Patents

Literature

122 results about "Methylhydrazine" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

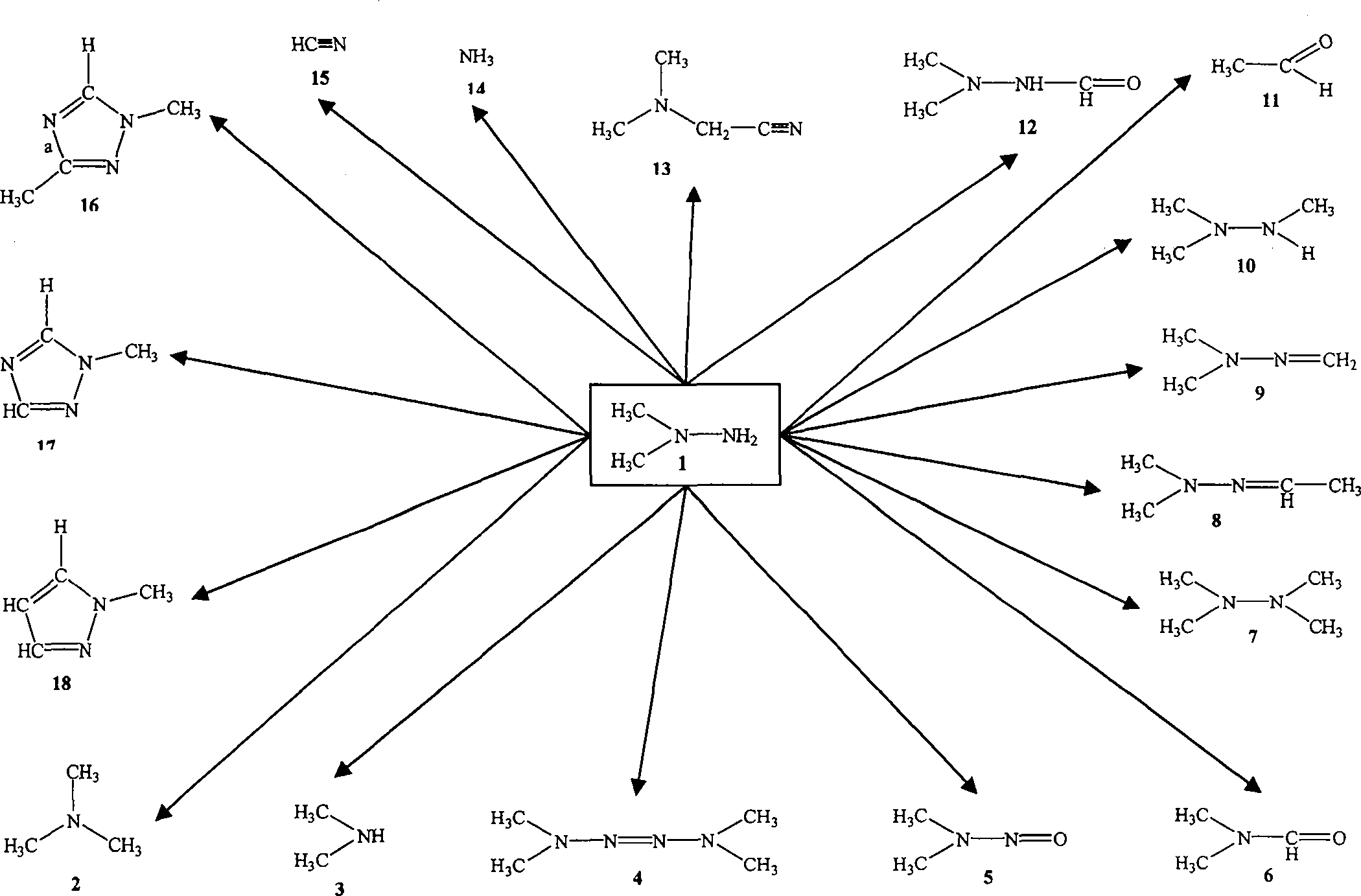

Hydrazines substituted by one or more methyl groups.

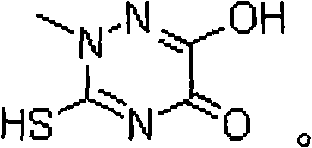

Method for synthesizing triazine ring

The invention discloses a method for synthesizing triazine ring, which is implemented by reacting aqueous methylhydrazine solution with ammonium sulfocyanate, and then preparing amino methyl sulfourea methanol solution by using methanol; performing cyclization reaction on amino methyl sulfourea methanol solution with dimethyl oxalate and sodium methylate, adjusting pH value with hydrochloric acid after finishing cyclization reaction, removing excessive sodium methylate, and filtering to prepare triazine ring sodium salt; aciding out the triazine ring sodium salt to obtain a crude triazine ring product; agitating the crude triazine ring product with hot water, washing, cooling, crystallizing, and drying to obtain a fine triazine ring product. The invention has high yield and low material cost, reduces labor intensity and pollution of waste gas, waste water and industrial residue.

Owner:NANTONG NABAIYUAN CHEM

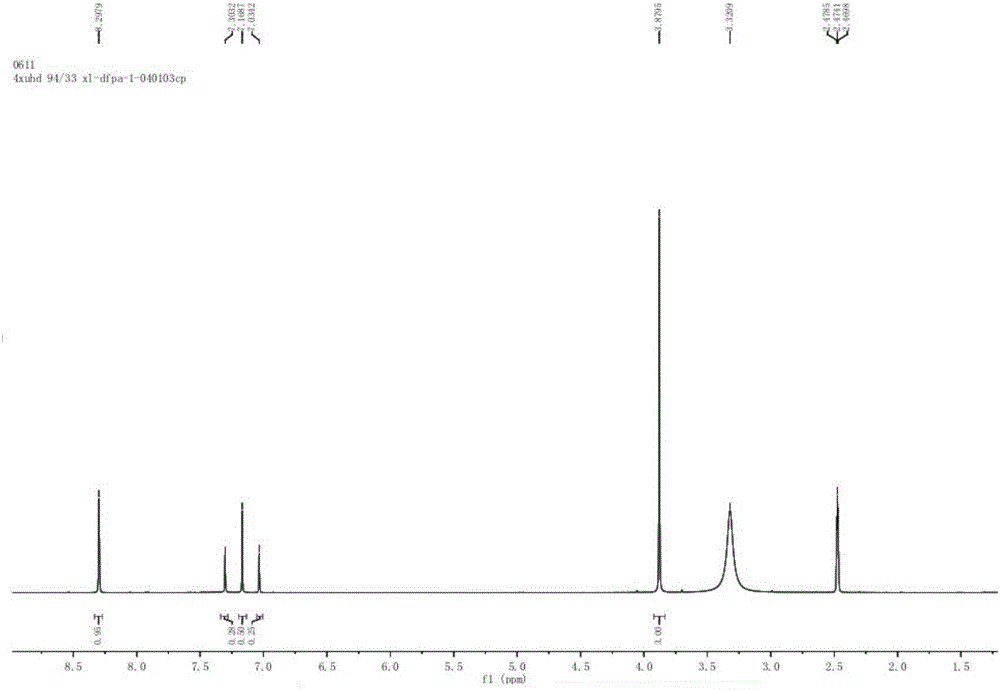

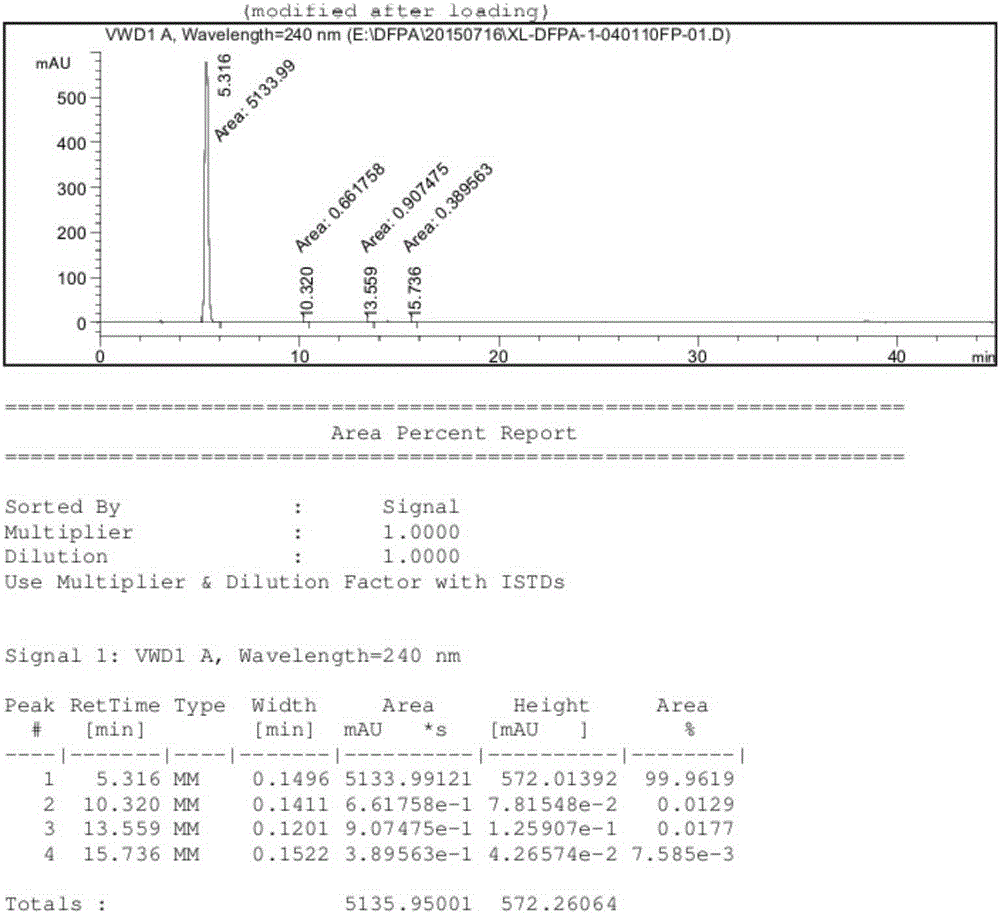

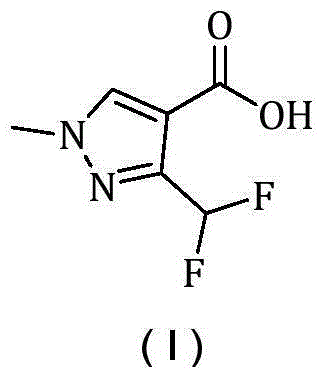

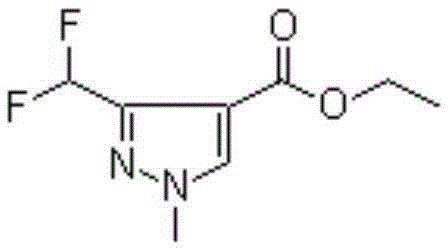

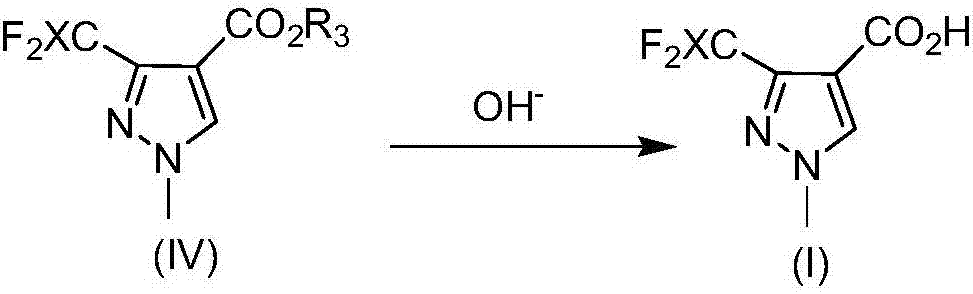

Synthesis method of 3-(difluoromethyl)-1-methyl-1H-pyrazole-4-carboxylic acid

The invention discloses a synthesis method of 3-(difluoromethyl)-1-methyl-1H-pyrazole-4-carboxylic acid, and relates to the synthesis method of the fine chemical intermediate. The method includes the following four steps: step 1, with dichloro ethyl acetoacetate as a raw material, and under the action of an alkali, carrying out a reaction with a Vilsmeier reagent to obtain an intermediate (IV); step 2, carrying out a cyclization reaction of the intermediate (IV) and methyl hydrazine to obtain 1-methyl-3-dichloromethyl-ethyl-4-pyrazole carboxylate (V); step 3, carrying out a halogen exchange reaction of the intermediate (V) with a fluorination reagent to obtain 3-(difluoromethyl)-1-methyl-1H-ethyl-4-pyrazole carboxylate (VI); and step 4, carrying out a hydrolysis reaction of the intermediate (VI) obtained in the step 3 with a sodium hydroxide solution, then carrying out neutralization treatment with an acid to obtain high-purity 3-(difluoromethyl)-1-methyl-1H-pyrazole-4-carboxylic acid (I). The method has the advantages of easily bought raw materials, low price, simple preparation method, mild reaction conditions and low requirements on equipment, and is suitable for industrialized production.

