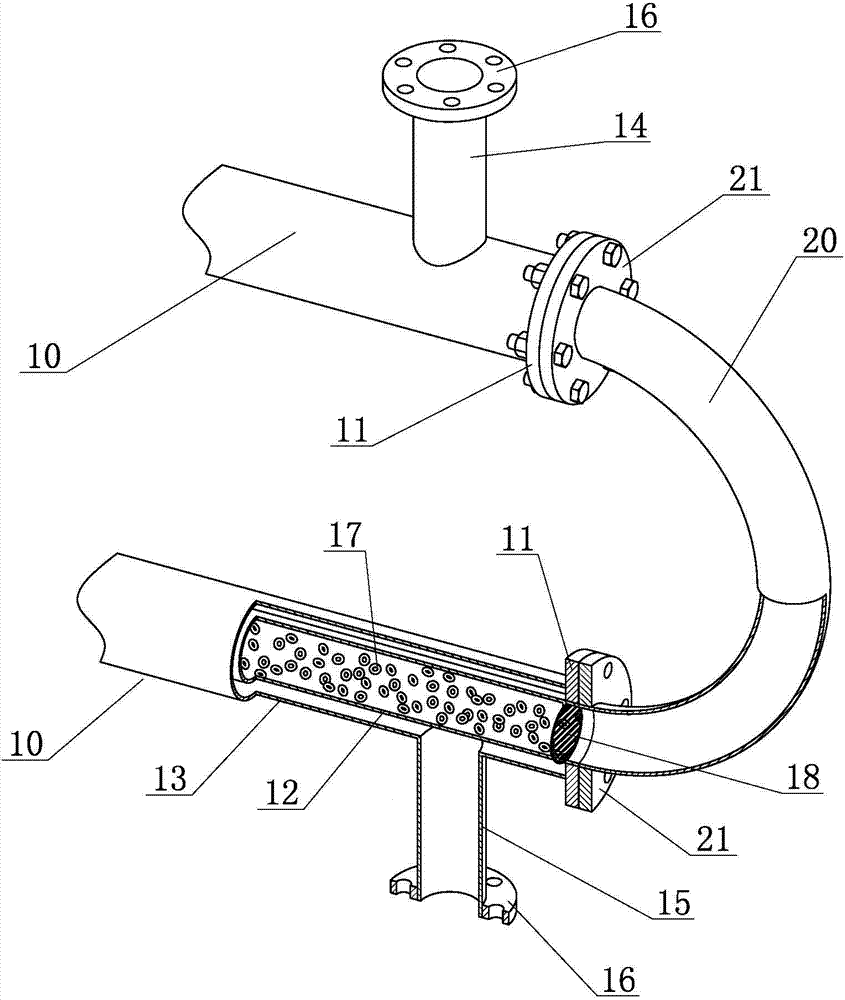

[0051] Embodiment one, a kind of synthesis reactor, such as figure 1 , figure 2 .

[0052] Described synthesis reactor is provided with many jacketed pipes 10 and connecting elbow 20, is provided with the inner pipe 12 of flowing reaction medium and the outer pipe 13 outside the inner pipe in described jacketed pipe, the outer pipe 13 of jacketed pipe Both ends are provided with sealing flanges 11, forming a temperature-regulating medium flow space between the sealing flange and the inner and outer tubes of the jacket pipe, and the outer tube is provided with a temperature-regulating medium inlet pipe 14 and a temperature-regulating Medium outlet pipe 15; connecting flanges 21 are provided at both ends of the connecting elbow, and the two ends of the multiple jacketed pipes are connected end to end through connecting elbows, and one end of the jacketed pipe arranged in the first place is used as a composite The reaction medium inlet 30 of the reactor is arranged at one end ...

Embodiment 2

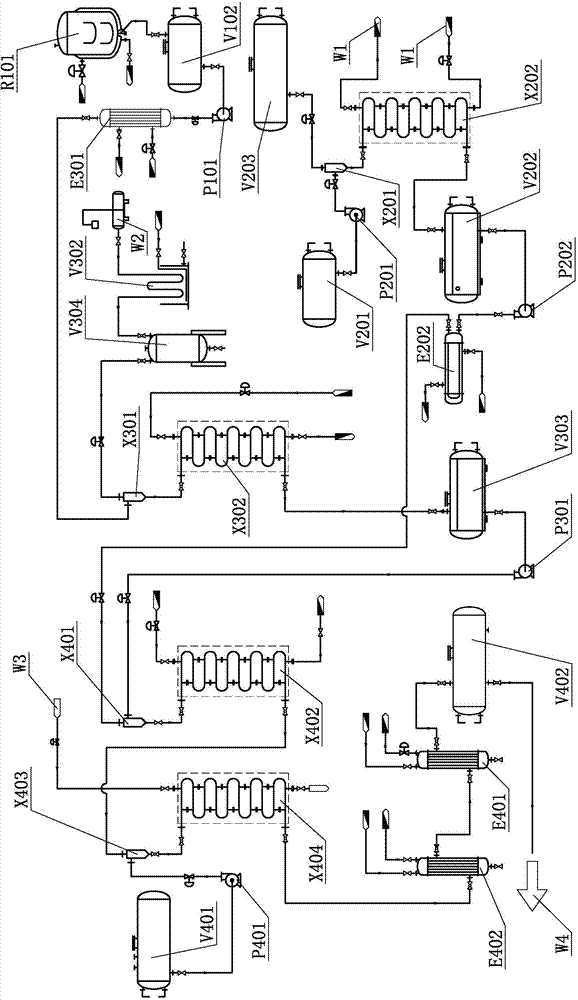

[0062] Embodiment two, a kind of chloramine synthesis methylhydrazine device, such as image 3 .

[0063] It includes an ammonia water preparation unit, a sodium hydroxide preparation unit, a sodium hypochlorite preparation unit, and a methylhydrazine generation unit; it is characterized in that:

[0064] The ammonia water preparation unit includes a liquid ammonia storage tank V203, an ammonia water mixing reactor X201, and an ammonia water preparation device X202. The ammonia water mixing reactor is provided with two input ports, and the liquid ammonia storage tank is connected to the The first input port of the ammonia water mixing reactor, the second input port of the ammonia water mixing reactor is connected to a soft water storage tank V201 through a pipeline provided with a valve and a pressurizing pump P201, and the ammonia water preparation device is the one described in embodiment one. A synthesis reactor, the inlet of the reaction medium of the ammonia water prepar...

Embodiment 3

[0072] Embodiment three, adopt the method for the device synthetic methylhydrazine described in embodiment two to comprise the following steps:

[0073] A. Preparation of ammonia water:

[0074] Mix liquid ammonia and soft water to prepare ammonia water with a mass concentration of 50-90%, and the reaction temperature is 0-60°C; this step is carried out in the ammonia water preparation unit described in Example 2;

[0075]The liquid ammonia from the liquid ammonia storage tank V203 and the soft water from the soft water storage tank V201 are pumped into the ammonia water mixing reactor X201 through the soft water pump P201 according to a certain ratio (mass concentration is 50-90%), and then enter the ammonia water preparation device X202, the mixing is exothermic. The jacketed cooling water of the ammonia water preparation device takes away the heat of the reaction, so that the system is maintained at about 0-60°C, and the configuration of ammonia water with different mass co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com