Content-adjustable methylhydrazine synthetic-fluid refining apparatus and method

A refining device and technology of methyl hydrazine, applied in the preparation of hydrazine, organic chemistry, etc., can solve the problems of no way to recycle caustic soda, cannot continue production, pollute groundwater, etc., to avoid repeated evaporation and condensation, and reduce run-off Drip, pollution reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

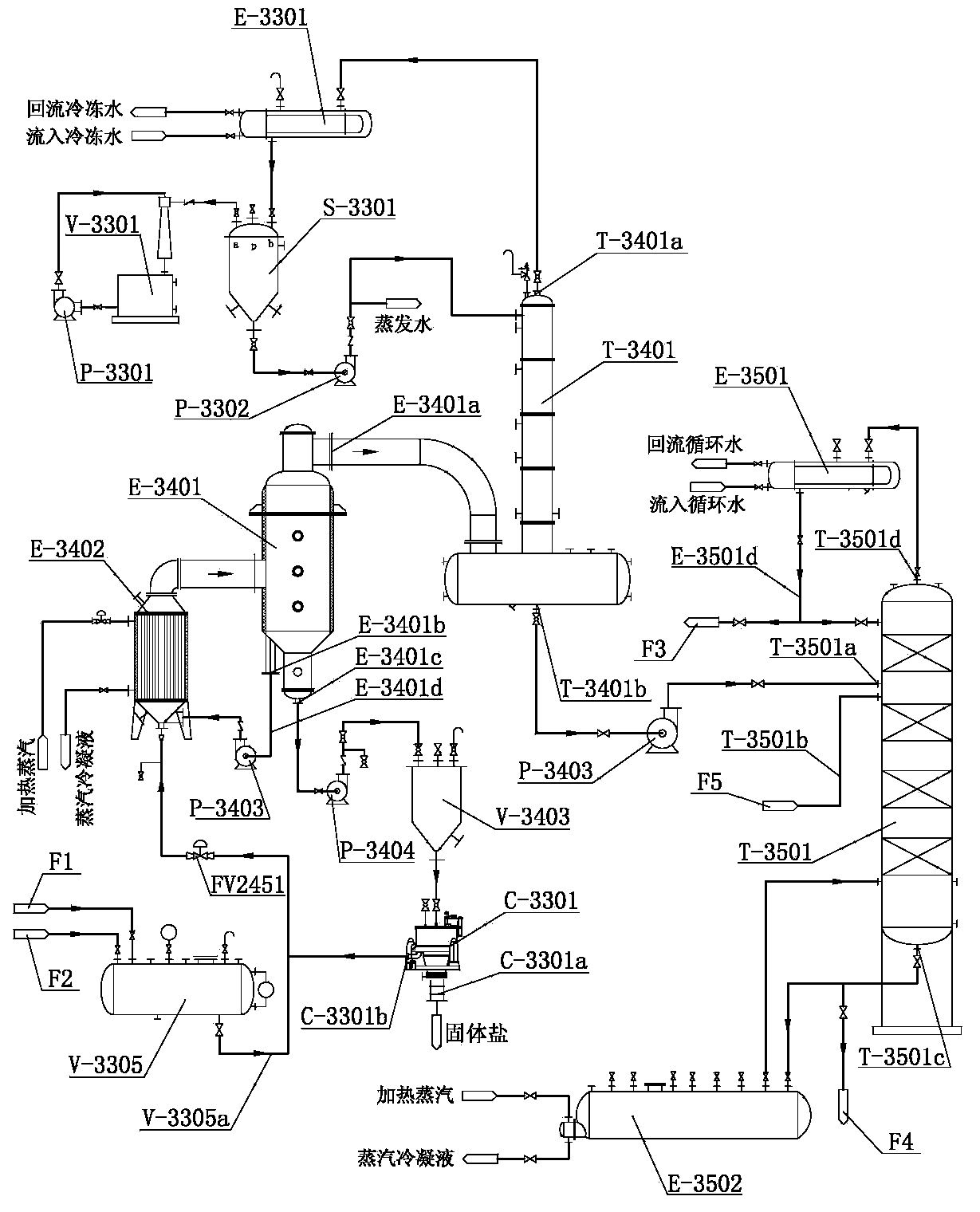

[0040] like figure 1 , a methylhydrazine synthesis liquid refining device with adjustable content, including evaporative distillation feed tank V-3305, evaporative heater E-3402, evaporator E3401, evaporative distillation tower T-3401, finished product tower T3501, and then Boiler E-3502 and automatic centrifuge C-3301; it is characterized in that, the feed inlet of described evaporative rectification feeding tank is provided with the methylhydrazine synthesis liquid F1 that removes ammonia and monomethylamine outside the boundary area The connected pipeline, the discharge port of the evaporative distillation feed tank is connected to the feed port of the evaporation heater through the feed pipeline V-3305a provided with a flow regulating valve FV2451, and the evaporative distillation feed tank is provided with a working pressure of Nitrogen F2 input port with a pressure of 0~1.5MPa;

[0041] The discharge port of the evaporation heater is connected to the feed port of the ev...

Embodiment 2

[0057] A method for refining methylhydrazine synthesis liquid with adjustable content, said method is the method for the methylhydrazine product whose refining concentration is 20% to 99% in the device described in embodiment one; the steps of said method are:

[0058] a. Send the methylhydrazine synthesis liquid from ammonia and monomethylamine into the evaporative rectification feed tank, input nitrogen into the evaporative rectification feed tank, and start the gas-liquid separation of the evaporative distillation tower described in Example 1 The vacuum pump connected to the device;

[0059] b. The methylhydrazine synthesis liquid in the evaporative rectification feed tank is sent to the evaporator heater for heating and vaporization under the vacuum degree and nitrogen pressure generated by the vacuum pump;

[0060] c. The methylhydrazine synthesis liquid heated in step b enters the evaporator for evaporation to obtain three products: a liquid phase product, a solid pha...

Embodiment 3

[0069] This embodiment is a specific implementation of the method described in Example 1; the steps of the method are:

[0070] a. Send the methylhydrazine synthetic liquid that removes ammonia and monomethylamine into the evaporative rectification feed tank, and input pressure into the evaporative rectification feed tank with a pressure of 0.2 MPa of nitrogen to start the evaporative rectification tower The vacuum pump connected to the gas-liquid separator, the vacuum pressure of the vacuum pump is gauge pressure-0.08MPa.

[0071] b. The methylhydrazine synthesis liquid in the evaporative rectification feed tank is sent to the evaporator heater for heating and vaporization under the vacuum degree and nitrogen pressure generated by the vacuum pump;

[0072] c. The methylhydrazine synthesis liquid heated in step b enters the evaporator for evaporation to obtain three products: a liquid phase product, a solid phase and liquid phase mixed product containing solid salt, and a g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com