Owner:JIANGSU HERUN PHARMA CO LTD

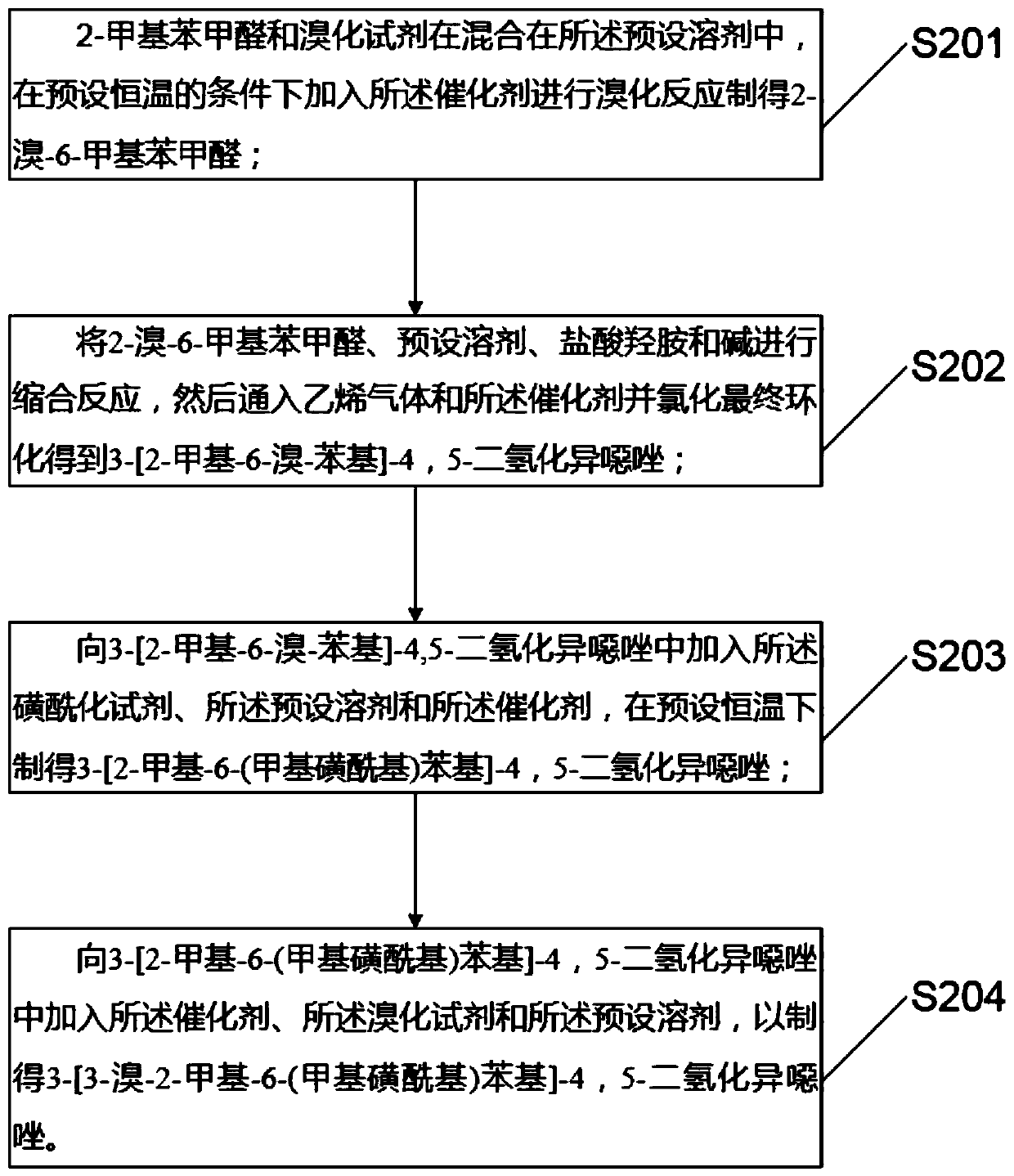

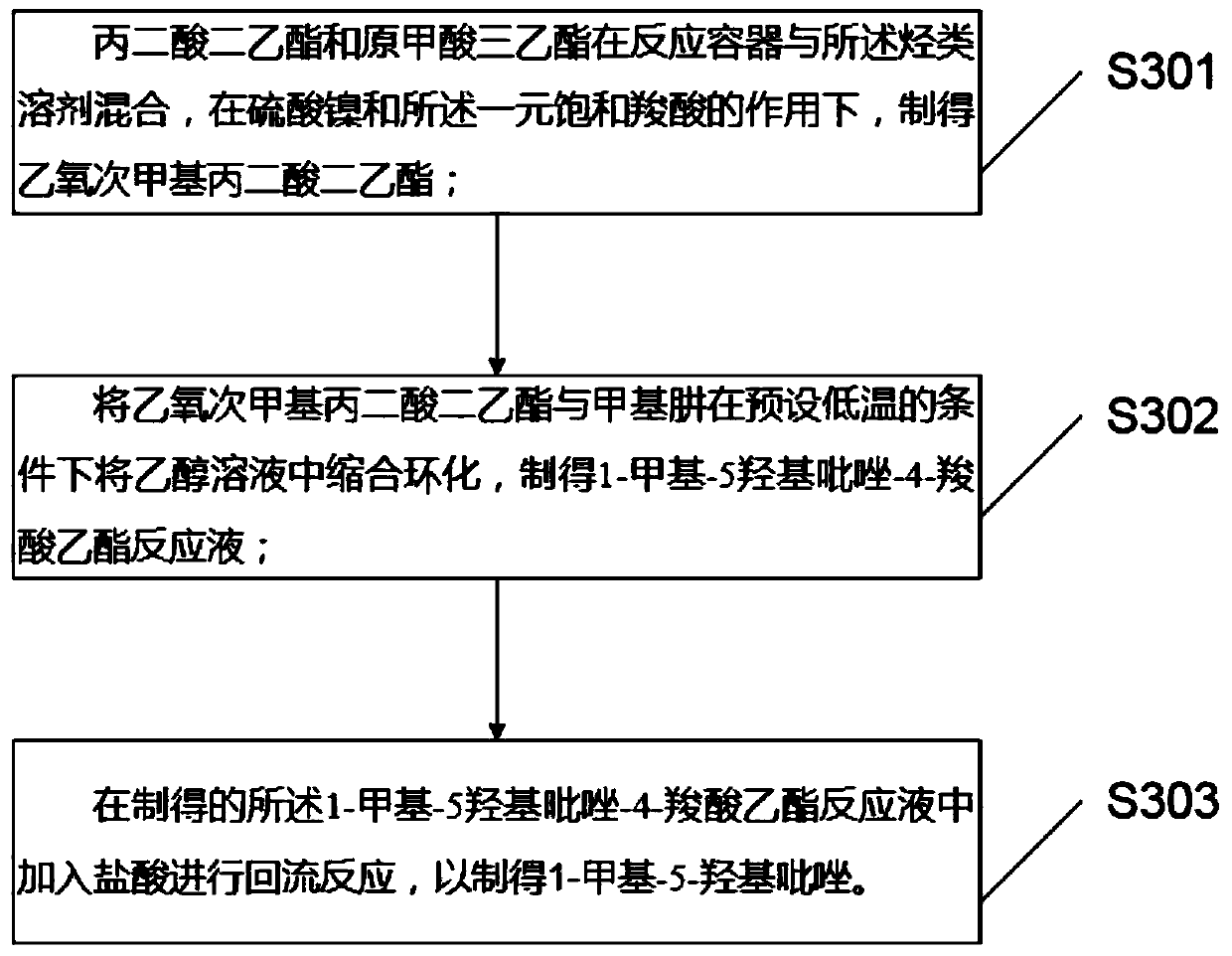

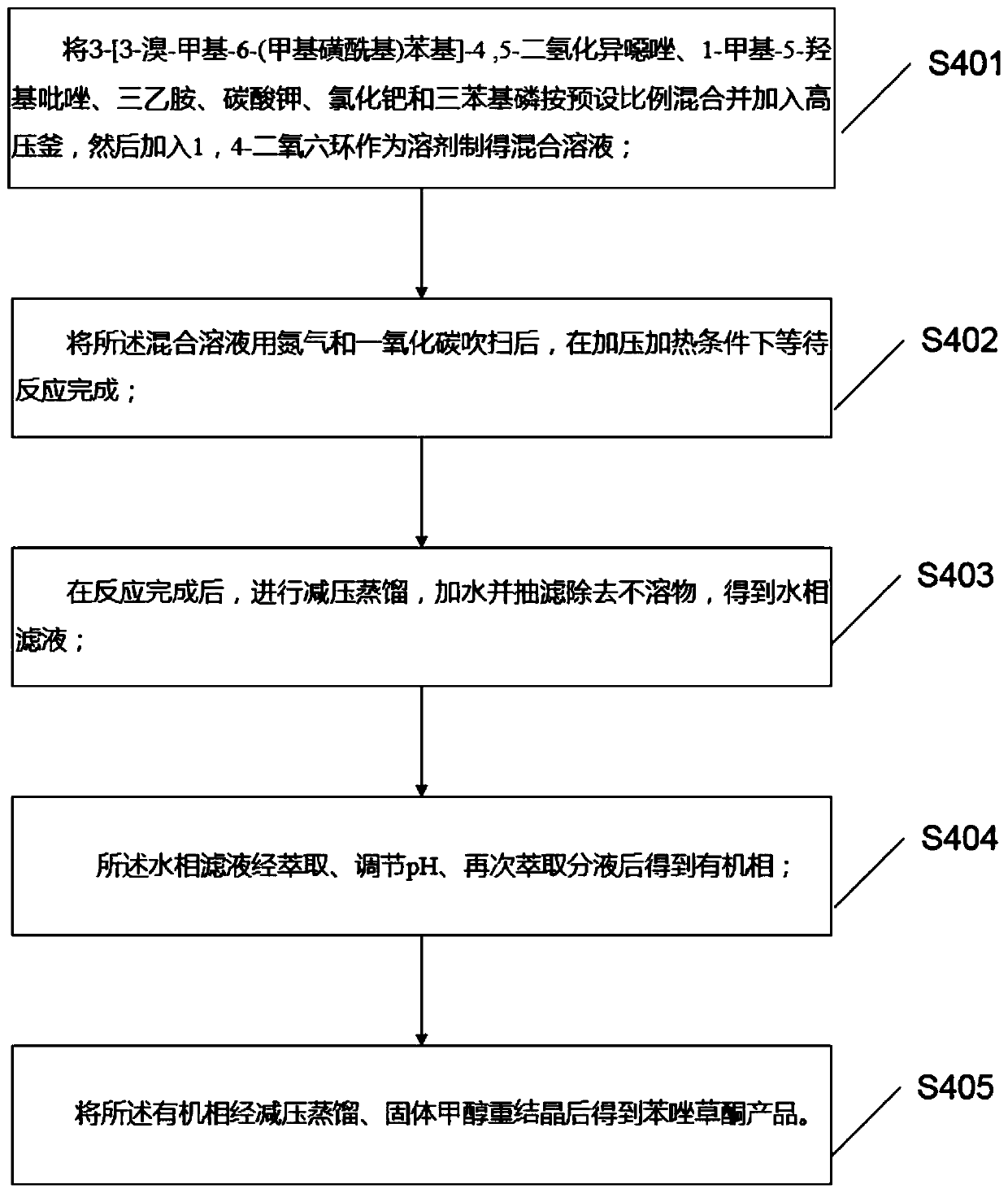

Preparation method and application of topramezone

PendingCN111440160AAvoid smelly problemsHigh yieldBiocideOrganic chemistryHydroxylamine HydrochloridePotassium carbonate

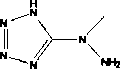

The invention discloses a preparation method and application of topramezone, and the preparation method comprises the following steps: taking 2-methylbenzaldehyde, a bromination reagent, a catalyst, hydroxylamine hydrochloride, an alkali, ethylene gas, a sulfonylation reagent and a preset solvent as reaction raw materials, and preparing 3-[3-bromo-methyl-6-(methylsulfonyl) phenyl]-4, 5-dihydroisoxazole through a first reaction process; taking diethyl malonate, triethyl orthoformate, nickel sulfate, monobasic saturated carboxylic acid, methylhydrazine, a hydrocarbon solvent, an ethanol solutionand hydrochloric acid as reaction raw materials, and carrying out a second reaction process to prepare 1-methyl-5-hydroxypyrazole; and taking the 3-[3-bromo-methyl-6-(methylsulfonyl) phenyl]-4, 5 dihydroisoxazole,-1-methyl-5-hydroxypyrazole, triethylamine, potassium carbonate, palladium chloride, triphenylphosphine, 1, 4-dioxane, water, a saturated NaHCO3 solution and a hydrochloric acid solutionas reaction raw materials, and carrying out a third reaction process to prepare the topramezone. The problems that a sulfur-containing intermediate can emit odor and the raw materials are difficult to obtain in the existing process are solved.

Owner:黑龙江省绥化农垦晨环生物制剂有限责任公司

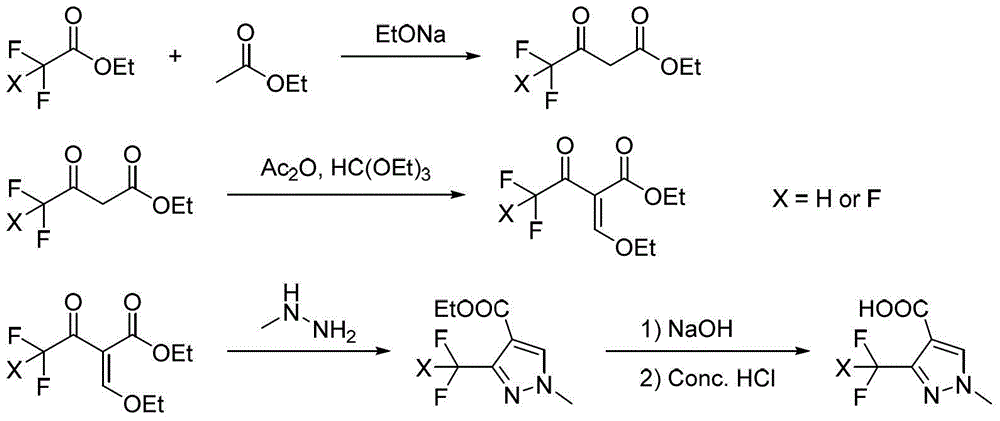

Preparation method for polyfluoromethylpyrazole compound, and intermediate of compound and preparation method thereof

The invention discloses a preparation method for a polyfluoromethylpyrazole compound, and an intermediate of the compound and a preparation method thereof. The invention provides a preparation method for a compound 1 as defined in the specification. The preparation method comprises a step of subjecting a compound 2 as defined in the specification and methylhydrazine to a ring-closure reaction in an organic solvent so as to obtain the compound 1, wherein R<1> is a C1-4 alkyl group, R<2> is a methyl or ethyl group and x is 2 or 3. The preparation method provided by the invention uses cheap and easily available raw materials and is mild in reaction conditions, safe to operate, environment friendly, low in production cost, high in reaction conversion rate, low in the content of isomer in by-products, high in reaction yield and product purity and suitable for industrial production.

Owner:LIANHE CHEM TECH YANCHENG +4

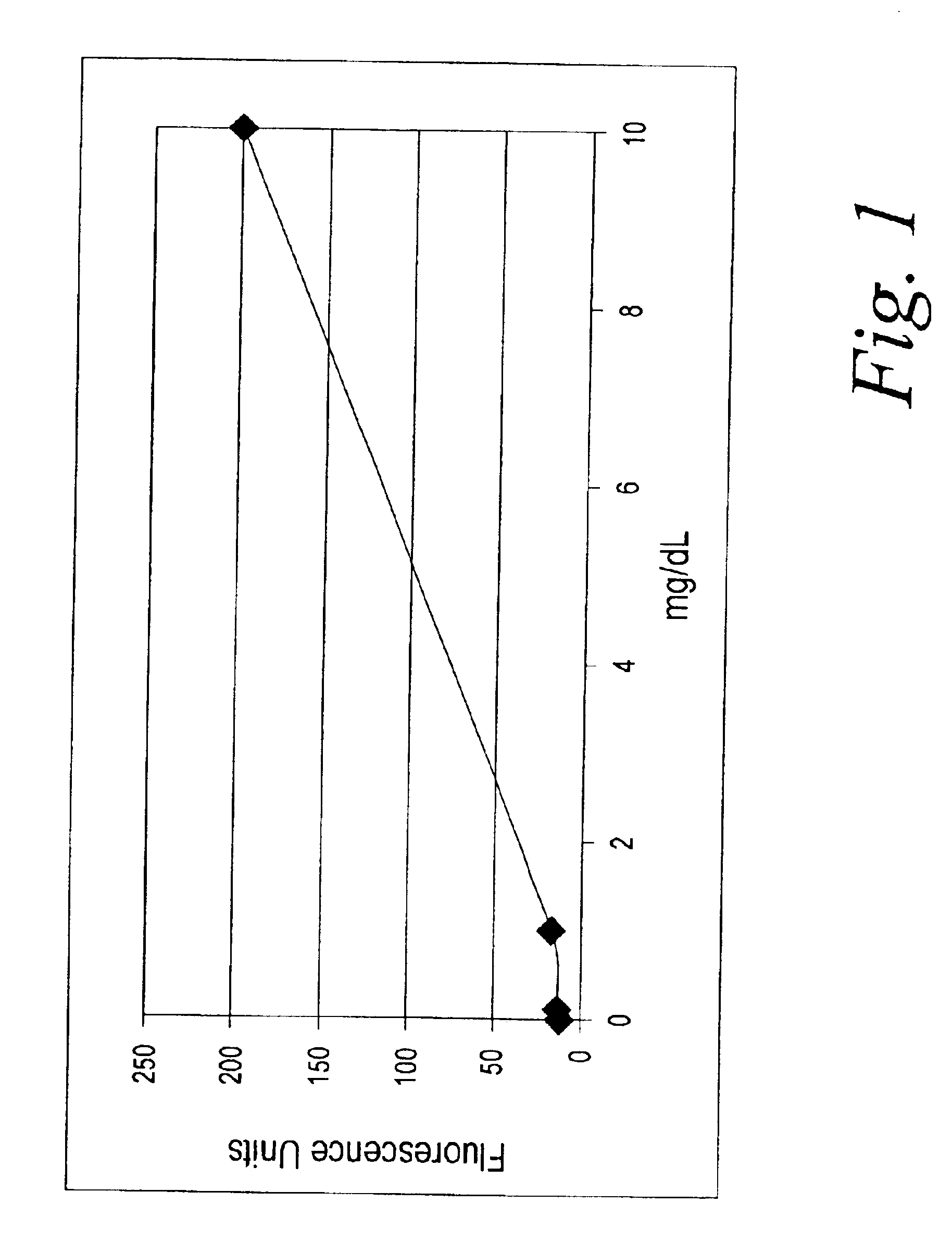

Fluorescent creatinine assay

InactiveUS6872573B2Analysis using chemical indicatorsMaterial analysis by observing effect on chemical indicatorCreatinine riseCopper

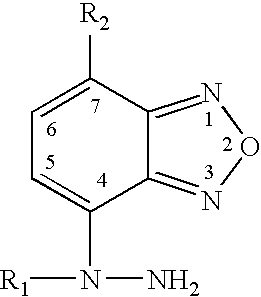

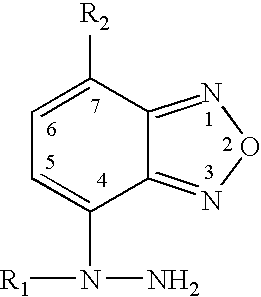

A method of detecting creatinine in body fluids using an indicator which produces a fluorescent response when oxidized in the presence of a copperII / creatinine complex. A preferred indicator is 4-(1-methylhydrazino)-7-nitro benzooxadiazole (MNBDH).

Owner:SIEMENS HEALTHCARE DIAGNOSTICS INC

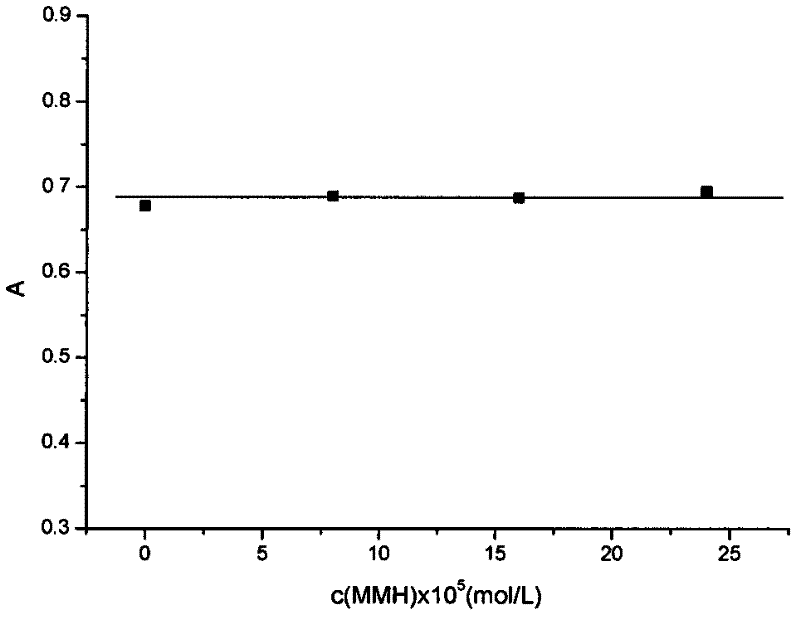

Analysis method of N,N-dimethylhydroxylamine

InactiveCN102252984AAccurate determination of concentrationAvoid churnColor/spectral properties measurementsPhenanthrolineOxygen

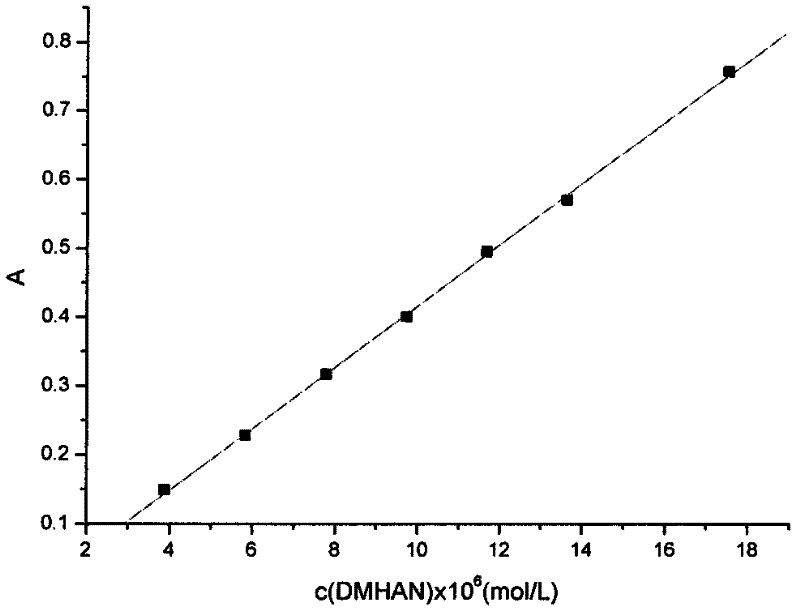

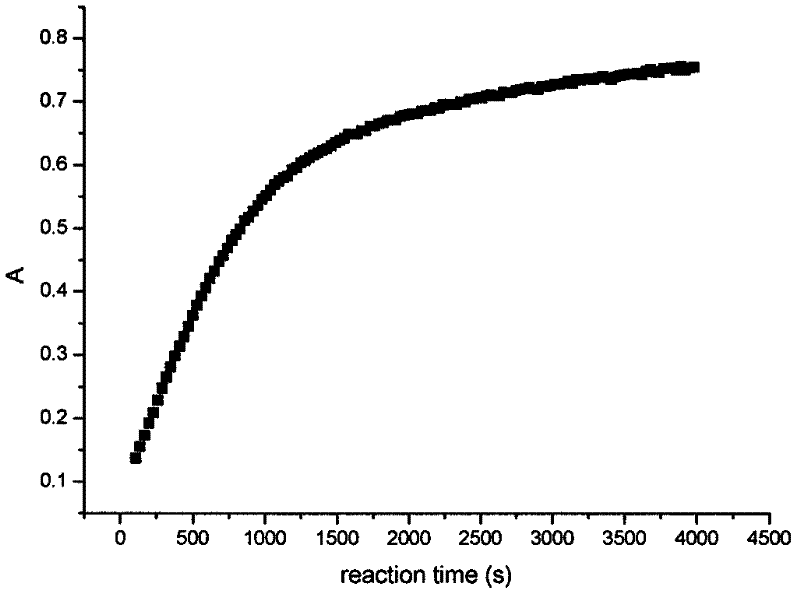

The invention discloses an analysis method of N,N-dimethylhydroxylamine. The method comprises the following steps: (1) preparing standard solution of N,N-dimethylhydroxylamine; (2) preparing acidic aqueous solution of Fe3+ / phenanthroline as a color-developing agent; (3) making a standard curve showing variation of the absorbance value along with the concentration of N,N-dimethylhydroxylamine; (4) extracting the acidic solution containing Pu3<+>, methanol, formaldehyde, formic acid, methylamine, dimethylamine, ethanol, methylhydrazine and N,N-dimethylhydroxylamine multiple times with TODGA (N,N,N,N-tetraoctyl-3-oxy-glutaramide) solution; and (5) measuring the absorbance value of each sample at 510nm with an ultraviolet-visible spectrophotometer and computing the concentrations of N,N-dimethylhydroxylamine in the samples according to the standard curve. The analysis method has the advantages of simple and convenient operation, effective avoidance of interference, small sampling amount and low measuring lower limit.

