Material drying device and material drying equipment

A technology of drying device and drying equipment, which is applied in the direction of dryers, dryers, and dryers for static materials, and can solve the problems of high energy consumption, long drying time, and low drying efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

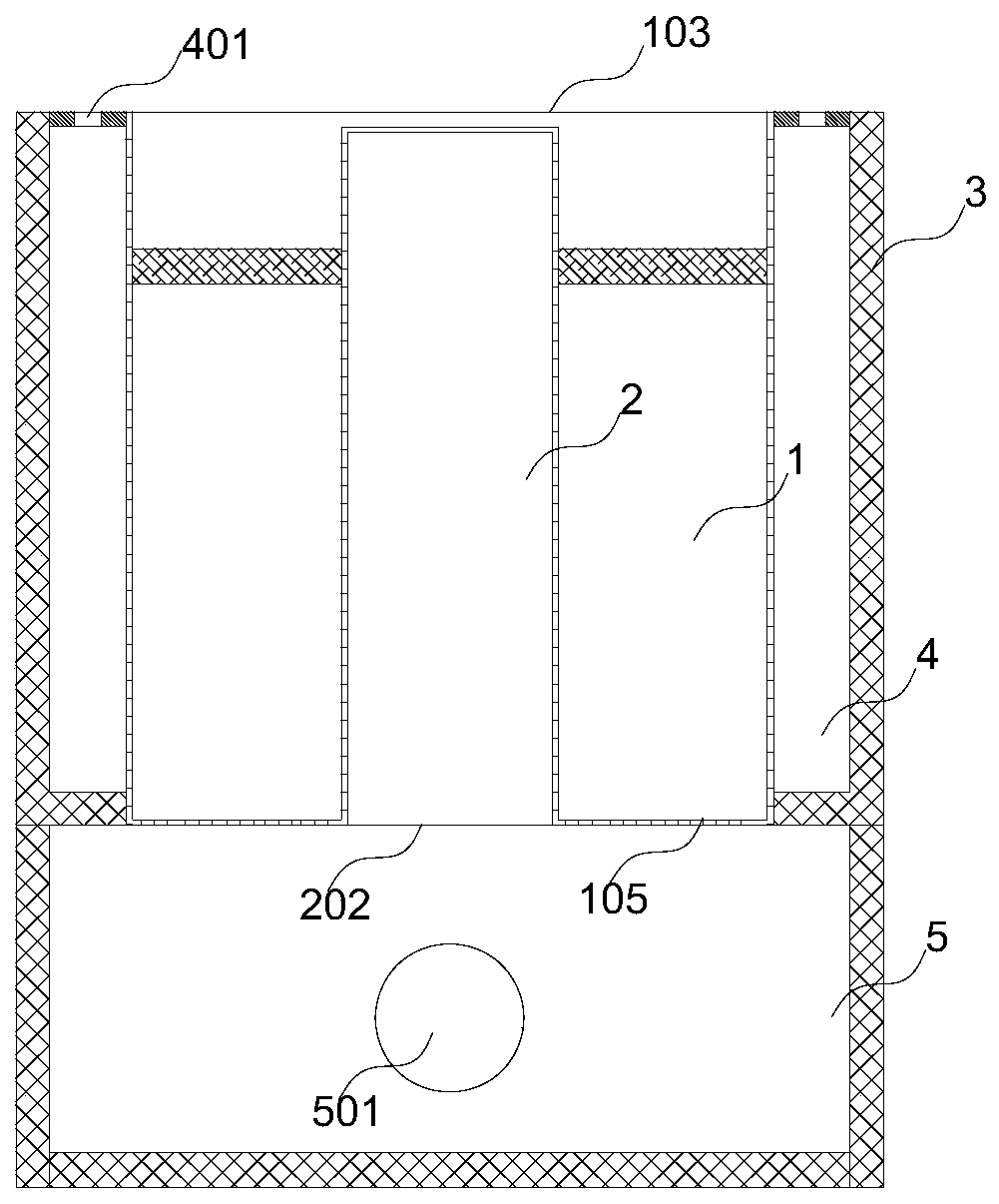

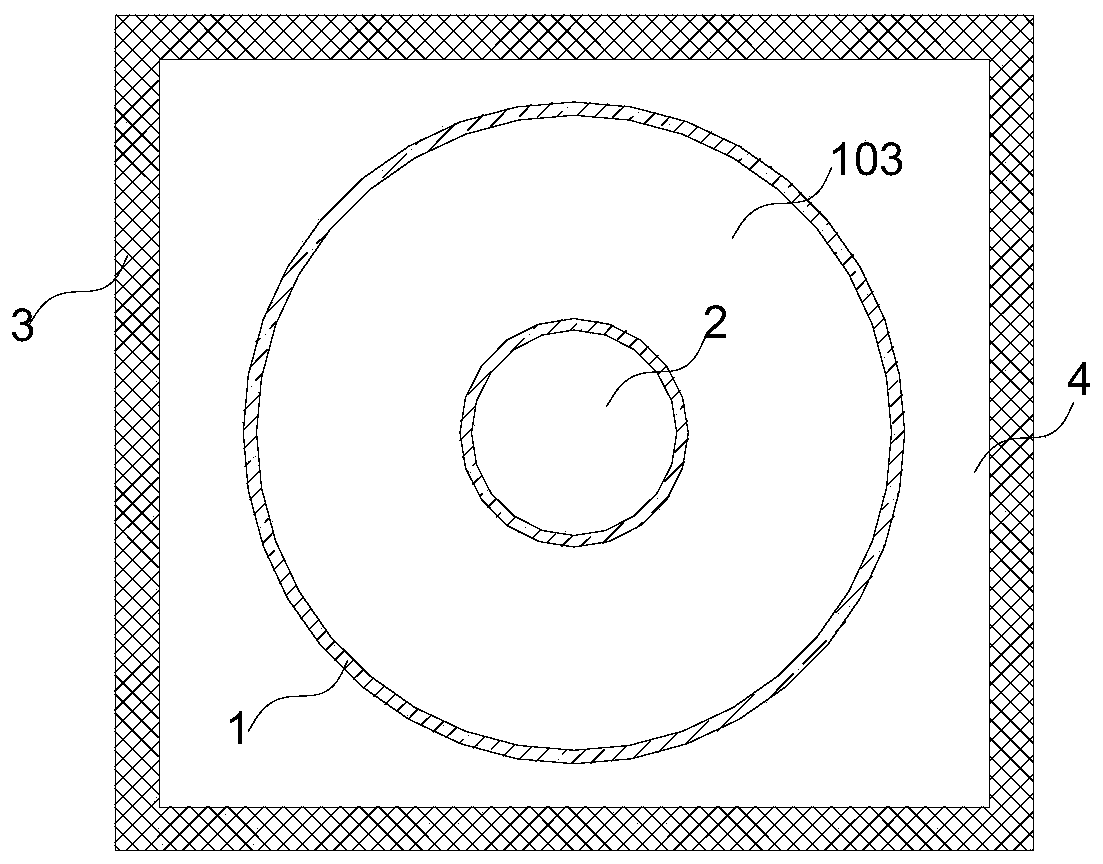

[0040] Please refer to figure 1 This embodiment provides a material drying device, which includes a container 1 for containing particulate matter, and a core body 2 with a hollow structure is arranged in the container 1 . The core 2 is provided with a first air inlet 202 for passing hot air into the core 2, although the first air inlet 202 is as figure 1 As shown, it is installed at the lower part of the core body 2, however, it may be installed at any position of the core body 2. The core body 2 is provided with several first air holes 201, although in this solution the first air holes 201 are all arranged on the side wall of the core body 2, but the first air holes 201 can also be arranged on the side wall of the core body 2 top. A moisture outlet 103 is provided at the top end of the container 1 . By injecting hot air into the first air inlet 202 provided on the core body 2, the hot air will enter the container 1 outside the core body 2 from the first vent hole 201 on th...

Embodiment 2

[0048] The main difference between this embodiment and the above-mentioned embodiment 1 is that the bottom end of the container 1 is not provided with several second air holes 104 , and the opening structure only communicates with the first air inlet 202 of the core body 2 . After the bellows 5 is filled with hot air, the hot air will heat the bottom of the container 1, and the heat at the bottom will still rise to heat the bottom material 7.

