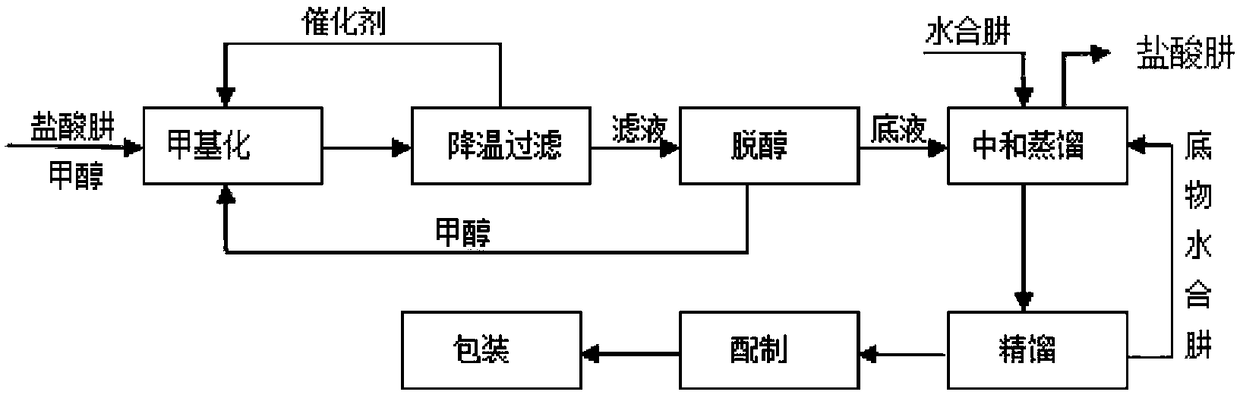

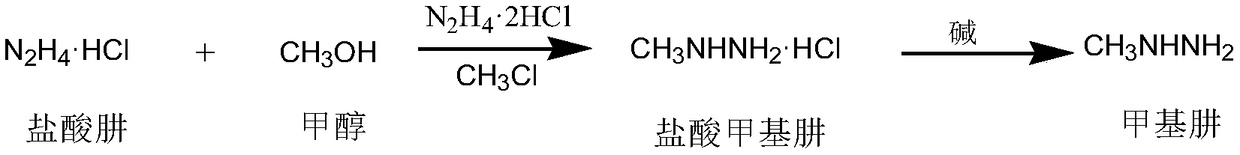

Preparation technology of methylhydrazine

A preparation process, a technology of methyl hydrazine, applied in the preparation of hydrazine, organic chemistry, etc., can solve the problems of loss, yield only, catalyst pressure relief, etc., achieve good conversion rate and selectivity, convenient and thorough application, and conducive to free effect of operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] In the methylation reaction kettle, add 275g (4mol) of hydrazine hydrochloride, 650mL methanol (16mol), 26g (0.2mol) of hydrazine sulfate, then add 70ml of water, seal the reaction kettle, control the system temperature at 90°C to 100°C, and stir React for 3 hours, the pressure of the reaction process system is 0.4-0.5MPa, the reaction is completed, the system is lowered to room temperature and stirred for 1 hour, and filtered to obtain 185g of solid dry product (containing 25g of hydrazine sulfate and 125g of hydrazine hydrochloride). After the filtrate is distilled to recover methanol, add hydration Hydrazine was free, and the fraction was rectified to obtain 210 g of 40% methylhydrazine solution.

Embodiment 2

[0028] In the methylation reactor, add 150 g of the recovered hydrazine sulfate and hydrazine hydrochloride mixture (containing 25 g of hydrazine sulfate, 125 g of hydrazine hydrochloride), 150 g of hydrazine hydrochloride, 500 mL of methanol, then add 80 ml of water, close the reactor, and control the temperature of the system at 50 ℃~60℃, stirred and reacted for 2h, the system pressure was 0.3~0.5MPa during the reaction process, the reaction was completed, the system was lowered to room temperature and stirred for 1h, filtered to obtain 210g of solid wet product (including 25g of hydrazine sulfate and 152g of hydrazine hydrochloride), and the filtrate was distilled After methanol was recovered, hydrazine hydrate was added for freeing, and the fraction was rectified to obtain 177 g of 40% methylhydrazine solution.

Embodiment 3

[0030] In the methylation reaction kettle, add 80% hydrazine hydrate 74g (1.2mol), 36% concentrated hydrochloric acid 120g (1.2mol), after stirring evenly, add the recovered hydrazine sulfate and hydrazine monohydrochloride mixture 150g (containing hydrazine sulfate 25g , hydrazine hydrochloride 125g, 1.8mol), 600mL methanol, airtight reactor, control the system temperature 75 ℃ ~ 85 ℃, stirring reaction 4h, the reaction process system pressure at 0.3 ~ 0.4MPa, the reaction is over, the system is lowered to room temperature and stirred for 1h, filtered , to obtain solid wet product 168g (containing hydrazine sulfate 24g, hydrazine hydrochloride 123g), after the filtrate recovered methanol through distillation, added hydrazine hydrate to free, and the fraction was rectified to obtain 120g of 40% methylhydrazine solution.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com