Owner:CHINA INSTITUTE OF ATOMIC ENERGY

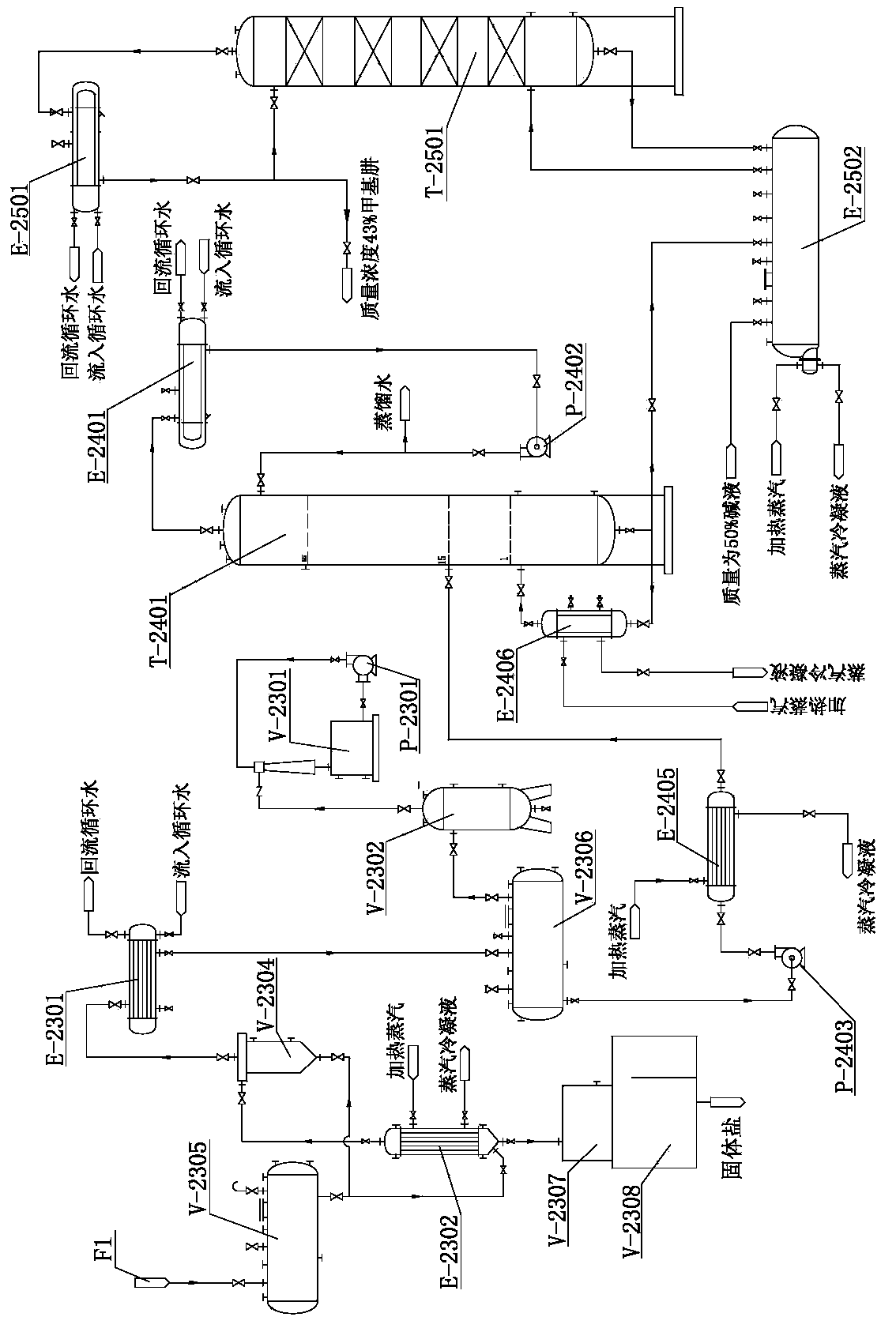

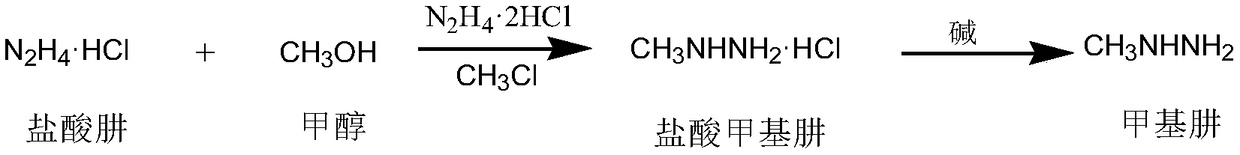

Synthesis of 1-methylhydrazine

The invention relates to a synthesis method for methyl hydrazine, which comprises the following steps: causing hydrazine hydrate and dimethyl sulfate to react at a temperature of 115 and 125 DEG C by using hydrochloric acid as a protecting agent and tetrabutyl ammonium bromide as a catalyst, adding alkali to neutralize and dissociate out the methyl hydrazine, cooling and removing salt, and rectifying the filter liquor to obtain an aqueous solution of the methyl hydrazine. The synthesis method has the advantages of low raw material cost, simple production equipment, quick reaction rate, high yield, and the like.

Owner:SHANDONG UNIV

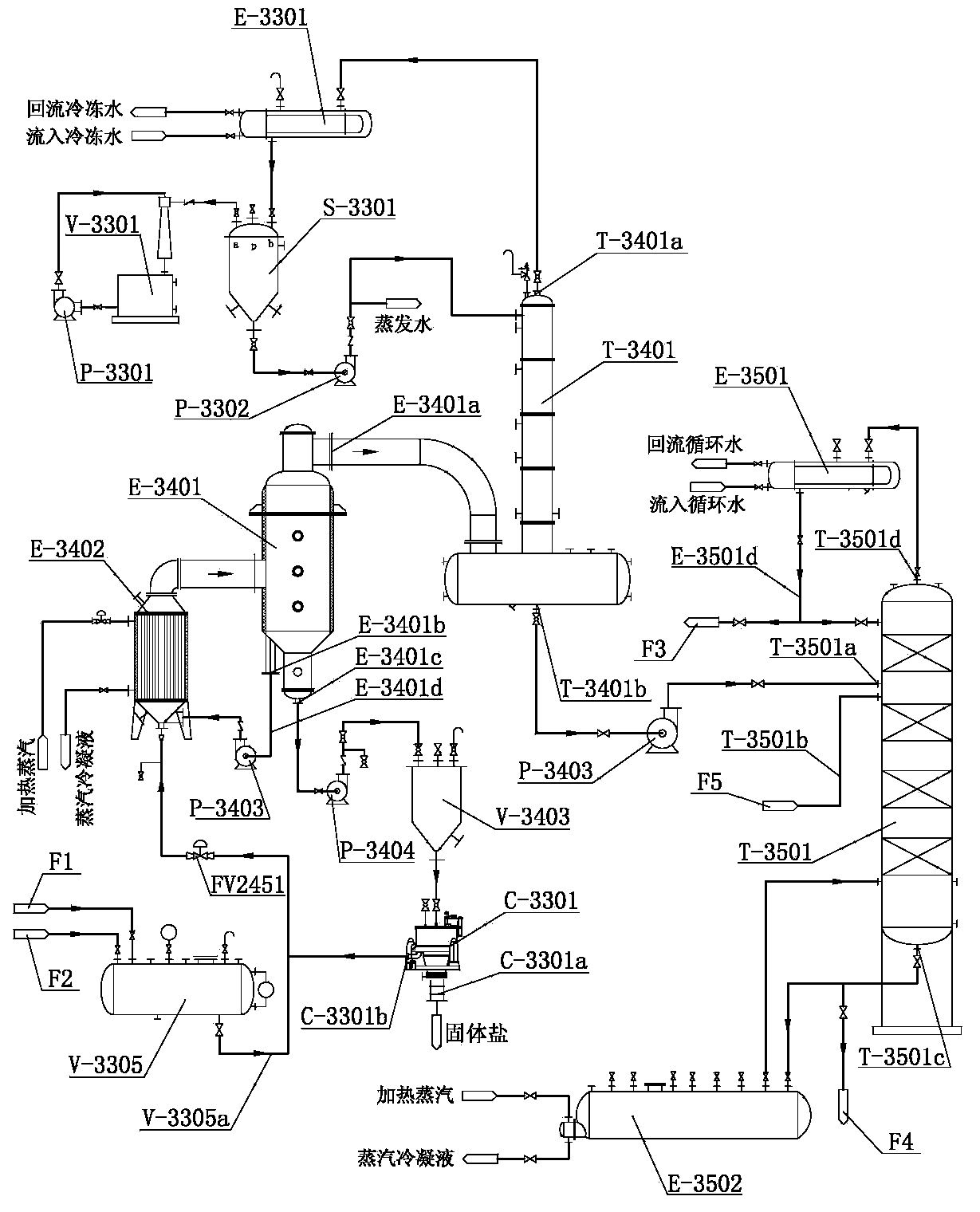

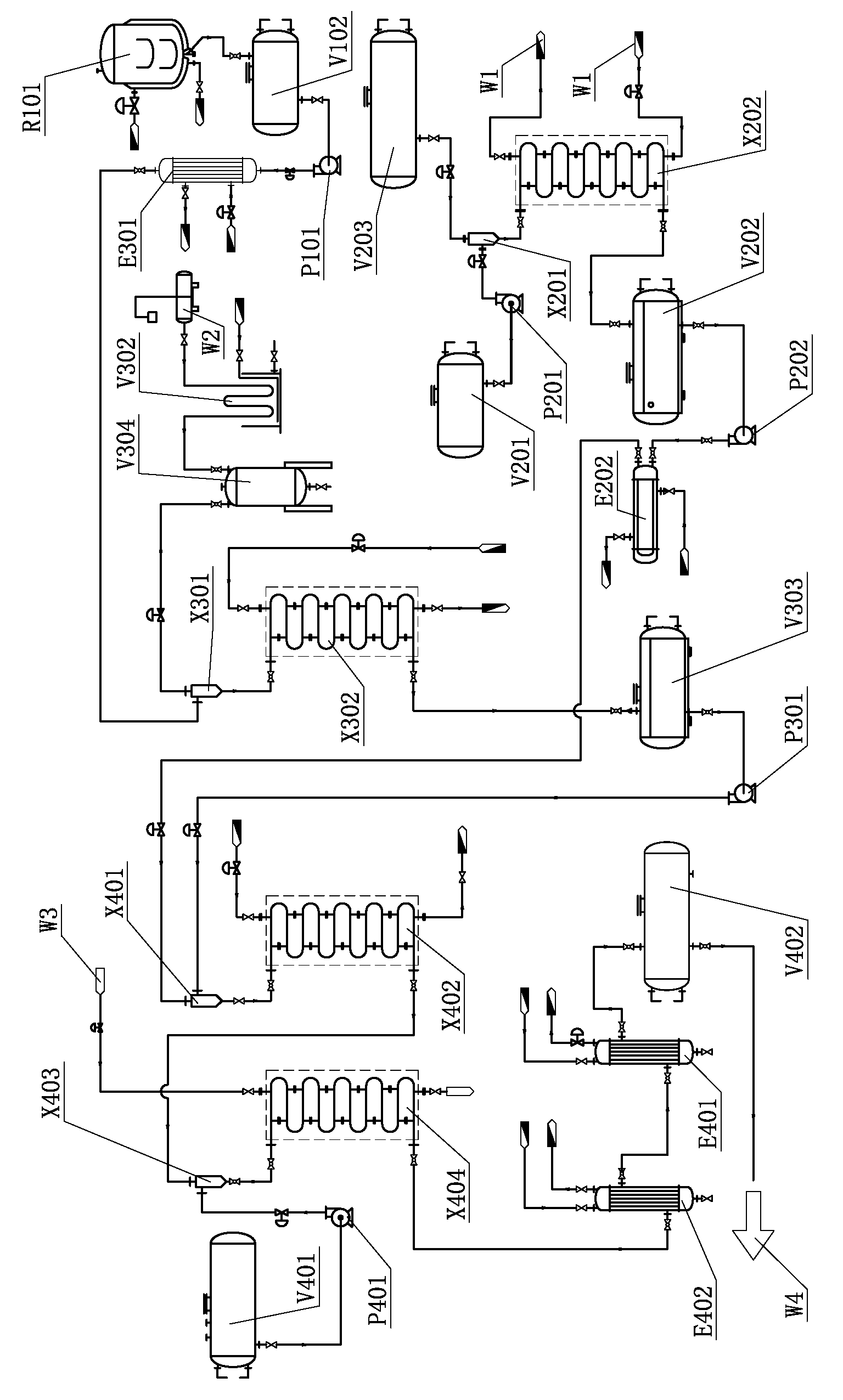

Content-adjustable methylhydrazine synthetic-fluid refining apparatus and method

InactiveCN103396335AAvoid repeated evaporationAvoid condensationHydrazine preparationAutomatic controlReboiler

The invention relates to a content-adjustable methylhydrazine synthetic-fluid refining apparatus and a method. The apparatus comprises an evaporation rectification feeding tank, an evaporation heater, an evaporator, an evaporation rectifying column, a finished-product column, a reboiler and an automatic centrifuge, and is used to refining a methylhydrazine synthetic fluid. The benefits of the apparatus and the method comprises: the technological flow of refining methylhydrazine is improved, production energy consumption is substantially reduced; pollution is reduced; the methylhydrazine content in the refined methylhydrazine synthetic fluid can be adjusted in a larger scope; and the apparatus and the method are applicable to production of multiple methylhydrazine synthetic fluid with different methylhydrazine content, and help to realize continuous production and automatic control.

Owner:上海海唇机械设备工程技术有限公司

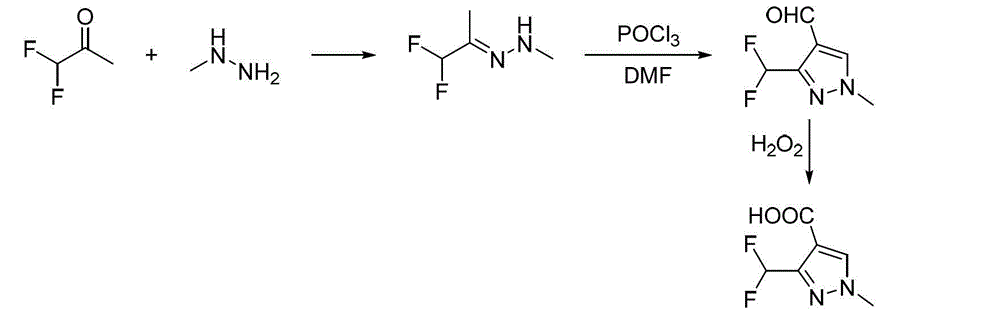

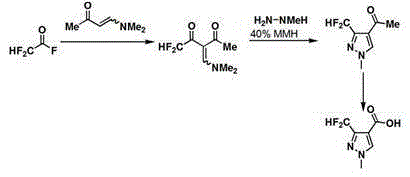

Synthesis method of 3-difluoromethyl-1-methylpyrazole-4-formic acid

InactiveCN106554310ARaw materials are easy to getHigh yieldOrganic chemistrySynthesis methodsHydrazine compound

The invention discloses a synthesis method of 3-difluoromethyl-1-methylpyrazole-4-formic acid, and belongs to the technical field of difluoromethyl pyrazole synthesis. According to the synthesis method, 3-difluoromethyl-1-methylpyrazole-4-formic acid is prepared from 1-dimethylamino-1-butylene-3-one, difluoroacetyl fluoride, and methyl hydrazine through a series of reactions. The provided synthesis method has the advantages of easily available raw materials and high yield, can be applied to industry, and has a comprehensive yield more than 65%.

Owner:陈旭

Preparation method of methylhydrazine

ActiveCN106543026AReduce decompositionReduced responseHydrazine preparationHydrazine compoundSolvent

The invention discloses a method for one-step preparation of methylhydrazine. The method comprises that under the protection of inert gas, hydrazine hydrate and methanol are subjected to alkylation reaction under an action of a catalyst for one-step synthesis of methylhydrazine, excess methanol is kept in the reaction process, and a mixed solution after the reaction is finished is rectified to obtain a high-purity methylhydrazine solution. The method has the following advantages of short process route, simple operation, high reaction yield, high selectivity of the catalyst, mild reaction conditions, and fewer by-products and side reactions; the catalyst and unreacted methanol and hydrazine can be recycled for use in the alkylation reaction, no solvents are used, no three wastes are generated, and the method is green and environmentally friendly.

Owner:石家庄金派医药化工有限公司

Halogen substituted compound and preparation method and application thereof

The invention relates to a preparation method of a halogen substituted compound. A piperazine derivative shown as a formula I reacts with a halogenated acetyl halide derivative shown as a formula VI to generate the halogen substituted compound shown as a formula II. The invention further relates to a preparation method of a pyrazole derivative from the halogen substituted compound, the halogen substituted compound shown in the formula II reacts with methylhydrazine, a pyrazole ring is closed, and a halogen substituted alkyl-1-methylpyrazole derivative shown in a formula IV is generated; or thehalogen substituted compound shown in the formula II reacts with methylhydrazine benzaldehyde hydrazone to generate a hydrazone compound as shown in a formula III, the pyrazole ring is closed, and the halogen substituted alkyl-1-methylpyrazole derivative shown in the formula IV is generated. The invention also relates to the structure of an intermediate compound. The preparation methods of the halogen substituted compound and the pyrazole derivative are suitable for industrial production.

