Hypergolic Liquid Or Gel Fuel Mixtures

a liquid or gel fuel mixture and hypergolic technology, applied in the field of fuel mixtures, can solve the problems of destroying the rocket motor, negating the achievement of the mission objective, and high toxicity of the compound, and achieve the effect of minimal toxicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

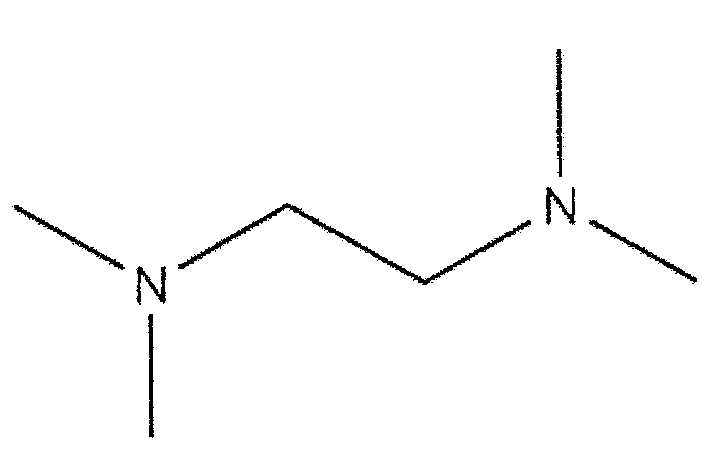

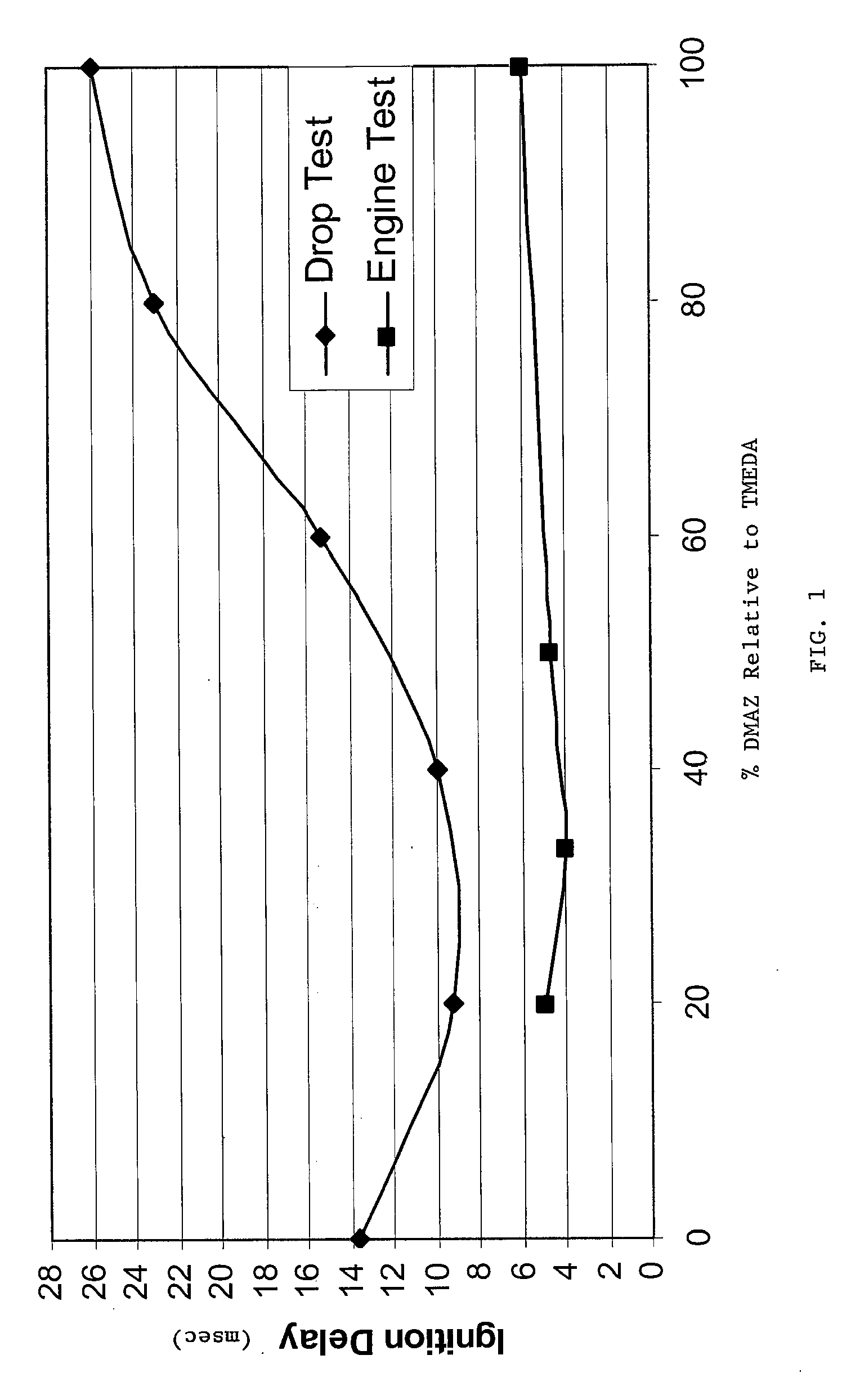

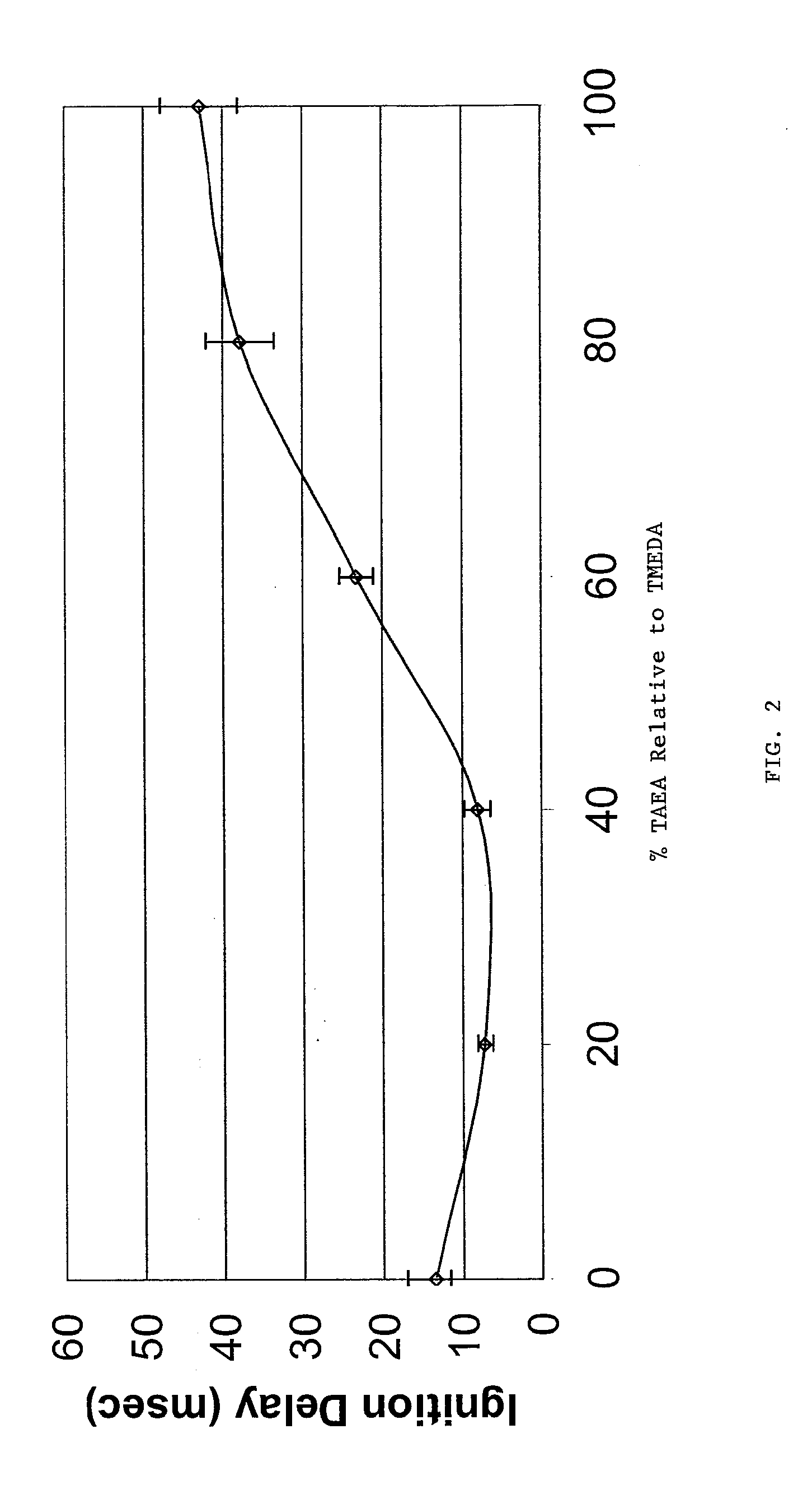

[0030]Referring now to FIGS. 1-15, a plurality of mixtures of compounds are disclosed for use as hypergolic liquid or gel fuels in bipropellant propulsion systems. A plurality of combinations of amine azide compounds and tertiary diamine compounds are disclosed as providing suitable hypergolic bipropellant fuels with sufficiently short ignition delay times, including TMEDA (see FIG. 5) when mixed with one of the compounds of DMAZ (see FIG. 7), TAEA (see FIG. 8), PYAZ (see FIG. 9), BAZ, DBN (see FIG. 10), DBU (see FIG. 11), or monocyclic compounds similar to DBN. Also disclosed is the use of tertiary tri-amines such as PMDETA (see FIG. 6), to achieve sufficiently short ignition delay times when mixed with one or more of the compounds of DMAZ, TAEA, PYAZ, BAZ, DBU, DBN, or monocyclic compounds similar to DBN.

[0031]Previously disclosed alternative fuel compounds proposed for replacement of MMH in fuel, specifically DMAZ, BAZ and PYAZ mixed with IRFNA, have been investigated and found b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density impulse | aaaaa | aaaaa |

| density specific impulse | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com