A new method of catalytic synthesis of methylhydrazine under normal pressure

A synthetic method and technology of methylhydrazine, applied in the preparation of hydrazine, organic chemistry, etc., can solve the problems of high toxicity of dimethyl sulfate, increase of sodium salt treatment cost, difficulty in industrial production, etc., to achieve convenient continuous production, improve Product selectivity, the effect of easy industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

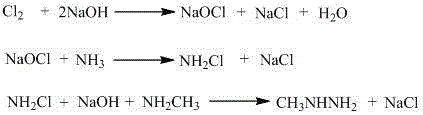

Problems solved by technology

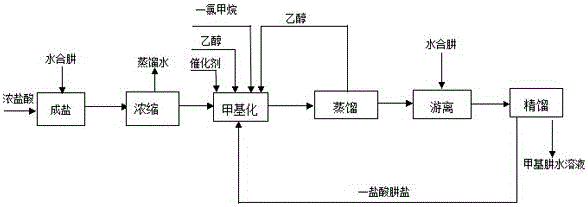

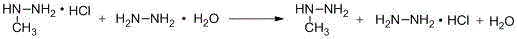

Method used

Image

Examples

Embodiment 1

[0041] Slowly add 192.1 g (2.0 mol) of 38% concentrated hydrochloric acid dropwise into 125 g (2.0 mol) of 80% hydrazine hydrate. Under the condition of stirring, control the temperature at 20~30°C and keep it warm for 2 hours. After the reaction is complete, measure the pH=6, distill off the water under reduced pressure, mix the obtained hydrazine salt with 138 g (3 mol) of ethanol, and add coarse porous microspherical silica gel 16.0 g. Raise the reaction temperature to 73° C. and condense to reflux. Chloromethane was slowly introduced into the mixed solution at a rate of 0.56 mL / min to react for 2.3 h. The mixed solution after the reaction is distilled to separate ethanol and a small amount of water, and the ethanol can be recycled. The remaining raffinate was added to 136.0 g of hydrazine hydrate with a mass fraction of 80% for freeing. Finally, the dissociated solution was heated and rectified, and the fraction at 102-110°C was collected to obtain 98.0 g. The content of...

Embodiment 2

[0043] Add 96.05 g (1.0 mol) of 38% concentrated hydrochloric acid dropwise to 62.5 g (1.0 mol) of 80% hydrazine hydrate. Under the condition of stirring, control the temperature at 20~30°C and keep it warm for 1.5 hours. After the reaction is complete, measure the pH=6, distill off the water under reduced pressure, mix the obtained hydrazine salt with 92 g (2.0 mol) of ethanol and add microporous microspheres Type 8.3g of silica gel, raise the reaction temperature to 64°C and condense to reflux, slowly inject methyl chloride into the mixed solution at a rate of 0.22mL / min to react for 2 h. The mixed solution after the reaction is distilled to separate ethanol and water, and the ethanol can be recycled. The remaining raffinate was added to 50 g of hydrazine hydrate with a mass fraction of 80%. Finally, the dissociated solution was heated and rectified, and the fraction at 102-108°C was collected to obtain 63.3 g fraction, with a gas phase detection content of 38.12%. The rem...

Embodiment 3

[0045] Add 134.6 g (1.4 mol) of 38% concentrated hydrochloric acid dropwise to 127.5 g (1.4 mol) of 80% hydrazine hydrate. Under the condition of stirring, control the temperature at 20~30°C and keep it warm for 1.0 h. After the reaction is complete, measure the pH=6, distill off the water under reduced pressure, mix the obtained hydrazine salt with 96.6 g (2.1 mol) of ethanol and add coarse-pored microspheres Type 9.3 g of silica gel, raise the reaction temperature to 51°C and condense to reflux, slowly inject methyl chloride into the mixed solution at a rate of 0.294 mL / min, and react for 1.0 h. The mixed solution after the reaction is distilled to separate ethanol and water, and the ethanol can be recycled. The remaining raffinate was added to 130 g of hydrazine hydrate with a mass fraction of 80%. Finally, the dissociated solution was heated and rectified, and the fraction at 102-108°C was collected to obtain 42.9 g of fraction, whose gas phase detection content was 32.02...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com