Owner:科莱博(江苏)科技股份有限公司

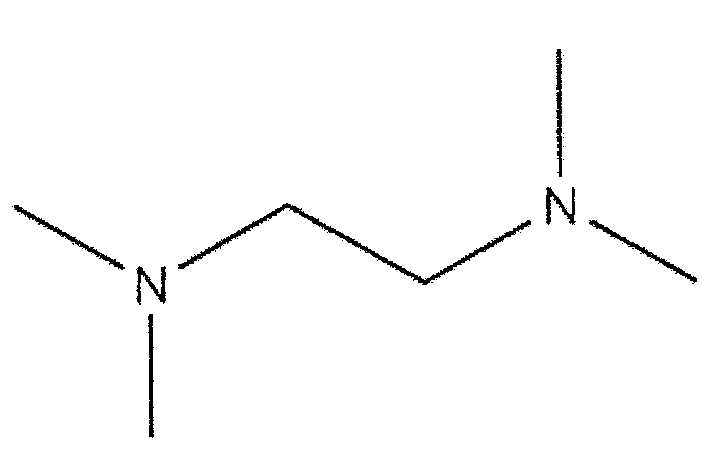

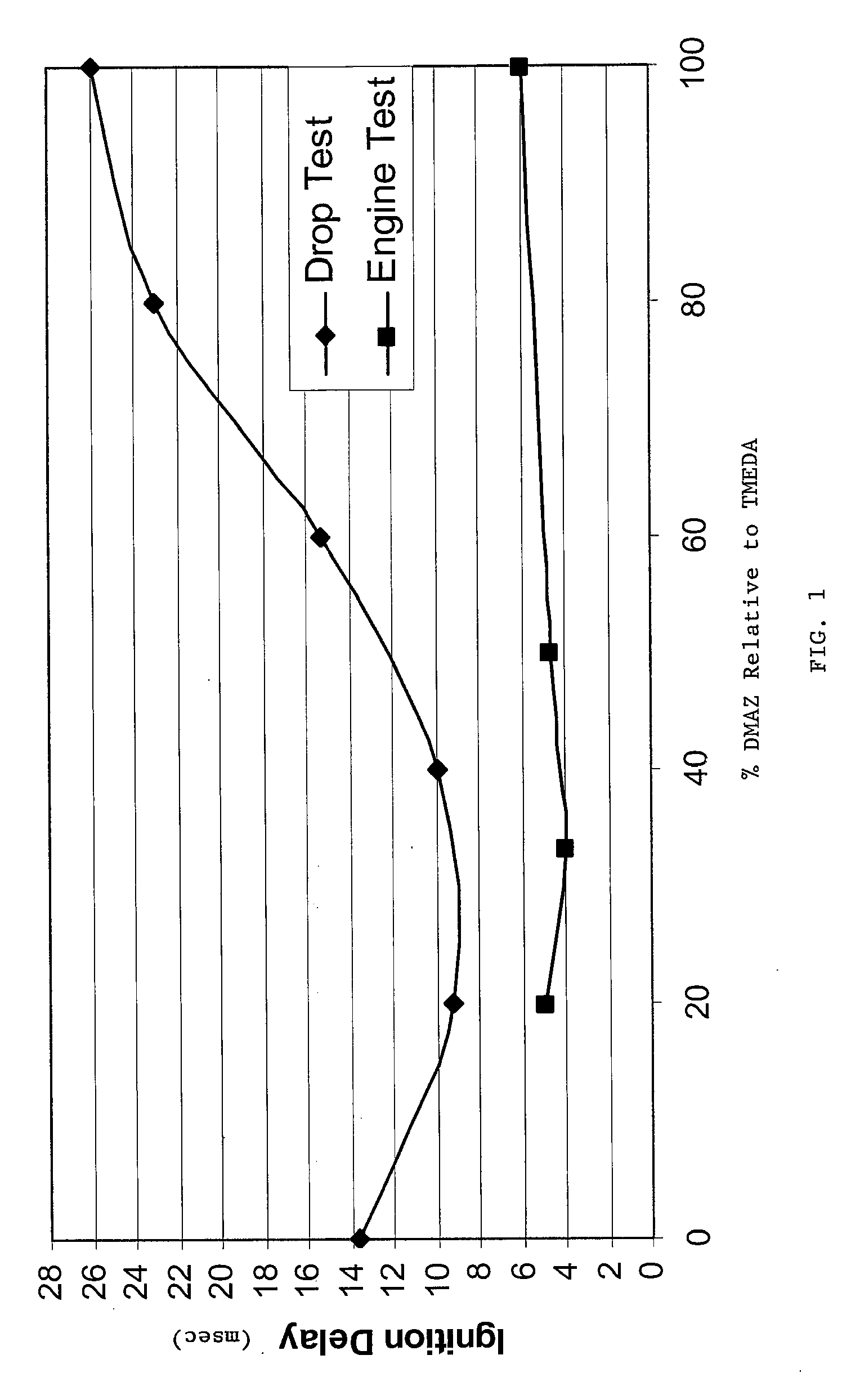

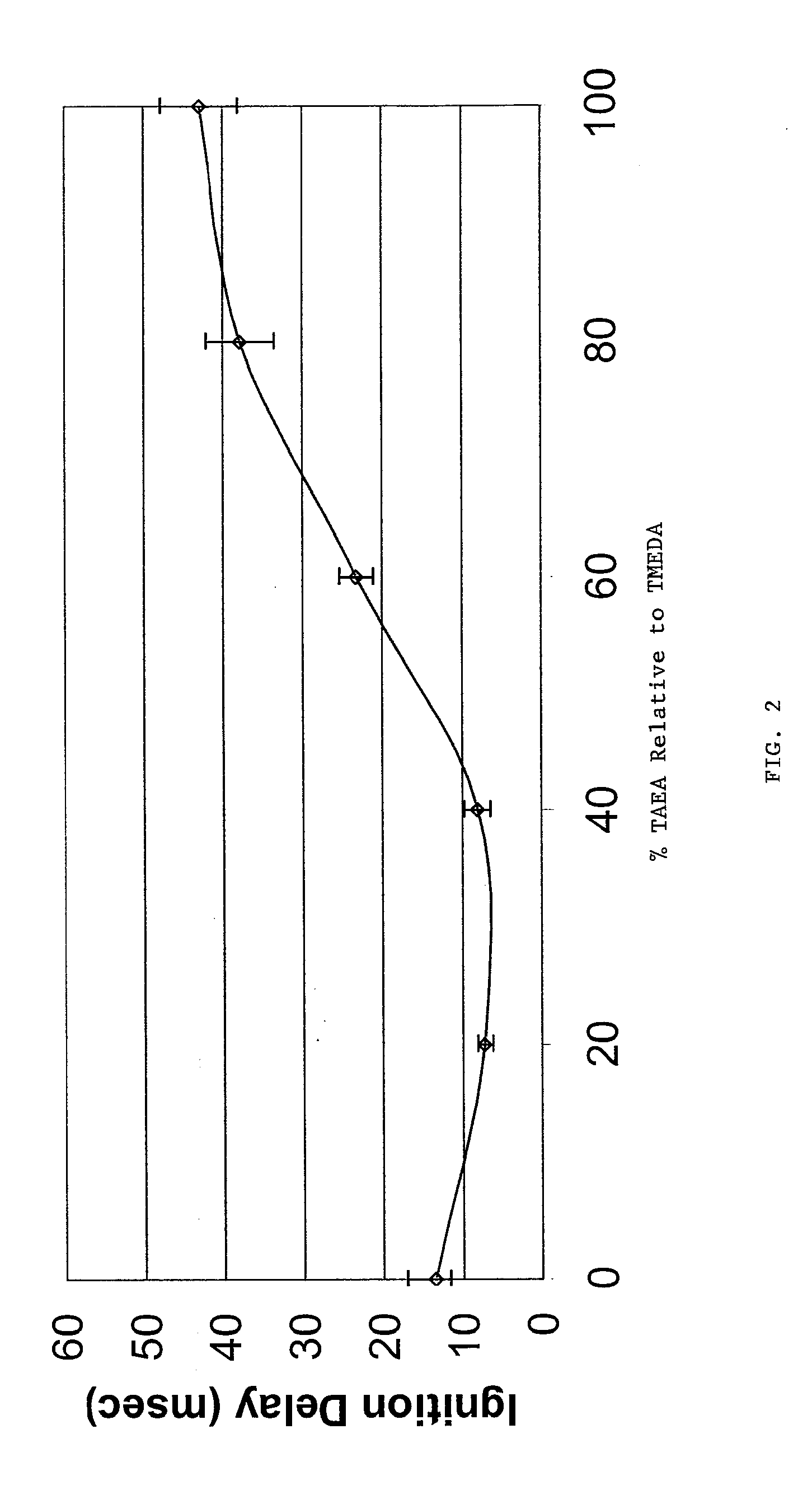

Hypergolic Liquid Or Gel Fuel Mixtures

Hypergolic liquid or gel fuel mixtures utilized in bipropellant propulsion systems are disclosed as replacements for fuels containing toxic mono-methylhydrazine. The fuel mixtures include one or more amine azides mixed with one or more tertiary diamine, tri-amine or tetra-amine compounds. The fuel mixtures include N,N,N′,N′-tetramethylethylenediamine (TMEDA) mixed with 2-N,N-dimethylaminoethylazide (DMAZ), TMEDA mixed with tris(2-azidoethyl)amine (TAEA), and TMEDA mixed with one or more cyclic amine azides. Each hypergolic fuel mixture provides a reduced ignition delay for combining with an oxidant in fuel propellant systems. The fuel mixtures have advantages in reduced ignition delay times compared to ignition delay times for each unmixed component, providing a synergistic effect which was not predictable from review of each component's composition. Additional fuel mixtures include various tertiary diamine, tertiary tri-amine or tetra-amine compounds combined with one or more amine azides or imidic amide compounds, to provide clean burning, high performing, and non-toxic fuels.

Owner:UNITED STATES OF AMERICA REPRESENTED BY SEC OF ARMY

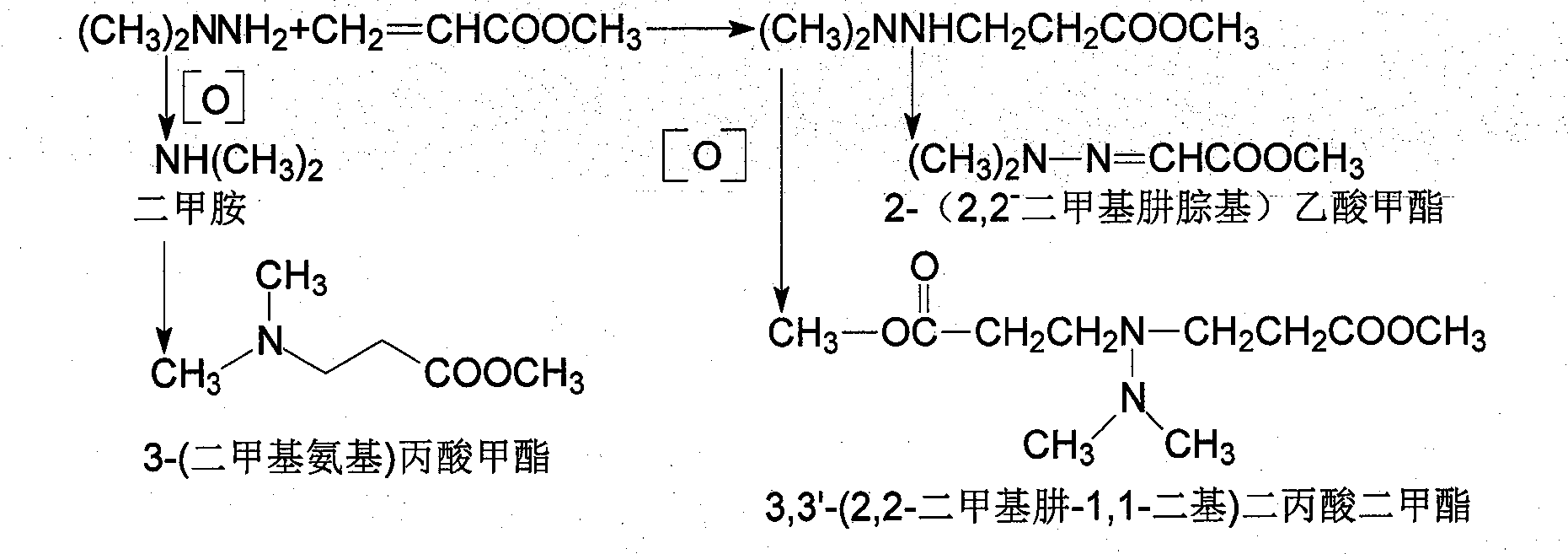

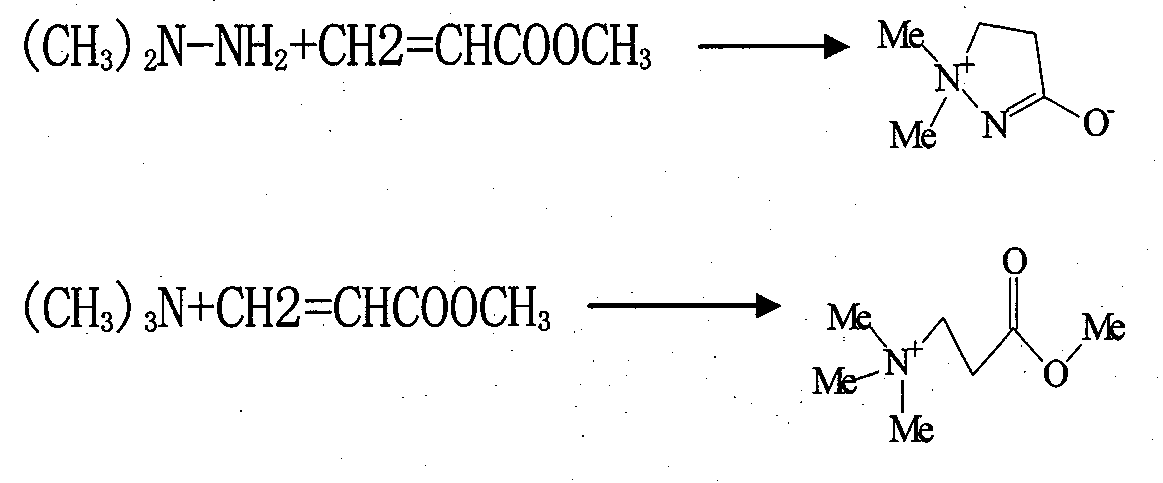

Method for improving preparation technology of 3-(2,2-dimethylhydrazino)methyl propionate and 3-(2,2,2-trimethylhydrazino)methyl propionate

InactiveCN104163776AGuarantee product qualityImprove stabilityHydrazine preparationAutomatic controlMethyl acrylate

The invention discloses a method for improving the preparation technology of 3-(2,2-dimethylhydrazino)methyl propionate and 3-(2,2,2-trimethylhydrazino)methyl propionate. The 3-(2,2-dimethylhydrazino)methyl propionate and 3-(2,2,2-trimethylhydrazino)methyl propionate are intermediates of a mildronate bulk drug. In the prior art, the intermediates are prepared by the following steps: making 1,1-dimehtylhydrazine carry out reactions with methyl acrylate, and then subjecting the reaction products to methylation reactions so as to obtain the target products; but the conventional technology has the disadvantages that the quality and stability of the obtain products are bad, thus the technology for producing the mildronate bulk drug becomes more complicated, and the synthesis cost is increased. The provided method separates two reactions in the synthesis route, exothermic reaction material feeding automatic control of each reaction is realized under mild conditions, the final products are subjected to a primary cooling precipitation and a secondary special purifying technology so as to obtain high purity products without complicated steps like recrystallization and washing, moreover the stability and yield of the products are both improved, the treatment time is shortened, the shelf life of the products is prolonged from two years to four years, and the method can be applied to commercial massive production.