Embodiment 3

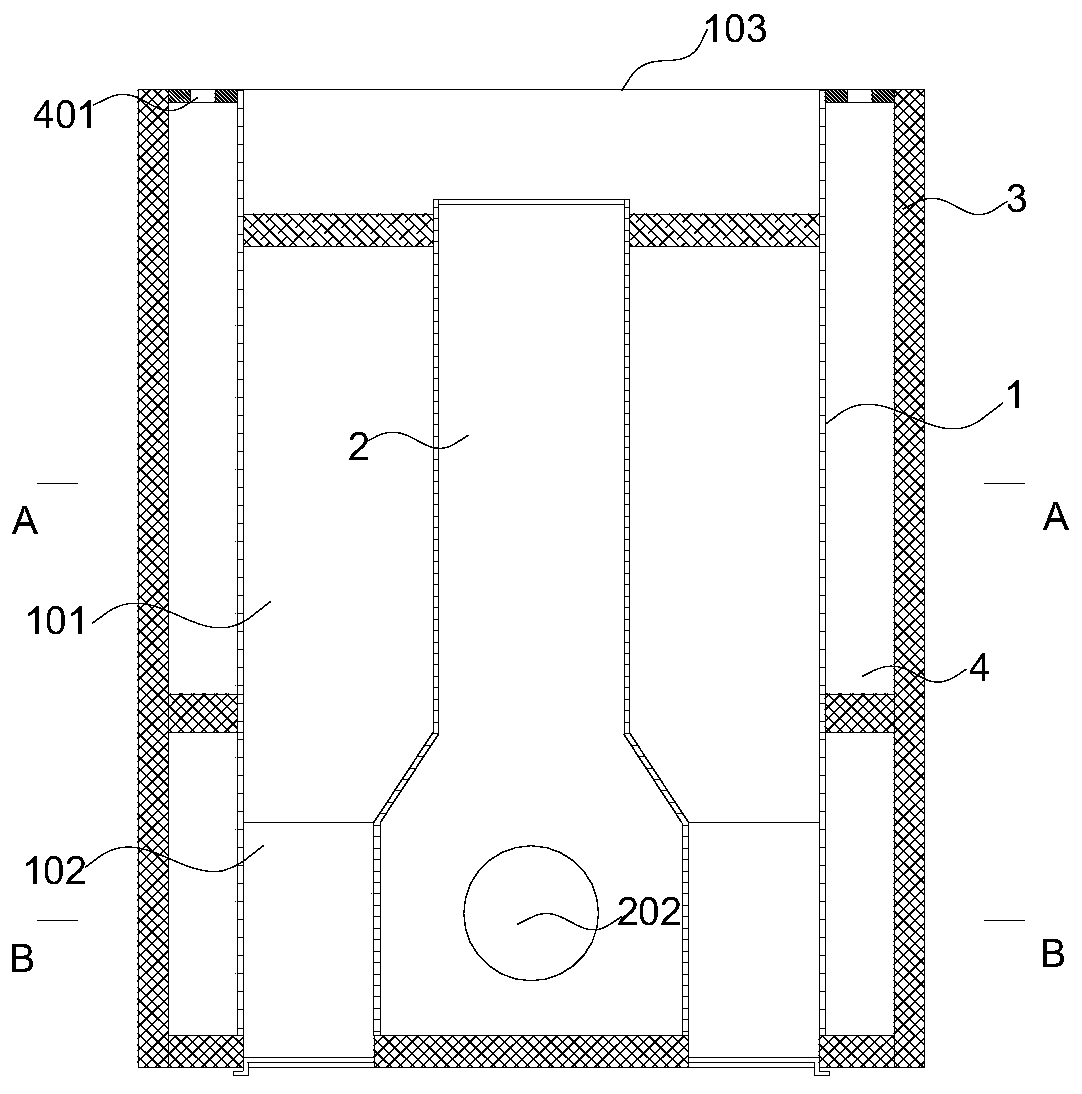

[0050] see Figure 2-7 , The main difference between this embodiment and the above-mentioned Embodiment 1 is that no bellows is provided in this solution. In this solution, the container 1 is sequentially divided into a carrying part 101 and a feeding part 102 from top to bottom, and the bottom of the feeding part 102 is provided with a discharge port. The material 7 after drying in the container 1 is conveniently unloaded through the discharge port. At the same time, the projected area of the blanking part 102 on the bottom surface of the container 1 is smaller than the projected area of the carrying part 101 on the bottom surface of the container 1 . The core 2 corresponds to the carrying part 101 and the blanking part 102 in the container 1 and is divided into an upper part and a lower part from top to bottom, because the projected area of the blanking part 102 on the bottom surface of the container 1 is smaller than that of the carrying part 101 on the bottom surfac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com