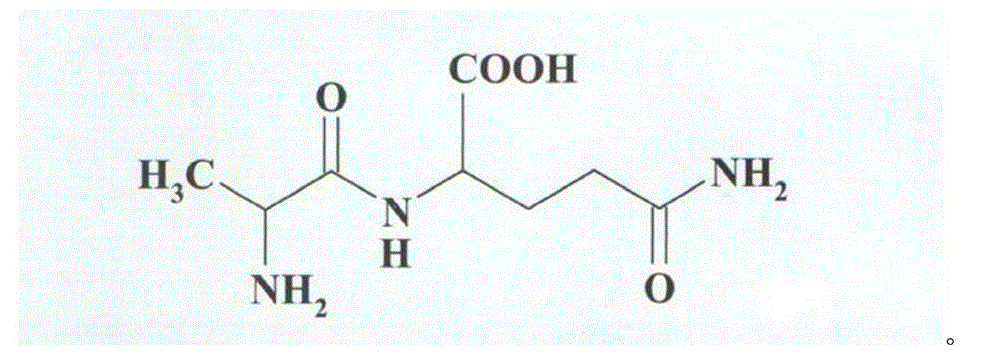

L-alanyl-L-glutamine special ultrafine powder freeze dried preparation, and preparation method thereof

A technology of alanyl glutamine and ultrafine powder, which is applied in the field of medicine, can solve the problems of low purity, small specific surface area, and poor solubility of alanyl glutamine, and achieve reduced drug consumption, large specific surface area, The effect of less impurities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Take 0.2 mol of commercially available N-(α-chloro)-propionyl-glutamine, dissolve it in 1000ml of water, then add 0.22 mol of methylhydrazine, and react at 55°C under normal pressure, The reaction time was 18 hours, then concentrated, and cooled at a low temperature of 10°C to precipitate the crude product of alanyl glutamine, and the content of alanyl glutamine was measured to be 85.52%.

[0031] At a temperature of 10°C, add anhydrous methanol to the crude product of alanyl glutamine, the amount of anhydrous methanol is 80% of the volume of alanyl glutamine, then vigorously stir to form a slurry, and then pump Consider removing the methanol solution to obtain a filter cake containing alanylglutamine, and wash it 3 times with methanol, and the volume of methanol used for each washing accounts for 1 / 3 of the slurry or suspension volume. In this step, the methanol solution obtained by filtration and the methanol solution obtained by washing are recycled. Therefore, a sm...

Embodiment 2

[0036] Take 0.2 mol of commercially available N-(α-chloro)-propionyl-glutamine, dissolve it in 1200ml of water, then add 0.22 mol of methylhydrazine, and react at 60°C under normal pressure, The reaction time was 16 hours, then concentrated, and cooled at a low temperature of 15°C to precipitate the crude product of alanyl glutamine, and the content of alanyl glutamine was measured to be 85.63%.

[0037]At a temperature of 10°C, add anhydrous methanol to the crude product of alanyl glutamine, the amount of anhydrous methanol is 80% of the volume of alanyl glutamine, then vigorously stir to form a slurry, and then pump Consider removing the methanol solution to obtain a filter cake containing alanylglutamine, and wash it 3 times with methanol, and the volume of methanol used for each washing accounts for 1 / 2 of the slurry or suspension volume. In this step, the methanol solution obtained by filtration and the methanol solution obtained by washing are recycled. Therefore, a sma...

Embodiment 3

[0042] Take 0.2 mol of commercially available N-(α-chloro)-propionyl-glutamine, dissolve it in 1300ml of water, then add 0.22 mol of methylhydrazine, and react at 65°C under normal pressure, The reaction time was 15 hours, then concentrated, and cooled at a low temperature of 13°C to precipitate a crude product of alanyl glutamine, and the content of alanyl glutamine was measured to be 85.58%.

[0043] At a temperature of 10°C, add anhydrous methanol to the crude product of alanyl glutamine, the amount of anhydrous methanol is 80% of the volume of alanyl glutamine, then vigorously stir to form a slurry, and then pump Consider removing the methanol solution to obtain a filter cake containing alanylglutamine, and wash it 3 times with methanol, and the volume of methanol used for each washing accounts for 1 / 2 of the slurry or suspension volume. In this step, the methanol solution obtained by filtration and the methanol solution obtained by washing are recycled. Therefore, a smal...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com