Owner:DONGLI NANTONG CHEM +1

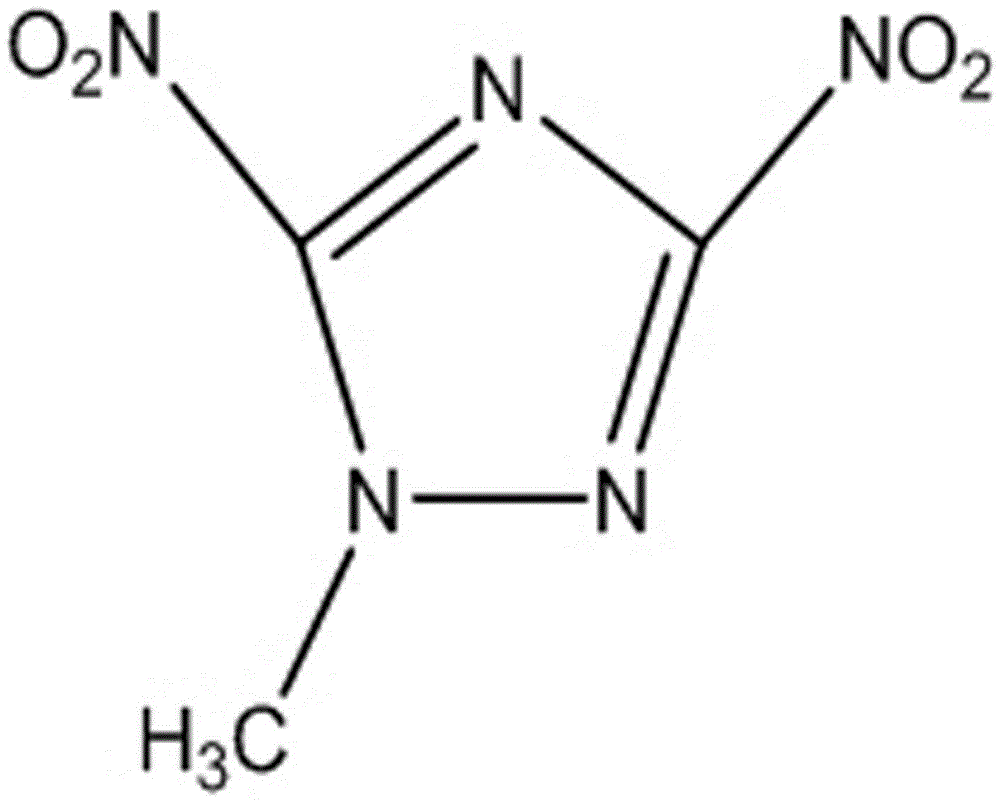

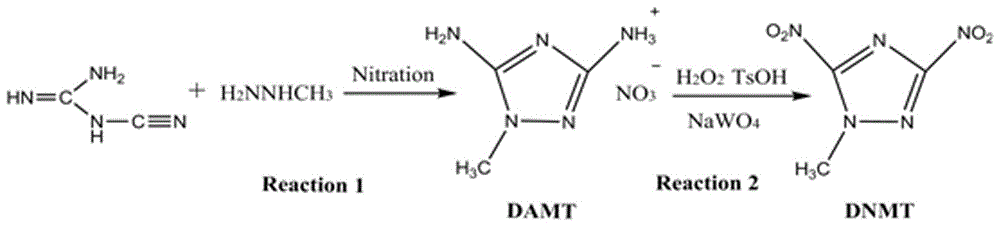

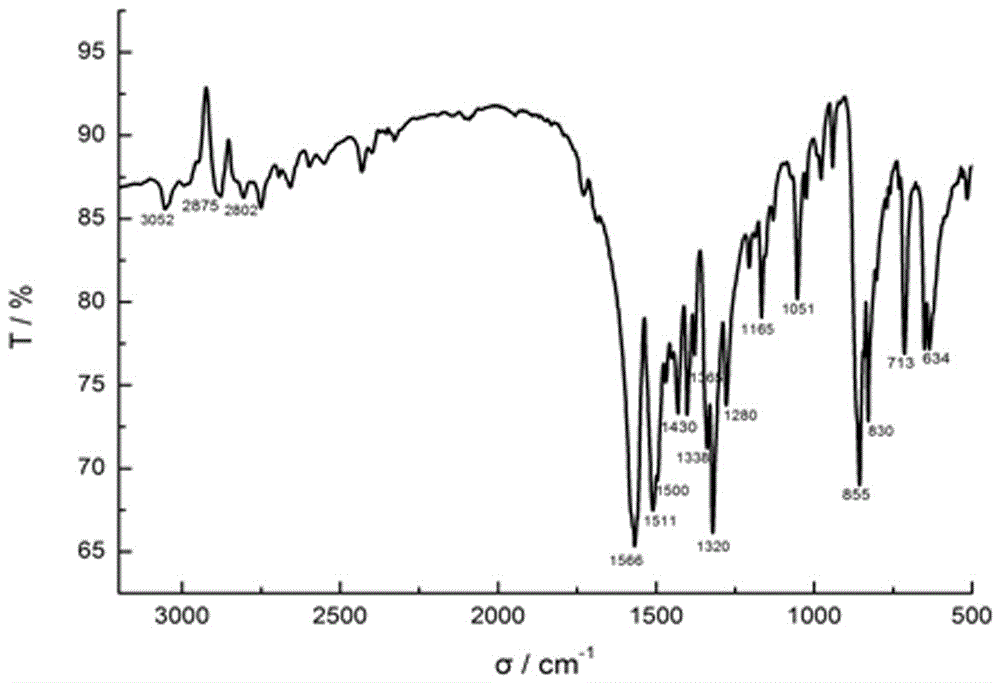

Preparation method of 1-methyl-3,5-binitro-1,2,4-triazole

InactiveCN106831621ASynthetic Amplification Successfully RealizedSolve the danger of reaction thermal runawayOrganic chemistryNitrateMethylhydrazine

The invention discloses a preparation method of 1-methyl-3,5-binitro-1,2,4-triazole, belongs to the technical field of organic energetic materials and aims at solving the problems in the prior art that a two-step method for preparing DNMT is relatively high in cost, a potential safety hazard exists, wastewater ingredients are complicated and difficult to treat and the final product is low in yield and low in purity. The method comprises the steps of preparing a product 1 of which the main ingredient is 1-methyl-3,5-binitro-1,2,4-triazole nitrate (DAMT) from methylhydrazine and dicyandiamide as reaction raw materials through condensation and cyclization; and carrying out oxidation reaction on the product 1 and hydrogen peroxide to prepare a product 2 DNMT. The 1-methyl-3,5-binitro-1,2,4-triazole is high in yield and high in purity, and the risk of thermal runaway of reaction in the reaction process is avoided.

Owner:ZHONGBEI UNIV

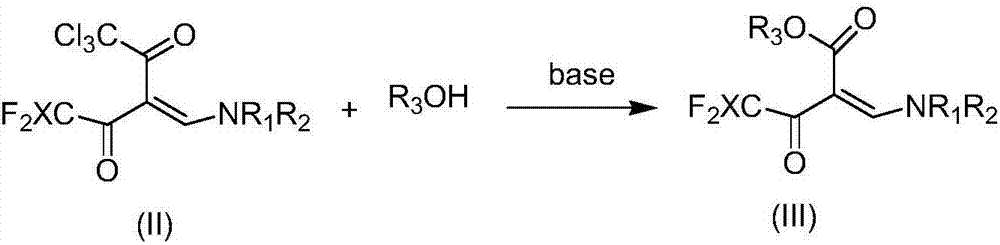

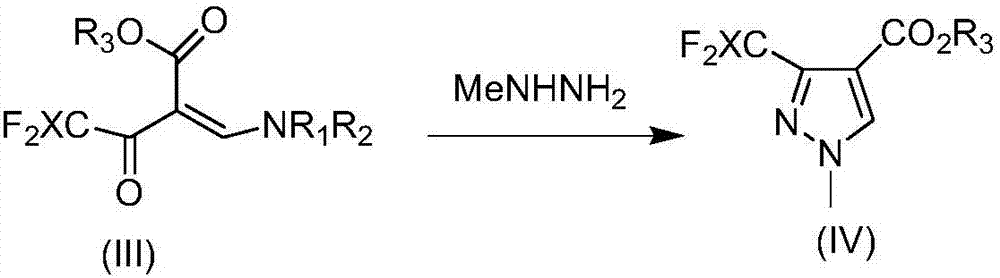

Method for preparing 3-difluoromethyl-1-methyl-1H-pyrazol-4-carboxylic acid

The invention provides a method for preparing 3-difluoromethyl-1-methyl-1H-pyrazol-4-carboxylic acid. The method comprises the following steps: under the action of an alkali, enabling 1,1,1-trichlorine-3-(substituted amino methylene)-5,5-difluoro-2,4-pentanedione to react with n-alcohol to generate 2-(substituted amino methylene)-4,4-difluoro-3-oxo-butyrate, further reacting with a methylhydrazinesolution to generate 3-difluoromethyl-1-methyl-1H-pyrazolyl-4-formate, and finally performing hydrolysis under an alkali condition, thereby obtaining the 3-difluoromethyl-1-methyl-1H-pyrazol-4-carboxylic acid. The invention provides a novel economic method, and 2-(substituted amino methylene)-4,4-difluoro-3-oxo-butyrate which is high in yield and high in purity is firstly prepared, and is furtherhighly selectively converted into a target product, namely 3-difluoromethyl-1-methyl-1H-pyrazol-4-carboxylic acid.

Owner:SHANGHAI INST OF TECH

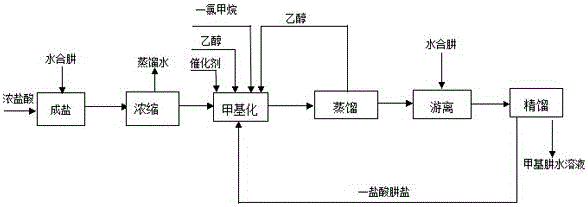

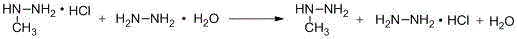

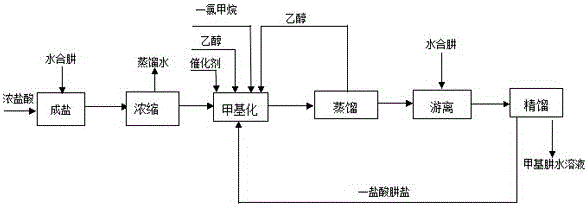

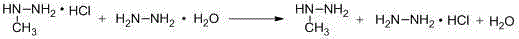

Novel method of catalytic synthesis of methylhydrazine under normal pressure

InactiveCN105037196AIncrease contact areaReduce generationHydrazine preparationHydrazine compoundSolvent

The invention discloses a novel method of catalytic synthesis of methylhydrazine under normal pressure. The method is characterized in that hydrazine hydrate and methane chloride react under normal pressure and 70-74 DEG C by taking hydrochloric acid as a protective agent, silica gel as a catalyst and ethyl alcohol as a solvent, thus generating methylhydrazine hydrochloride. A hydrazine ionization method is adopted, after methylhydrazine is ionized by the hydrazine hydrate, and a methylhydrazine aqueous solution is obtained by a rectification process. The ionized side product hydrazine monohydrochloride can be repeatedly used. The method has the following advantages: equipment cost and raw material price are lower in cost, reaction yield is high, the selectivity is good, three wastes are not generated, environment friendliness is good, and the process realizes internal circulation, continuous production can be conveniently performed, moreover, reaction is performed under normal pressure, operation is simple and production is safe.

Owner:UNIV OF JINAN

Halogen substituted intermediate compound and preparation method and application thereof

PendingCN110577477AEasy to purifyImprove product qualityHydrazine preparationBiocideHydrazoneHalogen

The invention relates to a preparation method of a halogen-substituted intermediate compound. The halogen-substituted intermediate compound shown as a formula VIII is generated by reacting a compoundshown as a formula VII with a halogenated acetyl halide derivative shown as a formula VI. The invention relates to a preparation method for preparing a pyrazole derivative from the halogen substitutedintermediate compound, and the preparation method comprises the following steps: reacting the halogen substituted intermediate compound as shown in the formula VIII with methylhydrazine, and closinga pyrazole ring to generate a halogen substituted alkyl-1-methylpyrazole derivative as shown in a formula IV; or reacting the halogen substituted intermediate compound as shown in the formula VIII with methylhydrazine benzaldehyde hydrazone to generate a hydrazone compound as shown in a formula III, and closing the pyrazole ring under the action of an acid to generate the halogen substituted alkyl-1-methylpyrazole derivative as shown in the formula IV. The invention also relates to the structure of the intermediate compound. The preparation methods of the halogen-substituted intermediate compound and the pyrazole derivative are suitable for industrial production.

Owner:SUQIAN KEYLAB BIOCHEMICAL CO LTD

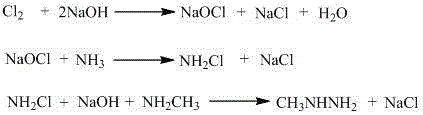

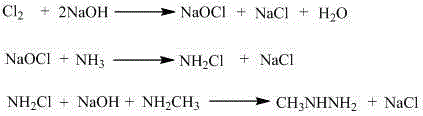

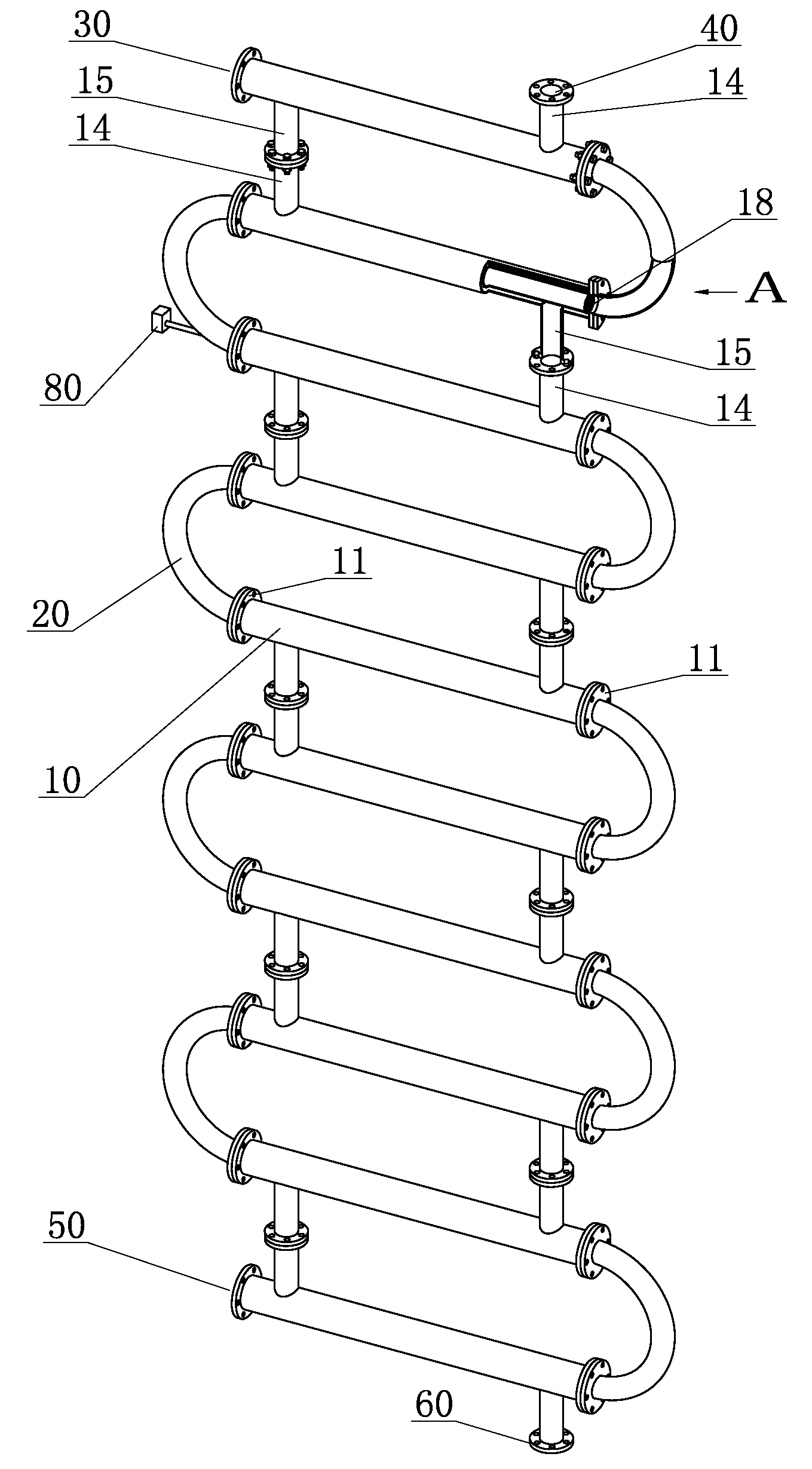

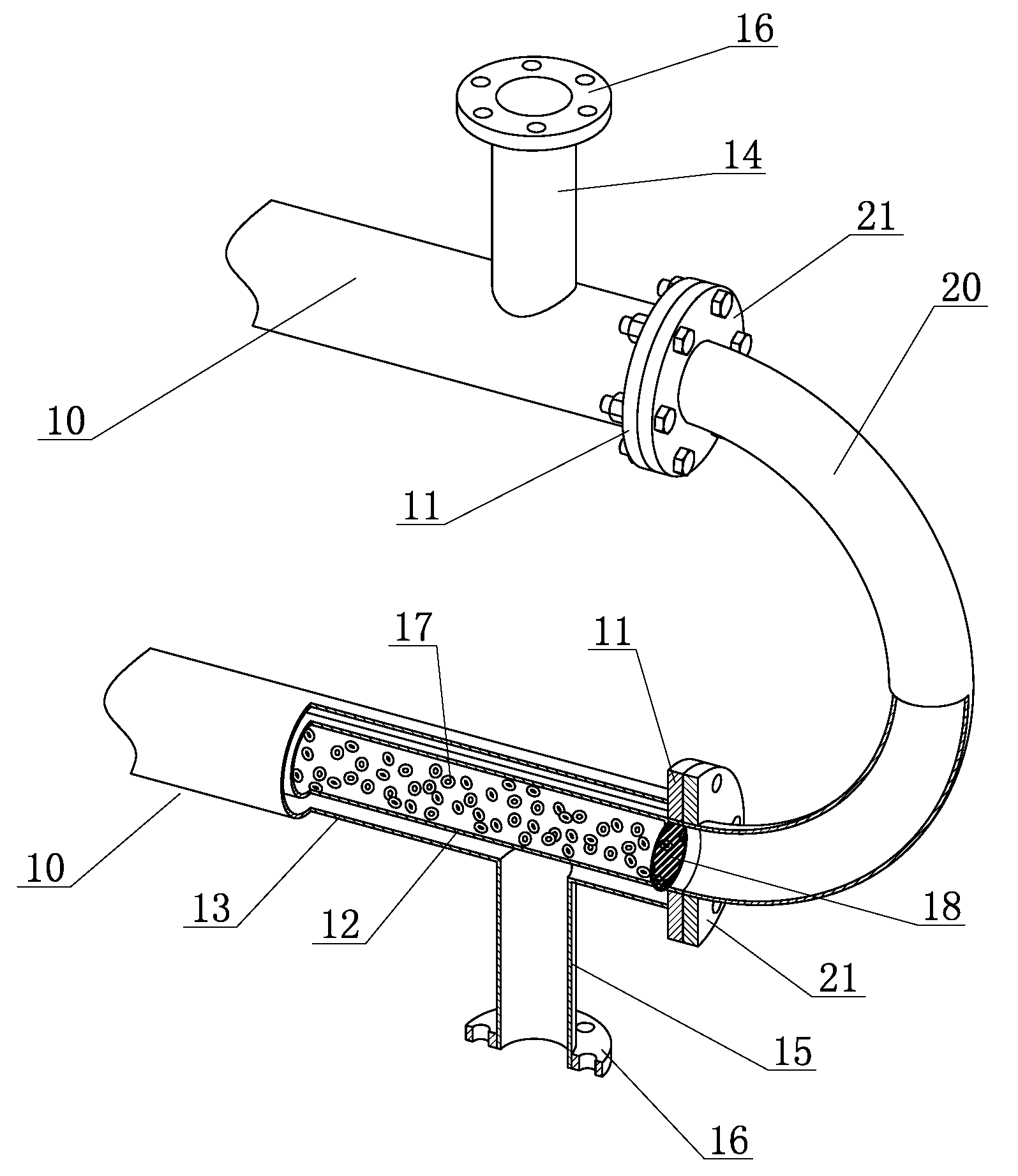

Synthesis reactor and device and method for synthesizing methylhydrazine by chloramine process

InactiveCN103263884AIncrease productivityInhibition of mass productionHydrazine preparationChemical/physical/physico-chemical stationary reactorsChloramine BMethylhydrazine

The invention relates to a synthesis reactor and a device and method for synthesizing methylhydrazine by a chloramine process. The synthesis reactor is provided with multiple jacket pipes and a connecting bend, wherein an efficient mixed stuff is filled in each jacket pipe; a medium flow space is formed between an inner pipe and an outer pipe of the jacket pipe; and a temperature regulation medium inlet pipe and a temperature regulation medium outlet pipe are arranged at the two ends of the outer pipe. The device for synthesizing methylhydrazine by a chloramine process comprises an ammonia water preparation unit, a sodium hydroxide preparation unit, a sodium hypochlorite preparation unit and a methylhydrazine generation unit. The method comprises the steps of: preparation of ammonia water, preparation of a sodium hydroxide solution, preparation of a sodium hypochlorite solution, preparation of a chloramine solution and preparation of a methylhydrazine solution. According to the synthesis reactor and the device and method provided by the invention, the technology for producing methylhydrazine by a chloramine process has the characteristics of high yield and selectivity, low energy consumption and few three wastes, continuous large-scale production is realized, and the production cost is about 2 / 3 of that of a traditional chloramine process.

Owner:上海海唇机械设备工程技术有限公司

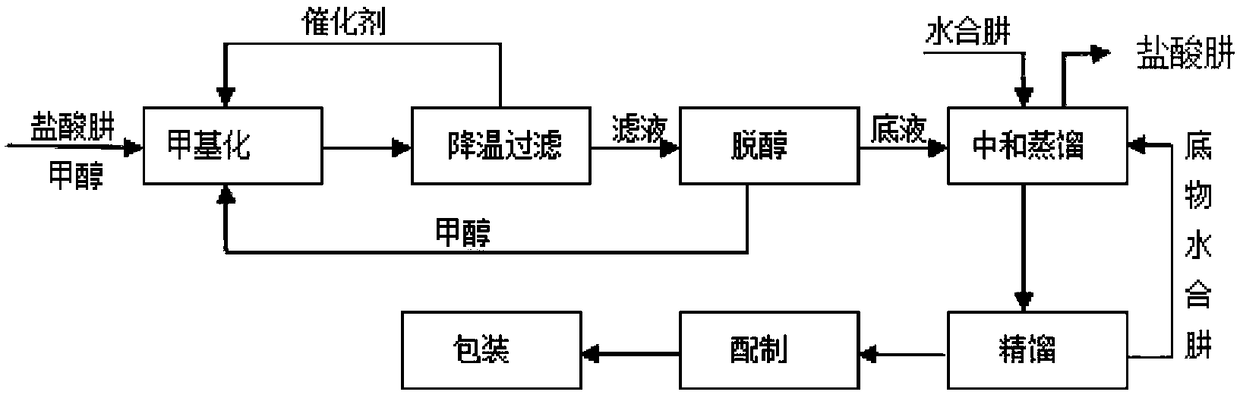

Preparation technology of methylhydrazine

ActiveCN109503418AHigh yieldImprove conversion rateHydrazine preparationOrganic synthesisMethylhydrazine

The invention discloses a preparation technology of methylhydrazine, and belongs to the technical field of organic synthesis. The preparation technology comprises the following steps: (1) adding hydrazine monohydrochloride and methanol into a reaction kettle, then adding water and a catalyst, and then rising the temperature for carrying out methylation, thus obtaining methylhydrazine hydrochloride; (2) directly cooling feed liquid after reaction, separating a solid catalyst from unreacted hydrazine hydrochloride, and carrying out dealcoholizing, dissociating, rectifying and the like on filtrate, thus obtaining the methylhydrazine. The preparation technology disclosed by the invention has the advantages that the reaction selectivity is good, the reaction pressure is low, the catalyst can becompletely and mechanically used, and safety, cleanliness, environment protection and the like are realized.

Owner:河北合佳医药科技集团股份有限公司

Synthesis method of 1-methyl-3-trifluoromethyl pyrazol

ActiveCN101824000AReduce volatilityAvoid it happening againOrganic chemistrySynthesis methodsDistillation

The invention discloses a synthesis method of 1-methyl-3-trifluoromethyl pyrazol. In the synthesis method, trifluoroacetyl vinyl alkyl ether is used as a main raw material to react with methylhydrazine to generate 1-methyl-3-trifluoromethyl pyrazol in the presence of the action of alkali in a medium solvent, wherein the medium solvent is water, a mixture of water and methanol or a mixture of water and alcohol, and the reaction is carried out at normal temperature. In the invention, the water or the mixture of the methanol or the alcohol with the water is used as a medium, a strong-volatility organic solvent is avoided being used, thereby reducing volatilization and avoiding the generation of excessive waste liquid, and the technological conditions of high temperature, harmful solvents, dangerous operation, special devices, and the like are also avoided. One-pot reaction is adopted in the invention, and the processes of decompression, distillation and purification are not needed. A product with higher purity can be obtained only by extracting the 1-methyl-3-trifluoromethyl pyrazol by using the solvent and then decompressing and concentrating, and the yield is improved.

Owner:JIANGSU ZHONGDAN PHARMA RES +1

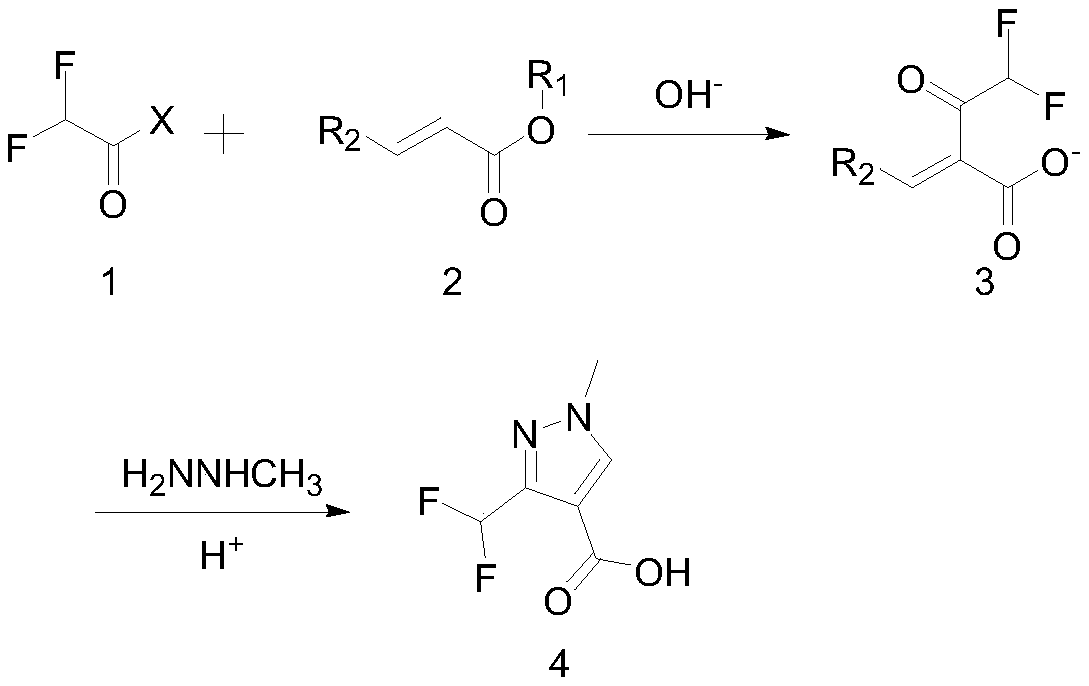

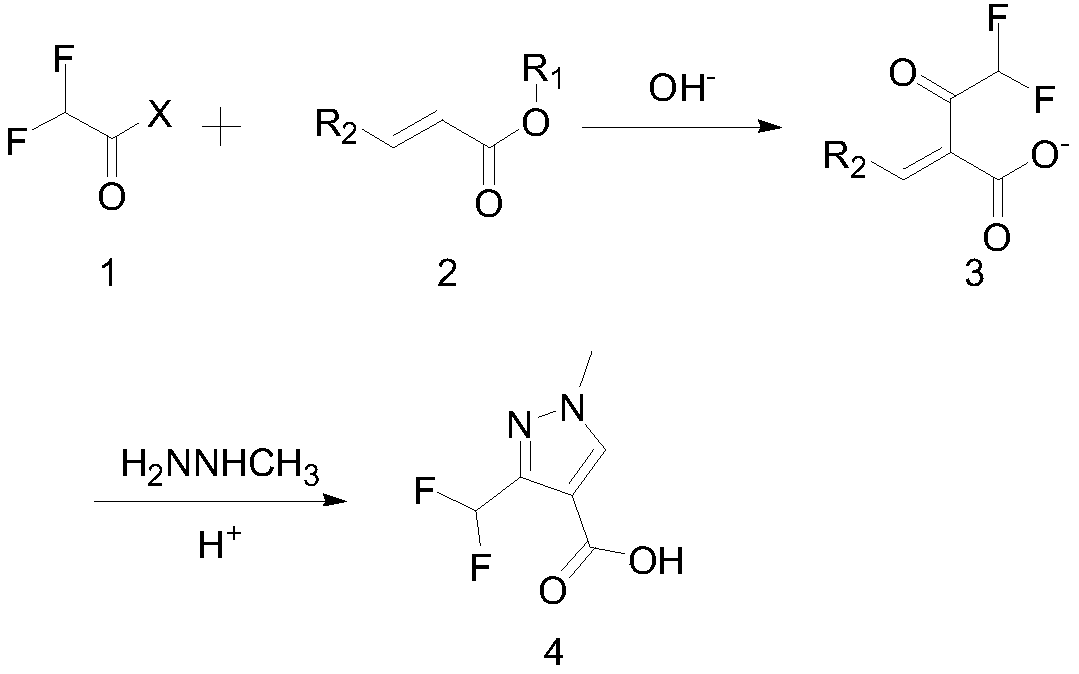

Preparation method of 3-(difluoromethyl)-1-methyl-1H-pyrazole-4-carboxylic acid

ActiveCN111362874ASimple and fast operationRaw materials are easy to getOrganic chemistryPtru catalystOrganic synthesis

The invention discloses a preparation method of 3-(difluoromethyl)-1-methyl-1H-pyrazole-4-carboxylic acid, and belongs to the technical field of organic synthesis. The preparation method comprises thefollowing steps: by taking 2, 2-difluoroacetyl halide as a raw material, performing addition with alpha, beta-unsaturated ester, performing alkaline hydrolysis to obtain alpha-difluoroacetyl intermediate carboxylic acid, condensing and cyclizing the 3-(difluoromethyl)-1-methyl-1H-pyrazole-4-carboxylic acid with a methylhydrazine aqueous solution in the presence of a catalyst to obtain a 3-(difluoromethyl)-1-methyl-1H-pyrazole-4-carboxylic acid crude product, and recrystallizing to obtain a pure product of the 3-(difluoromethyl)-1-methyl-1H-pyrazole-4-carboxylic acid. The method has the advantages of simple operation, easily available raw materials, high reaction yield, reduction of isomers through a plurality of ways in the reaction process, and convenience in product purification.

Owner:徐州圣元化工有限公司

Method for preparing (1-methyl-1H-[1,2,4] triazole-3-yl)-methyl alcohol

The invention discloses a method for preparing (1-methyl-1H-[1,2,4] triazole-3-yl)-methyl alcohol, belonging to the technical field of organic chemistry. The method comprises the following steps: by taking 2-glycolamide as a raw material, protecting hydroxy by adopting triphenylmethyl; carrying out formylation reaction on 2-glycolamide and ethyl formate, and performing condensation ringclosure deprotection with methylhydrazine to obtain (1-methyl-1H-[1,2,4] triazole-3-yl)-methyl alcohol. According to the preparation method, the yield is high, the cost is low, operation condition can be easilycontrolled, and the preparation method is suitable for industrial production.

Owner:SHANGHAI TBBMED CO LTD

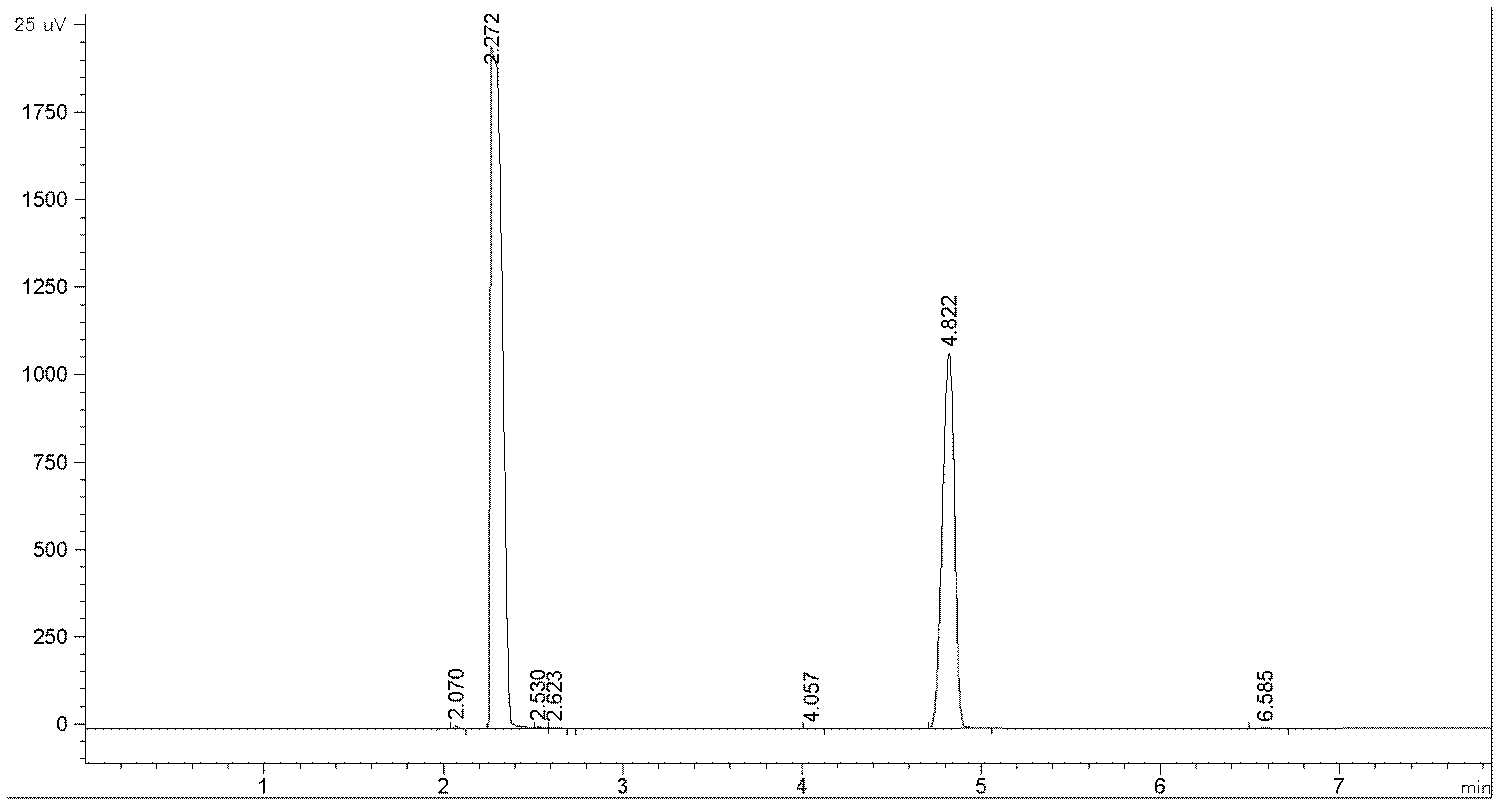

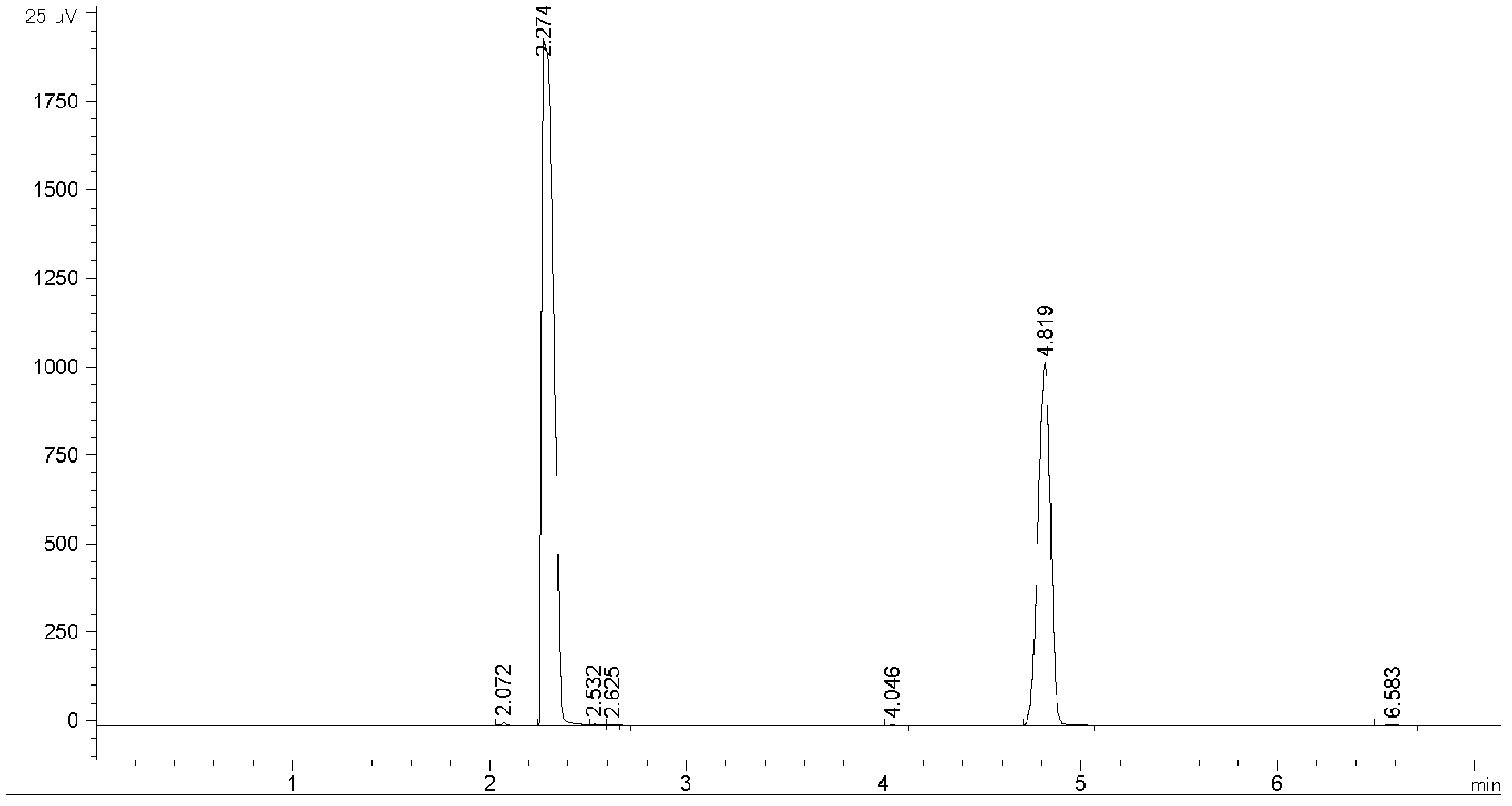

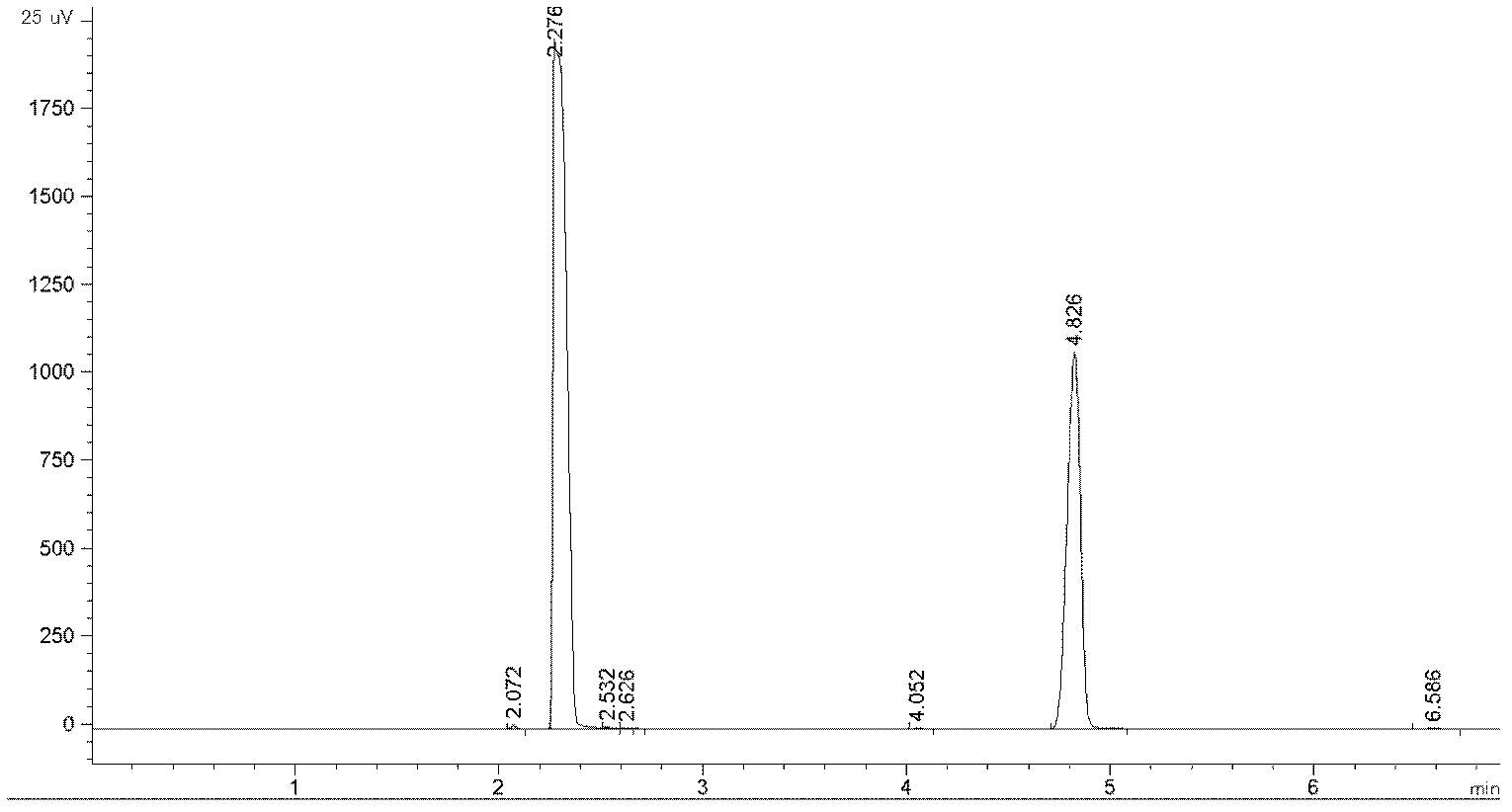

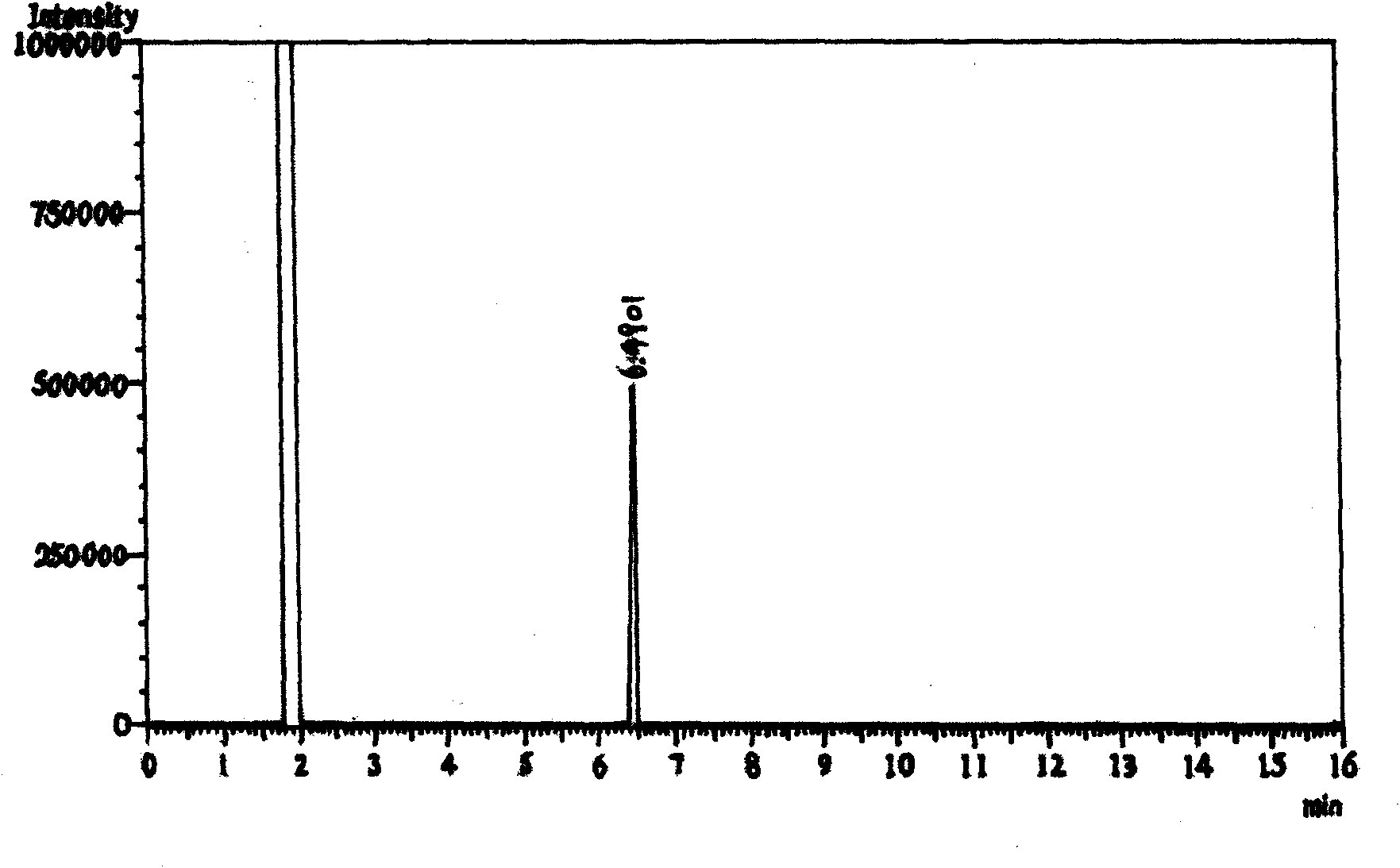

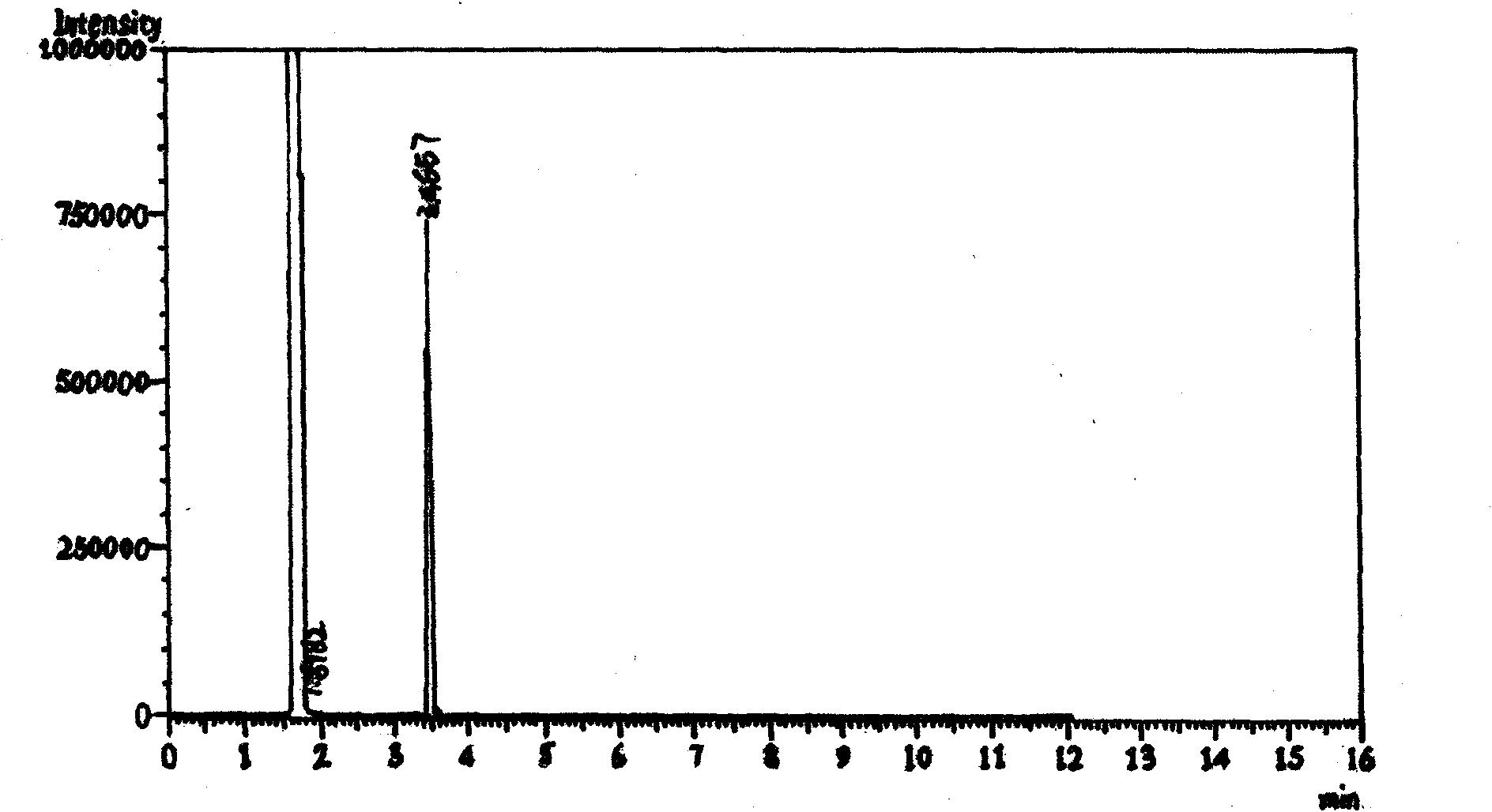

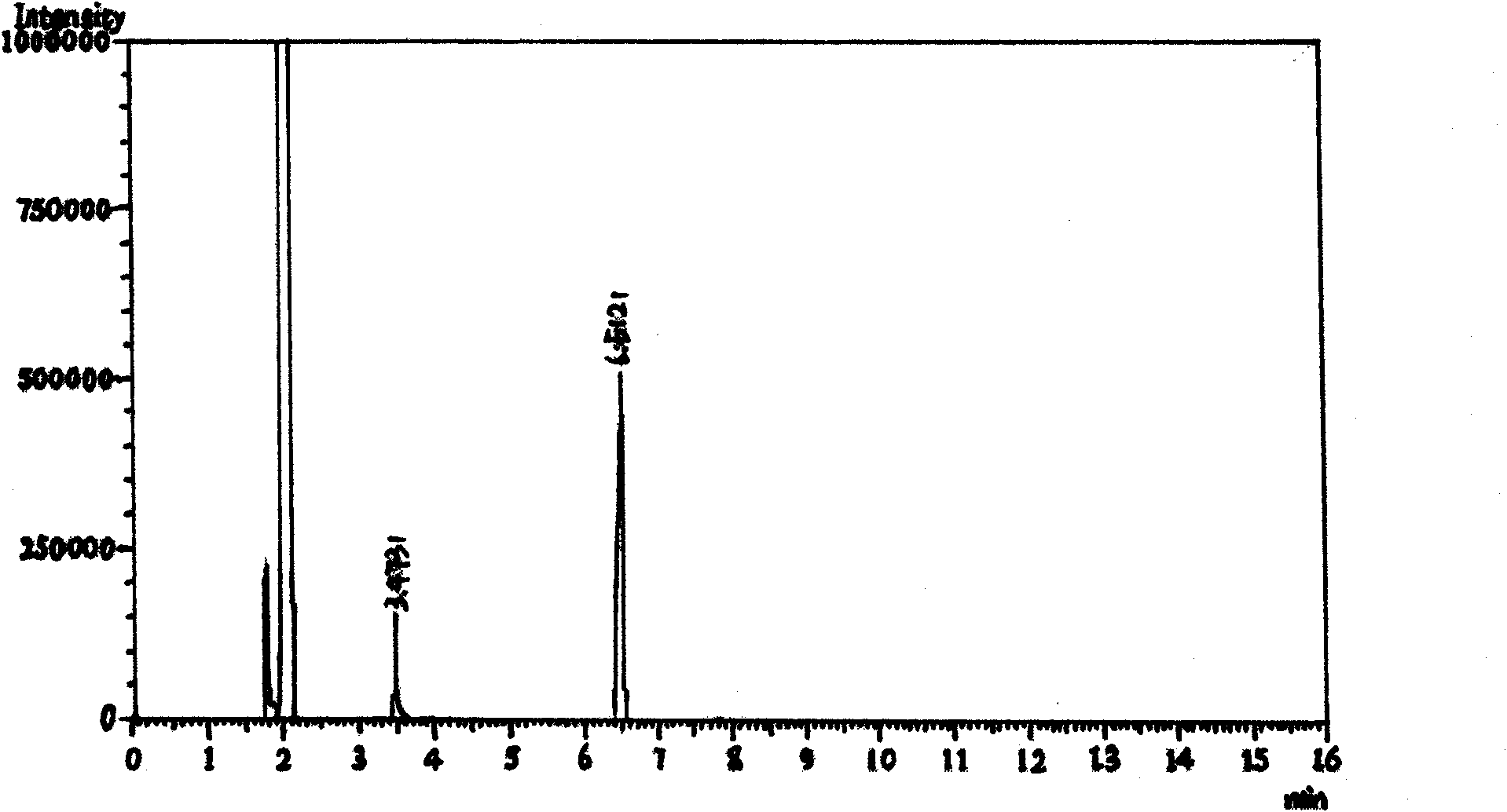

Method for measuring impurity content in methylhydrazine

InactiveCN102608242AEasy to operateThe result is accurateComponent separationMethylhydrazineAnalysis method

The invention relates to a method for measuring the impurity content in methylhydrazine. The method comprises the steps of introducing samples, gasifying, separating, detecting and calculating the content of the impurities and the like. The method solves the technical problems that in the existing analysis method, only the content of the methylhydrazine can be measured, and the various impurity contents in the methylhydrazine cannot be measured, according to the method, the impurity content in the methylhydrazine can be detected simply and rapidly, the measuring result is accurate, and the relative error is less than 5%, and the method is suitable for control analysis of the quality of the methylhydrazine in the industrial production.

Owner:XIAN HANGJIE CHEM TECH

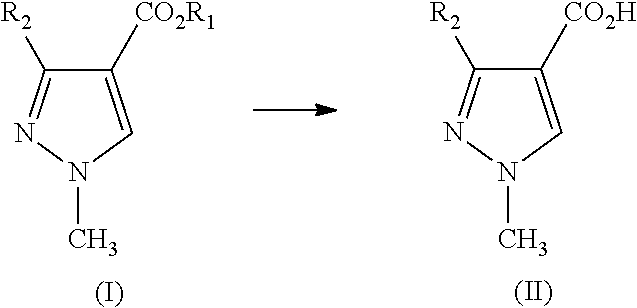

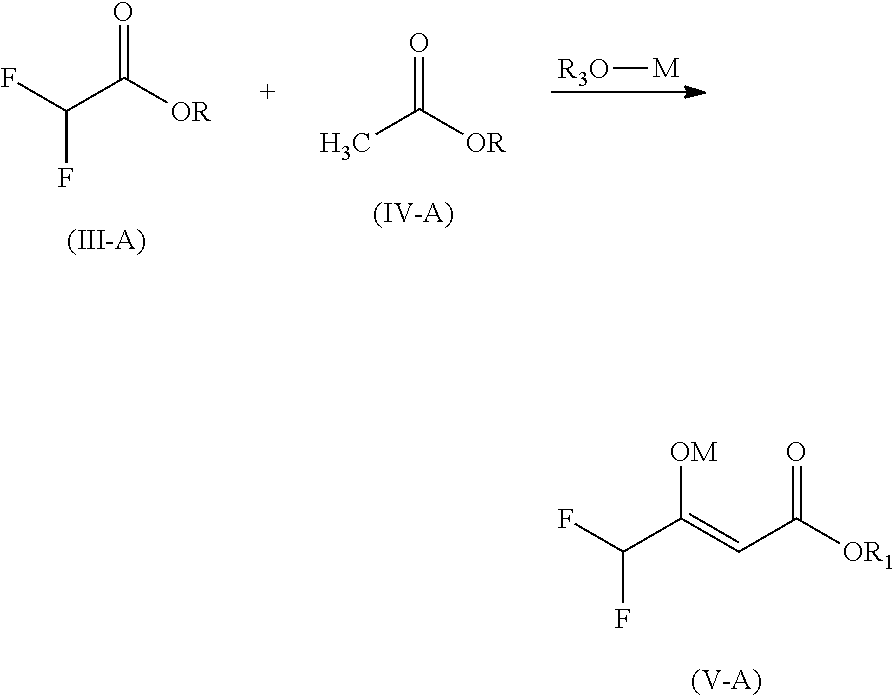

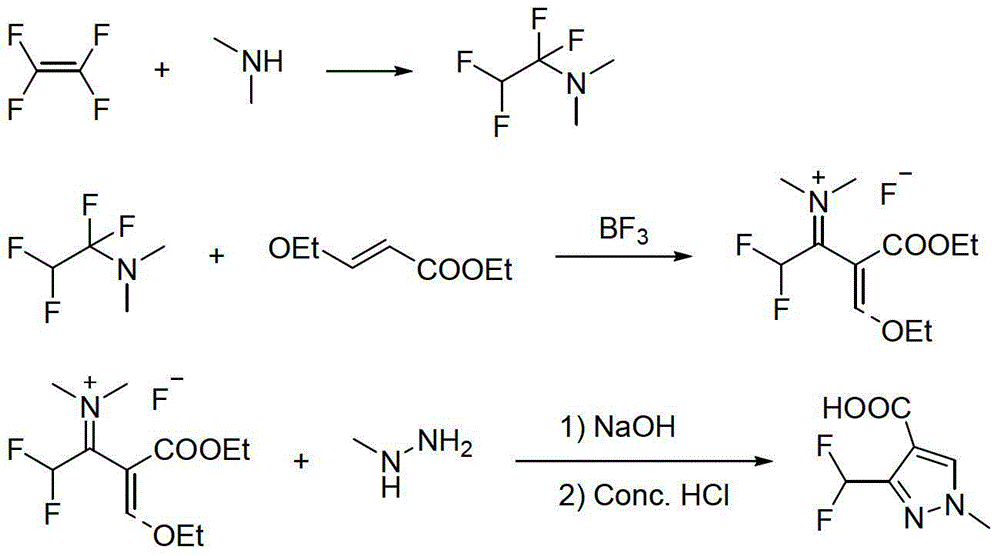

Preparation of alkyl 3-difluoromethyl-1-methyl-1h-pyrazole-4-carboxylic acid ester

InactiveUS20140221669A1Improved reaction work-upHigh yieldOrganic compound preparationPreparation by carbon monoxide or formate reactionMethylhydrazineCarboxylic acid

The present disclosure provides a novel and economically advantageous process for preparation of compounds of Formula I, such as alkyl 3-difluoromethyl-1-methyl-1H-pyrazole-4-carboxylic acid ester. The process includes acidification of the sodium enolate of alkyl difluoroacetoacetate by carbonic acid generated in situ by reacting carbon dioxide with water. The disclosure also includes promoting the ring closure reaction in which alkyl 2-alkomethylene-4,4-difluoro-3-oxobutyrate is reacted with methylhydrazine in two phase system with a weak base such as Na2CO3 or K2CO3.

Owner:KINGCHEM

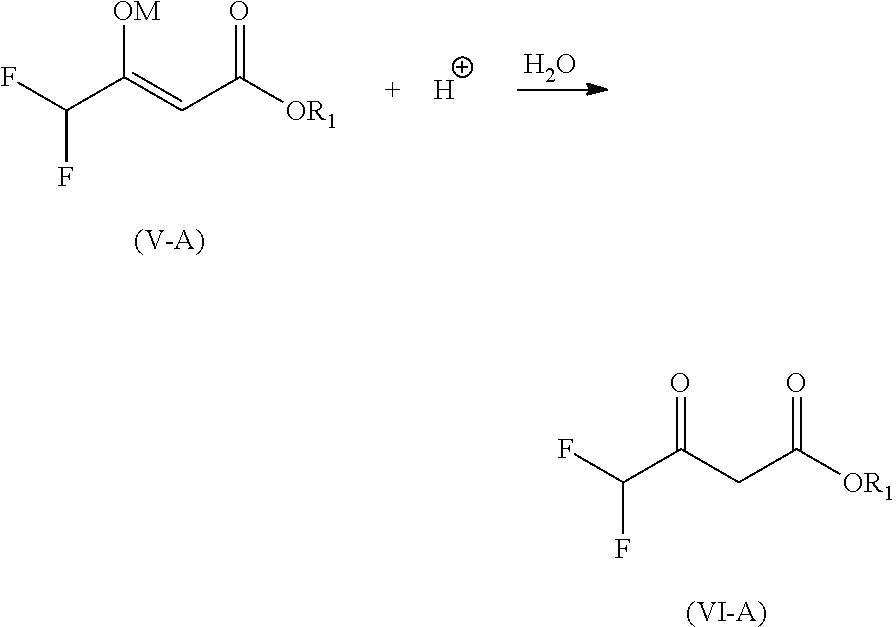

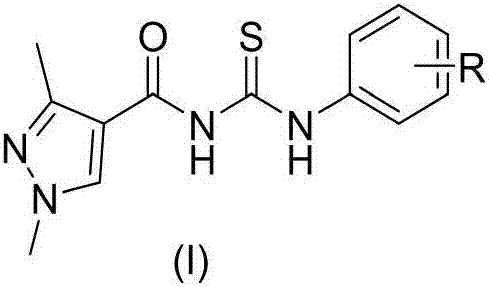

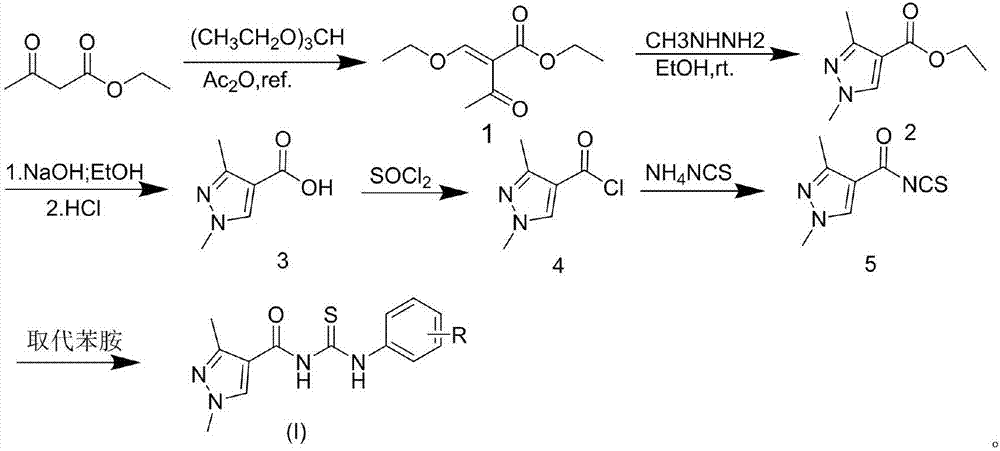

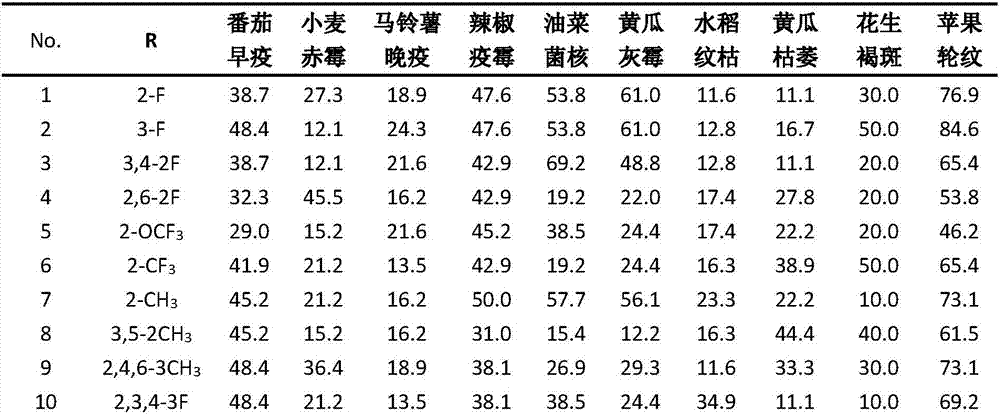

Acyl thiourea compound containing 1,3-dimethyl-1H-pyrazole structure and preparation method and application thereof

InactiveCN107033082AHas bactericidal activityEasy to prepareOrganic chemistryFungicidesThioureaAlternaria solani

The invention discloses an acyl thiourea compound containing a 1,3-dimethyl-1H-pyrazole structure and a preparation method and application thereof. The preparation method comprises the following steps: firstly using ethyl acetoacetate, triethyl orthoformate and methylhydrazine as raw materials to synthesize 1,3-dimethyl-1H-pyrazole-4-formic acid, performing the acylating chlorination to obtain 1,3-dimethyl-1H-pyrazole-4-formyl chloride, and reacting with ammonium thiocyanate and substituted anilines to obtain a final product (I). The raw materials are simple and are easily obtained, the preparation method is simple, the aftertreatment is convenient, and the product yield is high. The compound has the antifungal activity, and has the good sterilizing effect in allusion to sclerotinia sclerotiorum, rhizoctonia solani, Cercospora arachidicola Hori, Macrophoma kawatsukai, and alternaria solani especially. The foundation is provided for new pesticide research and development.

Owner:ZHEJIANG UNIV OF TECH

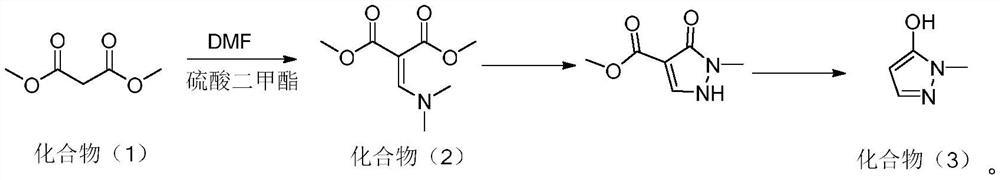

5-(1'-methyl)hydrazinotetrazolium and its metal salt derivative

The invention discloses a novel tetrazolium compound and its metal salt derivative, and preparation methods of the above compounds, and belongs to the fields of novel chemical materials and preparation technologies thereof. 5-(1'-methyl)hydrazinotetrazolium is prepared through reacting a cyanogen halogenide with sodium azide in a solvent, and reacting the resultant mixed solution / filtrate with methylhydrazine in the solvent. The metal salt of the 5-(1'-methyl)hydrazinotetrazolium is obtained through reacting 5-(1'-methyl)hydrazinotetrazolium / sodium 5-(1'-methyl)hydrazinotetrazolium with a metal hydroxide / metal sulfate / metal nitrate in water. The 5-(1'-methyl)hydrazinotetrazolium and the 5-(1'-methyl)hydrazinotetrazolium metal salt derivative prepared in the invention have a high nitrogen content and a good stability, can be used in energetic materials, can have magnetic characteristics, and have the advantages of simple preparation process and high purity.

Owner:SICHUAN UNIV

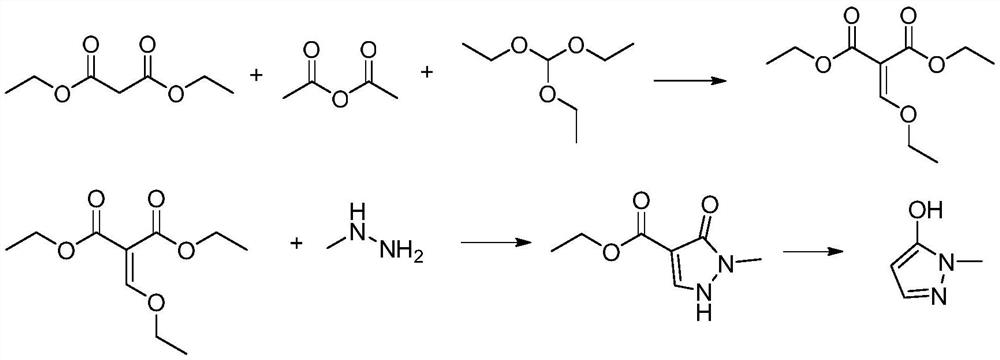

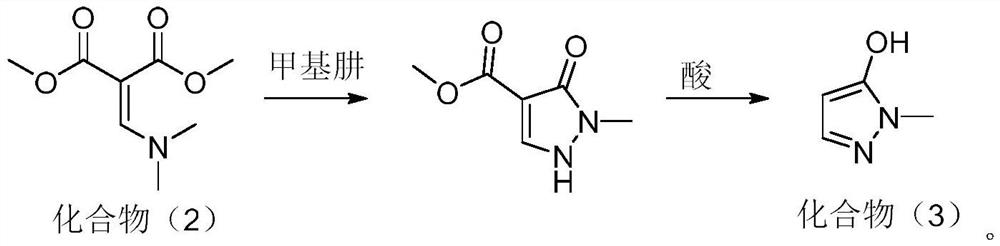

Preparation method of pyrazole type herbicide intermediate 1-methyl-5-hydroxypyrazole

The invention belongs to the technical field of preparation of pyrazole type herbicide intermediates, and particularly relates to a preparation method of a pyrazole type herbicide intermediate 1-methyl-5-hydroxypyrazole. The preparation method of the 1-methyl-5-hydroxypyrazole comprises the following steps: (1) in the presence of alkali, enabling dimethyl malonate of a compound (1) to react with aformamide compound and an alkylation reagent in a solvent to generate a compound (2); and (2) carrying out cyclization reaction on the obtained compound (2) and methylhydrazine / hydrazine hydrate in asolvent, and carrying out hydrolysis and decarboxylation by using an acid to obtain a compound (3). According to the method, DMF, an alkylation reagent and the compound (1) react to obtain the compound (2), the obtained compound (2) is good in selectivity when being subjected to ring-closure reaction with methylhydrazine (or hydrazine hydrate), and a target product compound (3) with higher yieldand purity can be obtained. Moreover, the raw materials used in the synthesis method disclosed by the invention are relatively weak in corrosivity, easy to recover and relatively low in price, so thatindustrial production is facilitated.

Owner:PAPANNA BEIJING TECH

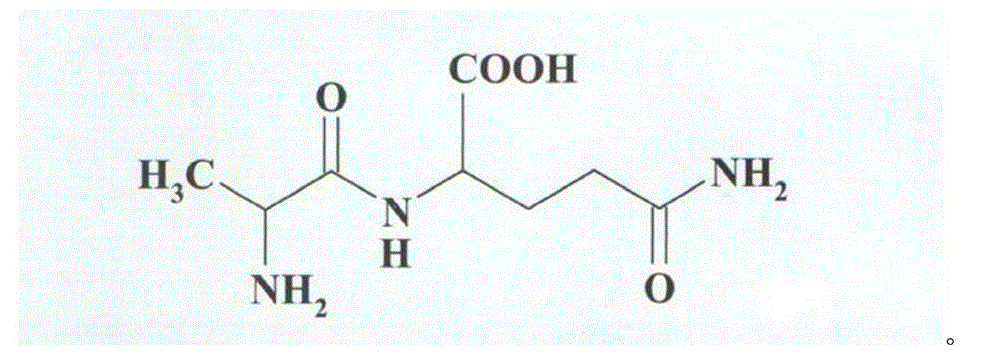

L-alanyl-L-glutamine special ultrafine powder freeze dried preparation, and preparation method thereof

ActiveCN104856964AImprove solubilityHigh purityPowder deliveryDipeptide ingredientsL-alanyl-l-glutamineFreeze-drying

The invention discloses an L-alanyl-L-glutamine special ultrafine powder freeze dried preparation, and a preparation method thereof. The preparation method comprises following steps: step 1, N-(alpha-chloro)-propionyl-glutamine is taken as a raw material, methylhydrazine is taken as an ammonification agent, reaction is carried out under normal pressure, concentration and low temperature cooling are carried out, and an L-alanyl-L-glutamine crude product is obtained via precipitation; step 2, at 10 DEG C, absolute methanol is added into the L-alanyl-L-glutamine crude product, stirring is carried out, and methanol solution is removed via air pump filtration so as to obtain a filter cake containing L-alanyl-L-glutamine; step 3, the filter cake containing L-alanyl-L-glutamine is dissolved in water, an obtained mixed solution is heated to 75 DEG C, and the temperature is maintained for a certain time for condensation, ethanol is added, gradient cooling and recrystallization are carried out so as to obtain purified L-alanyl-L-glutamine; step 4, crystallized L-alanyl-L-glutamine is subjected to centrifugal washing and drying; and step 5, the dried L-alanyl-L-glutamine is smashed into ultrafine powder with gas stream, and freeze drying is carried out.

Owner:HAINAN LINGKANG PHARMA CO LTD +2

A new method of catalytic synthesis of methylhydrazine under normal pressure

InactiveCN105037196BIncrease contact areaReduce generationHydrazine preparationHydrazine compoundSolvent

Owner:UNIV OF JINAN

Improved technology of mono-methyl hydrazine production process

InactiveCN111320554AAvoid Methyl DiversificationGuaranteed single productionHydrazine preparationMethylhydrazineMethyl palmoxirate

The invention discloses an improved technology of a mono-methyl hydrazine production process. An improved process is invented on the basis of a hydrochloric acid methanol hydrazine hydrate method, andthe defects of many byproducts, low reaction yield, environmental pollution caused by formation of highly toxic polybasic hydrazine in a reaction solution, and the like, when mono-methyl hydrazine issynthesized by using a hydrochloric acid methanol hydrazine hydrate method at present are overcome. According to the method, further methyl diversification of the target product mono-methyl hydrazinegenerated firstly in the reaction process is avoided, single production of the target product is guaranteed, more importantly, the process is simplified and environmentally friendly, the yield is increased, and the cost is reduced.

Owner:DONGLI NANTONG CHEM +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com

![Method for preparing (1-methyl-1H-[1,2,4] triazole-3-yl)-methyl alcohol Method for preparing (1-methyl-1H-[1,2,4] triazole-3-yl)-methyl alcohol](https://images-eureka.patsnap.com/patent_img/2f3e51a6-de26-4435-8409-4e0a8314e563/BDA0001521067420000021.png)